`planning scheme` definition, intensive animal husbandry means the

advertisement

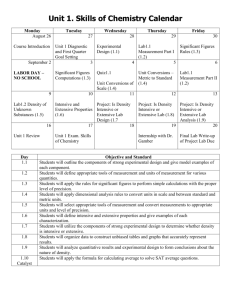

ABN – 39 109503 835 Intensive Agriculture Study Yarra Ranges Council October 2014 prepared by Tony Pitt Des Williams Ag-Challenge Consulting Intensive Agriculture Study - Yarra Ranges Council 1. Background and Objectives for this Study Yarra Ranges’ Council is considering changes to its planning scheme to expand the areas in the municipality where intensive animal husbandry may be allowed subject to a planning permit. Within the current provisions of the scheme intensive animal husbandry is a prohibited land use in a number of rural areas including the Green Wedge Zone Schedules 1, 2 and 3 areas. By ‘planning scheme’ definition, intensive animal husbandry means the keeping and care of agricultural animals where the primary food source is brought in from outside the holding area, as opposed to grazing on the land. Grazing or foraging on the land is defined as ‘extensive animal husbandry.’ With changing agricultural practices this definition of intensive animal husbandry now encompasses a variety of agricultural pursuits, and possibly beyond what was originally envisioned. In considering any future changes to its planning scheme, Council wants to consider the current and emerging farming enterprises that would come under the current definition of ‘intensive animal husbandry’ and the implications of any changes to its current planning scheme. The Council does not want the provisions of the planning scheme to impose unnecessary constraints on emerging industries. This report aims to identify some of these emerging industries and examine the present controls other than planning that impact on the operation of the enterprise. The list of enterprises considered is not comprehensive but is of sufficient scope to identify where constraints may and may not exist, and what steps can be taken to reduce constraints were this is deemed appropriate. Yarra Ranges Council would also like to consider the implications of the existing definition of intensive animal husbandry and whether there are other definitions that are more appropriate or more current. Any change to the definition would reflect the changes in farming systems. This will assist Council in future discussions with the State Government about the current land use definitions and Codes of Practice to facilitate a more streamlined approach to agriculture and planning. 2. Current Planning Provisions The following provisions of the Yarra Ranges Council Planning Scheme relevant to this project are: The Yarra Ranges Planning scheme is guided by the Upper Yarra Valley and Dandenong Ranges Regional Strategy Plan Relevant sections of the Planning Scheme considered are: a. The Green Wedge Zone – sets out a range of purposes i. Schedule 1 – GWZ 1 ii. Schedule 2 – GWZ 2 iii. Schedule 3 - GWZ 3 b. Green Wedge A Zone – prohibits intensive animal husbandry c. Rural Conservation Zone – prohibits intensive animal husbandry The Planning Scheme sets out in Clause 74 Land Use Terms – definition with associated Nesting Diagram Clause 75 The definition sets out “intensive” animal husbandry - “Land used to keep or breed farm animals, including birds, by importing most food1 from outside the enclosure …and includes: Broiler animal production Cattle feedlots Within the Schedule to Clause 53.01and under the heading “Intensive Animal Industries” the schedule states that land must not be used for intensive animal industries This applies to the 3 areas considered above (a, b, c) 1 The term most food is deemed to mean when more than 50% of the feed requirement comes from outside the farm area. A further refinement of this can be where it comes from outside the enclosure which houses the animals. That is the food is grown on the farm but harvested and transported to the areas where the animals are kept. DRAFT ONLY for DISCUSSION. Prepared by Ag-Challenge Consulting for Yarra Ranges Council 1 Intensive Agriculture Study - Yarra Ranges Council Extensive animal husbandry is able to operate across these areas (a – no permit, b – no permit, c – permit required) 3. Overview of Intensive Animal Industries Agriculture is dynamic and farms and farming practices change and will continue to change into the future as they respond to markets, consumers, environmental constraints, new farming technologies and their own financial sustainability. One change is the emergence of different forms of farming enterprises responding to an increasing number of consumers wanting food that has attributes such as organic, free range, produced locally to where it will be consumed and is environmentally and ethically responsible. National and various regional food strategies recognise these changes as an opportunity to diversify the mix and form of agricultural enterprises within a region, connecting consumers to the food production system and linking this to regional food tourism. There are opportunities to meet domestic demand as well as overseas demand. However, in some cases these different forms of farming enterprise do not fit easily into current descriptions and definitions used to describe certain forms of agricultural activity. This is particularly true for animal industries, as new types of enterprises may blur between the definition of intensive and extensive, notably free range animal production systems. Any uncertainty as to what constitutes an intensive animal industry has implications for local councils and the interpretation of state and local sections of planning schemes. Traditional production based agriculture, in most cases, has a consistency to the farming system e.g. dairy and beef (breeding or finishing) production based on rain fed or irrigated pasture production with limited off-farm feed being brought into the system. Beef production in this form is the Yarra Ranges largest animal industry, with only a few dairy farms remaining in the area. In Victoria other ‘meat’ industries predominantly involve the production of pigs, goats, veal and deer. The pork and goat industries are the largest in terms of value and volume. While many of these livestock species are produced by commercial businesses, large numbers – particularly goats and pigs – are kept on hobby farms. In 2010, an estimated 6,039 properties had goats, pigs, alpaca or deer, but only about half of these were commercial operations. Domestic interest in meats such as pork, chevron (goat meat) and venison has increased in recent years. This has been linked to changes in the ethnic composition of Australia's population and an expansion in the tastes and preferences of consumers. Such livestock can be farmed in both extensive or intensive systems with a range of variations within these terms e.g. free range pigs where all breeding and suckling animals are housed and only grower animals are allowed free range or goat production where breeding stock are run as an extensive system while young stock are finished in a semi-intensive system to specific slaughter weights. While the production of various bird meats (chicken, turkey, pheasant, emu or ostrich) will in all cases take the form of an ‘intensive’ farming system with the bulk of feed brought onto the farm, the level of intensity does vary, and some free range systems provide a much lower risk of environmental problems. Broiler production – chicken meat - is the largest of these industries operating across Victoria. There is an increasing number of smaller enterprises operating ‘free range’ chicken meat production systems. This is also true for egg production. Again these systems have various forms, but all would be deemed ‘intensive’ as most feed consumed by the animals is from outside the property. All these production systems would thus be a prohibited use within the Green Wedge Zone schedules 1 – 3 and would require a permit in the Green Wedge Zone. Free range production systems can take various forms and what constitutes ‘free range’ is contested and unclear – with the main issue being stocking density. Within the poultry and egg production industries, ‘truth’ in labelling as to how the