risk assessment form - Electrical & Information Engineering

advertisement

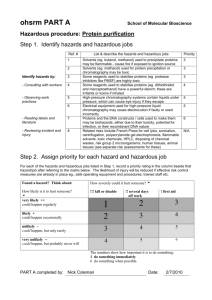

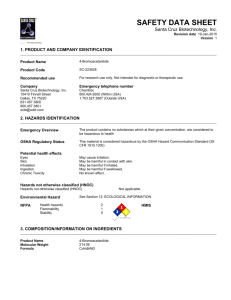

SCHOOL OF ELECTRICAL AND INFORMATION ENGINEERING RISK ASSESSMENT FORM – RESEARCH PART 1. DETAILS OF PROJECT/EXPERIMENT/WORK ACTIVITY Title of project/experiment/work activity: Click here to enter text. Staff/Student’s Information Last name: Click here to enter text. First name: Click here to enter text. Position/Degree: Click here to enter text. Supervisor’s name: Click here to enter text. Commencement year: Click here to enter text. Staff/Student ID Click here to enter text. Phone: Click here to enter text. Email: Click here to enter text. Location/Laboratory (where activity will take place): Click here to enter text. Brief description of project/experiment/work activity: Note: 1. For activities using hardware equipment, experiment titles and equipment involved in each experiment are required to list here; 2. For activities only using PCs, state “PC only” in the box below and go to Part 6 – Declaration. Revision date: 14 Jan 2015 Page 1 of 9 PART 2. SUMMARY OF POSSIBLE HAZARDS Voltage Levels - Are voltage levels hazardous to operator? Specify the voltage level. Current Levels – Are current level hazardous to operator? Specify the current level Ionizing Radiation – Are radiation sources to be used? Please specify the isotope to be used Laser – Are lasers to be used? Please specify Class (power level) of laser to be used Electrical – Is electrical equipment to be used? ☐Yes ☐No Click here to enter text. ☐Yes ☐No Click here to enter text. ☐Yes ☐No Click here to enter text. ☐Yes ☐No Click here to enter text. ☐Yes ☐No Please attach schedule of electrical equipment to be used and advise the following: (a) type of equipment, Click here to enter text. (b) maximum voltage present, Click here to enter text. (c) maximum current present, Click here to enter text. (d) maximum instantaneous power of each electrical device. Click here to enter text. Chemicals/Substances – ☐Yes ☐No Are chemicals/substances hazardous to health to be used? Please attach a list of hazardous chemicals/gases/substances to be used. Please advise estimates of quantities of hazardous substances (a) stored Click here to enter text. (b )used daily Click here to enter text. (c) used throughout the life of the experiment. Click here to enter text. Mechanical – Are you using mechanical, pneumatic, ☐Yes pressure vessels, hydraulics, motor drives, lifting gear etc? ☐No Please attach schedule of mechanical equipment to be used and advise the following: (a )type of equipment Click here to enter text. (b) maximum pressure, weight lifted and other relevant information about Click here to enter text. Revision date: 14 Jan 2015 Page 2 of 9 the magnitude of risk Other hazards – Are there any other hazards which pose ☐Yes unusual risks, such as high temperature/pressure, long periods at a computer, working at height, manual handling etc? ☐No Please attach schedule of other hazards identifying the nature of each hazard. Click here to enter text. Revision date: 14 Jan 2015 Page 3 of 9 PART 3. RISK ASSESSMENT AND CONTROL MEASURES Where you have answered ‘yes’ in Part 2 please provide a written 'Safe System of Work' or the control measures to be put into place for these activities. Items Potential Hazards Control Measures Risk Priority 1 Click here to enter text. Click here to enter text. Choose an item. 2 Click here to enter text. Click here to enter text. Choose an item. 3 Click here to enter text. Click here to enter text. Choose an item. 4 Click here to enter text. Click here to enter text. Choose an item. 5 Click here to enter text. Click here to enter text. Choose an item. 6 Click here to enter text. Click here to enter text. Choose an item. 7 Click here to enter text. Click here to enter text. Choose an item. 8 Click here to enter text. Click here to enter text. Choose item. an Note: To complete this section, please consider carefully all the possible risks, and ways in which the equipment (preferably) or the methodology can be adapted to eliminate the hazards How to analysis risk Definitions Hazard: The potential for harm. Risk: The probability (or likelihood) of harm actually occurring and the severity of its consequences Risk Assessment: The process of deciding on actions to be taken to reduce risk to an acceptable level by implementing control measures. Hazards identified: List all potential hazards, e.g. those that may arise from substances, electricity, equipment or machines and the ways in which people use or misuse those items etc. Control measures: These are things you will be putting in place to reduce risks to their lowest level. Revision date: 14 Jan 2015 Page 4 of 9 Risk matrix (to determine risk priority) Found a hazard? Think about: How severely could it hurt someone? How likely is it to hurt someone? !!! kill or disable !! several days off work ! first aid very likely ++ could happen regularly 1 2 3 likely + could happen occasionally 2 3 4 unlikely could happen, but only rarely 3 4 5 very unlikely -could happen, but probably never will 4 5 6 Risk priority: 1 to 2 = High Risk 3 to 4 = Moderate Risk 5 to 6 = Low Risk Hierarchy of hazard control 1. Eliminate the hazard or task if the risks outweigh the potential benefits. 