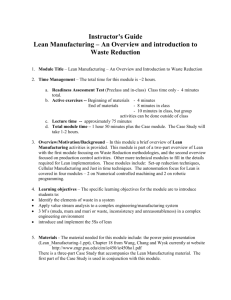

Lean certification programs

advertisement

SME, AME, SHINGO: LEAN CERTIFICATION LOCATION: US-based; remote personal study; exam and course locations at sites across US. CERTIFICATES/CERTIFICATION OFFERED: Bronze level, Silver level, Gold level Certification is valid for 3 years before re-certification or pursuit of the next level is required. CONTENT COVERED: The Lean Body of Knowledge – lean content divided into 4 modules (Cultural Enablers, Continuous Process Improvement, Consistent Lean Enterprise Culture, Business Results) (http://www.sme.org/downloads/cert/lean/BOK.pdf) as well as the following recommended/required reading… Bronze Level - Gemba Kaizen, Masaaki Imai - Lean Production Simplified, Pascal Dennis - Lean Thinking, James P. Womack and Daniel T. Jones - Learning to See, Mike Rother and John Shook Silver Level - Practical Lean Accounting, Brian Maskell and Bruce Baggaley - The Lean Design Guidebook, Ronald Mascitelli - Office Kaizen, William Lareau - Real Numbers, Orest J. Fiume and Jean E. Cunningham - The Toyota Way, Jeffrey Liker - Toyota Production System, Taiichi Ohno Gold Level - Creating a Lean Culture, David Mann - Lean Solutions, James P. Womack and Daniel T. Jones - Lean Transformation, Bruce A. Henderson and Jorge L. Larco - Natural Capitalism, Paul Hawken, Amory Lovins, L. Hunter Lovins - Today & Tomorrow, Henry Ford TARGET PARTICIPANT/PROGRAM GOAL: Bronze level: Demonstrates solid understanding of basic lean principles and tools, and ability in tactical implementation that drives improvement and shows measurable results. Silver level: Recognition of experience as a lean project leader on value stream transformations. It represents career progression in knowledge and responsibility as one becomes a senior employee and team leader. Gold level: Recognition of understanding of all aspects of Lean transformation across an entire enterprise. It represents career progression to a point of influence and authority over assets, processes and people. INSTRUCTION/LEARNING METHOD: 1. Independent reading/study 2. Independent application of principles to own workplace 3. Bronze only: 2 day review course (optional) ($549, or $499 for AME members) 4. Bronze only: Work with a Lean mentor (optional) PRE-REQUISITE(S): Bronze level: [none] Silver level: valid/current Bronze certification Gold level: valid/current Silver certification CERTIFICATION REQUIREMENTS/ASSESSMENT(S): Bronze level 1. Written exam based on recommended reading; open book (3 hours, 170 questions) 2. Submission and evaluation of experience portfolio. Must document events, projects or activities to which specific lean principles and tools were applied and the results. Silver level 1. Written exam based on recommended reading; open book (3 hours, 150 questions) 2. Submission and evaluation of an experience portfolio. Must provide documentation that participant has led a lean transformation of a complete value stream. Must also show participation in 5 lean events, projects or activities that applied and integrated lean principles, along with the results. 3. Proof of having mentored another Lean practitioner Gold level 1. Written exam based on recommended reading; open book (3 hours, 150 questions) 2. Submission and evaluation of an experience portfolio. Must provide documentation of leadership in an ongoing lean transformation. Must also show record of having led 4 value stream transformations (Demand, Delivery, Development, Support). 3. Proof of having developed a training strategy and delivery for other lean practitioners. COST: List price SME/AME member or Shingo Prize examiner Prior Bronze Certified SME/AME member or Shingo Prize examiner Prior Bronze Certified Non-member Prior Silver Certified SME/AME member or Shingo Prize examiner Prior Silver Certified Non-member BRONZE $690.00 SILVER $1,330.00 GOLD $1,970.00 -35% -35% -43% $448.50 $864.50 $1,142.60 --- -60% -43% $532.00 $886.50 --- -35% -25% $864.50 $1,477.50 --- --- $591.00 --- --- $886.50 -70% -55% PROGRAM LINK: http://www.sme.org/cgi-bin/certhtml.pl?