TEC

Charge transport in solids with Cobra4

Related concept

Electron conductivity, ion conductivity.

Principle

Measuring the temperature dependence of the resistivity of solids provides information on the mechanism of conduction.

.Material

2

2

1

1

1

1

1

1

1

1

1

1

5

1

2

Cobra4 USB Link

Cobra4 Sensor-Unit Electricity

Software measure Cobra4

Holder for Cobra4

Stand for Cobra4

Digital thermometer

Immersion probe NiCr-Ni, Teflon

Power supply, universal

Magnetic heating stirrer

Magnetic stirrer bar, l = 30 mm

Support rod, l = 500 mm, M10 thread

Support rod, l = 250 mm

Right angle clamp

Universal clamp

Insulating pin

12610-00

12644-00

14550-61

12680-00

12681-00

07050-00

13615-05

13500-93

35751-93

46299-02

02022-20

02031-00

37697-00

37715-00

07807-00

2 Connecting cord, l = 500 mm, red

1 Connecting cord, l = 750 mm, red

2 Connecting cord, l = 750 mm, blue

1 Beaker, 1000 ml, short

1 Scissors, 180 mm, straight

1 Copper wire, d = 0.2 mm, 100 m

1 Iron wire, d = 0.2 mm, 100 m

1 Constantan wire, d = 0.2 mm, 100 m

1 Water, distilled, 5 l

07361-01

07362-01

07362-04

36017-00

64798-00

06106-00

06104-00

06100-00

31246-81

Additional equipment

PC with USB interface, Windows XP or

1

higher

-

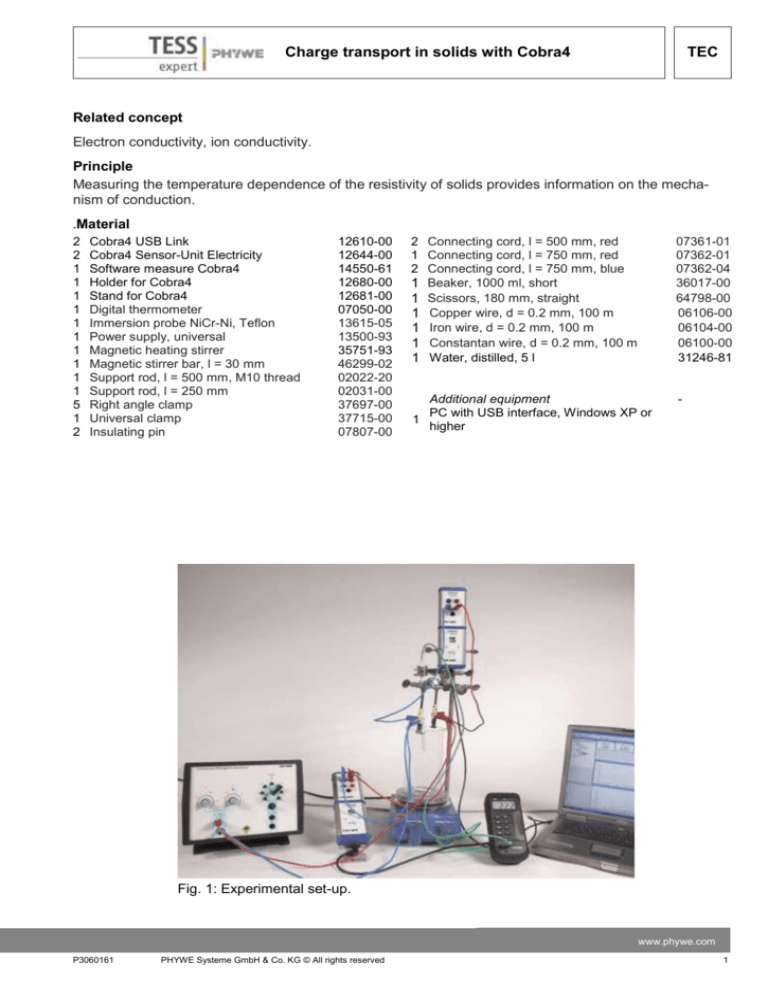

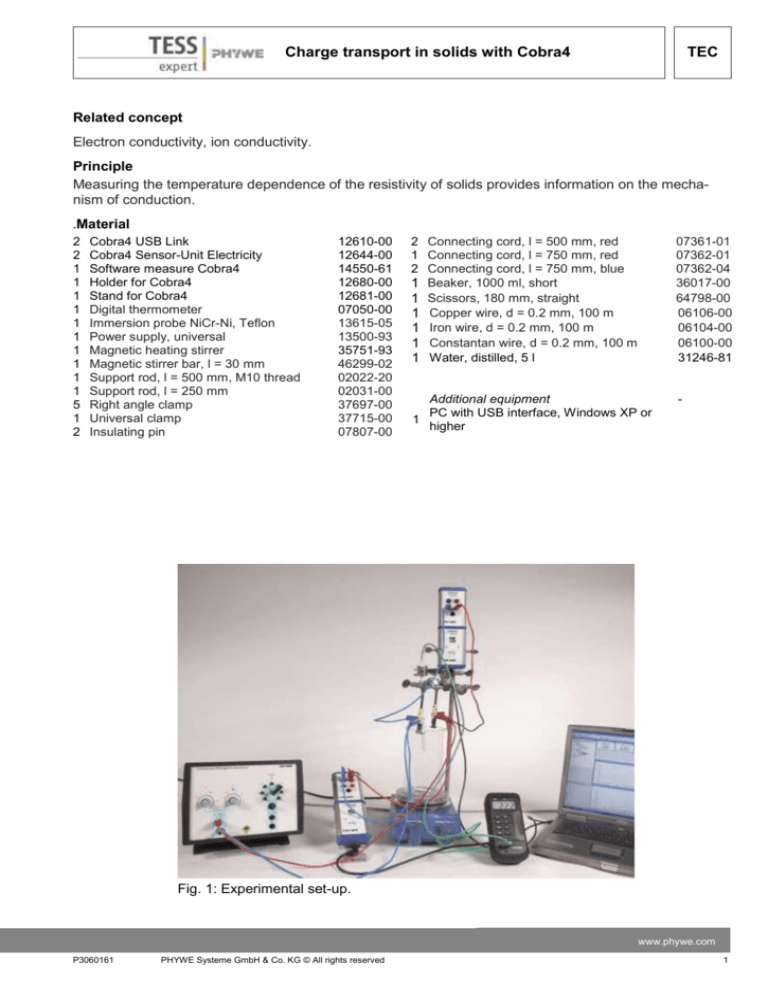

Fig. 1: Experimental set-up.

www.phywe.com

P3060161

PHYWE Systeme GmbH & Co. KG © All rights reserved

1

TEC

Charge transport in solids with Cobra4

Safety instructions

When handling chemicals, you should wear suitable protective gloves, safety goggles, and suitable

clothing. Please refer to the appendix for detailed safety instructions.

Tasks

Determine the temperature coefficient of iron wire, copper wire and constantan wire in the range of room

temperature to 95°C.

Set-up and preparation

Set up the experiment as shown in Fig. 1.

Prepare a sample of each of the three types of wire. To do this, cut off a piece of wire about 30 cm

