spill containment program

advertisement

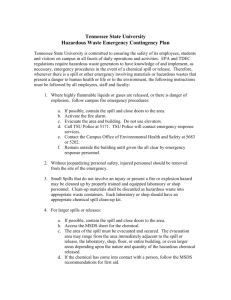

SPILL CONTAINMENT PROGRAM THE PROBLEM: The Hazwoper Standard requires employers to implement a spill containment program as part of the site-specific Health and Safety Plan (HASP). The purpose of the spill containment program is to set out procedures to contain and isolate the entire volume of a hazardous substance spill and minimizes worker exposure to hazardous substance spills. HOW TOOL HELPS SOLVE THE PROBLEM: Although the spill containment program— like the overall HASP—must be site-specific, the Model below can be used as a general template that you can adapt. Like the Model, make sure that your own spill containment covers at least the following elements: tial spill actions and response; Spill cleanup procedures; ; and -incident review and evaluation. ABC COMPANY SPILL CONTAINMENT PROGRAM 1. PURPOSE The objective of this section of the HASP is to meet the requirements of 29CFR 1910.120 (b)(4)(ii)(j). The spill containment program must address all hazardous substance spill scenarios that are likely to occur at the site, and must also provide procedures to contain and isolate the entire volume of any hazardous substance spilled in the course of a transfer, accident, or onsite release. 2. PREPLANNING To develop a successful spill containment program, an assessment must be conducted of the site conditions, current operations and planned activities. The assessment must carefully examine all hazardous materials on site for where and how the materials are: , location, type of container); , processed, used, transferred); and Each area or activity must be analyzed for potential accidental releases or spills. Examples of situations that have potential for spill or release are: Bulging or corroded containers; seals, misaligned connections); Metal fatigue of storage tanks; Leaking or inoperable valves; and Many potential spills can be avoided through application of proper engineering controls to hazards identified in the assessment. In areas where storage, handling, and transportation activities occur, preplanning to contain the largest volume of material that could be released in the area will minimize worker exposure. The containment measure must be appropriate to the hazardous material(s) identified and must be installed in the area or located nearby. Examples of measures most frequently used: Salvage containers (e.g., overpack drums); Bermed, lined pads; ike; Procedures must be developed to properly maintained and replace, as necessary, all spill containment equipment and fixtures. 3. REPORTING & INITIAL SAFETY Upon discovery of a hazardous substance spill, personnel must be instructed to: Health Officer (SSO), and/or the Project Manager; 4. INITIAL SPILL ACTION Factors that limit the employee's response at the site of a spill include: Level of training; Personal safety; onal protective equipment (PPE); and Knowledge of the substance. Employees must limit their actions to those that will not endanger themselves or others which might include: Shutting off equipment or pumps; Closing valves; ns within the path of the spill; and Unauthorized persons must be excluded from the area. 5. SPILL RESPONSE EVALUATION The identity and hazards of the spilled material must be determined before decisions about spill containment and control are made. The SSO or Project Manager must evaluate the hazards associated with the spill and decide whether project employees or external response organizations must conduct the cleanup. If the Project Manager determines that project response personnel cannot safely perform the spill cleanup, the Project Manager must notify and request the assistance of, the Emergency Response Coordinator, and the ERP must be activated. 6. ORGANIZING A SPILL RESPONSE If the Project Manager determines that cleanup can be performed safely with project response personnel, the SSO may act as the spill team leader and designate required procedures. Safety practices for small spill operations closely parallel procedures implemented during routine hazardous materials handling operations. Before work begins, the SSO must conduct a hazard identification and assessment with response personnel. The following must be discussed and established: ls of PPE and safety procedures; Safety and work zones; teps of the response activities; es or methods for cleanup; Means of containment; Leak or spill control; Decontamination procedures; and 7. SPILL CLEANUP PROCEDURES After care of injured personnel, containment of the released hazardous material must be the next consideration to limit its effect on the safety of personnel, the public, and the environment. The SSO must determine the methods of control which depend upon the nature and extent of the spill. Actions documented in the Emergency Response/Contingency Plan of this HASP must also be consulted. Decontamination must be accomplished in accordance with the Decontamination section of this HASP and disposal of contaminated materials must meet all regulatory requirements. 8. POST-INCIENT FOLLOW-UP The Project Manager or SSO must implement necessary steps to ensure that the incident is properly documented and that spill response equipment is replenished. The Project Manager must direct the necessary corrective actions to prevent recurrence and evaluate the response.