Health Zone Ultima

advertisement

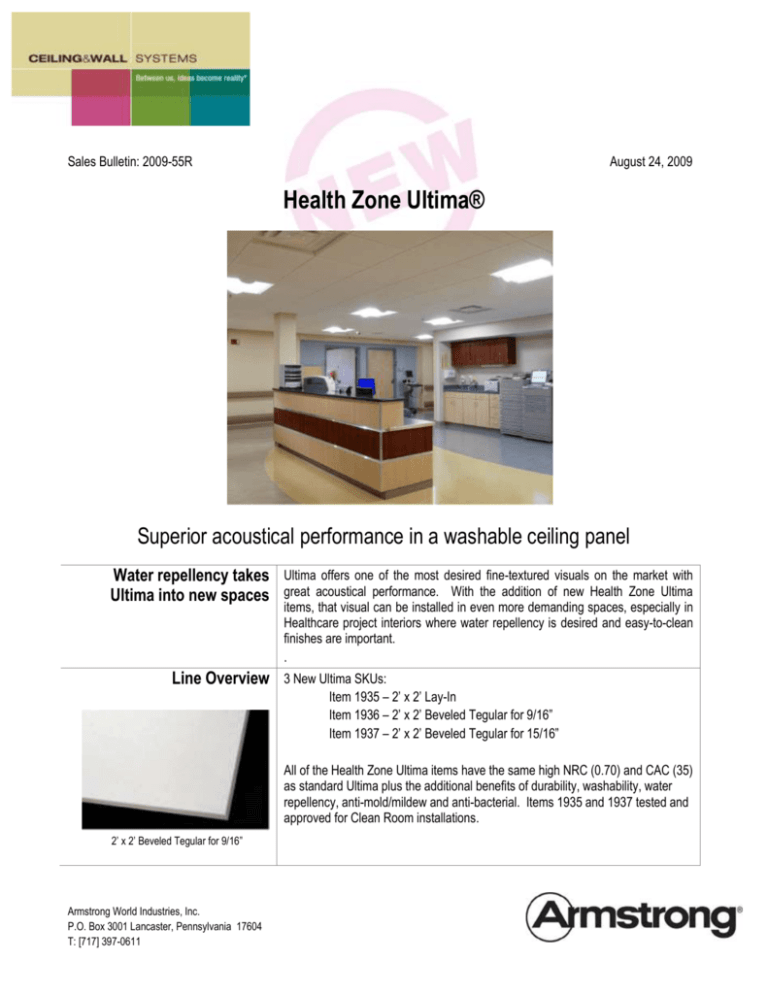

Sales Bulletin: 2009-55R August 24, 2009 Health Zone Ultima® Superior acoustical performance in a washable ceiling panel Water repellency takes Ultima into new spaces Line Overview Ultima offers one of the most desired fine-textured visuals on the market with great acoustical performance. With the addition of new Health Zone Ultima items, that visual can be installed in even more demanding spaces, especially in Healthcare project interiors where water repellency is desired and easy-to-clean finishes are important. . 3 New Ultima SKUs: Item 1935 – 2’ x 2’ Lay-In Item 1936 – 2’ x 2’ Beveled Tegular for 9/16” Item 1937 – 2’ x 2’ Beveled Tegular for 15/16” All of the Health Zone Ultima items have the same high NRC (0.70) and CAC (35) as standard Ultima plus the additional benefits of durability, washability, water repellency, anti-mold/mildew and anti-bacterial. Items 1935 and 1937 tested and approved for Clean Room installations. 2’ x 2’ Beveled Tegular for 9/16” Armstrong World Industries, Inc. P.O. Box 3001 Lancaster, Pennsylvania 17604 T: [717] 397-0611 Benefits to Architects and Designers Benefits to Contractors Typical Applications State-of-the-art acoustical ceiling solution for spaces that require Clean Room functionality o Lay-in and tegular edges are factory painted o Clean Room ISO 14644-1 Class 5 (FED STD 209E Class 100) with a Clean Room gasketed grid system o No hold down clips required Water repellent paint is durable and acoustically transparent o Washable and Scrubbable for 500 cycles + o NRC 0.70 and CAC 35 for excellent speech privacy Easy to clean and compatible for use with disinfecting agents: - Sodium hypochlorite - Isopropyl alcohol - Hydrogen peroxide - Quaternary ammonium o Helps reduce hospital acquired infections Meets USDA/FSIS guidelines for use in food processing areas o Achieves FDA standards of smooth, durable and easily cleanable High recycled content (70-80%); 100% recyclable; no added formaldehyde; does not contain PBT Dioxine (A term new to us; helps us meet Green Guide for Healthcare requirements. We have no PBT Dioxine in either this product or Tierra.) Coordinating visual with Ultima and Optima 30-Year Limited System Warranty against visible sag, mold/mildew and bacterial growth Acoustic alternative to vinyl covered gypsum in areas where a washable ceiling panel is required – commercial kitchens and food prep areas Same installation method as standard Ultima and Optima Non-directional visual reduces installation time and scrap Lightweight and durable Healthcare o Patient rooms o Treatment rooms o Emergency rooms o Nurses’ stations o Corridors o Lavoratories and restrooms Higher education o Laboratories Clean Rooms Kitchens and food prep areas -2- Competitive Advantages Health Zone Ultima offers superior acoustical performance in a washable ceiling panel. Health Zone Ultima NRC 0.70 vs. Vinyl Gyp NRC of 0.10 Health Zone Ultima CAC 35 vs. Ecophon Hygiene CAC 27 Higher CAC value addresses privacy concerns, especially in healthcare settings, while the water repellent