meat or eggs were produced is an ongoing debate with large retailers and animal rights groups seeking greater clarity of what a term like ‘free range’ means. In the mind of a consumer the meaning may be quite different to what happens on the farm. DRAFT ONLY for DISCUSSION. Prepared by Ag-Challenge Consulting for Yarra Ranges Council 2 Intensive Agriculture Study - Yarra Ranges Council It is apparent that the terms and definitions used within the State Planning Scheme do not reflect the current diversity in animal husbandry enterprises. There are several factors that must be met for any intensive animal industry; Guaranteed access to water at the right quality and quantity; Climatic conditions in a range conducive to animal production; Access to a low cost reliable feed source; and Transportable distance to processing works. Within this context the following enterprises would normally fall within the definition of being an intensive animal industry and thus be a prohibited land use in the Green wedge Zone Schedules 1 3. This list has no particular order of priority and is not comprehensive: Free range chicken Free range egg production Intensive goat farming for meat White veal Free range pig farming Turkey farming Emu farming Pheasant farming Ostrich farming Farmed Rabbit Goat dairy Sheep dairy Free range duck Vealer finishing – semi feedlot Cattle feedlot Barn laid and shed laid egg production Chicken meat production (shed production) Super fine wool merino in housed production There are other enterprises that are commonly encountered on smallholdings where the stocking rates are high and as such the farming system appears to be intensive animal husbandry. However these enterprises below are essentially pasture based production systems, and either the feed maintenance requirement of the animals is low, or the management practice uses saved paddock feed to run large numbers of stock for short periods, giving the appearance of intensive animal husbandry. These systems would not usually be an intensive animal industry under the definition: Vealer finishing – pasture based Alpacca farming Dairy heifer finishing Cashmere goat farming Holding pens for abattoirs or saleyards ( Note: abattoirs and saleyards are classified as separate land uses – not included in Intensive animal husbandry). Within the list of intensive animal industries, the first ten enterprises have been examined in more detail. For each enterprise a tabular list has been prepared of the overall description of the industry and the enterprise, any current trends, lists of the various constraints and Industry Codes of Practice that impact on the enterprise, examine the environmental issues and planning constraints, and the options to address these issues. This has been provided in the following tables. DRAFT ONLY for DISCUSSION. Prepared by Ag-Challenge Consulting for Yarra Ranges Council 3 Enterprise Free Range Pig Production Description of Enterprise A free range pig herd is rotated on pastures or cropland. There are variations to the production system across farms e.g. sows farrow in a shed, piglets grow and are weaned in open paddock, growers may be finished in shelters Free-range pigs are typically kept in distinct groups based on age, sex, size, and stage of pregnancy They receive the majority of their nutritional needs from prepared feed in the form of a grain ration In the Yarra Ranges area it would be sourced from off the farm Paddocks where the pigs are run, would provide pasture or forage as some level of supplementary feed 'Free-range' implies that animals are not confined in enclosures - they may be fed in a shed, but normally have free access to paddocks Free range systems require specific environmental and climatic requirements thus limiting where they can be located Preferable geographical areas for free-range pig farming are those with low rainfall (suggested less than 750 mm a year) or moderate rainfall throughout the year with no excessive heat in summer Most management practices of free-range piggeries are similar to those of fully housed piggeries Current Status of the Industry Around 5 % of pigs grown in Australia are raised on free range farms From 2010 to 2011, the number of farming establishments with pigs declined by 23 % As of 30 June 2011, there were 450 establishments in Victoria with a total of 505,055 pigs, a 0.95 % reduction in pig numbers over the previous year Current Location of Production & Trends Victoria has 22% of Australia’s 2.28m pigs Victoria's pig farms are concentrated in the Loddon, Goulburn, Wimmera and Mallee regions (85.5%of production) Areas with concentrated rainfall patterns, combined with extremes of humidity and/or air temperature (particularly prolonged extremes), are likely to cause stress in pigs The past decades trend has been for less piggeries but with larger numbers Between 2009 and 2011, the number of pigs slaughtered in Victoria increased by 20.6 per cent In 2010 83% of breeding sow herds were found on farms with less than 100 sows and 3.6 % were found on pig farms with 1,000 or more sows Large farms account for almost half of the Victorian herd Pig farms holding less than 100 sows are sometimes referred to as 'opportunistic' producers, with herd sizes fluctuating, depending on prices for pigs relative to other commodities Minimum Holding Size / Stocking Rates Victorian code of practice for piggeries sets out the stocking rates and area required for both housed and free range pigs outdoors: Space allowances for outdoor systems. Maximum stocking rate recommendations in paddocks 20-25 Dry sows sows/ha 9-14 Lactating sows sows/ha with piglets Feeding facilities are included in this allowance. The amount of land required to operate a freerange piggery will be determined on a nutrient mass balance approach and is influenced by climate, soil type, cropping regimes within any keeping areas, land topography, pasture cover and SPU number kept within the areas On-site vegetative buffer zones around sensitive sites are required, as well appropriate separation between neighbours and the pig keeping activity. Queensland DPI provide an on-line calculation “the Free Range Piggery Assessment spreadsheet” which allows entering the details of a proposed freerange piggery and calculate the required area needed to accommodate a number of pigs Codes of Practice & Regulatory Controls Victorian Pig Welfare Standards and Guidelines. Code of Practice for Piggeries 1992. A planning code instructing farmers on how to set up their piggery. Code of Practice for the Land Transport of Pigs Code of Practice for the welfare of livestock at sale yards Traceability - Property Identification Codes for Pig Owners The National Environmental Guidelines for Piggeries provide a general framework for managing environmental issues Victorian State Planning Scheme Yarra Ranges Planning Scheme Prevention of Cruelty to Animals Act Impounding of Livestock Act (ILA) Livestock Management Act Environmental Protection Act Port Phillip & Western Port Catchment Management Plan Potential Environmental & Amenity Issues Free-range piggeries should be located on relatively flat land with a gradient and soil type that will minimise soil, and therefore nutrient, erosion from the pig keeping areas to adjacent surface waters Site topography is a critical issue to managing off-site impacts Free Range pigs should not be exposed to land with chemical contaminated soil (e.g. DDT or dieldrin) The stocking rate should reflect the biophysical capacity of the property to undertake an environmentally sustainable business E.g. accommodate the herd - to assimilate the nitrogen and phosphorus deposited by the pig herd on the pig keeping areas. Piggeries should be sited with an adequate separation distance to address amenity concerns Specifically, odor, dust and noise from the operation must not adversely impact upon neighbouring properties and communities A well-established and maintained vegetative buffer zone can improve visual amenity, odor dispersion and reduce dust and noise. Planning Constraints Piggeries – housed or free range are not noted in the Agriculture nesting Diagram