Included chemicals, mixtures and solutions

advertisement

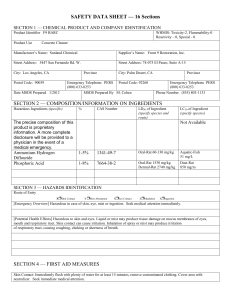

See Instructions in EMV´s HMS-page Risk Assessment of Department Group Date Tasks included in the risk assessment Included chemicals, mixtures and solutions Chemical, mixture or solution CAS Number Amount Indication of danger (hazard statement and limit value) Ethanol 99,5% 64-17-5 800 ml H225 Highly flammable liquid and vapour Level limit value Ceiling limit value Short-term value Total dust Respirable dust [ppm] [mg/m3] [ppm] [mg/m3] [ppm] [mg/m3] [mg/m3] [mg/m3] 500 Ethanol 95% 64-17-5 700 ml 1000 1000 1900 H225 Highly flammable liquid and vapour Level limit value Ceiling limit value Short-term value Total dust Respirable dust [ppm] [mg/m3] [ppm] [mg/m3] [ppm] [mg/m3] [mg/m3] [mg/m3] 500 Ethanol 80% 64-17-5 200 ml 1000 1000 1900 H225 Highly flammable liquid and vapour Level limit value Ceiling limit value Short-term value Total dust Respirable dust [ppm] [mg/m3] [ppm] [mg/m3] [ppm] [mg/m3] [mg/m3] [mg/m3] 500 Hydrochloric acid, conc 37% 7647-01-0 5 ml 1000 1000 1900 H314 Causes severe skin burns and eye damage. H335 May cause respiratory irritation. Level limit value Ceiling limit value Short-term value Total dust Respirable dust Chemical, mixture or solution CAS Number Amount Indication of danger (hazard statement and limit value) [ppm] [mg/m3] [ppm] [mg/m3] [ppm] [mg/m3] [mg/m3] [mg/m3] 5 Xylene 1330-20-7 600 ml 8 H226 Flammable liquid and vapour. H312 Harmful in contact with skin. H315 Causes skin irritation. H332 Harmful if inhaled. Caution! Skin penetrating substance according to The Swedish Work Environment Authority’s provisions and on occupational exposure limit values, AFS 2011:18 Level limit value Ceiling limit value Short-term value Total dust Respirable dust [ppm] [mg/m3] [ppm] [mg/m3] [ppm] [mg/m3] [mg/m3] [mg/m3] 50 242 g? 221 100 442 Tris(hydroxymetyl)aminometan (s) 77-86-1 H315 Causes skin irritation. H319 Causes serious eye irritation. H335 May cause respiratory irritation. SDS (s) 151-21-3 H228 Flammable solid. H302 Harmful if swallowed. H311 Toxic in contact with skin. H315 Causes skin irritation. H319 Causes serious eye irritation. H335 May cause respiratory irritation. Isobutyl alcohol 78-83-1 H226 Flammable liquid and vapour. H315 Causes skin irritation. H318 Causes serious eye damage. H335 May cause respiratory irritation. H336 May cause drowsiness or dizziness. NB! Skin penetrating substance according to The Swedish Work Environment Authority's provisions and on occupational exposure limit values, AFS 2011:18 Level limit value Ceiling limit value Short-term value Total dust Respirable dust [ppm] [mg/m3] [ppm] [mg/m3] [ppm] [mg/m3] [mg/m3] [mg/m3] 50 150 75 250 Chemical, mixture or solution CAS Number Amount Indication of danger (hazard statement and limit value) Identification of risks of accident or ill-health, assessment of risks and suggestion of preventive measures Task Identified risk/problem Assessment of risk, see risk matrix Consequence Run the gel (electrophoresis) Probability Preventive measures Assessed Risk Potential for exposure via inhalation and direct contact with eyes and skin. Potential fire hazard. Use labcoat, safety goggles and disposable nitrile gloves. Work in fume hood or on ventilated bench with Plexiglas hood. Write in handling and safety instruction. Potential for exposure via inhalation and direct contact with eyes and skin. Potential fire hazard. Use labcoat, safety goggles and disposable nitrile gloves. Change gloves frequently, especially if you suspect contamination. Remove gloves carefully without touching skin. Work in fume hood. Write in handling and safety instruction. The limit values for hydrochloric acid and ethanol are not exceeded at any occasion. All staff participate in mandatory fire training every 5 years.. Labs are equipped with fire extinguishers. No risk associated with task. Use labcoat, safety goggles and disposable nitrile gloves. Potential for serious electrical shock or electrocution due to leaking chamber, faulty or corroded electrode cables, or faulty power supply. Potential for exposure via inhalation and direct contact with eyes and skin Potential fire hazard Mycket allvarliga Möjligt Mycket riskfyllt Ensure all equipment is in good working order, and that lid is always on electrophoresis tank when in operation. Write in handling and safety instruction. Estimated risk after preventive measure Acetic acid Potential for exposure to highly corrosive vapours, and for direct contact of corrosive solution with eyes and skin Clean and take care of waste Potential for exposure via inhalation and direct contact with eyes and skin Potential fire hazard. Potential environmental risk. Transport and handle chemicals and bottles Drop bottles or chemicals potential risk for exposure via inhalation or direct contact with eyes and skin. Potential fire hazard. Allvarliga Möjligt Riskfyllt Store acids and bases below waist height. Transport on trolley or in a bucket. Make sure that you are prepared in case of a spillage. Write in handling and safety instruction Centralt placerade spillkit samt tillhörande instruktion tas fram, se EMV:s HMS-handlingsplan för 2013. In case of power or ventilation failure or if evacuation is necessary Fumes evaporate to lab Moderate Low High risk Close containers and close fume hood. Write in handling and safety instruction. At power failure or evacuation Fumes evaporate to lab Cleaners If glass ware not rinsed before sending to be washed, potential for exposure via direct contact with eyes and skin. Same personal protective equipment as during the task Dispose of as chemical waste. Close containers and close fume hood. Write in handling and safety instruction. Serious Possible Moderate risk Before sending glass ware to be washed it must be properly rinsed. Write in in handling and safety instruction. Cleaning must only be performed in free areas and cleaners must not wipe spill. Write in instruction for cleaners. Have hazardous tasks been defined and rules for working alone been considered? Have risks during power/water failure etc or because of evacuation been considered? Do you have preparedness in case of spillage, eg first aid, absorption material, gloves? Do you have a written handling and safety instruction for this work? Do you have a written instruction for cleaners and other maintenance personal? References Protocol for Task in the Improvement plan for EMV 2013 Ej riskfyllt SDS for all chemicals LU´s Handling Regulations for Management of hazardous waste EMV:s HMS-webpage Participants Reviewed by Approved by Research Group Leader Name in printing