/cert/lean_certification.htm&&SME& BROCHURE: http://www.sme.org/downloads/cert/lean/lean_brochure.pdf PRODUCTIVITY INC.: LEAN MANAGER CERTIFICATION LOCATION: Fisher College of Business at The Ohio State University, USA. CERTIFICATES/CERTIFICATION OFFERED: Lean Manager Certification TARGET PARTICIPANT/PROGRAM GOAL: From the program website: THE LEAN MANAGER CERTIFICATION IS designed for middle and toplevel executives at any company who seek the essential knowledge necessary to drive Lean throughout their entire organization. Over four non-consecutive weeks, each participant will experience a series of learning modules focusing on the four key phases of Lean implementation: Plan, Pilot, Deploy and Integrate. In between the weeks of training, students need to apply the methods that they have learned in operations at their own companies and present their results to the class. Upon completion, participants should be able to: - Perform as a principal change agent - Lead and direct site teams in completing plant-wide deployment of Lean methodologies - Mentor and coach project leaders, managers, and supervisors in specific tools/methods - Mentor and coach suppliers' change agents to address quality/delivery problems CONTENT COVERED: Week 1: Plan Strategic Thinking; Organizational Innovation; Value Stream Management and Analysis Planning & Deployment; Project Management; Six Sigma (DMAIC, SIPOC, CEDAC); Project Chartering, Week in Review, Exam & Homework Week 2: Pilot Homework Projects; Total Productive Maintenance; Visual Workplace; Standard Work; Quick Changeover; Mistake Proofing; Plant Application; Project Roundtable, Week in Review, Exam & Homework Week 3: Deploy Homework Reports; Kanban; Pull Production; Homework Reports; Continuous Flow; Plant Application; 3P (Pre-Production Planning); Green in the Workplace; Lean Measurables Review, Exam & Homework, Assignments Week 4: Integrate Lean Logistics; Lean Supply Chain; Lean Finance; Lean Leadership; Final Project Reports; Manager, Supervisor Role & Responsibilities; 4 Week Program Recap, Final Exam, Graduation Dinner INSTRUCTION/LEARNING METHOD: During week-long instructions sessions: Lecture/workshop Simulations During weeks between instructions sessions: Homework assignments including: “gathering and analyzing information to facilitate planning for your transformation process, selecting an initial application (pilot) area, completing your current state value stream map, designing manufacturing cells, and implementing Kanban pull systems. PRE-REQUISITE(S): It is required that each participant in the program have a corporate sponsor to attest to the participant's qualification for the program and to the results achieved through the homework assignments. CERTIFICATION REQUIREMENTS/ASSESSMENT(S): 1. 2. 3. 4. Successful completion of the four-week training Successful completion of the mentoring program Must pass a two-hour certification exam Must demonstrate successful implementation in one’s own facility COST: Lean Enterprise Certification Duration 20 days Price $15,000 PROGRAM LINK: http://www.productivityinc.com/certification/mac.shtml BROCHURE: http://www.productivityinc.com/pdf/LMAC_SPRING_2010_BROCHURE.pdf INSTITUTE FOR LEAN SYSTEMS: LEAN MANAGER CERTIFICATION LOCATION: Louisville, Kentucky, USA and Brunswick VIC, Australia. CERTIFICATES/CERTIFICATION OFFERED: Lean System Certification Series Lean Leadership Certification Series TARGET PARTICIPANT/PROGRAM GOAL: Lean System Certification From the website: This series is designed for change agents and leaders responsible for implementing your transformation strategy. The series is intellectually rigorous but is tailored to be appropriate for all team members. CEOs, Presidents, managers, supervisors, and team members from all departments have successfully completed this series. Lean Leadership Certification From the website: This series is designed to equip participants to serve as internal consultants and coaches to sustain your continuous improvement culture. The series is intellectually rigorous and is not appropriate for all team members. We expect that participants will have already mastered lean operations and tools. CONTENT COVERED: Lean System Certification Series Week 1 – Designing the Lean System: VSM, analysis, and design workshop. Discuss and apply detailed practical approaches for creating flow, and explore a variety of pull systems. Week 2 – The Lean Work System: 5S workplace organization, workstation design, visual controls, standardized work, SMED, source quality, and pull systems. Week 3 – Managing the Lean System: Explore the role of people in a lean system; problem solving strategies include C4, Six Sigma, and TRIZ; Daily Management System. Lean Leadership Certification Week 1 – Transformation Technology: Map and redesign technical systems to support and sustain lean operations. Apply useful analytic techniques to decide how to structure operations, management, and control systems. Apply lean systems design principles to transactional and internal logistics processes as well as lean auditing systems and total equipment management. Explore the concepts of factory physics and discover how useful these tools are for analyzing complex operations and problems. Week 2 – Leadership the Lean Way: Explore the value and methods of developing servant leadership in organizations; Introduction of