in length and coil it to a loose coil by winding it around a pencil. The individual windings must not

touch each other.

Place the beaker on the heater and put a magnetic stirrer bar into it.

Fill the beaker with distilled water.

Attach the insulting pins using the universal clamps und right angle clamps to the support stand as

shown in figure 1.

Connect the Cobra4 Sensor Units Electricity to the Cobra4 USB Links and attach them to the support rod with the holders for Cobra4.

Connect the temperature probe to the digital thermometer.

Connect one of the insulting pins with the “+” socket of the power supply and the other insulting pin

with the “+” current socket of one of the Cobra4 Sensor-Units Electricity using red connecting cords.

Connect the “-” current socket of the same Cobra4 Sensor-Unit with the “-” socket of the power supply using a blue connecting cord.

Connect one insulting pin with the “-” voltage socket and the other one with the “+” voltage socket of

the second Cobra4 Sensor-Unit.

Attach the first sample to be measured to the two insulating pins and immerse it in the beaker.

Immerse the temperature probe into the water.

Adjust the magnetic stirrer to a medium stirring speed.

Start the PC and connect the Cobra4 USB-Link with the computer via a USB cable.

Call up the “Measure” programme.

Boot the experiment “Charge transport in solids with Cobra4” (experiment > open experiment). The

measurement parameters for this experiment are loaded now.

To record the individual measurement series, set a voltage of approximately 0.25 V for the copper

wire and one of 1.2 V for the iron and constantan wire.

-

Start the measurement with

-

Record the first point measured at 25°C by pressing

.

Increase the temperature by heating the water under continuous stirring and take the values at intervals of 5°C with

until the temperature reaches 95 °C.

