CHPStandardOperatingProcedureform

advertisement

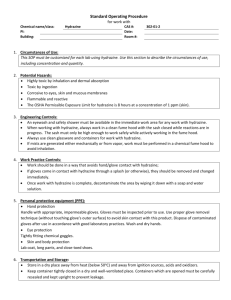

Standard Operating Procedure (SOP) Template University of Iowa Keep both a readily accessible hard copy and an electronic copy of the completed procedure in the lab. Lab and Contact Information Date SOP Title Principal Investigator Room and Building Lab Phone Number Refer to Guidance/Tips for SOP Preparation for assistance before completing this template. Section 1 – Description (Provide a brief summary of the purpose for this SOP and what it covers) SOP is for a specific chemical or class of chemicals with similar hazards (examples: air-reactive or unstable chemicals, oxidizing acids, hydrofluoric acid); SOP is for a general lab operation/process that could apply to several chemicals (examples: distillation, rotary evaporation); SOP is for a specific protocol/experiment/procedure (examples: a specific chemical synthesis reaction, perfusion of rodents with paraformaldehyde solution). Description: Section 2 – Hazardous Chemicals (List all chemicals used in this procedure or process and any common synonyms that will be used.) Section 3 – Potential Hazards (Describe physical and health hazards for chemicals or categories of chemicals; describe potential process and/or equipment hazards.) Section 4 – Hazard Control Measures, Containment/Equipment (Describe engineering/ventilation controls such as fume hoods or containment devices such as glove boxes) Section 5 – Hazard Control Measures, Special Handling Procedures and Storage Requirements (Describe safe work and storage practices to minimize hazards such as temperature control, keep containers closed at all times, incompatibilities with other materials, etc.) Section 6 – Personal Protective Equipment/PPE (Describe specific PPE needed to minimize exposure) Section 7 – Spill and Accident Procedures (Describe any spill management supplies that will be maintained readily accessible and any other special procedures to follow in case of an accident.) Section 8 – Waste Management/Disposal (Describe any special waste management procedures if different than described in the EHS Waste Management Guidelines and Procedures document.) Section 9– Approvals Required (Describe, if applicable, any special approvals required before conducting this work such as approval by Principal Investigator or lab supervisor before beginning work.) Section 10 – Designated Area/Communications (For work involving particularly hazardous materials, identify the area where the work will be conducted and to where it will be confined; identify any communication that will be done to assure other lab staff know the hazards and location of this work.) Section 11 – Decontamination (Describe any procedures necessary to clean work areas or equipment after use or to keep hazardous material fully contained in the controlled area described in Section 8.) Section 12 – Process Steps (Optional) Process Steps Safety Measures Section 13 - Training Documentation Name (Printed) Signature Date Guidance/Tips for SOP Preparation If the chemicals or hazards are: These controls may be needed (including but not limited to the examples below) (including but not limited to the examples below) All chemicals/equipment Fine powders that can easily become airborne Chemicals that easily vaporize Toxicity, Adverse Health Effects Eliminate the hazard if at all possible Substitute the material or process with a less hazardous one Isolate/control the hazard at the source and do not allow it to migrate to the air or surroundings o Use an engineering control such as a fume hood or biosafety cabinet Use an administrative control such as a safe work practice to minimize exposure to the hazard (e.g., use only with another person present, restrict use for specific time period, use only in a designated location) Use personal protective clothing and equipment to minimize contact with/exposure to the material(s) Become aware of the route of exposure for your material and process (inhalation, eye/skin contact, injection Become aware of any exposure limits for your material, if any Plan how you will label containers to alert others to contents and hazards Plan ahead to safely transport the material from one location to another so spills/releases are minimized Become aware of the safe storage method for the material (e.g., what is it incompatible with it?), any expiration dates, and any periodic testing needed to assure material stays stable Emergency preparedness plans (spill and accident prevention and procedures) Use in fume hood or biosafety cabinet Use in solution as much as possible (use wet methods to control dust release) Avoid/minimize activities that cause the material to become airborne (pouring, agitation, shaking, stirring, vibration, etc.) To weigh if balance is not enclosed in hood or other enclosure, tare a container, add powder to container in the fume hood, cover container before returning to weigh material using the balance Emergency preparedness plans (spill and accident prevention and procedures) Use in fume hood (Do not use in biosafety cabinet) Keep containers closed as much as possible to prevent vapor release Use in a closed system Avoid/minimize activities that cause the material to become airborne, including production of aerosols (pouring, agitation, shaking, stirring, vibration, etc.) Emergency preparedness plans (spill and accident prevention and procedures) Use in fume hood or with other protective ventilation device Substitute safer material if possible Keep work area well controlled to prevent spread of hazardous material Assure all coworkers have knowledge of material hazards Assess need for respiratory protection Emergency preparedness plans (spill and accident prevention and procedures) If the chemicals or hazards are: These controls may be needed (including but not limited to the examples below) (including but not limited to the examples below) Flammability Reactivity Body contact Use in fume hood Prevent contact with ignition source Keep away from heat sources Control electrostatic discharge Control temperature of reaction Do not use metal or sparking tools Keep away from fuel sources Control use in an inert atmosphere Evaluate need for flame-retardant, flame-resistant clothing Emergency preparedness plans (spill and accident prevention and procedures; appropriate fire extinguisher is available) Use in fume hood, glove box or bag, other engineering control Control use in dry atmosphere Control use in an inert atmosphere Place a blast shield between you and your work Evaluate need for flame-resistant, flame-resistant clothing Separate from other materials with which chemical is reactive where possible Emergency preparedness plans (spill and accident prevention and procedures) Lab coats Chemical Safety Goggles Face Shield Chemical Apron Nitrile, vinyl, or latex gloves Specific chemical-resistant gloves, heavier barrier gloves Thermal or insulated gloves Cut-resistant gloves Flame-retardant, flame-resistant clothing, gloves Goggles that block specific wavelengths, intensity (e.g., for lasers, UV lights, infrared-emitting process or equipment) UV face shield Lead apron Assure eye wash is available Assure safety shower is available Emergency preparedness plans (spill and accident prevention and procedures)