but would be captured in section 2 of GWZ – intensive animal husbandry ‘ other than’ broiler or feedlot – a catch all statement . In some cases animals may be slaughtered at an approved abattoir but the carcasses are returned to the property for processing and direct sale. This processing falls under the definition of ‘rural industry’ and would be permitted in the GWZ All piggeries, whether housed or free range, fall into the planning definition of ‘intensive animal husbandry’ Options to Address Issues Changes to the Schedule to clause 53 to allow intensive animal husbandry with a permit Add to the definition of intensive animal industry to specifically have a group called ‘other’ giving examples of these; free range pig, poultry or other free range bird production Council could approve a planning permit for free range piggeries with the following permit conditions: A detailed and comprehensive Environmental Management Plan (EMP) for the rotational free range piggery The EMP would include the methodology of calculation of the minimum ground cover of 75% required to be maintained on operational areas of the rotational piggery EMP would include detailed sustainable pasture management and animal husbandry management which will ensure that odor problems will not arise. EMP would also address how effluent management, odor and fly amenity issues would be addressed by ongoing management. The Guidelines for Biosolids Application to Land could be used to minimise the risk of nitrogen and phosphorus pollution to soils, surface waters and groundwater Intensive Agriculture Study - Yarra Ranges Council Enterprise Free Range Egg Production Description of Enterprise There are three main production systems used to produce eggs; caged, barnlaid and free-range. The three systems of egg production are guided by the National Model code of practice for the welfare of animals - domestic poultry 4th edition Free range production systems provide birds with the ability to range or move around in both indoor and outdoor areas Birds can nest, dust bathe, perch and move freely. Birds are also exposed to both natural and artificial lighting. Free range commercial sheds range from 2000 to 10,000 birds. The semi commercial backyard industry has shed sizes from 100 to 2000 birds. Some small free range systems have mobile shelters that can be moved around to allow rotation of the range area All systems require the majority of feed to be bought onto the farm Free range production is more costly for a number of reasons including the greater area of land and labour required per bird Free range egg production would come under the current definition of ‘intensive animal husbandry’ Current Status of the Industry Over the 13 years to 2009-10, the number of farms where the primary activity was the production of eggs in Victoria declined from 145 to 86(within ABAR definitions – would not capture small producers) This reflected consolidation and concentration of production within the industry Victorian egg production increased gradually in the early 2000's before stabilising at between 60 and 80 million dozen per year. Gross value of egg production for human consumption in Victoria in 2009-10 was $108.7 million Current Location of Production & Trends The last decade has seen egg products become increasingly differentiated by production methods, creating opportunities for growers and egg companies and increasing choices for consumers About 28% of eggs sold in Australia are produced from free range systems (65% cage, 7% barn) There are a number of voluntary egg production accreditation schemes operating in Australia Egg producers can choose which scheme to be accredited with The major problem is that in Australia there is no legal national definition of the term 'free range' which makes it impossible to maintain accountability in the industry (recent ACCC court case in NSW) Victoria's chicken egg production is located predominantly in the Barwon, Melbourne, Loddon and Gippsland regions The increasing desire for choice from consumers has opened up new opportunities for growers and egg companies to be innovative and to differentiate their products DRAFT ONLY for DISCUSSION. Prepared by Ag-Challenge Consulting for Yarra Ranges Council Minimum Holding Size / Stocking Rates Stocking rates are a contested area within the industry, with various commercial and animal welfare groups having differing interpretations e.g. 1500 to 10,000 / hectare Free-range egg standards in the Model Code include the following. hens have access to an outdoor area (range) during daylight hours for a minimum of eight hours per day, shaded areas and shelter from rain and windbreaks there is a maximum of 1500 hens per hectare, however, higher numbers are acceptable if hens are regularly rotated onto fresh range areas and continuing fodder cover is provided As hens are housed in sheds when not out on the range, the Model Code sets out guidelines for the maximum number of hens that can be housed and this applies to both freerange and barn laid systems of production. 5 Codes of Practice & Regulatory Controls Animal Welfare and the Model Code - National Victorian Food Act 1984 (reference to on farm production) November 2012 National Primary Production and Processing Standard for Eggs and Egg Product More than 100 birdsthe farm is legally required to have a PIC under the Livestock Disease Control Act 1994. Yarra Ranges Planning Scheme Prevention of Cruelty to Animals Act Livestock Management Act Environmental Protection Act Port Phillip & Western Port Catchment Management Plan Biosecurity for Poultry Production Comment: Under planning, biosecurity, animal welfare and environmental requirements free range poultry have the same legal responsibilities as cages or barn production systems Potential Environmental & Amenity Issues Free-range poultry should be located on relatively flat land with a gradient and soil type that will minimise soil, and therefore nutrient, erosion from the poultry keeping areas to adjacent surface waters Site topography is a critical issue to managing off-site impacts Free Range poultry should not be exposed to land with chemical contaminated soil (e.g. DDT or dieldrin) The stocking rate should reflect the biophysical capacity of the property to undertake an environmentally sustainable business E.g. accommodate the flock to assimilate the nitrogen and phosphorus deposited The poultry system should be sited with an adequate separation distance to address amenity concerns Specifically, odour, dust and noise from the operation must not adversely impact upon neighbouring properties/communities Planning Constraints Egg production – housed or free range is not noted in the Agriculture nesting Diagram ( definition) but would be captured in the section 2 of GWZ – intensive animal husbandry ‘ other than’ broiler or feedlot – a catch all statement Planning scheme makes no reference or determination on egg production systems or number of birds that would fall within requirements for planning DPI use 100 birds as a trigger for registration of a PIC number. This could be used by Council as a means of determining the number of birds that would trigger the need for a planning permit It would be assumed that the majority of egg production systems, caged, free range or variations within these definitions require the majority of feed to come from off the farm. Options to Address Issues Changes to the Schedule to clause 53 to allow intensive animal husbandry with a permit Add to the definition of intensive to specifically have a group called ‘other’ giving examples of these; free range poultry with flocks greater than 100 birds Council could approve a planning permit for free range poultry with the following permit conditions: A detailed and comprehensive Environmental Management Plan (EMP) for the rotational free range system A EMP would include the methodology of calculation of the minimum ground cover of 75% required to be maintained on operational areas of the flock EMP would include detailed sustainable pasture management and animal husbandry management which will ensure that odor problems will not