Stop the measurement by pressing .

Send all data to “measure”.

-

-

2

PHYWE Systeme GmbH & Co. KG © All rights reserved

P3060161

Charge transport in solids with Cobra4

-

TEC

Save the measurement (File> Save measurement as…).

Figs. 3 - 5 show the graphs as they are presented by the programme when the measurement is

stopping.

Fig. 3: Dependence of resistance vs. temperature (iron wire).

Fig. 4: Dependence of resistance vs. temperature (copper wire).

Fig. 5: Dependence of resistance vs. temperature (constantan wire)

Theory and evaluation

Solids conduct electric current according to the type of bonding of their components, which are mainly

metal bonding and ionic bonding. Accordingly we must concern ourselves with electronic conductivity

and ionic conductivity.

www.phywe.com

P3060161

PHYWE Systeme GmbH & Co. KG © All rights reserved

3

TEC

Charge transport in solids with Cobra4

Electronic conductivity is observed in metals, alloys and those substances which have metallic lustre,

such as graphite, some metal oxides, metal sulfides and others. Most of the semiconductors used in

electronics and electrical technology and isolating materials are also electronic conductors. This kind of

conductivity is connected with metal bonds. In this, the outer electrons in the metal grid are only loosely

bound, and can move between the atomic cores. They act there more or less like cement, in a similar

way as in atomic bonding. In contrast to that, however, the bonding electrons do not belong to two particular atoms, but to all of them, and the bond has no spatial direction. The mobile particles present in the

metal grid are the cause of electrical conductivity. The band theory of the movement of electrons in solids explains the phenomenon on the basis of different energy states of the electrons in the solid. Conductivities range over 30 orders of magnitude from isolators with specific conductivities near 1022 Ω-1 ·

cm-1 to the very good conductance of purest metals at low temperatures, with specific conductivities up

to 10-8 Ω-1 cm-1.

Ionic conductivity is the ability of a substance to conduct an electric current by means of the movement

of ions. All electrolyte solutions, molten salts and those solid salts which are chemically typical ionic

compounds are ionic conductors. Because of the strong binding in the ionic lattice of solid salts, the ionic

mobility, and therefore also the conductivity, is very small at room temperature. With increasing temperature the bonds are slowly loosened, and the ions become more and more mobile. This phenomenon continues up to the melting point and beyond. The rise of temperature is connected with a decrease of resistivity. This is the opposite temperature dependence to that of the electrical conductivity. With metals an

increase of temperature will not increase the number or mobility of the electrons. In fact the opposite is

true, the mobility decreases as the increasing thermal energy of the metal ions increases their thermal

oscillations around their position in the lattice. As a result, there is a corresponding increase in the number of collisions of electrons and metal ions, which decreases the mean free path length of the electrons.

This is followed by a decrease in the electrical conductivity.

From the experimental values of current and voltage, the resistance R can be calculated from:

𝑅=

U

I

𝑈

𝐼

(1)

Voltage in V

Current in A

The temperature coefficient of resistivity is defined as the slope of the curve of resistivity versus temperature:

𝑅𝑇2 −𝑅𝑇1

𝛼=𝑅

(2)

𝑇1 (𝑇2 −𝑇1 )

This only holds true if the curve of resistivity versus temperature is a straight line, which it is not over a

wider range of temperature. For a more correct description the differential quotient

1

𝑑𝑅

𝛼 = 𝑅 ∙ 𝑑𝑇

(3)

must be used. This shows that the temperature coefficient itself is temperature dependent.

Data and results

The temperature coefficient of resistivity can be calculated from the experimental values:

𝛼=

Rc

4

1 ∆𝑅

∙

𝑅𝑐 ∆𝑇

(4)

Resistance at 20 °C

PHYWE Systeme GmbH & Co. KG © All rights reserved

P3060161

Charge transport in solids with Cobra4

∆𝑅

∆𝑇

TEC

Slope of the compensation straight line

By means of equation (4) we obtain αFe = 4.6 · 10-3 K-1 and αCu = 4 · 10-3 K-1.

In the case of constantan (alloy Cu 60 / Ni 40) the measured resistivity is constant over the total temperature range.

www.phywe.com

P3060161

PHYWE Systeme GmbH & Co. KG © All rights reserved

5

TEC

Charge transport in solids with Cobra4

Space for notes.

6

PHYWE Systeme GmbH & Co. KG © All rights reserved

P3060161