Nuclear energy production process

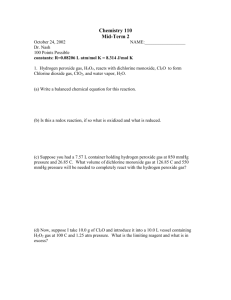

advertisement

Nuclear Energy Production Summary Nuclear Fuel Production - Uranium is as common as tin or zinc on Earth. About 63% of the world's production of uranium comes from Kazakhstan, Canada and Australia (Figure 14-12a). Worldwide production in 2009 amounted to about 50000 tonnes. This is the only nuclear fuel that can be mined naturally. Other nuclear fuels such as plutonium are derived from uranium in breeder reactor. Uranium ore - The primary uranium ore is uraninite (UO2), and pitchblende (UO3, U2O5 - collectively referred to as U3O8). A range of other uranium minerals can be found in various deposits. Some of the highest grade uranium ores in the world were found in the Democratic Republic of Congo. Milling and refining - After mining the ores, they are crushed and then leached with sulfuric acid in the mill. The uranium oxides are separated to yield a substance in dry power form called "yellowcake" which is sold on the market as U3O8. Conversion - Natural uranium is 99.274% U238, with the fissile U235 only constituting about 0.7205% of its weight. The crude material has to go through a process to increase the U235 percentage. But many of the enrichment processes require the substance in gaseous form, which only exists in uranium hexafluoride (UF6). Uranium hexafluoride can be solid, liquid, or gas depending on temperature and pressure. It is a solid or gas depending on whether temperature is below or above 57oC. It is in liquid form at 1.5 atmospheric pressure or higher and temperature greater than 64oC. Thus, the yellowcake has to be converted to uranium hexafluoride by treating it with strong acids and alkalis. Enrichment - According to cost and efficiency the enrichment methods are referred to by number of generation. The 0th generation is the calutron (California University Cyclotron) used in World War II, the 1st generation employing gaseous diffusion is being phased out presently, the 2nd one is the method of choice currently using the centrifuge techniques. Future generation is still in development using infrared laser to separate the isotopes. Regardless of enrichment methods, uranium fuel has to contain 3 to 4% U235 for nuclear reactors. Bomb grade uranium requires purification of U235 greater than 90%. Gas Centrifuge - This process uses rotating cylinder to create a strong centrifugal force F (a fictitious force associated with rotating frame). For angular velocity , distance r from the rotational axis, and m the mass of the object: F = mr2 so that the heavier UF6 molecules containing U238 move toward the outside and the lighter ones rich in U235 is collected close to the center (Diagram c, Figure 14-11d). This technique produces about 54% of the world's enriched uranium now. Fuel Fabrication - The UF6 gas is chemically treated to form uranium dioxide (UO2) powder. This powder is then processed into ceramic pellets and loaded into metal tubes (fuel rod), which are subsequently bundled into fuel assemblies for use in nuclear reactor. Nuclear Reactors - For efficient production of energy in nuclear reactors, the neutrons must be slowed down by moderation to increase their capture probability in fission reactors. Specifically, the initial fission of U-235 produces neutrons with mean energy of 2 Mev. Neutron with this energy has a fission probability about 1000 times less than a neutron with energy of 0.025 ev. So they need to be slowed down, on average, by a factor of 100 million. Some nuclear reactors use heavy water (D2O) to slow down (moderate) the neutrons, while ordinary water can be used to minimize neutron loss (via the H2O + 2n D2O reaction), which is harmful to health. The control rods used to regulate the rate of reaction are mainly composed of stainless steel tubes encapsulating silver-indium-cadmium (neutron) absorber material.