arise The Guidelines for Biosolids Application to Land could be used to minimise the risk of nitrogen and phosphorus pollution to soils, surface waters and groundwater Intensive Agriculture Study - Yarra Ranges Council Enterprise Free Range Chicken Meat Description of Enterprise Free-range chicken meat comes from chickens that have access to an outdoor area during the day. At night, free-range chickens are kept in sheds or barns. Birds can nest, dust bathe, perch and move freely. This is unlike traditional broiler production with birds permanently housed. In all other respects free range meat chickens are produced using similar management, housing and feeding practices as conventional meat chickens. Conditions on free-range farms vary greatly. On some farms, the range area is large, provides grass for foraging, has access to shade and shelter, and all birds are able to come and go from the range during the day; on others, the range area may be a limited fenced area with minimal amenity for birds. The time birds are allowed out of the shed can vary greatly e.g. 2to 8 hours. All systems require the majority of feed to be bought onto the farm. Free range production is more costly for a number of reasons including the greater area of land and labour required per bird. Free range chicken meat production would come under the current definition of ‘intensive animal husbandry. Current Status of the Industry The chicken meat industry ids vertically integrated from producer to wholesaler through a small number of companies (Inghams, Steggles, Golden Poultry, Eatmore Poultry) In 2010-11, Australian per capita consumption rose to 43.9kg and the total consumer expenditure related to chicken meat in its various forms is estimated to be $5.6 billion There are several large players in the industry e.g. Lillydale Poultry that produce a ‘free range product’. Despite the dominance of the major companies, there is an increasing number of smaller free range poultry meat enterprises. Current Location of Production & Trends In 1963 Australians ate an average of 4.2kg of chicken a year. By 2010 that figure has increased tenfold, making chicken the most popular meat in Australia. This huge shift in consumption is due to a combination of supply and demand factors. Within this, free range chicken meat has until recently been a specialty product. Demand for free range chicken has grown significantly. Five years ago free range chicken could most accurately be described as a cottage industry. In a relatively short period of time it has grown to be around 15 per cent of the total market In terms of demand for free range chicken, based on trends oversees and in the Australian table egg market, it is expected that free range will grow to become between 20 per cent and 25 per cent of the total market The main driver for location is the proximity to processing works (required to be 100ks or less ) DRAFT ONLY for DISCUSSION. Prepared by Ag-Challenge Consulting for Yarra Ranges Council Minimum Holding Size / Stocking Rates Stocking rates is a contested area within the industry, with various commercial and animal welfare groups having differing interpretations e.g. 1500 to 140,000 birds per hectare 6 Codes of Practice & Regulatory Controls Australian Codes of Practice for the Welfare of Animals (including the Model Codes of Practice for the Welfare of Animals Domestic Poultry, Land Transport of Poultry, and Livestock at Slaughtering Establishments National Animal Welfare Standards for the Chicken Meat Industry Australia New Zealand Food Standards Code (the Code) under the FSANZ Act 1991. The processing and marketing of chicken meat is governed by the Code Yarra Ranges Planning Scheme Prevention of Cruelty to Animals Act Livestock Management Act Environmental Protection Act Port Phillip & Western Port Catchment Management Plan Biosecurity for Poultry Production Comment: Under planning, biosecurity, animal welfare, food safety and environmental requirements free range poultry have the same legal responsibilities as a broiler farm. Potential Environmental & Amenity Issues Free-range poultry should be located on relatively flat land with a gradient and soil type that will minimise soil, and therefore nutrient, erosion from the poultry keeping areas to adjacent surface waters Site topography is a critical issue to managing off-site impacts Free Range poultry should not be exposed to land with chemical contaminated soil (e.g. DDT or dieldrin) The stocking rate should reflect the biophysical capacity of the property to undertake an environmentally sustainable business E.g. accommodate the flock to assimilate the nitrogen and phosphorus deposited The poultry system should be sited with an adequate separation distance to address amenity concerns Specifically, odour, dust and noise from the operation must not adversely impact upon neighbouring properties/communities Planning Constraints Broiler production e.g. chicken meat is defined in the Planning Scheme The scheme does not referrer to free range chicken meat production – which would still fall under the definition of ‘intensive animal husbandry It would be assumed the same planning would apply to free range as for broiler (and also to caged, barn or free range egg systems – each system faces the same environmental and amenity issues As such would be captured in the section 2 of GWZ – intensive animal husbandry ‘ other than’ broiler or feedlot – a catch all statement (subject to 52.31) Currently broiler farms are prohibited under the provisions of Clause 53 as part of Intensive Animal husbandry. Options to Address Issues Changes to the Schedule to clause 53 to allow intensive animal husbandry with a permit Add to the definition of intensive to specifically have a group called ‘other’ giving examples of these; free range poultry with flocks greater than 100??? Council could approve a planning permit for free range poultry with the following permit conditions: A detailed and comprehensive Environmental Management Plan (EMP) for the rotational free range system A EMP would include the methodology of calculation of the minimum ground cover of 75% required to be maintained on operational areas of the flock EMP would include detailed sustainable pasture management and animal husbandry management which will ensure that odor problems will not arise • The Guidelines for Biosolids Application to Land could be used to minimise the risk of nitrogen and phosphorus pollution to soils, surface waters and groundwater Intensive Agriculture Study - Yarra Ranges Council Enterprise White Veal Description of Enterprise White veal comes from milk fed young calves in housed systems. This form of veal production is geared to high end restaurants and some consumers value and are prepared to pay a high price for the product The production system in Victoria uses calves from the states large dairy industry Most production comes from three to four day old dairy calves (mix of sex and breed e.g. dairy beef cross calves) sent direct for slaughter. Some opportunistic production can also develop where these calves are purchased to be grown out. Calves are generally reared in groups in sheds (some with access to pasture) and fed milk or milk replacer. This specialist calf-rearing method results in rose (pink) veal. Holding of calves in rearing crates is not allowed in Australia Almost 70% of veal feeds (by weight) are milk products. Most popular are whey and whey protein concentrate (WPC), byproducts of the manufacture of cheese. Larger white veal calves are slaughtered before they reach 18–20 weeks of age, 200 to 230 kg Current Status of the Industry Very Limited data available, ABS data combines both beef and veal data – so unable to separate. The definition for veal would also include bobby calves slaughtered. The industry is growing. In 2010 to 2011 44,137 tons of veal was produced in Australia, up 14,000 tons from 2006. This is 32% growth in five years. Current Location of Production & Trends There are several large specialist white veal producers in Australia promoting their product (web info). However, there are also increasing numbers of smaller