Conventional Fire Alarm Control Panels

advertisement

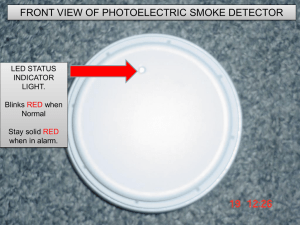

Fire Alarm System Control Panel Fire Alarm Control Panel Fire Alarm Control Panel is the controlling component of a Fire Alarm System. The panel receives information from environmental sensors designed to detect changes associated with fire, monitors their operational integrity and provides for automatic control of equipment, and transmission of information necessary to prepare the facility for fire based on a predetermined sequence. Conventional Fire Alarm Control Panels Conventional panels have been around ever since electronics became small enough to make them viable. Conventional panels are used less frequently in large buildings than in the past, but are not uncommon on smaller projects such as small schools, stores, restaurants, and apartments A conventional Fire Alarm Control Panel employs one or more circuits, connected to sensors (initiating devices) wired in parallel. These sensors are devised to dramatically decrease the circuit resistance when the environmental influence on any sensor exceeds a predetermined threshold. In a conventional fire alarm system, the information density is limited to the number of such circuits used. To facilitate location and control of fire within a building, the structure is subdivided into definite areas or zones. Floors of a multistory building are one type of zone boundary. Addressable Fire Alarm Control Panels Addressable panels are usually more advanced than their conventional counterparts, with greater information capacity and control flexibility Addressable Fire Alarm Control Panels employ one or more Signaling Line Circuits, slang usually referred to as loops or SLC loops - ranging between one and thirty. Depending on the protocol used, a Signaling Line Circuit can monitor and control several hundred devices. Some protocols permit any mix of detectors and input/output modules, while other protocols have 50% of channel capacity restricted to detectors/sensors and 50% restricted to input/output modules. Each SLC polls the devices connected, which can number from a few devices to several hundred, depending on the manufacturer. Large systems may have multiple Signaling Line Circuits Each device on a SLC has its own address, and so the panel knows the state of each individual device connected to it. Common addressable input (initiating) devices include Releasing (Fire Fighting) panels Releasing panels are capable of using solenoids to disperse fire-fighting chemical agents such as water from piping located throughout a building. A releasing panel usually will have a manual abort switch to abort an accidental release which could damage property or equipment. Releasing capability can be part of both addressable and conventional panels Detector Smoke Detector Smoke detector is a device that detects smoke, typically as an indicator of fire. Commercial, industrial, and mass residential devices issue a signal to a fire alarm system, Smoke detectors are typically housed in a disk-shaped plastic enclosure about 150 millimetres (6 in) in diameter and 25 millimetres (1 in) thick, but the shape can vary by manufacturer or product line. Most smoke detectors work either by optical detection (photoelectric) or by physical process (ionization), while others use both detection methods to increase sensitivity to smoke. Sensitive alarms can be used to detect, and thus deter, smoking in areas where it is banned such as toilets and schools. Smoke detectors in large commercial, industrial, and residential buildings are usually powered by a central fire alarm system, which is powered by the building power with a battery backup. However, in many single family detached and smaller multiple family housings, a smoke alarm is often powered only by a single disposable battery. Optical An optical detector is a light sensor. When used as a smoke detector, it includes a light source (incandescent bulb or infrared LED), a lens to collimate the light into a beam, and a photodiode or other photoelectric sensor at an angle to the beam as a light detector. In the absence of smoke, the light passes in front of the detector in a straight line. When smoke enters the optical chamber across the path of the light beam, some light is scattered by the smoke particles, directing it at the sensor and thus triggering the alarm. Ionization An ionization smoke detector uses a radioisotope such as americium-241 to produce ionization in air; a difference due to smoke is detected and an alarm is generated. Ionization detectors are more sensitive to flaming fires than optical detectors, while optical detectors are more sensitive to smoldering Fires. An ionization type smoke detector is generally cheaper to manufacture than an optical smoke detector; however, it is sometimes rejected because it is more prone to false (nuisance) alarms than photoelectric smoke detectors It can detect particles of smoke that are too small to be visible. Air-sampling An air-sampling smoke detector is capable of detecting microscopic particles of smoke. Most air-sampling detectors are aspirating smoke detectors, which work by actively drawing air through a network of small-bore pipes laid out above or below a ceiling in parallel runs covering a protected area. Small holes drilled into each pipe form a matrix of holes (sampling points), providing an even distribution across the pipe network. Air samples are drawn past a sensitive optical device, often a solid-state laser, tuned to detect the extremely small particles of combustion. Air-sampling detectors may be used to trigger an automatic fire response, such