full public report

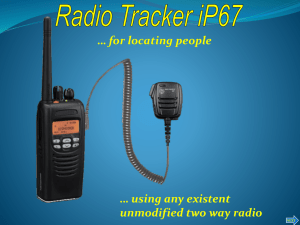

advertisement