opportunistic producers who move into the industry when price signals are profitable. DRAFT ONLY for DISCUSSION. Prepared by Ag-Challenge Consulting for Yarra Ranges Council Minimum Holding Size / Stocking Rates The stocking density of pens or yards must take into account age, size, behavioral needs, movement and feeding patterns of cattle. In any event, an absolute minimum space In the case of housed animals an absolute minimum of 2.5m2 must be provided for each animal (reference code of acceptable farming practice for the management of cattle – DPI) Usually no more than 20 to 30 calves should be placed in a single pen 7 Codes of Practice & Regulatory Controls Australian Animal Welfare Standards and Guidelines. referred to as the Land Transport Standards has specific requirements for bobby calves The Victorian Code for Cattle Feedlots Livestock Management Act 2010 Land Transport Standards - Saleyards Code of Acceptable Framing Practice for Management of Cattle Yarra Ranges Planning Scheme Prevention of Cruelty to Animals Act Livestock Management Act Environmental Protection Act Port Phillip & Western Port Catchment Management Plan Potential Environmental & Amenity Issues White veal production systems should be located on relatively flat land with a gradient and soil type that will minimise soil, and therefore nutrient, erosion from the animal keeping areas to adjacent surface waters Site topography is a critical issue to managing off-site impacts The stocking rate should reflect the biophysical capacity of the property to undertake an environmentally sustainable business E.g. accommodate the animals to assimilate the nitrogen and phosphorus deposited from the housed system The housed production system should be sited with an adequate separation distance to address amenity concerns Specifically, odour, dust and noise from the operation must not adversely impact upon neighbouring properties/communities Planning Constraints This enterprise would be considered an ‘intensive animal husbandry’ activity under planning definition re: cattle feedlot. As such would be captured in the section 2 of GWZ – intensive animal husbandry ‘ broiler or feedlot ( subject to 52.26 Options to Address Issues The potential for this industry to develop within the Yarra Ranges Council is limited due to the low number of existing dairy establishments and the absence of milk processing facilities. If deemed under the definition of a ‘feedlot’ then existing planning scheme applies. Intensive Agriculture Study - Yarra Ranges Council Enterprise Intensive Goat Meat Production Description of Enterprise Goat meat mostly comes from extensive operations based on pasture based or rangeland based farming systems. There are however small intensive production systems where animals are fed high energy supplements to target specific markets and for specific times of the year. Intensive systems involve partial feedloting or use of feed pads to grow out goats to specific slaughter weights Sheds or arks (mobile sheds) are sometimes used to house and shelter goats Breeding animals are run on a pasture based system with kids at weaning moving into the intensive feeding system for finishing The partial feedlot system requires feed from either off farm or feed that is grown on the farm and carried to the feedlot system. Grain feeding often results in fatter carcasses than carcasses from animals of similar live weight that have been grazing. This "fattening" can be used to advantage to finish goats to meet certain market specifications. Current Status of the Industry Victoria's goat industry is based on broad acre production systems. Intensive systems are a very minor part of the industry. In 2011, 632 businesses were involved in the production of goats, holding 38,806 head. Current Location of Production & Trends The majority of Australian goat meat production comes from wild (rangeland) goats, in New South Wales and Queensland. In Victoria, most goat meat production comes from specialist meat (Boer goat) producers The Victorian goat meat industry experienced significant growth in the last decade in response to strong export demand. Domestic demand has also increased. The number of goats slaughtered in Victoria increased from 849 in 1996 to approximately 600,728 in 2010–11 Around 55 per cent of Victoria's goat production occurs in the Gippsland, East Gippsland and Goulburn regions Farms are also located in Barwon and the peri urban regions of outer Melbourne which produce about 22 per cent of Victoria's goats DRAFT ONLY for DISCUSSION. Prepared by Ag-Challenge Consulting for Yarra Ranges Council Minimum Holding Size / Stocking Rates No information on stocking rates for intensive housing or feedlots available Confined goats should have enough space to be able to lie down, stretch, stand up and to exercise. They should have access to shelter, food and water 8 Codes of Practice & Regulatory Controls Code of Accepted Farming Practice for the Welfare of Goats Code of Practice for the Land Transport Code of Practice for the welfare of livestock at sale yards Traceability - Property Identification Codes Yarra Ranges Planning Scheme Prevention of Cruelty to Animals Act Impounding of Livestock Act (ILA) Livestock Management Act Environmental Protection Act Port Phillip & Western Port Catchment Management Plan Code of Practice for the Tethering of Animals. Potential Environmental & Amenity Issues Intensive goat production systems should be located on relatively flat land with a gradient and soil type that will minimise soil, and therefore nutrient, erosion from the animal keeping areas to adjacent surface waters Site topography is a critical issue to managing off-site impacts The stocking rate should reflect the biophysical capacity of the property to undertake an environmentally sustainable business E.g. accommodate the animals to assimilate the nitrogen and phosphorus deposited from the housed system The housed production system should be sited with an adequate separation distance to address amenity concerns Specifically, odour, dust and noise from the operation must not adversely impact upon neighbouring properties/communities Planning Constraints This enterprise could be considered an ‘intensive animal husbandry’ activity under planning deoending on the management system. As such would be captured in the section 2 of GWZ – intensive animal husbandry ‘ other” Options to Address Issues Changes to the Schedule to clause 53 to allow intensive animal husbandry with a permit Add to the definition of intensive to specifically have a group called ‘other’ giving examples of these; intensive goat production – feedloting to finish goats Council could approve a planning permit for intensive goat systems with the following permit conditions: A detailed and comprehensive Environmental Management Plan (EMP) A EMP would include the methodology of calculation of the minimum ground ground cover of 75% required to be maintained on operational areas EMP would include detailed sustainable pasture management and animal husbandry management which will ensure that odor problems will not arise. The Guidelines for Biosolids Application to Land could be used to minimise the risk of nitrogen and phosphorus pollution to soils, surface waters and groundwater. Intensive Agriculture Study - Yarra Ranges Council Enterprise Turkey Farming (free range ? or housed) Description of Enterprise There is a broad range of enterprise sizes and production systems. Production can either be housed or free range. Free-range turkey meat come from turkeys that have continuous access to an outdoor area. Unlike chickens they are not housed at night. Conditions on free-range farms vary greatly. On some farms, the range area is large, provides grass for foraging, has access to shade and shelter, and all birds are able to come and go from the range during the day; on others, the range area may be less attractive for the birds. A hen may lay over 100 eggs/year but fewer than 90 poults will probably survive to processing weight from these eggs. Birds are held on separate breeder farms, each farm holding up to 7,000 hens. These layers are in