periodic1-publishable-summary

advertisement

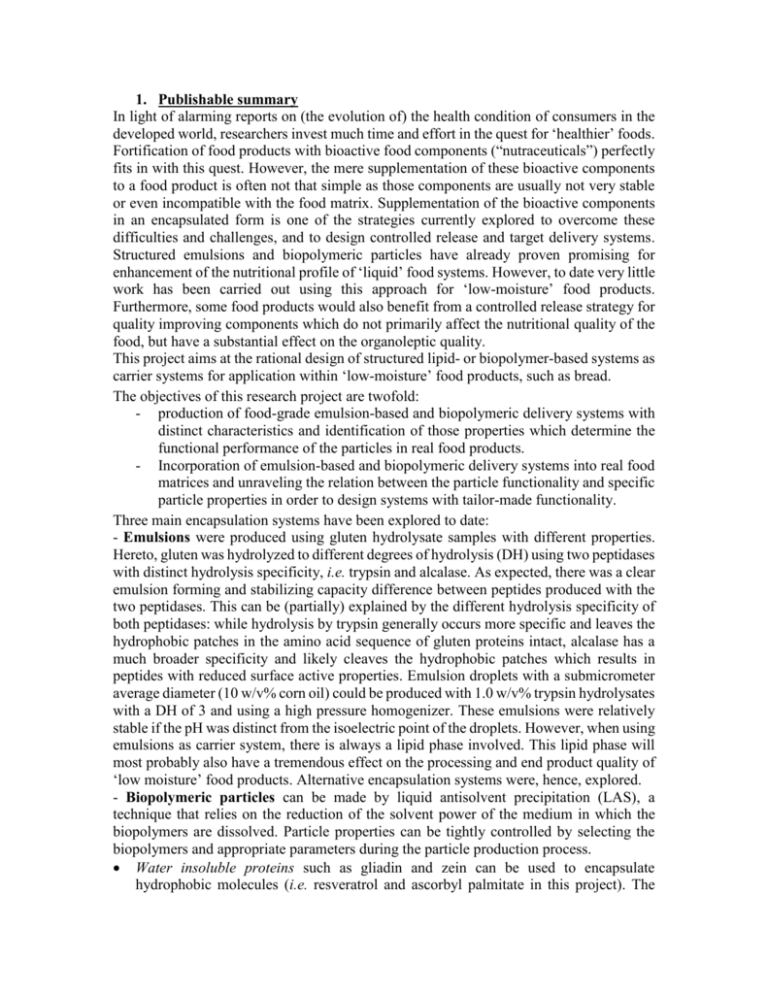

1. Publishable summary In light of alarming reports on (the evolution of) the health condition of consumers in the developed world, researchers invest much time and effort in the quest for ‘healthier’ foods. Fortification of food products with bioactive food components (“nutraceuticals”) perfectly fits in with this quest. However, the mere supplementation of these bioactive components to a food product is often not that simple as those components are usually not very stable or even incompatible with the food matrix. Supplementation of the bioactive components in an encapsulated form is one of the strategies currently explored to overcome these difficulties and challenges, and to design controlled release and target delivery systems. Structured emulsions and biopolymeric particles have already proven promising for enhancement of the nutritional profile of ‘liquid’ food systems. However, to date very little work has been carried out using this approach for ‘low-moisture’ food products. Furthermore, some food products would also benefit from a controlled release strategy for quality improving components which do not primarily affect the nutritional quality of the food, but have a substantial effect on the organoleptic quality. This project aims at the rational design of structured lipid- or biopolymer-based systems as carrier systems for application within ‘low-moisture’ food products, such as bread. The objectives of this research project are twofold: - production of food-grade emulsion-based and biopolymeric delivery systems with distinct characteristics and identification of those properties which determine the functional performance of the particles in real food products. - Incorporation of emulsion-based and biopolymeric delivery systems into real food matrices and unraveling the relation between the particle functionality and specific particle properties in order to design systems with tailor-made functionality. Three main encapsulation systems have been explored to date: - Emulsions were produced using gluten hydrolysate samples with different properties. Hereto, gluten was hydrolyzed to different degrees of hydrolysis (DH) using two peptidases with distinct hydrolysis specificity, i.e. trypsin and alcalase. As expected, there was a clear emulsion forming and stabilizing capacity difference between peptides produced with the two peptidases. This can be (partially) explained by the different hydrolysis specificity of both peptidases: while hydrolysis by trypsin generally occurs more specific and leaves the hydrophobic patches in the amino acid sequence of gluten proteins intact, alcalase has a much broader specificity and likely cleaves the hydrophobic patches which results in peptides with reduced surface active properties. Emulsion droplets with a submicrometer average diameter (10 w/v% corn oil) could be produced with 1.0 w/v% trypsin hydrolysates with a DH of 3 and using a high pressure homogenizer. These emulsions were relatively stable if the pH was distinct from the isoelectric point of the droplets. However, when using emulsions as carrier system, there is always a lipid phase involved. This lipid phase will most probably also have a tremendous effect on the processing and end product quality of ‘low moisture’ food products. Alternative encapsulation systems were, hence, explored. - Biopolymeric particles can be made by liquid antisolvent precipitation (LAS), a technique that relies on the reduction of the solvent power of the medium in which the biopolymers are dissolved. Particle properties can be tightly controlled by selecting the biopolymers and appropriate parameters during the particle production process. Water insoluble proteins such as gliadin and zein can be used to encapsulate hydrophobic molecules (i.e. resveratrol and ascorbyl palmitate in this project). The particles produced, however, are not very stable as protein particle suspensions are generally stabilized through electrostatic repulsion which makes them very susceptible to changes in pH or ionic strength. Additional stability can be achieved by including proteins with flexible structures (e.g. sodium caseinate) or polysaccharides (e.g. pectin) in the particle structure. Hereto, the particles can be coated after particle production by electrostatic deposition or by coprecipitating the biopolymers dissolved in the antisolvent phase during particle production. Pectin and sodium caseinate successfully increased the stability of gliadin and zein particles, respectively. Furthermore, the inclusion of these biopolymers in the particle structure had a tremendous effect on the particle size and increased the encapsulation efficiency of the particles for resveratrol. However, the particles, bare or uncoated, were still relatively unstable at pH conditions commonly found in food. Conjugation of dextran to zein prior to particle production resulted in the formation of particles that were stable over the entire pH range relevant for food and at high ionic strength. Water soluble proteins (e.g. whey protein and gelatin) and polysaccharides (e.g. octenyl succinate starch) were used to produce particles through LAS that could be used to encapsulate hydrophilic compounds (i.e. anthocyanins, fluorescein isothiocyanate (FITC) dextran and potassium iodate in this project). Particles produced from water soluble biopolymers, however, tended to redissolve once reintroduced in an aqueous phase. The particles could be stabilized through crosslinking of the biopolymers or by coating them with water insoluble biopolymers such as gliadin. Most of the crosslinking strategies explored adversely affected the integrity of the encapsulated bioactive molecule or did not sufficiently improve the stability of the particle structure. The coating strategy indeed improved the stability of whey protein particles against redissolution. However, the encapsulation efficiency and retention capacity of these particles for anthocyanins, i.e. low molecular weight molecules, were limited. Conversely, the gliadin coated whey protein particles efficiently encapsulated and retained high molecular weight molecules such as FITC dextran. Fluorescence quenching experiments were used to study interactions between proteins and bioactive molecules such as anthocyanins and resveratrol. The quenching experiments e.g. revealed that resveratrol interacts with zein through hydrogen bonds while interactions with gliadin were dominated by hydrophobic interactions. These results are very valuable as they shed light on the strength and nature of the interactions and, hence, enable the design of protein particles with tailor-made properties and functionality (encapsulation and release characteristics). - Starch granules were used as alternative anthocyanin encapsulation systems. As the pores of bare starch granules were very large relative to the anthocyanins, these molecules readily diffused out of the granules. Starch granules were coated with proteins or lipids by spray drying in order to restrict the diffusion of anthocyanins out of the granules. However, none of the investigated coatings efficiently restricted the diffusion of the anthocyanins. In conclusion, different encapsulation strategies and systems have been explored. All of them hold promise to be used in real food products. This will be the focus of the research conducted in the third and final year of this project. The identification of emulsion-based and biopolymeric delivery systems suitable for bioactive and quality improving components and with the desired functionality in food products will come to the benefit of the design of healthier food products.