as a gaseous fire suppression system, in high-value or mission-critical areas, such as archives or computer server rooms. Heat Detector Fixed temperature heat detectors This is the most common type of heat detector. Fixed temperature detectors operate when the heat sensitive eutectic alloy reaches the eutectic point changing state from a solid to a liquid. Thermal lag delays the accumulation of heat at the sensitive element so that a fixedtemperature device will reach its operating temperature sometime after the surrounding air temperature exceeds that temperature. The most common fixed temperature point for electrically connected heat detectors is 136.4°F (58°C). Technological developments have enabled the perfection of detectors that activate at a temperature of 117°F (47°C), increasing the available reaction time and margin of safety. This type of technology has been available for decades without the use of batteries or electricity as shown in the picture. Rate-of-rise heat detectors Rate-of-Rise (ROR) heat detectors operate on a rapid rise in element temperature of 120° to 150°F (67° to 83°C) increase per minute, irrespective of the starting temperature. This type of heat detector can operate at a lower temperature fire condition than would be possible if the threshold were fixed. It has two heat-sensitive thermocouples/ thermistor. One thermocouple monitors heat transferred by convection or radiation. The other responds to ambient temperature. Detector responds when first’s temperature increases relative to the other. Rate of rise detectors may not respond to low energy release rates of slowly developing fires. To detect slowly developing fires combination detectors add a fixed temperature element that will ultimately respond when the fixed temperature element reaches the design threshold. Linear Heat Detector Linear Heat Detection (LHD) is a versatile and economical fire detection product. Designed for use in a wide variety of fire and heat detection applications, LHD cable is particularly suited for harsh environmental conditions, where maintenance access is in a physical or hazardous area, and/or where there is a requirement to cost-effectively install fire detection in close proximity to the hazard. Linear Heat Detection cable is a combination of advanced polymer and digital technologies that can detect heat conditions anywhere along the length of the cable. The cable is comprised of two tri-metallic conductors individually insulated with a heat sensitive polymer outer-layer, and engineered to break down at specific fixed temperatures. This allows the twisted conductors to make contact and initiate a fire alarm condition at the control panel, without any calibration for changes in the ambient temperature. Nor is it required that a specific length be heated in order to initiate a fire alarm, adding to the versatility of this unique product. Gas Detector A gas detector is a device which detects the presence of various gases within an area, usually as part of a safety system. This type of equipment is used to detect a gas leak and interface with a control system so a process can be automatically shut down. A gas detector can also sound an alarm to operators in the area where the leak is occurring, giving them the opportunity to leave the area. Gas detectors can be used to detect combustible, flammable and toxic gases, and oxygen depletion. They also be used in firefighting. Gas detectors are usually battery operated. They transmit warnings via a series of audible and visible signals such as alarms and flashing lights, when dangerous levels of gas vapors are detected. As detectors measure a gas concentration, the sensor responds to a calibration gas, which serves as the reference point or scale. As a sensor’s detection exceeds a preset alarm level, the alarm or signal will be activated. As units, gas detectors are produced as portable or stationary devices. Originally, detectors were produced to detect a single gas, but modern units may detect several toxic or combustible gases, or even a combination of both types Flame Detector The optical flame detector is a detector that uses optical sensors to detect flames. There are also ionization flame detectors, which use current flow in the flame to detect flame presence, and thermocouple flame detectors. Ultraviolet Ultraviolet (UV) detectors work with wavelengths shorter than 300 nm. These detectors detect fires and explosions within 3–4 milliseconds due to the UV radiation emitted at the instant of their ignition. False alarms can be triggered by UV sources such as lightning, arc welding, radiation, and sunlight. In order to reduce false alarm a time delay of 2-3 seconds is often included in the UV Flame detector design. Infrared Infrared (IR) flame detectors work within the infrared spectral band. Hot gases emit a specific spectral pattern in the infrared region, which can be sensed with a thermal imaging camera (TIC) a type of thermo graphic camera. False alarms can be caused by other hot surfaces and background thermal radiation in the area as well as blinding from water and solar energy. A typical frequency where single frequency IR flame detector is sensitive is in the 4.4 micrometer range. Typical response time is 3-5 seconds. UV/IR UV and IR flame detectors compare the threshold signal in two ranges in "AND" configuration and their ratio to each other to confirm the fire signal and minimize false alarms. IR/IR flame detection Dual IR (IR/IR) flame detectors compare the threshold signal in two infrared ranges. In this case one sensor looks at the 4.4 micrometer range the other sensor at a reference frequency.