Module 1: What is Discrete Event Simulation (DES)?

advertisement

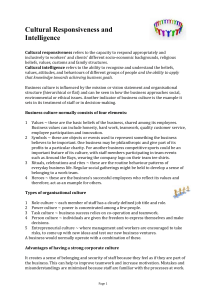

Why Clash Today When You Can Clash Tomorrow? Discrete Event Simulation Case Study Using Autodesk® Navisworks® Jonghoon “Walter” Kim – DPR Construction MP5692-V Traditionally, Autodesk Navisworks has either been used for Clash Detection or 4D Simulations. Less common, is the practice of combining both of the tools into one process, to allow one to perform discrete event simulation, or more simply, 4D clash detection. Discrete event simulation is a lean practice which is commonly used in many industries, such as manufacturing, healthcare, and even capital investing, but is just beginning to gain foothold within the construction industry. This class will walk through what discrete event simulation is and its various applications within the construction industry. It will cover a case study of applying the process to a multi-phased mechanical upgrade at the University of Virginia Old Jordan Hall. Learning Objectives At the end of this class, you will be able to: Learn What discrete event simulation is and how it’s applied in various industries Find out Construction processes which can benefit from discrete event simulation Figure out how to use Autodesk Navisworks to link Clash Detection with Timeliner Describe Practical examples of using this process on the University of Virginia Old Jordan Hall Mechanical Upgrade project About the Speaker Jonghoon is senior BIM project manager for DPR Construction working from DC office. Since joining DPR, Jonghoon has been involved in BIM implementation and innovative construction technology adoption on various projects including health care, advance technology, higher education, and office buildings. He received a PhD degree in Civil Engineering from Stanford University. At Stanford, he experienced a wide variety of R&D projects on Virtual Design and Construction, working with industry member companies and academic institutes to advance the research in Building Information Modeling. His works were published in academic publications. He also acted as an assistant consulting professor at Stanford to teach a class and advise research projects. Jonghoon is an active participant in Digital Building Lab at Georgia Institute of Technology and teaching classes for the AGC Certificate of Management-Building Information Modeling (CM-BIM) training. walterk@dpr.com Why Clash Today When You can Clash Tomorrow? Discrete Event Simulation Case Study Using Autodesk® Navisworks® Module 1: What is Discrete Event Simulation (DES)? This module covers the basic idea of discrete event simulation, shows the main components of discrete event simulation and its results. It also shows popular applications of discrete event simulation in various industries. Discrete event simulation is a process of codifying the behavior of a complex system as an ordered sequence of well-defined events1. Components of Discrete Event Simulation 1 In discrete event simulation there is a system with chronological sequence of events. Seen here is a bank office where customers arrive to receive services from a teller and they leave after the service. The customer arrivals and departures are a series of event. In discrete event simulation, each event occurs at a specific moment in time. After five minutes, customer #1 leaves the bank. There are still three customers receiving service from a teller, but there is no one waiting in line. The event, departure of the customer, changes the state of the system. The number of people in waiting line has been changed from 1 to 0. According to the number of customer arrivals and departures, teller status also might be changed from busy to idle. http://whatis.techtarget.com/definition/discrete-event-simulation-DES 2 Why Clash Today When You can Clash Tomorrow? Discrete Event Simulation Case Study Using Autodesk® Navisworks® Main components of discrete event simulation are queue of events, time when the event occurs, state changes, and system states changed by these events. Main purpose of discrete event simulation is to quantify the variables of interest and isolate them within the larger operations of the system. In this example, the bank wants to know the average waiting time of their customers and determine the number of tellers required to serve the customers. Applications of Discrete Event Simulations in Various Industries Service Industry Airport – DES is used to evaluate luggage-handling facility requirements to meet the baggage screen needs. Hospital - DES models are used to evaluate number of required nurses to increase patient retention rates. Manufacturing Industry Personal Computer Assembly - DES is implemented along computer assembly lines to test performance, namely possible throughput, the level of utilization of operators, and any potential problems. Module 2: Construction Processes Which Can Benefit from Discrete Event Simulation This module presents construction processes which can benefit from discrete event simulation. It shows two examples from construction industry that uses DES. The first case is a model used for constructionrelated production planning. The second case shows how discrete event analysis detects time-space conflicts during MEP system installation. 3 Why Clash Today When You can Clash Tomorrow? Discrete Event Simulation Case Study Using Autodesk® Navisworks® Planning of Construction Related Production System The construction process is a function of production rate. Flow of construction activities is determined by the production rate. So when there are different construction scenarios, it is important to analyze how production rates will affect the flow of the scenarios. However, with typical Critical Path scheduling method, it is hard to consider production rates of activities during the scheduling. This is an area that discrete event simulation can enhance. In this example, “Activity #1” started on Day 1. It is a new on-site event. The activity has a certain quantity of work and a crew. The duration of the activity is determined by the work amount and production rate of the crew. When the information is coded in a discrete event model, it is possible to track the details of the process. On day 4, a new event, “Activity #2”, has been added. It changes the number of on-site activities from one to two. The activity #1 is still in progress. The second activity has different quantity of work, crew, and production rate. The model now tracks two activities in the system. Lastly, “Activity #3” started on day 6 (not shown in the figure). Now there are three activities in progress. Since discrete event model keeps on tracking progress of the three activities, it is possible to pull the production data from the model. 