Outbound Logistics Assignment Specification

Volvo Car Group

Organization

Outbound Logistics

Name of document

Guidelines for inspection personnel

Issuer (dept,name,CDS-id)

84340, Riitta Honkanen

Type of document

Instruction

Issue Issue date

1.0

Reg.No.

1

2013-10-28

Security Class

Proprietary

Page

1 (3)

Guidelines for vehicle inspection and assessment of transport damages

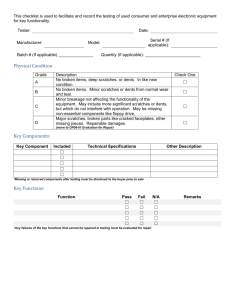

The instructions given below are guidelines to help in assessing damage during normal transport circumstances.

If there is a reason to suspect that a total delivery of vehicles is damaged through contamination, such as fall out, stone chips, big events (storm damage), etc a more thorough inspection shall be carried out.

Inspections are required in order to prevent forwarding damaged vehicles at each transportation stage. Result of the inspection must be reported to logistic departments and suitable countermeasures should be taken timely after investigating the cause. It is desirable that inspection is done both prior and after each transportation process such as trailer, train and vessel transportation.

The vehicles must be thoroughly inspected by walk around the vehicle and the items listed on the drawing (see further) must be checked, also common sense must be used when inspecting the vehicle, such as look from all different angles and on all possible places, or normal travel stain conditions, and cars to be checked in the condition they arrive in. Observe surface by through-looking, meaning inspecting at a 20 to 30 degree of angle to the surface.

Operational requirements for inspection : wear clean- and car friendly work wear which is free from exposed buttons and zippers. Any unprotected metal objects such as rings, watches, belts with buckle, cell phones, clip-boards etc. are not allowed.

Specific remarks:

"Consequential damage" : Following to be considered as transport damages as a consequence from another transport damage

1. Flat tyre : if a flat tyre has been replaced by the spare wheel, also the used spare wheel should be replaced

2. Emblems, decals, mouldings, seals etc : if there is a need to remove these parts due to repair of a transport damage these must then be replaced with new ones

Hidden damage : to be reported within 48 hours to carrier and to claims department

Guidelines for inspection personnel

Organization

Outbound Logistics

Name of document

Guidelines for inspection personnel

Volvo Car Group

Type of document

Instruction

Issue

1.0

Issue date

2013-10-28

Page

2 (3)

Guidelines for inspection personnel

Volvo Car Group

Organization

Outbound Logistics

Name of document

Guidelines for inspection personnel

Damage Assessment

Definitions

Exterior paint surface(section of the vehicle when doors and lids are closed)

Exterior/Interior components:

Tires and Rims:

Technical Defects

Type of document

Instruction

Issue

1.0

Issue date

2013-10-28

Page

3 (3)

Transport damage

Scratches (caught by finger nail)/paint chips which would require repaint.

NOTE: Scratches/damages to any surface which was covered by vehicle cover or rap gard is accepted as transport damage if there are signs the cover has been affected.

Scratches on unpainted bumpers, moldings, inserts etc. which have damaged the texture

Non-transport damage

Paint work damage caused by vehicle cover or loose rap gard

Polished out scratches(“hairline scratches”)

Scratches on unpainted bumpers, moldings etc. which have not damaged the texture

Dents, outwards and wavy panels(stress marks)

Broken/cracked glass and plastic panels not caused by material defect (stress cracks distortion)

Dents

Dirt,oil, grease or similar on the driver seat or on the interior fittings on the driver side

Water leakage caused by not properly closed window, door, sunroof, lids

Other damage to interior trim caused by break-in or vandalism

Missing or damaged standard equipment, such as remote keys, spare wheel or air compressor kit, jack, sealed bag with small loose part (e.g. lockable wheel bots, DVD,booklets) with evidence it has occurred during distribution

Damages such as scratches and dents on the undercarriage and spoilers with traces of external influence

Distortion in surfaces of component

Stress cracks in glass and plastic panels caused by material defect

Paint chips on edges of boot lid, tail gate, bonnet, petrol cap, doors(except driver door)

Water leakage caused by bad/missing sealing

Missing optional and standard equipment (with evidence not being installed)

Obvious assembly damages such as scratches, which run underneath moldings, bumbers and stickers/decals

Scratches and chips on the rim sidewall

Puncture, flat tire with external evidence

(bolts, screws, nails)

Cut in the sidewall, deep cut or damage to tire tread surface

Chafe marks from the wheel bolt equipment or roller test

Normal tire wear

Non starters, gear box problems, oil leakages etc.

Guidelines for inspection personnel