flocks of up to 3,000 and are held in broiler sheds, typically 4 to 5 on large farms Straw, wood shavings and sawdust are the bedding materials used. Diets are specially formulated and hens are fed ad libitum, but toms are usually restricted from 16–18 weeks onwards Current Status of the Industry In Australia, the larger hatcheries supply contract growers while there are some smaller hatcheries which provide day-old turkey poults to backyard poultry keepers. Inghams Enterprises dominates the market with, on average, 46,000 turkeys processed per week (60 to 65% of market share. Production appears to be relatively stable but there may be some future growth in free range production following the trend observed in chicken meat industry. Current Location of Production & Trends Much of the larger commercial production units are located in the grain belt of Victoria. Demand for whole turkeys is mainly at Christmas and is usually for the smaller birds of 4.5 – 6.5 kg live weight. For the rest of the year, demand is for further processed products, mainly from heavy toms, such as boned or semi de-boned products. Free range turkeys, commanding a premium price, are produced on a few small farms. Rainbow Valley Turkeys, a major grower, produces about 650,000 turkey eggs/year. Many of these are sold to producers for hatching and some of the poults are purchased by small farmers for growing out. DRAFT ONLY for DISCUSSION. Prepared by Ag-Challenge Consulting for Yarra Ranges Council Minimum Holding Size / Stocking Rates Variations between housed and free range. Free range stocking rates vary and are not defined To be certified by Humane Choice, free range turkeys are to be at a maximum stocking rate of 1500 birds per hectare. 9 Codes of Practice & Regulatory Controls Australian Codes of Practice for the Welfare of Animals (including the Model Codes of Practice for the Welfare of Animals Domestic Poultry, Land Transport of Poultry, and Livestock at Slaughtering Establishments National Animal Welfare Standards for the Chicken Meat Industry Australia New Zealand Food Standards Code (the Code) under the FSANZ Act 1991. The processing and marketing of chicken meat is governed by the Code Yarra Ranges Planning Scheme Prevention of Cruelty to Animals Act Livestock Management Act Environmental Protection Act Port Phillip & Western Port Catchment Management Plan Comment: Under planning, biosecurity, animal welfare, food safety and environmental requirements free range or housed turkey production have the same legal responsibilities as broilers farm Potential Environmental & Amenity Issues Free-range poultry, including turkey, should be located on relatively flat land with a gradient and soil type that will minimise soil, and therefore nutrient, erosion from the poultry keeping areas to adjacent surface waters Site topography is a critical issue to managing off-site impacts Free Range poultry should not be exposed to land with chemical contaminated soil (e.g. DDT or dieldrin) The stocking rate should reflect the biophysical capacity of the property to undertake an environmentally sustainable business E.g. accommodate the flock to assimilate the nitrogen and phosphorus deposited The poultry system should be sited with an adequate separation distance to address amenity concerns Specifically, odour, dust and noise from the operation must not adversely impact upon neighbouring properties/communities Planning Constraints Broiler production e.g. chicken meat is defined in the Planning Scheme – could also include turkey The scheme does not referrer to free range chicken/ turkey or other bird species meat production – which would still fall under the definition of ‘intensive animal husbandry It would be assumed the same planning would apply to free range as for broiler (and also to caged, barn or free range egg systems – each system faces the same environmental and amenity issues As such would be captured in the section 2 of GWZ – intensive animal husbandry ‘ other than’ broiler or feedlot – a catch all statement (subject to 52.31) Options to Address Issues Changes to the Schedule to clause 53 to allow intensive animal husbandry with a permit. Add to the definition of intensive to specifically have a group called ‘other’ giving examples of these; free range turkey flocks Council could approve a planning permit for free range turkey with the following permit conditions: A detailed and comprehensive Environmental Management Plan (EMP) for the rotational free range system A EMP would include the methodology of calculation of the minimum ground cover of 75% required to be maintained on operational areas of the flock EMP would include detailed sustainable pasture management and animal husbandry management which will ensure that odor problems will not arise The Guidelines for Biosolids Application to Land could be used to minimise the risk of nitrogen and phosphorus pollution to soils, surface waters and groundwater. Intensive Agriculture Study - Yarra Ranges Council Enterprise Emu Farming Description of Enterprise Emus are farmed for their meat, leather and oil. Most production systems use caged enclosures. Emus are kept in situations that vary from extensive grazing to closely managed flocks in confined areas, with and without housing. In a grazing situation pasture alone doesn’t meet the nutritional needs of birds and feed grain is required Females produce up to 20 eggs per year. Once hatched the chicks are raised in separate enclosures away from adult birds. Chicks require special attention until they lose their ‘stripe’ appearance, which usually occurs by 12 weeks of age. Current Status of the Industry The emu industry in Australia has gone through several phases over the past 20 years from a very small production base in Western Australia to a high level of interest in breeding for meat products, and now with a commercial focus on meat and skin production International and domestic markets have not proved to be stable with fluctuations in demand and price. Several small landholdings have emus as a novelty Current Location of Production & Trends No production data of meat or hide sales is available. Industry appears to currently be in decline with little positive outlook. DRAFT ONLY for DISCUSSION. Prepared by Ag-Challenge Consulting for Yarra Ranges Council Minimum Holding Size / Stocking Rates Holdings range in size from just one breeding pair up to several hundred birds. Difficult to organize processing for small holders Recommended stocking rates for adult bird are 16 birds per ha. Where breeding pens are utilised, wire netting (rabbit netting) to a height of 450 mm must be provided on all fences to prevent the chicks escaping Recommended that chicks be housed in groups of up to 50 for the first four weeks of life. Where the yearlings must be grouped together they should be housed at maximum stocking rates of 18 per hectare for dry or bare conditions and up to 24 per hectare for lush or irrigated conditions. 