4 Why Clash Today When You can Clash Tomorrow? Discrete Event Simulation Case Study Using Autodesk® Navisworks® This is a line of balance graph, which visualizes the data from the discrete event simulation. It shows very interesting analysis. Obviously “Activity #2” was completed quicker than other activities. Even though it started 3 days later than “Activity #1”, it was completed one day earlier. If “Activity #1” should have been done prior to “Activity #2”, for instance door frame should come prior to door installation, in some area “Activity #2” crew had to wait one day until “Activity #1” crew finished their work. In this example, knowing what activities need more resource to prevent the workflow from stopping is a huge benefit of discrete event simulation. 4D Model-Based Time-Space Conflict Analysis 4D model-based time-space conflict analysis is another example which applies DES in the construction industry. It is very useful especially to understand potential safety risks. The more time-space conflicts, the more safety risks. It is also useful to evaluate potential productivity loss because severe workspace congestions and conflicts will decrease efficiency. In this example, there are three MEP activities in the queue; “Install Ductwork,” “Install Pipes,” “Install Light Fixtures.” The first event in the system is “Install Ductwork”. Because the duct must be hung below the floor above, it is necessary for the crew to stay in work area and use lift cars to reach the ductwork, requiring space for crew and lift cars. The green box in the figure below represents space required for the ductwork installation. 5 Why Clash Today When You can Clash Tomorrow? Discrete Event Simulation Case Study Using Autodesk® Navisworks® Next event, “Install Pipes” that starts on day 7, also requires work space. The pink box shown in the figure below represents work space required for the pipe installation. Since the ductwork installation is still in progress, there exists a work space conflict between the pipe installation and the ductwork installation. In this case, as events come to the system, state of time-space conflict changes. The results of this simulation show what days which events have time-space conflicts. This conflict can be resolved in different ways. It can be resolved by re-arranging start time of the activities or changing sequence of the activities. The DES model can be used repetitively until all the time-space conflicts are eliminated. Module 3: Navisworks to Link Clash Detection with Timeliner This module covers how to link clash detection to Timeliner in Navisworks. It shows how to setup test(s) for clash detection, run clash detection with Timeliner, and review the clash detection results. 6 Why Clash Today When You can Clash Tomorrow? Discrete Event Simulation Case Study Using Autodesk® Navisworks® What is 4D Clash Detection? Clash detection based on 3D model is now very common. Less common is the practice of combining both of the tools into one process, to allow one to perform discrete event simulation, or more simply, 4D clash detection. 4D clash detection simulates a sequence of events, such as construction activities in a 4D model and detects clashes when each event occurs. 4D Clash Detection Process 4D clash detection process is similar to 3D clash detection; 1) 3D modeling and scheduling, 2) Linking 3D model and schedule, 3) Clash detection with Timeliner linked. While 3D clashes requires revising 3D models to resolve clashes, 4D clashes can be resolved by changing sequence of the activities as well. Case example in this module shows an instance of schedule change to resolve a 4D clash. Example: Interior Wall Layout Change In this example, two existing walls (in red) need to come out and new walls (in yellow) need to be installed. Flow diagram in the figure below is demo and new installation sequence. Tip! - 3D modeling for 4D clash detection. First it is recommended to breakdown 3D model into appropriate level to make the level of detail match to construction activities. Second, layer names with activity type in them would make the link of 3D model to activities easy. 4D Clash Detection in Navisworks Process to run 4D clash detection is very similar to that of 3D clash detection. Add Test First step is to add Test. Go to Clash Detective window and click Add Test. In this case, three tests are added, intended to run clash detection against existing condition each time a new wall is installed. Existing condition is in dynamic situation because demolition and new installation continuously occur. For example, when “New Wall #1” is being installed, “New Wall #2 and #3” do not exist. When “New Wall #3” is being installed, “New wall #1 and #2” already exist and “Existing Wall #1” came out. 7 Why Clash Today When You can Clash Tomorrow? Discrete Event Simulation Case Study Using Autodesk® Navisworks® Select Files (or Components) Next step is selection of components to run clash detection. For the test “New Wall #3 vs. Existing” “New Wall #3” is selected to run clash detection against walls that potentially exist, including two existing walls to demolish and two other new walls that may or may not be installed. In this case clash detection was performed with 1” tolerance to avoid catching clashes between walls butting each other. To incorporate timeline for the clash detection, link to the Timeliner must be selected. The selection is what really makes 4D clash detection. Click Run Test. 8 Why Clash Today When You can Clash Tomorrow? Discrete Event Simulation Case Study Using Autodesk® Navisworks® Review Clash(es) Navisworks detected a clash between the “New Wall #3” and “Existing Wall #2”. It is because the “Existing Wall #2” did not come out until the “New Wall #3” installation starts. Clash detection results show zero clash for the “New Wall #1 and #2” installation. Even though the “New Wall #2” has a clash with the “Existing Wall #1” in the 3D world, it becomes no clash because the “Existing Wall #1” is demolished prior to the installation of “New Wall #2”. The clash between the “New Wall #3” and “Existing Wall #2” can be resolved by simply re-sequencing the activities to make “Existing Wall #2” demolished before the installation of the “New Wall #3.” As this case shows, 4D clash detection is a discrete event simulation. It is possible to link timeline, keep track state changes, in other words record clashes each time a new event occurs. In addition to that, 4D model allows you to investigate the clashes and review the processes before and after the clashes. Module 4: 4D Clash Detection on the University of Virginia Old Jordan This module presents the case study of University of Virginia’s Old Jordan Hall project where 4D clash detection was used to address challenges in related to the multi-phased mechanical upgrade at the project. Old Jordan Hall Mechanical Upgrade Old Jordan Hall is a part of University of Virginia Health System. DPR Construction was hired for a comprehensive mechanical renovation to increase the capacity of the physical plant and replace the majority of the original equipment. Although the scope of DPR’s renovation was much larger than discussed here, this module presents only the efforts that tied-into the 4D clash detection. Built in 1972, the seven-story building had eight original air handlers in the basement mechanical room. The air handlers provided single pass conditioned air throughout the building. The air handling units and supply 9 Why Clash Today When You can Clash Tomorrow? Discrete Event Simulation Case Study Using Autodesk® Navisworks® ductwork were severely deteriorated. During the mechanical upgrade air handlers were demolished two at a time, two new temporary air handlers were installed on the roof to provide service while a pair was being taken offline, and the new air handlers was installed two at a time as well. The supply air ductwork was also demolished and replaced. The equipment replacement is what was modeled and will be discussed. Existing System The model here is for the existing system before the upgrade. It did indeed exist in its entirety at on time and absolutely there is no clash among air handlers and ductwork. 10 Why Clash Today When You can Clash Tomorrow? Discrete Event Simulation Case Study Using Autodesk® Navisworks® New System The model is for the new system after the upgrade. This model, even with renovation, will not look like this when installation finishes, as it will still have connections to the existing mechanical equipment that is allowed to remain. New and Existing System Superimposition When both static models are combined as a single model, it is just a spatial overlap with no temporal ordering. The conflicts shown in this combined model become useless. However, when time is introduced, the system becomes dynamic and it is possible to check actual clashes as they occur in the 4D model. In this case study we combined these two static models in Navisworks, and checked clashes each time when a specific event was introduced. In other words, we performed clash detection each time new two air handling units and supply ductwork were installed. Order of Discrete Events For the order of discrete events, or simply order of demolition and installation, we used the sequence noted in the contract documents. 4D Model in Navisworks Based on the 3D models and phasing notes, we developed a 4D model in Navisworks. The 4D model visualizes the whole renovation process fairly well. However, it is hard to detect the clashes by just looking at the 4D simulation. The renovation is a continuous simultaneous demolition and installation process, and it is not necessarily a clash free process. We linked 4D model to the clash detection engine in Navisworks and analyzed the flow in terms of 3D coordination. This is kind of like a film. While the movie shows dynamic scenes, each frame of the movie is a still frame. Navisworks performed clash check at each scene during the dynamic simulation. 11 Why Clash Today When You can Clash Tomorrow? Discrete Event Simulation Case Study Using Autodesk® Navisworks® Clash Test Setup in Navisworks This figure shows clash test setup for the first new two air handling units and ductwork vs. existing condition. Section B in the figure below shows all existing air handlers and ductwork were selected to run clash detection against. It was not known which existing system already came out and what still remained. Since link to the Timeliner was selected, Naviworks ran clash detection between the new system and remaining old system. Clash Detection Results - #1 Clash detection results show a clash between a new duct and existing duct on Aug. 10, 2010. When the new duct installation started, this existing duct still remained, causing a clash. The image at bottom right shows outlook of the new duct at completion. There exists no clash. As a conclusion the existing duct should have been removed before the new duct installation. This issue was resolved by ordering demolition of the existing duct ahead of installation of the new duct. 12 Why Clash Today When You can Clash Tomorrow? Discrete Event Simulation Case Study Using Autodesk® Navisworks® Clash Detection Results - #2 This figure shows another clash between a new air handling unit and an existing air handler on Aug 20, 2010. The image on the right bottom shows that the existing duct was eventually came out and the new system does not have any clashes. This clash was also resolved by re-sequencing the activities. In this way, we found 10 major clashes. We revised demolition and installation sequence and performed 4D clash detection repetitively until all the clashes were eliminated. The successful 4D clash detection in this project enabled smoother phasing during a multi-phased mechanical upgrade, and consequently we saved time and money from the uninterrupted process. 13