surface allows panel to be easily cleaned to prevent hospital acquired infections. These photos document an industry standard AATTC test method called the “Parallel Streak Method.” As you can see, the parallel lines are brushed bacteria from the left side of the test area, across the surface of Health Zone Ultima, and across to the far right side of the test area. Clearly, the Health Zone Ultima provides what is referenced in the industry as a “Zone of inhibition”, which inhibits the growth of bacterial odors. AATTC Test Method 147-2004 -- Anti-Bacterial Assessment of Textile Materials: Parallel Streak Method. -3- Technical Background Water repellency is tested by “hold-out” time, or the amount of time it takes for the panel to absorb the water. There is no ASTM test method for this procedure; however lab tests proved that Health Zone Ultima withheld water for 15 minutes 95% of the time. Health Zone Ultima panels can be cleaned using a damp cloth, sponge or soft bristled brush with water, mild detergent or disinfectant. Gently wipe or scrub the panel surface with medium pressure. Panels can also be sprayed with a cleaning agent or disinfectant and wiped clean with a dry cloth. Acceptable disinfections include: - Sodium hypochlorite - Isopropyl alcohol - Hydrogen peroxide - Quaternary ammonium Tinted disinfectants SHOULD NOT be used because they can discolor the scrim. Installation Considerations TechLine has updated the Cleaning Recommendations to include Health Zone Ultima. Cleaning recommendations will also be posted on the web. Testing for Clean Room Class 5 (Class 100) was completed with full size Lay-In (1935) and 15/16” Beveled Tegular (1937) and Clean Room gasketed grid. For rooms that require field cut perimeter panels, use Lay-In panels (1935) or Tegular panels (1937) with Lay-In panels (1935) at the perimeter. Armstrong Super Coat Touch Up Paint #5760/5761 can be used to paint field cut tegular edges to match the surface. To seal the cut edges, use a vinyl latex paint or polyester film tape. Field cut panels have not been tested for Clean Room installations. Sales Tools Literature: Data page CS-4066 (This product will also be added on the web and for future reprints of Clean Room, Ultima Lay-in and Tegular and Clean Room Grid data pages.) Sales tools: 5”x 8” Presentation Box CS-4134 (Highlighting tegular edge) included in launch kits (8/rep). 6” 15/16” Clean Room grid samples will also be available. Samples: 6”x 6” Lay-In and Tegular Submittals samples included in launch kits (8/rep) and available at the National Sample Center Web: Search Health Zone Ultima or Ultima Rep Link-to-learn email Customer PowerPoint Presentations: Available in Sales Content Folder September 21. -4- Availability and Ordering Available for order: October 1, 2009 Service category: A Initial Lead time: 2 weeks Order process: Orders for Health Zone Ultima are taken by the Customer Focus Center. Pricing Questions See pricing summary for Fall 2009 launches. $0.25 adder to standard Ultima items. Please have your questions ready for the upcoming America Sales Meeting or contact the CFC & TechLine. -5-