10 Codes of Practice & Regulatory Controls Model Code of Practice for the Welfare of Animals: Husbandry of Captive-Bred Emus Prevention of Cruelty to Animals Act Emus are protected in Victoria in accordance with the Wildlife Act 1975. People with the appropriate licence from the Department of Sustainability and Environment are permitt ed to keep, rear and sell native animals specifi ed in the Wildlife Regulations 2002. Potential Environmental & Amenity Issues Emu production should be located on relatively flat land with a gradient and soil type that will minimise soil, and therefore nutrient, erosion from the poultry keeping areas to adjacent surface waters Site topography is a critical issue to managing off-site impacts Emu production should not be exposed to land with chemical contaminated soil (e.g. DDT or dieldrin) The stocking rate should reflect the biophysical capacity of the property to undertake an environmentally sustainable business E.g. accommodate the flock to assimilate the nitrogen and phosphorus deposited The system should be sited with an adequate separation distance to address amenity concerns Specifically, odour, dust and noise from the operation must not adversely impact upon neighbouring properties/communities Planning Constraints Intensive Emu Farming, housed or free range is not noted in the Agriculture nesting Diagram ( definition) but would be captured in the section 2 of GWZ – intensive animal husbandry ‘ other than’ broiler or feedlot – a catch all statement Planning scheme makes no reference or determination on emu farming systems or number of birds that would fall within requirements for planning Options to Address Issues Changes to the Schedule to clause 53 to allow intensive animal husbandry with a permit. Add to the definition of intensive to specifically have a group called ‘other’ giving examples of these; intensive emu production Council could approve a planning permit for intensive emu production with the following permit conditions: A detailed and comprehensive Environmental Management Plan (EMP) for the rotational free range system A EMP would include the methodology of calculation of the minimum ground cover of 75% required to be maintained on operational areas of the flock EMP would include detailed sustainable pasture management and animal husbandry management which will ensure that odor problems will not arise The Guidelines for Biosolids Application to Land could be used to minimise the risk of nitrogen and phosphorus pollution to soils, surface waters and groundwater. Intensive Agriculture Study - Yarra Ranges Council Enterprise Ostrich Description of Enterprise Ostriches are farmed for their meat and leather. Ostrich feathers are a by-products. . Birds are mostly kept in caged enclosures and in closely managed flocks. The confined areas can be with or without housing. In a grazing situation pasture alone doesn’t meet the nutritional needs of birds and feed grain is required. Females produce up to 20 eggs per year. Once hatched the chicks are raised artificially. Current Status of the Industry The Australian ostrich industry is a young industry with the first commercial interest developing in the late 1980’s and early 1990’s. Production initial went through a rapid expansion from a virtually zero base to an industry with a strong commercial focus on meat and skin production International and domestic markets have not proved to be stable with fluctuations in demand and price. Today the industry in Victoria has a few larger farms producing product for sale while many small landholder have ostriches as a novelty. Current Location of Production & Trends No production data of meat or hide sales available. Export of both meat and leather. Some of the leather processing used to be offshore. Initially the industry was dominated by a large number of quite small production units. Anecdotal observation is that there has been some extensive rationalisation and there are now a smaller number of quite large production units DRAFT ONLY for DISCUSSION. Prepared by Ag-Challenge Consulting for Yarra Ranges Council Minimum Holding Size / Stocking Rates Commercial holding can be as small as one cock bird servicing just two or three females. Larger holdings are more common, but there is little or no information on large flock sizes. 11 Codes of Practice & Regulatory Controls Prevention of Cruelty to Animals Act. Australian Standard for the Hygienic Production of Ratite (Emu, Ostrich). Meat for Human Consumption FCARM report No 71, Australian Standard 5010/2001 Potential Environmental & Amenity Issues Ostriches should be located on relatively flat land with a gradient and soil type that will minimise soil, and therefore nutrient, erosion from the poultry keeping areas to adjacent surface waters Site topography is a critical issue to managing off-site impacts Ostriches should not be exposed to land with chemical contaminated soil (e.g. DDT or dieldrin) The stocking rate should reflect the biophysical capacity of the property to undertake an environmentally sustainable business E.g. accommodate the flock to assimilate the nitrogen and phosphorus deposited The farming system should be sited with an adequate separation distance to address amenity concerns Specifically, odour, dust and noise from the operation must not adversely impact upon neighbouring properties/communities Planning Constraints Ostrich Farming, is not noted in the Agriculture nesting Diagram ( definition) but would be captured in the section 2 of GWZ – intensive animal husbandry ‘ other than’ broiler or feedlot – a catch all statement Planning scheme makes no reference or determination on ostrich farming systems or number of birds that would fall within requirements for planning Options to Address Issues Changes to the Schedule to clause 53 to allow intensive animal husbandry with a permit. Add to the definition of intensive to specifically have a group called ‘other’ giving examples of these; ostriches. Council could approve a planning permit for ostrich farming with the following permit conditions: A detailed and comprehensive Environmental Management Plan (EMP) for the rotational free range system A EMP would include the methodology of calculation of the minimum ground cover of 75% required to be maintained on operational areas of the flock EMP would include detailed sustainable pasture management and animal husbandry management which will ensure that odor problems will not arise The Guidelines for Biosolids Application to Land could be used to minimise the risk of nitrogen and phosphorus pollution to soils, surface waters and groundwater. Intensive Agriculture Study - Yarra Ranges Council Enterprise Pheasant Farming Description of Enterprise Pheasants are raised commercially in much the same way as commercial broiler chickens. The formation of the NSW Branch of the Pheasant and Waterfowl Society of Australia by a number of commercial and semi-commercial pheasant producers has further assisted the development of pheasant production. Current Status of the Industry Current Location of Production & Trends Minimum Holding Size / Stocking Rates Mostly located in sheds that have been converted from other purposes. Small scale producers tageting specific markets, mainly restairant based. The demand for table No information available pheasants in New South Wales has increased in recent years. There are now a number of restaurants, particularly in Sydney, regularly featuring pheasant dishes on their menus Presumably this trend also applies to Victoria DRAFT ONLY for DISCUSSION. Prepared by Ag-Challenge Consulting for Yarra Ranges Council 12 Codes of Practice & Regulatory Controls Australian Codes of Practice for the Welfare of Animals (including the Model Codes of Practice for the Welfare of Animals Domestic Poultry, Land Transport of Poultry, and Livestock at Slaughtering Establishments National Animal Welfare Standards for the Chicken Meat Industry Australia New Zealand Food Standards Code (the Code) under the FSANZ Act 1991. The processing and marketing of chicken meat is governed by the Code Yarra Ranges Planning Scheme Prevention of Cruelty to Animals Act Livestock Management Act Environmental Protection Act Port Phillip & Western Port Catchment Management Plan Biosecurity for Poultry Production Comment: Under planning, biosecurity, animal welfare, food safety and environmental requirements free range poultry have the same legal responsibilities as broilers farm Potential Environmental & Amenity Issues Should be located on relatively flat land with a gradient and soil type that will minimise soil, and therefore nutrient, erosion from the poultry keeping areas to adjacent surface waters Site topography is a critical issue to managing off-site impacts Should not be exposed to land with chemical contaminated soil (e.g. DDT or dieldrin) The stocking rate should reflect the biophysical capacity of the property to undertake an environmentally sustainable business E.g. accommodate the flock to assimilate the nitrogen and phosphorus deposited The poultry system should be sited with an adequate separation distance to address amenity concerns Specifically, odour, dust and noise from the operation must not adversely impact upon neighbouring properties/communities Planning Constraints Broiler production