plastics furniture

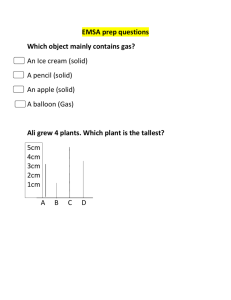

advertisement