Introduction to Genano 310

Genano Case Study

A breathe of fresh air in your print room

QPP road tests are normally reserved for pre-press, print, print finishing and despatch equipment or software; but what else do you need to create and manufacture print?

We could argue that print is driven by demand and taking that as a given the key ingredient has got to be, people. Proper tactile print requires a skilled team of personnel to help others communicate on paper.

New technology offers faster production, improved quality and reduced running costs, resulting in the print industry constantly up-grading to the latest kit. To some extent, people in print have benefited from digital technology. Less moving parts creates less dust and a reduction in equipment down time when operators have to get involved with the workings of the machinery. Do you remember those heady days of having to stick different parts of your body in a photocopier?

Improving staff well being is important to the delivery of all services and in print, the air quality is particularly relevant.

Decontamination of airborne paper and toner particles, plus all types of viruses, bacteria spores,

ozone and odours are achievable with a Genano air purifying system.

Not knowing all of the specific print pathogens and also not wanting to be labelled a scaremonger, the safest way forward we decided was to get a Genano

310 on site in our print room to improve our working environment and access any reduction in staff downtime.

The first noticeable difference is that our new revitalised air was having a positive effect on the people breathing it. Strangely the need to keep opening the windows and losing our heat in the lingering winter, was hugely reduced and no one is quite sure why.

The atmosphere is clearly cleaner but we hadn’t previously been concerned by any fumes or aware of ozone smog clouding over our workplace. A print room in South London which had a Genano 310 installed, said that their customers had remarked time and again that the print room did not have the normal associated print smells and seemed to them a lot fresher than they could remember.

Certainly, the knowledge that we are now all performing our print miracles in the best quality atmosphere has increased our staff and customer satisfaction levels to a new high. It must be the knowledge that we all care about our work environment that has brought about our new feel good factor, I am sure there is a boffin out there waiting to

prove that there is something in the air, or was that

Thunderclap Newman?

Introduction to Genano 310

Why do we need a decontamination unit?

The Genano 310 ensures clean air, free of contaminants.

What is the performance of Genano 310 in comparison to other air purifiers?

The Genano 310 unit is the only decontamination device on the market, which is able to filter the harmful micro particles. Not only does the Genano

310 need very little power, but also it does not produce unwanted smells and does not need expensive filter (HEPA or ULPA) changes.

Is it suitable for your premises?

The Genano 310 can be placed in any type of room, either mobile on the floor or fixed to the wall. It can decontaminate up to 100m2 space. The unit is connected to a standard power socket.

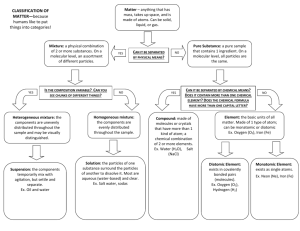

What is the technology used in the Genano 310?

The device uses the Genano technology of multiionised beams; the negatively charged particles in the airflow are projected onto the positively charged inner

wall of the device. The wall is automatically rinsed at regular intervals. The inactivated residue is collected in a container at the foot of the unit.

How does it work?

Air moves through the air cleaning chamber. Negative ions project particles into positive charged walls where they are captured. The positive charged wall is routinely washed using water and Genano cleaning fluid. Flushed particles are collected in a container at the bottom of the unit and then disposed off safely.

Service of Genano 310

The unit undergoes an automatic inside cleaning sequence and once a year a complete maintenance is required by trained service personnel. The exchange of the active carbon filter takes place at the same time.

The advantages of using Genano 310 in any work environment is that it maintains healthy, clean purified air in comparison to any other devices available on the market that protects both staff and customers, reducing cross contamination in all public and work areas and saving energy over other air purification systems.

Introduction to Genano

The Genano LTD Company was established in

Finland in 1999 and is represented in over 20 countries worldwide.

With the Genano Technology for the decontamination of air, there are thirty years of intensive research and development involved, with the cooperation of

Universities and research institutes.

Available Publications:

Installation of Genano 310 units in the hematology hospital, Warsaw, Gdansk and Poznan.

Certifications:

The Karol Marcinkowski University of medical

Sciences, Poznan, Poland. Tests for removing microorganisms from the air Laboratoire National d’Essai

(LNE) France. Tests for particles size 0.3-10 m.

Microbes.

The University of Greifswald Germany. Tests for removing microorganisms from the air certified by

SGS-Fresenius.

Genano 310 Medical is certified according MDD

93/42EEC as Medical Device Class 1. sales@genano www.genano.co.uk

QPP Quick Print Pro magazine July 2013