Datasheet - ESR Technology

advertisement

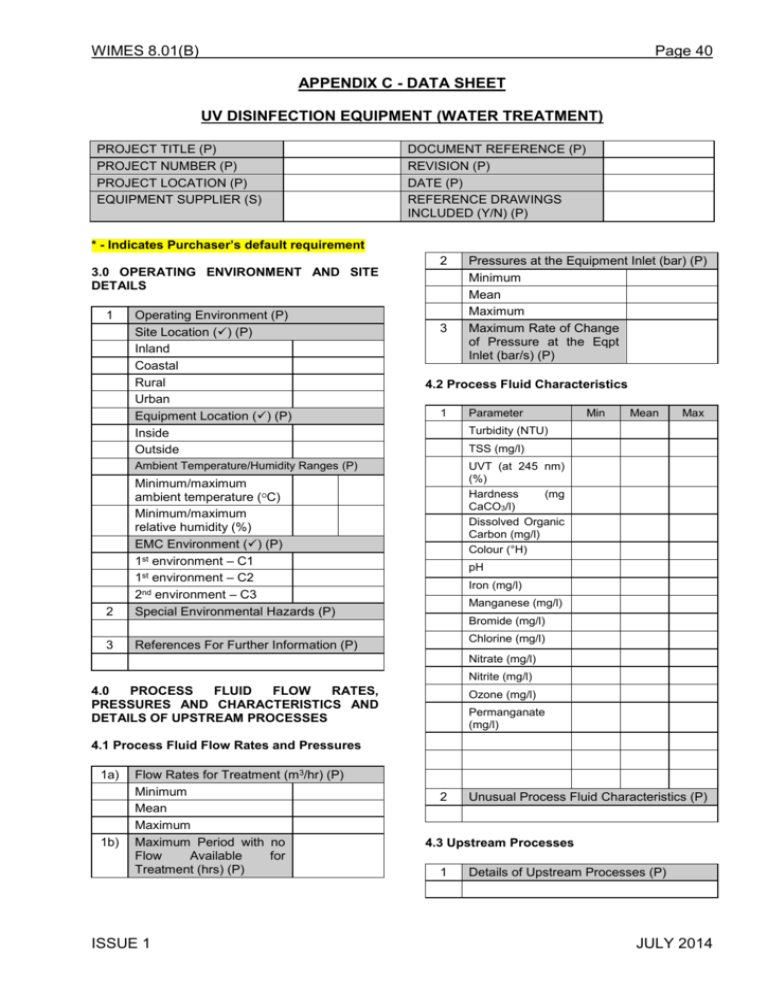

WIMES 8.01(B) Page 40 APPENDIX C - DATA SHEET UV DISINFECTION EQUIPMENT (WATER TREATMENT) PROJECT TITLE (P) PROJECT NUMBER (P) PROJECT LOCATION (P) EQUIPMENT SUPPLIER (S) DOCUMENT REFERENCE (P) REVISION (P) DATE (P) REFERENCE DRAWINGS INCLUDED (Y/N) (P) * - Indicates Purchaser’s default requirement 2 3.0 OPERATING ENVIRONMENT AND SITE DETAILS 1 Operating Environment (P) Site Location () (P) Inland Coastal Rural Urban Equipment Location () (P) Inside Outside 3 4.2 Process Fluid Characteristics 1 2 3 References For Further Information (P) Parameter Min Mean Max Turbidity (NTU) TSS (mg/l) Ambient Temperature/Humidity Ranges (P) Minimum/maximum ambient temperature (OC) Minimum/maximum relative humidity (%) EMC Environment () (P) 1st environment – C1 1st environment – C2 2nd environment – C3 Special Environmental Hazards (P) Pressures at the Equipment Inlet (bar) (P) Minimum Mean Maximum Maximum Rate of Change of Pressure at the Eqpt Inlet (bar/s) (P) UVT (at 245 nm) (%) Hardness (mg CaCO3/l) Dissolved Organic Carbon (mg/l) Colour (°H) pH Iron (mg/l) Manganese (mg/l) Bromide (mg/l) Chlorine (mg/l) Nitrate (mg/l) Nitrite (mg/l) 4.0 PROCESS FLUID FLOW RATES, PRESSURES AND CHARACTERISTICS AND DETAILS OF UPSTREAM PROCESSES Ozone (mg/l) Permanganate (mg/l) 4.1 Process Fluid Flow Rates and Pressures 1a) 1b) Flow Rates for Treatment (m3/hr) (P) Minimum Mean Maximum Maximum Period with no Flow Available for Treatment (hrs) (P) ISSUE 1 2 Unusual Process Fluid Characteristics (P) 4.3 Upstream Processes 1 Details of Upstream Processes (P) JULY 2014 WIMES 8.01(B) 5.0 PERFORMANCE SPECIFICATION Page 41 5.4.3 Service Lives and Costs of Consumable Components 5.1 General 1 1 Guaranteed (G) and Expected (E) Service Lives of Components Life (x 103 hrs) (S) Component (P) Lamps (G and E) Ballasts (G and E) Sleeves (E) UVRI sensors (E) UVRI sensor windows (E) UVRI sensor window seals (E) Wiper rings (E) Wiper arm seals (E) Temperature sensors (E) Level sensors (E) Access flange seals (E) 2/3 Costs of Components (£)/Time Required to Replace Components (hrs) (S) Component Cost Time Lamps Ballasts Sleeves UVRI sensors UVRI sensor windows UVRI sensor window seals Wiper rings Wiper arm seals Temperature sensors Level sensors Access flange seals Service Life (Years) (P) 5.2 Disinfection Performance 1 Disinfection Performance (P) 2 Validation Protocol () (S) UVDGM ONORM DVGW Other (specify) 3rd Party Responsible for Validation (S) 4 5 5 Limiting Operating Conditions to Maintain Validated Performance (S) Maximum flow rate (m3/hr) Minimum UVT (%) EOLL and SF Factors used During Validation (S) EOLL factor SF factor 5.3 Pressure Rating and Pressure Drop 1 2 Pressure Rating (S) Steady state (bar) Maximum rate of change of pressure (bar/s) Pressure Drop (bar) (P/S) Maximum allowable (P) Rated (S) 5.4 Life Cycle Costs 5.4.1 General 1 LCC Assessment Required using WIMES LCC Model 05 (Y/N) (P) 5.4.2 Energy Costs 1 Maximum Equipment Power Input (kW) (S) ISSUE 1 JULY 2014 WIMES 8.01(B) Page 42 6.0 DESIGN SPECIFICATION 6.2 Equipment Configuration and Redundancy 6.1 General 1 6.1.1 General 1 6 7 8 9 11 Glass/Quartz Trap Required (Y/N) (P) Facilities for Mercury Retention Reqd. (Y/N) (P) Construction Strainer Required (Y/N) (P) Facilities for Capture and Disposal of Untreated Water Required (Y/N) (P) Reference for Particular Specification (P) 2 Number of Duty Process Streams (Reactors) (P/S) Process Stream Flow Capacity (m3/hr) Process Stream 1 Process Stream 2 Process Stream 3 Redundancy Requirements (P) 6.3 Flow Control System and Equipment Isolation 6.3.1 Flow Control System 6.1.3 Weights and Lifting Arrangements 2 1 1 Heaviest maintenance lift (kg)(S) Heaviest erection lift (kg) (S) a) b) 6.1.7 Health and Safety 4 Specific Interlocking Requirements (P) 6.1.8 Lagging Required) and Trace Heating c) 3 Type of Flow Control System Required/Provided for Equipment Inc. Multiple Process Streams () (P/S) Single control valve on common main/inlet manifold Dedicated control valve for each process stream Variable speed pumps Type of Control Valve (Where Required/Provided) (P/S) (Where 6.3.2 Equipment Isolation 1 2 Protection Afforded to: (Minus 10 OC) (P) Reference for Particular Specification (P) 3 AIV Operating (secs) (S) Time 6.4 Reactor(s) 6.1.9 O & M Manuals 2 1 Reference for Particular Specification (P) 3 6.1.10 Training 1 Reference for Particular Specification (P) 6.5 Lamps 1 ISSUE 1 Reactor Material (SS No. 1.4401) (P) Inlet and Outlet Connections (P/S) Size (NB) (mm) Flange type Lamp Details (S) Type () Low pressure Low pressure high output Medium pressure Further Details Manufacturer Model/reference number JULY 2014 WIMES 8.01(B) Page 43 6.6 Lamp Sleeve Cleaning System (Where Required/Provided) 6.9.3 Local Indication of Operating Parameters 2 1 Lamp Sleeve Cleaning System Required/ Provided (Y/N) (P/S) 6.9.4 Local Indication of Alarms and Status Signals 6.7 Monitoring Instruments 6.7.2 UVR Intensity Sensor(s) 1 2 Number of Sensors per Reactor (S) 1 Number of Monitors Required (P) Redundancy Requirements (P) 1 Remote Control Requirements (P) 6.9.5.2 Remote SCADA/Telemetry) 3 Type (Magnetic Flow Meter*) (P) 4 Reference for Particular Specification (P) 6.9.1 General Monitoring (e.g. via 2 Additional Remote Requirements (P) 4 Signal Output Requirements (i.e. Individual or Grouped) (P) 6.9 LV Assembly and Associated Electrical Installation 3 Information 6.9.5.1 Remote Control 6.7.4 Flow Meter(s) 2 Additional Alarm/Status Indication Requirements (P) 6.9.5 Remote Control and Monitoring (Where Required) 6.7.3 UVT Monitor(s) 1 Additional Operating Parameter Indication Requirements (P) Monitoring 6.9.6 Data Acquisition and Recording on Site Assembly Configuration () (P) Standalone Part of a larger assembly Reference for Particular Specification (P) 2 Additional Data Acquisition and Recording Requirements (P) 7.0 CONTROL PHILOSOPHY 4 11 11 16 Type of Control Required/Provided () (P/S) PLC based Micro-processor based Ballast Type () (S) Electronic Electromagnetic Ballast Voltages > 1000 V (Y/N) (S) Maximum Heat Dissipated by the Assembly (kW) (S) System 6.9.2 Operator Controls 3 Additional Operator Controls Required (P) ISSUE 1 7.1 General 1 Dose Control Strategy () (P) Calculated dose Set point intensity 8.0 TEST SPECIFICATION 8.1 General 1b) Witness FAT (Y/N) (P) Required 9.0 TRAINING REQUIREMENTS 1 Operator Training Required (Y/N) (P) JULY 2014 WIMES 8.01(B) Page 44 APPENDIX D – SUPPLIER’S SUPPLEMENTARY DATA SHEET INFORMATION Clause ISSUE 1 Supplementary Information JULY 2014