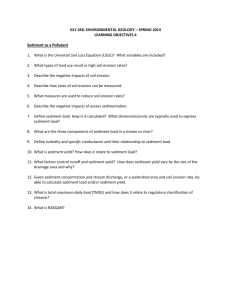

etc2540-sm-0001-SuppData-S1

advertisement

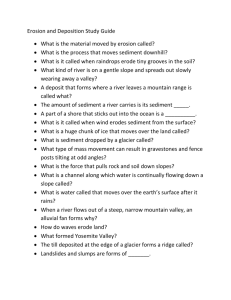

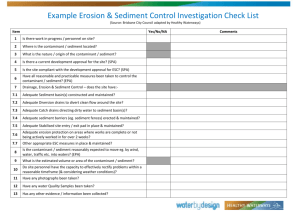

Supplemental Materials for C60-CAT Manuscript MATERIALS AND METHODS Chemical and reagents Fullerene (C60) (99.5%), and sublimed pyrene (99%) were purchased from Sigma-Aldrich. Chemicals and supplies purchased from Fisher Scientific include vanillin (98%), hexane (Pesticide grade), sulfuric acid (Trace Metal grade), hydrogen peroxide (H2O2: 30% (v/w)), bovine serum albumin (BSA: Fraction V), sand (standard Ottawa), and Teflon syringe filters (0.2 µm). Acetonitrile (HPLC grade), acetone (HPLC grade), and tetrahydrofuran (THF, Omnisolv grade) were purchased from EMD. Toluene (HPLC grade) and water (HPLC grade) were purchased from JT Baker. Methanol (HPLC grade) was from Honeywell. Chloroform (ACS grade) was purchased from EM Science. Sodium phosphate buffer (0.1M, pH=7.0) was obtained from BDH, and protein assay dye reagent was from Bio-Rad. Phosphoric acid (85% ACS grade) was purchased from Macron. Taq (10x) buffer solution was purchased from Gen Script. Kaolin clay was from MP and peat moss was obtained from the local Lowes. Water (>18MΩ) was obtained from a Barnstead NANOpure infinity system. Sediment Preparation One sediment was prepared by spiking sand (5 g) with THF that contained μC60 and mixing with 100 g dry sediment in a tumbler for 3 h. Spiked sediment was air-dried overnight to evaporate solvent before adding moderately hard water (100 mL) to cover spiked sediment. The sediment water system was then aerated for 14 d before the uptake experiment. Pyrene dissolved in THF was similarly introduced to separate aliquots of sediments to provide a positive control for BSAF and CAT comparisons. Pyrene concentration in sediment was selected to minimize adverse effects [25, 26]. THF was used to convey either C60 or pyrene into the sediment because C60 and pyrene are much more soluble in THF than in water. Higher solubility in a solvent allowed introduction of smaller sized C60 aggregates into the sediment. In addition, toxic effects to L. variegatus would be reduced if THF is used rather than toluene. Sediment containing bulk-C60 was prepared with direct addition of C60 powder to moist sediment (2% water w/w). The mixture was tumbled for a week prior to preparation of test systems for L. variegatus exposure. This route of introduction eliminated the solvent effect on test organisms, the size of C60 agglomerates, and C60 interaction with surfaces of solid components of sediments. Screening toxicity test The test was performed in 300 mL beakers with 100 g sediment and 150 mL overlying water. The bioassay was designed to meet EPA standards for a continuous introduction of water to replenish 2 volumes in each test system each day. Four replicates of 10 worms in each replicate were used for each concentration. The exposure temperature was controlled at 22 ± 2 °C. Dissolved oxygen, pH, total ammonia, hardness, and conductivity were measured on day 0 and day 10. L. variegatus were not fed during the exposure. Considering the low concentrations of C60 in the environment and the analytical method used, C60 treatments were 0.05, 0.13, 0.44, 1.51, 3.67 and 11.33 mg/kg dry weight sediment with controls and with THF solvent controls. Worms were collected on10 d for assessment of survival. Bioaccumulation test The exposure temperature was controlled at 22 ± 2 °C. Dissolved oxygen, pH, ammonia, hardness, and conductivity were measured on days 0, 7, 14, and 28. Concentrations of C60 and pyrene were selected to minimize toxicity but to allow the chance for pyrene to provide positive control for BSAFs and CAT activity. Sediment and worms were collected at day 3, 7, 14, and 28. Worms in each replicate were counted and subsampled for uptake and CAT activity determination. Worms were depurated in moderately hard water for 6 h and blotted dried before being snap-frozen in liquid nitrogen and stored at 80°C. Sediments were air dried and stored at -20 °C before nC60 quantification. Extraction