specific strategies and techniques for coaching, teaching, and facilitating change activities. Also: Hoshin and a related exercise. Week 3 – The Lean Enterprise: reviews the knowledge gained through all previous workshops and projects and requires successful application of principles, tools, techniques, and practices in a comprehensive extended enterprise simulation. INSTRUCTION/LEARNING METHOD: During week-long instructions sessions: Lecture/workshop Simulations During weeks between instructions sessions: Application of concepts PRE-REQUISITE(S): Lean System Certification Series: [none] Lean Leadership Certification Series: demonstrated prior Lean knowledge/ability CERTIFICATION REQUIREMENTS/ASSESSMENT(S): 1. Successful completion of the three-week training 2. Must complete two transformation projects with support from their management COST: Lean System Certification Series Lean Leadership Certification Series PROGRAM LINK: http://www.theleanway.com/services_certification.html Duration Price 15 days $7500 15 days $7500 TBM CONSULTING GROUP: LEAN AND LEAN SIGMA CERTIFICATION LOCATION: Durham, North Carolina, USA and others including Brazil, China, Mexico and the UK CERTIFICATES/CERTIFICATION OFFERED: Lean Certification: Kaizen Facilitator Lean Certification: Program Leader Lean Sigma Green Belt, Lean Sigma Black Belt TARGET PARTICIPANT/PROGRAM GOAL: Lean Certification: Kaizen Facilitator: Appropriate for candidates who want to learn how to lead kaizen events. By completion, a participant will have: - Knowledge of lean strategies, tools and methods which include the fundamentals of the Toyota Production System including takt, flow, pull and standard operations - The skills required to support kaizen events and conduct basic training for kaizen teams - Participation in a kaizen event in a process at a manufacturing facility - Develop a current and future value stream map for a facility or product family Lean Certification - Program Leader: Appropriate for lean practitioners and program managers responsible for leading lean deployments or multi-site continuous improvement objectives. Graduates complete the program with hands-on experience and knowledge to develop a lean transformation plan for a site, division or company. In addition to the goals listed for Kaizen Facilitator, a Program Leader will also know: - How to create, manage, communicate and promote a continuous improvement office - How to write a project charter, develop scope and objectives for a kaizen event - How to align operations metrics with financial performance - How to audit, report and sustain results from your lean deployment CONTENT COVERED: Lean Certification: Kaizen Facilitator and Lean Certification: Program Leader Essential Lean Learning – Online training and Exam (self paced online learning) Modules include: Introduction to lean; Waste elimination; Just-in-time principles of takt, flow and pull systems; Quality and productivity improvements through Jidoka; Production Smoothing, Standard Work, Standard Operations; 5S and the visual workplace; Value Chain Mapping, LeanSigma Implementation; and Roles in a lean deployment. Lean Tool Kit Workshop (5 days) Learn how lean tools are applied to transform your organization to deliver improved operational results. Through the use of a factory simulation students will be able to apply what they have learned. Kaizen Breakthrough Experience (5 days onsite at a TBM client location) Participants are divided into teams that are led by a TBM Lean Master. Team members are assigned roles; the event is planned, executed and evaluated. Kaizen Instructor Training (4 days) Train-the-trainer workshop to demonstrate how to deliver TBM’s one-day lean training and address the questions from participants in or impacted by a Kaizen event. Additional requirements for Lean Certification: Program Leader Creating a Continuous Improvement Office (4 days) Strategies, tools and skills required to set up an effective continuous improvement office; includes: communication, promotion, charter statements, operational metrics with financial objectives, lean progression assessment, and sharing best practices across the organization Sustaining Lean Results (5 days) How to audit, report and sustain kaizen results; Personality assessment, cultural change, dealing with resistance, performance measurement, layered audits and problem solving INSTRUCTION/LEARNING METHOD: Lecture/workshop Simulations Onsite Kaizen improvement project with a client company TBM Lean Mentor assigned to each participant to guide throughout process PRE-REQUISITE(S): Lean Certification: Kaizen Facilitator and Lean Certification: Program Leader Must have the ability to travel in order to complete improvement workshop