2. Substitute the hazard with something less hazardous eg., substitute a toxic substance with another that is non-toxic. 3. Isolate the hazard by using barriers or distance eg., put insulation around noisy equipment. 4. Use engineering controls, such as local exhaust ventilation to remove dust/fumes, or automate the process. 5. Minimise the size or volume of the hazard and the duration of exposure to the hazard. 6. Rearrange the work area and work flow eg., have deliveries made to the end-point to avoid re-handling, intersperse repetitive activity with different tasks to avoid overuse injuries etc. 7. Establish safe work practices, such as restricting access to the area, keeping the area free of clutter, being prepared for emergencies e.g., spills, and prepare and use safe work method statements for hazardous tasks. 8. Provide training and supervision appropriate to the level of expertise of the personnel involved. As a minimum, this would include familiarisation with local hazards and their control, safe work methods and emergency procedures. 9. Wear personal protective equipment such as robust footwear, gloves, laboratory coats, safety glasses, ear plugs/muffs, dust masks etc., as a secondary measure to supplement the other agreed risk controls. Revision date: 14 Jan 2015 Page 5 of 9 PART 4. STANDARD OPERATING PROCEDURE Describe Standard Operating Procedure and insert block schematic Diagram indicating voltage / current levels. Insert a Process Flow Diagram (if appropriate) Click here to enter text. Revision date: 14 Jan 2015 Page 6 of 9 PART 5. GENERAL SAFETY INFORMATION Personal Protection Equipment (PPE) Lab Coat ☐Yes ☐No Gloves ☐Yes ☐No Face Mask ☐Yes ☐No Ear Protection ☐Yes ☐No Eye Protection ☐Yes ☐No Foot Protection All Laboratories Special Monitoring (Hearing test, Eye test, Dust exposure etc). Is special monitoring required? ☐Yes ☐No Details: Click here to enter text. Waste Disposal Substances hazardous to health Information from MSDS as to disposal requirements Is Hazardous waste likely? ☐Yes ☐No Waste Disposal Procedures: Click here to enter text. First Aid First aid procedures in event of accident? Click here to enter text. Action required in the event of Equipment Failure Any special notification needed? Click here to enter text. Out of Hours Emergency Shut Down Procedure Any special procedural document must be kept Click here to enter text. near to experimental machine. ALWAYS THINK SAFETY Revision date: 14 Jan 2015 Page 7 of 9 PART 6. DECLARATION Are there any changes in this application from the previous submission? ☐ Yes ☐ No ☐ First submission I have understood and completed this form to accurately assess the WHS risks associated with my activity at the School of Electrical and Information Engineering. Name of Staff/Student: Click here to enter text. Signature: Click here to enter text. Date: Click here to enter a date. I have understood this form and accurately assess the WHS risks associated with my staff/student’s research activity at the School of Electrical and Information Engineering. Name of Supervisor: Click here to enter text. Signature: Click here to enter text. Date: Click here to enter a date. Revision date: 14 Jan 2015 Page 8 of 9 WORK PERMIT ROOMS/LABS: Click here to enter text. APPLICATION NO.: Click here to enter text. PROJECT TITLE: Click here to enter text. STAFF/STUDENT’S NAME: Click here to enter text. STAFF/STUDENT ID: Click here to enter text. SUPERVISOR’S NAME: Click here to enter text. PROJECT SAFETY CLASSIFICATION: Click here to enter text. CONDITIONS PERMITTED DURING NORMAL WORKING HOURS Click here to enter text. Click here to enter text. Name of Chair Phone number S. Sathiakumar 9351 4640 Name of Dept. Officer Phone number T. Huang 9351 2657 Revision date: 14 Jan 2015 CONDITIONS PERMITTED AFTER HOURS (ONLY ACTIVITIES WITH HAZARD RATING OF 5-6 ARE ALLOWED FOR AFTER HOURS ACCESS) Signature Date Click here to enter a date. Signature Date Click here to enter a date. Page 9 of 9