and analysis of C60 Extraction of nC60 from worm tissue was adapted from Isaacson et al. [28] by using 1 mL of toluene and mechanically shaken for 1 h. The extract was centrifuged. The supernatant was collected and filtered through 0.2 µm PTFE filter. Sediment and worm extracts were transferred into an autosampler vial for analysis by HPLC-UV (Agilent series 1100) at 335 nm. Chromatographic separation was achieved at room temperature using a COSMOSIL 5PBB column (250 mm*4.6 mm, 5 µm packing) and an isocratic toluene mobile phase at 2 ml/min. This method allowed matrix spike recoveries of 90.7 ± 4.5% (n=20) for sediment. For sediment samples, method developed in our research group was applied for C60 separation and quantification [27]. Slight modifications to accommodate worm tissues produced recovery of 94.0 ± 2.9% (n=15). Extraction and analysis of pyrene For all samples solvent exchange was made to acetonitrile before filtering through 0.2 µm PTFE filters and transfering into an autosampler vial for HPLC analysis. HPLC-FLD used a HIBAR® RT-18 column (125 mm * 4 mm, 5 µm packing). A gradient mobile phase ramped from 60% acetonitrile:40% water to 100% acetonitrile in 30 min at a. The injection volume was 25 µL with a flow rate of 0.8 mL/min. The excitation of pyrene was at 270 nm and emission was at 390 nm. Mean pyrene recovery from matrix spikes was 100.6 ± 5.3 % (n=15) and 98.0 ±4.6 % (n=15) from sediment and worms, respectively. Total lipid content Worm tissue homogenization was achieved by probe sonication in 2 mL mixture of chloroform:methanol (1:1(v:v)). Triplicate aliquots from each replicate were placed onto a 96-well plate (Costar® plate) and read at 490 nm (BioTek, Synergy 4). The standard curve included 0, 0.041, 0.204, 0.409, 0.545, 0.818 and 1.022 mg/mL of corn oil in chloroform:methanol. Preparation procedures were the same as the worm samples. Each 96-well plate had a series of standards while measuring the samples to allow error cancellation. Catalase extraction and determination In our preparation, 20-40 mg was added to 0.3 mL TAQ (1x) for homogenization by probe sonication. After two cycles of centrifugation the supernatant was used for CAT activity determination and total protein quantification. The analysis solution contained 180 µL of 50 mM sodium phosphate buffer (pH 7.0), 50 µL methanol, and 20 µL 3% H2O2. CAT extract (50 µL) was added to complete the total volume of 300 µL for reaction. The mixture was shaken moderately for 5 s prior to the UV absorbance reading at 240 nm for 4 min. Activity was quantified as follows. Activity (units ⁄ mg) = (ΔA × 1000) / (43.6 × (mg protein) / (mL Reaction Mix)) where ΔA is the difference of UV absorbance reading of the first 4 min at 240 nm; 43.6 represents the molar extinction coefficient (1/M-cm) of H2O2 at 240 nm. Total protein quantification Total protein in worms was measured using a modified colorimetric method [33] and included in calculation of CAT activity. CAT extract aliquots (2 µL) were diluted to 800 µL with autoclaved nanopure water in 1.5 mL Eppendorf tubes. Protein assay dye reagent (200 µL) was added for color development. For measurement, 0.2 mL of each sample preparation was transferred into a 96-well plate in triplicate and read at 595 nm (Costar® UV plate) using a plate reader Synergy 4 by BioTek. A standard curve was generated using BSA concentrations of 0, 5, 10, 15, 20 µL of 1 mg/mL. Preparation procedures for standards were the same as for protein samples. Each 96-well plate contained a series of standards to facilitate error cancellation. Supplemental Figures Supplemental Figure 1. Catalase activity in Lumbriculus variegatus after exposure to solvent control (tetrahydrofuran, THF), μ-C60 (5 mg/kg dw), and pyrene (55 mg/kg dw) over 28 days. Error bars represent ± 1 SD. * represents statistical difference by Dunnett test (p = 0.034). (n = 3 beaker replicates). Supplemental Figure 2. Catalase activity in Lumbriculus variegatus after exposure to bulk-C60 (5 mg/kg dw) over 28 days. Error bars represent ± 1 SD. (n = 3 beaker replicates). S Figure 1 S Figure 2