module CERTIFICATION REQUIREMENTS/ASSESSMENT(S): 1. Successful completion of all course work and site visits COST: Lean Certification: Kaizen Facilitator Lean Certification: Program Leader PROGRAM LINK: http://www.tbmcg.com/training-services/certification.html Duration Price 14 days $8,500 23 days $12,500 UNIVERSITY OF MICHIGAN: LEAN CERTIFICATION LOCATION: Ann Arbor, Michigan, USA. Remote/onsite training also available. CERTIFICATES/CERTIFICATION OFFERED: Lean Manufacturing Certification – 10 days (outlined below) Lean Healthcare Certification – 5 days (outlined below) Lean Office Certification – 5 days Lean Product Development Certification – 5 days Lean Supply Chain for Healthcare Certification – 4.5 days Lean Pharmaceutical Certification – 3 days Lean Supply Chain and Warehouse Management Certification – 10 days TARGET PARTICIPANT/PROGRAM GOAL: Prior Lean experience is not explicitly listed as a requirement. Content focus is geared towards the specific industries, as outline by title. Within each program, the recommended attendees list essentially spans all employees within an organization. CONTENT COVERED: NOTE: Given the quantity of Certification programs offered, two programs were chosen for illustration. They represent one of the 10 day programs, and one of the 5 day programs. Lean Manufacturing Certification This program provides multiple course configurations, selected from the complete list of single day courses listed below. Only one configuration is given per 2-week block of time. Participants select from the pre-configured options, instead of selecting each unit separately. Overview: (all required) History; Philosophy; Core methodologies Lean System Design: (at least 3 required) VSM: Current & Future State mapping; Design of Pull Mechanics of Pull systems: Kanban; Analytical tools to determine inventory Factory Layout for Lean Manufacturing: Basic Models; Practical solution methods The Physics of Lean: Throughput; Cycle times; Customer Service; Quality; Flexibility Build to Order: Supplier involvement; Material control systems; Logistic systems design Supporting Lean Tools and Methods: (at least 2 required) Cell Analysis and Design: Cell layout; Allocating work; Right-sizing equipment Implementing Kaizen Bursts: systems around tools; VSM into action; JIT & built-in-quality Learning to Levelize w/ Pull Systems: Mechanics of pull; Kanban; Container size; simulations Material Handling for Lean: Evaluate parameter impact; modeling; train the trainer Designing Std. Work and Job Instruction Training: Methods; Training tips; work break-down Lean Rapid Plant Assessment: learn to quickly assess a plant, its value & potential Leadership and team Management Tools and Methods: (at least 2 required) Integrating Six Sigma in lean: Integration; employees as problem solvers; DMAIC Leading the Change to Lean: Optimizing the system; Tools and methods Accounting and Measurements for Lean: alternative systems; Encouraging behavior Developing and Leading Work Groups: Fostering team work; Motivating problem solving Lean Healthcare Certification Day 1: Overview of Lean Healthcare and Lean Healthcare Simulation Day 2: Value Stream Mapping Healthcare Applications; UM Hospital case study Day 3: Toyota Practical Problem Solving and A3 Tools; UM Hospital case study Day 4: Lean Tools for Healthcare: 5S, visual management, standardized work, Andon systems, quick changeover, etc.; Lean healthcare case studies; hands-on exercises Day 5: Lean Leadership and Change Management; healthcare case study; Physicians panel/discussion INSTRUCTION/LEARNING METHOD: Lecture/workshop Simulations Discussion panels (ex: Physicians already working in a Lean healthcare environment) PRE-REQUISITE(S): [None] CERTIFICATION REQUIREMENTS/ASSESSMENT(S): Web-based exams - Manufacturing, Office and Supply Chain and Warehouse Management [none listed] - Healthcare, Product Development, Supply Chain for Healthcare and Pharmaceutical Certification. COST: Lean Manufacturing Certification Lean Healthcare Certification Lean Office Certification Lean Product Development Certification Lean Supply Chain for Healthcare Certification Lean Pharmaceutical Certification Lean Supply Chain and Warehouse Management Certification Duration 10 days 5 days 5 days 5 days 4.5 days 3 days 10 days Price $6,495.00 $3,450.00 $2,950.00 $2,950.00 $3,450.00 $2,295.00 $6,450.00 PROGRAM LINK: http://interpro.engin.umich.edu/Lean.htm BROCHURES: Manufacturing: http://confluence.engin.umich.edu/download/attachments/3958/leanManufacturing121109Web.pdf Healthcare: http://confluence.engin.umich.edu/download/attachments/3958/leanhealthcare.pdf Office: http://confluence.engin.umich.edu/download/attachments/3958/leanBusiness111108Web.pdf Product