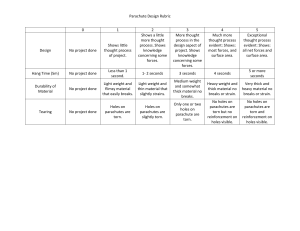

Product criteria of suitability for hot

advertisement

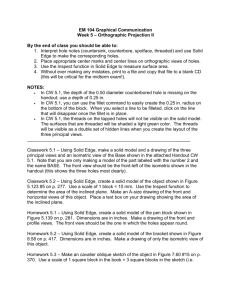

Product criteria of suitability for hot-dip galvanizing Description 1 Dimensions 2 3 Weight Thin-walled articles (wall thickness of 0,8-2 mm) Structures without holes or hinges Suitability for hot-dip galvanizing Design 13,6 х 2,2 х 3,1 m (LхWхD) recommended maximum 9 t Test galvanizing is required Method of loading on jig should be considered 5 Tanks, drums, pipe coils Unsuitable 6 Reservoirs, containers Each structure to be considered separately. 7 Pockets, closed cavities, air-pockets Unsuitable, or adaptation is required 8 Hollow products and Each structure to be articles of irregular shape considered separately Pipes, branch pipes, Unsuitable housings with blind plugs 4 9 10 Welded tube structures Suitable, if fabrication holes are available 11 Welding gap is less than 4 mm Blind gaps are not acceptable, through gaps can be sealed off with zinc 12 Welded structures where different steel grades are used Suitable Remarks Galvanizing of longer articles is possible upon prior agreement Limited by the crane capacity Risk of temperature deformation Additional provision of holes or hinges, or usage of special tooling Generally, fabrication holes are not acceptable in such structures, and galvanizing of structures with enclosed volumes is not acceptable. Formation of air pockets or areas with significant amount of trapped zinc is possible. All cavities should ensure unimpeded inlet and outlet of liquids, melted zinc and flux decomposition gases. Test galvanizing is required There is no free outlet of zinc from the interior volume of the product, formation of airpockets is possible Thorough examination of structure for availability of fabrication holes is required. For requirements to fabrication holes refer to table Relationship between pipe size and number of holes in plugs at their ends Liquid from pre-treatment area can penetrate into blind gaps causing explosion due to its evaporation during immersion into the zinc melt. Through gaps of less than 4 mm size are subject to intensive crevice corrosion over time Coating appearance on different steel grades can differ significantly 13 14 Internal stress concentration zones (unacceptable bend radius) Different wall thicknesses of structural components 15 Overlapping zones 16 Sheet metal products 17 Folded or flanged edges of metal sheets 18 Edge bend radii 19 Tanks, pipes: -for potable water -for service water -for process fluids transfer 25 26 27 Product surface has marks of paint coats, highlighters, silicon grease or sealants Product surface has marks of rust, scale, oils, greases, coolants Surface roughness Unsuitable Possible destruction at the galvanizing temperature Expansion of material and behavior of components with thin and thick walls during cooling down can differ depending on thickness ratio Presence of overlapping zones should be avoided, where possible Minimum and maximum thickness ratio should not exceed 1:5 Unsuitable Coating contains lead Suitable Suitable, if fluid рН is 5,5 to 12,5 and fluid temperature does not exceed 35оС Surface Such zones will not be galvanized Mechanical removal of such contaminants is required Small overlapping zones to be airtightly welded along the contour. For large overlapping zones, on the contrary, vent holes to be provided. Stability of sheet metal is It is preferable to use not flat not high. Besides, if sheets, but sheets with large there is no possibility for bend radius. product expansion during hot-dip galvanizing, then distortion can easily occur. Possibility of gap Particular care is required, so formation that during galvanizing acid or flux residuals did not sediment in crevices and these overlapping zones could be sealed off with zinc melt. Possibility of air-pockets It is required to ensure formation unimpeded inlet and outlet of zinc; if required, special holes should be provided. Purpose Suitable These contaminants to be removed in the pre-treatment zone Affects the coating thickness Surfaces with very deep roughness, for example, steel elements shot blasted using shots with very sharp edges, 28 29 Low quality surfaces having such defects as voids, flakes, stripes, wrinkles. Thread surfaces These are the reasons of low quality coating or coating unsuitable for operation Zinc coating thickness is significant, thus, this thread cannot be used without rethreading generally, form thicker zinc coating, since rough surface provides larger area for reaction. Mechanical removal of such defects is required Thread surfaces should be isolated before galvanizing by means of cloth tape (male thread), heat-proof mastic (female thread) Welded joints 30 Welded joints: - butt welding or doublesided welding, or singlesided welding with backing run; - overlapping loopback connections continuous along the perimeter, without gaps; -point or non-continuous welding; -pores, blowholes, cracks, slag inclusions, filler coupling of weld joins, splatters; -manual welding using high silicon electrodes 31 Products requiring preliminary degalvanizing Suitable Suitable Unsuitable Unsuitable Deseaming is required, sand blasting is recommended High silicon content causes visible difference of weld joint from other surface Suitable, but not recommended Special cases Suitable, but test galvanizing is recommended In case of thin-walled articles thickness can be reduced to undesirable tolerances. Products can have worse appearance than the ones non subject to degalvanizing, and this should be approved with the customer. Relationship between pipe size and number of holes in plugs at their ends Pipe type Holes quantity and size О □ ▭ 1 2 15 20 30 15 20 30 20х10 30х15 40х20 8 10 12 10 3 40 50 60 80 100 120 160 200 40 50 60 80 100 120 160 200 50х30 60х40 80х40 100х60 120х80 160х80 200х120 260х140 14 16 20 20 25 30 40 50 12 12 12 16 20 25 25 30 10 10 12 12 20 20 25 Diameters of fabrication holes should not be less than 10 mm. Actual sizes shall be selected from experience, namely, fabrication hole area of long-profile structures should be minimum1/7 – 1/10 of sectional area of profile included in the structure. The more the size of fabrication holes is, the smoother galvanizing proceeds and the higher is the coating quality. Large-sized parts should have fabrication holes of 15-25 mm diameter at 50 mm distance from the article end (parts longer than 2 m should have holes at two sides).