e.g. chicken meat is defined in the Planning Scheme The scheme does not referrer to pheasant production – which would still fall under the definition of ‘intensive animal husbandry It would be assumed the same planning would apply to free range as for broiler (and also to caged, barn or free range egg systems – each system faces the same environmental and amenity issues As such would be captured in the section 2 of GWZ – intensive animal husbandry ‘ other than’ broiler or feedlot – a catch all statement (subject to 52.31) Options to Address Issues Changes to the Schedule to clause 53 to allow intensive animal husbandry with a permit Add to the definition of intensive to specifically have a group called ‘other’ giving examples of these; free range poultry with flocks greater than 100??? Council could approve a planning permit for free range poultry with the following permit conditions: A detailed and comprehensive Environmental Management Plan (EMP) for the rotational free range system A EMP would include the methodology of calculation of the minimum ground cover of 75% required to be maintained on operational areas of the flock EMP would include detailed sustainable pasture management and animal husbandry management which will ensure that odour problems will not arise.. The Guidelines for Biosolids Application to Land could be used to minimise the risk of nitrogen and phosphorus pollution to soils, surface waters and groundwater problems will not arise Intensive Agriculture Study - Yarra Ranges Council Enterprise Farmed Rabbit Description of Enterprise Rabbit farming is primarily located in sheds which may house anywhere from 10 to over 100 breeding does The production is primarily targeted toward the restaurant trade but farmed rabbit is available in some specialty butchers Current Status of the Industry The industry was originally widely diversifed across southern with approximately 30 separate producers and with processing works at Bairnsdale and poowong Current Location of Production & Trends A recent decline in the number of producers has been reported anecdotally. DRAFT ONLY for DISCUSSION. Prepared by Ag-Challenge Consulting for Yarra Ranges Council Minimum Holding Size / Stocking Rates Rabbits require a minimum area of 0.6 m2 13 Codes of Practice & Regulatory Controls Model Code of Practice for the welfare of Animals – Intensive Husbandry of Rabbits Prevention of Cruelty to Animals Act. A licence is required to operate a rabbit farm under the DEPI Pest Licence arrangements. The Gourmet Rabbit Producers of Victoria work collectively to promote their industry and remove constraints Potential Environmental & Amenity Issues The enterprise size should reflect the biophysical capacity of the property to undertake an environmentally sustainable business E.g. accommodate the animals to assimilate the nitrogen and phosphorus deposited from the housed system The housed production system should be sited with an adequate separation distance to address amenity concerns Specifically, odour, dust and noise from the operation must not adversely impact upon neighbouring properties/communities Planning Constraints This enterprise would be considered an ‘intensive animal husbandry’ activity under planning definition re: cattle feedlot. Even the larger production units are however on a very small scale in comparison to cattle production systems. As such would be captured in the section 2 of GWZ – intensive animal husbandry ‘ broiler or feedlot ( subject to 52.26 Options to Address Issues If deemed under the definition of a ‘feedlot’ then existing planning scheme applies. 4. Relevance of the Current Planning Controls The terms and definitions set out in the Planning Scheme do not differentiate between free range systems and fully housed systems. There is no allowance for different forms of intensity. The ‘more than 50% of feed coming from off farm’ is the key determination. The various animal enterprises investigated, free range, housed and variations within these terms ALL require more that 50% of feed to come from outside the enclosure to sustain the animals. With good management and strong adherence to industry Codes of Practice some of these enterprises should have a low impact on the existing land and the general amenity of the area. The Green Wedge Zone sets out various purposes including, the provision of agricultural land while also recognizing, protecting and conserving land within the GWZ for agriculture and environment. The ‘purposes’ also seek to encourage sustainable farming activities and land management. Schedules to the Green Wedge Zone are referred to in Clause 53.01 of the planning scheme which states that NO intensive animal husbandry is allowed within the GWZ Schedules 1,2 and 3. It is assumed the intent of this is to protect the high value environmental and public amenity from negative impact that may arise from intensive animal husbandry re: broiler sheds and feedlots. A clear role of any planning scheme is to protect that which is valued – open landscapes with environmental and public amenity Thus it would appear that there may be some inconsistency in these provisions and there is a need to reconsider the prohibition of intensive animal husbandry in the Green Wedge Zones. If there is a reasonable expectation that some of these enterprises can be operated with a low environmental and amenity impact, their prohibition is against the stated objectives of the Green wedge Zone to encourage sustainable farming activities and land management. 5. Recommendations Some of the animal production systems looked at in this report could best be described as semi intensive, such as the ‘free range’ enterprises. With good management the enterprise could potentially address the environmental and public amenity issues. This could be done by proponents being required to satisfy that they adhere to published industry Codes of Practice and also provide an Environmental Management Plan that address environmental and amenity concerns as part of any approval (permit) process. This is a potential change to the provisions of the planning scheme that is within the control of the Yarra Ranges Council. Thus it is recommended that Yarra Ranges Council remove the prohibition of intensive animal husbandry from the Schedule attached to the Green Wedge Zone and replace it with a permit requirement for intensive animal industries which are not fully dependent on animals being housed at all times. The definition of intensive animal husbandry may be too broad to reflect the different environmental and amenity impact that would occur with different levels of intensity that are implemented in these enterprises. The definition should be reviewed to reflect the differing systems e.g. free range pig, free range poultry and other free range bird production systems along with semi intensive production e.g. goat meat, where animals breed on the farm and then spend a certain amount of time in confined areas to be finished prior to sale. A review of this definition is not a prerogative of the Yarra Ranges Council but needs to be undertaken by the State Government. Intensive Agriculture Study - Yarra Ranges Council A possible approach to reviewing the definition would be to describe two different intensive animal husbandry systems; One that has more the 50% of feed consumed coming off farm and animals are permanently confined to sheds or feeding pads (Feed and permanent confinement being the criteria for determination). The other, has more than 50% of feed consumed coming from off the farm with animals having access to open paddock areas as part of the production system. At any point in time 75% of the farm has to have an acceptable level of ground cover. That is the animals have access to open paddocks with stock rotation to manage ground cover and 75% of the property must maintain good ground cover at any point in time. It is recommended that Yarra Ranges Council make the appropriate representation for a review of this definition within the State section of the Planning Scheme. DRAFT ONLY for DISCUSSION. Prepared by Ag-Challenge Consulting for Yarra Ranges Council 15