Development: http://confluence.engin.umich.edu/download/attachments/3958/LeanProductProcess2.pdf Supply Chain for Healthcare: http://confluence.engin.umich.edu/download/attachments/3958/LeanLogisticsHealthcareMainBrochure.pdf Pharmaceutical: http://confluence.engin.umich.edu/download/attachments/3958/leanpharma91508.pdf Supply Chain and Warehouse Mgmt: http://confluence.engin.umich.edu/download/attachments/3958/leanlogistics10808Web.pdf UNIVERSITY OF NEBRASKA OMAHA: LEAN ENTERPRISE CERTIFICATION LOCATION: Omaha, Nebraska, USA. Remote/onsite training also available. CERTIFICATES/CERTIFICATION OFFERED: Lean Enterprise Certification CONTENT COVERED: Principles of Lean Manufacturing – Overview of Lean principles; Lecture and live simulation to show how Lean improves quality, reduces costs, and increases productivity Five S Workplace Organization - Five Pillars of the Visual Workplace and Five S Set-up Reduction / Quick Changeover - Fundamental principles of set-up reduction; Standard methodology in applying SMED to any industry and environment. Value Stream Mapping - Two-day workshop; current and future state maps created for participants’ own company's value stream. Cellular Flow Manufacturing - Link and balance manufacturing operations; MEP five-step process for designing and implementing work cells; Kanban and Pull methodology Standardized Work - How to analyze the interaction of people, materials, methods, and machines in a work process and develop the most effective combination of resources in the best sequence to achieve the desired output and reduce waste. Note: The Nebraska Business Development Center is the exclusive NIST/MEP-Certified Lean manufacturing service provider in the state. They use the methods and content established by NIST/MEP for the instruction of the program. TARGET PARTICIPANT/PROGRAM GOAL: Prior Lean experience is not explicitly listed as a requirement. Content focus is geared towards the specific industries, as outlined by title. Within each program, the recommended attendees list essentially spans all employees within an organization. INSTRUCTION/LEARNING METHOD: Lecture/workshop Simulations PRE-REQUISITE(S): [None] CERTIFICATION REQUIREMENTS/ASSESSMENT(S): 1. Must complete all 56 hours of course instruction 2. No formal examination listed COST: Lean Enterprise Certification PROGRAM LINK: http://nbdc.unomaha.edu/lean/leancertificate.cfm Duration 8 days Price $1,700 UNIVERSITY OF KENTUCKY: LEAN SYSTEMS CERTIFICATION LOCATION: Lexington, Kentucky, USA CERTIFICATES/CERTIFICATION OFFERED: Lean Systems Certification TARGET PARTICIPANT/PROGRAM GOAL: From the website: The University of Kentucky Lean Certification Program starts the development of your own internal support facilitators for the lean transformation process. Begun in the early 90’s, this “Train the Trainer” program has become known worldwide and has helped hundreds of companies nationally and internationally. Unlike other training programs, the University of Kentucky certification program is not a “Lean Champion” or “Lean Expert” program. Instead University of Kentucky is guided by Toyota’s belief that there is no such thing as a “kaizen specialist” or a “lean expert.” CONTENT COVERED: Week 1: Developing the Kaizen Mind for Leadership - Compare traditional versus lean thinking/culture - Describe the transformational image - List the organizational roles required for lean that sustains development - List “true lean” principles and behaviors - List the failure modes of lean - Practice Toyota’s techniques for process and flow study - Practice Toyota’s 8-Step Problem Solving methodology Week 2: Installing the Toyota Operations Development Group - Complete panel review of Week 1’s homework assignment - Evaluate the transformational image - Apply Toyota’s management improvement process named Jishuken - Describe Toyota’s learning process - Strengthen Process and Flow study - Strengthen Problem Solving skill Week 3: Maintaining Lean Through Standardization - Complete panel review of Week 2’s homework assignment - Apply the standardization principle - Apply Toyota’s annual strategic planning process called Hoshin Kanri - Describe transformational leadership - Apply Toyota’s Production Planning process called heijunka - Strengthen Problem Solving skill - Strengthen role understanding INSTRUCTION/LEARNING METHOD: Lecture/workshop Simulations Homework including application of ideas at one’s own work location PRE-REQUISITE(S): [none listed] CERTIFICATION REQUIREMENTS/ASSESSMENT(S): 1. Successful completion of all course work and homework 2. Attendance through all sessions COST: Lean Systems Certification PROGRAM LINK: http://www.mfg.uky.edu/lean/certification.html Duration Price 15 days $7,500