Experiment #4: Holography.

advertisement

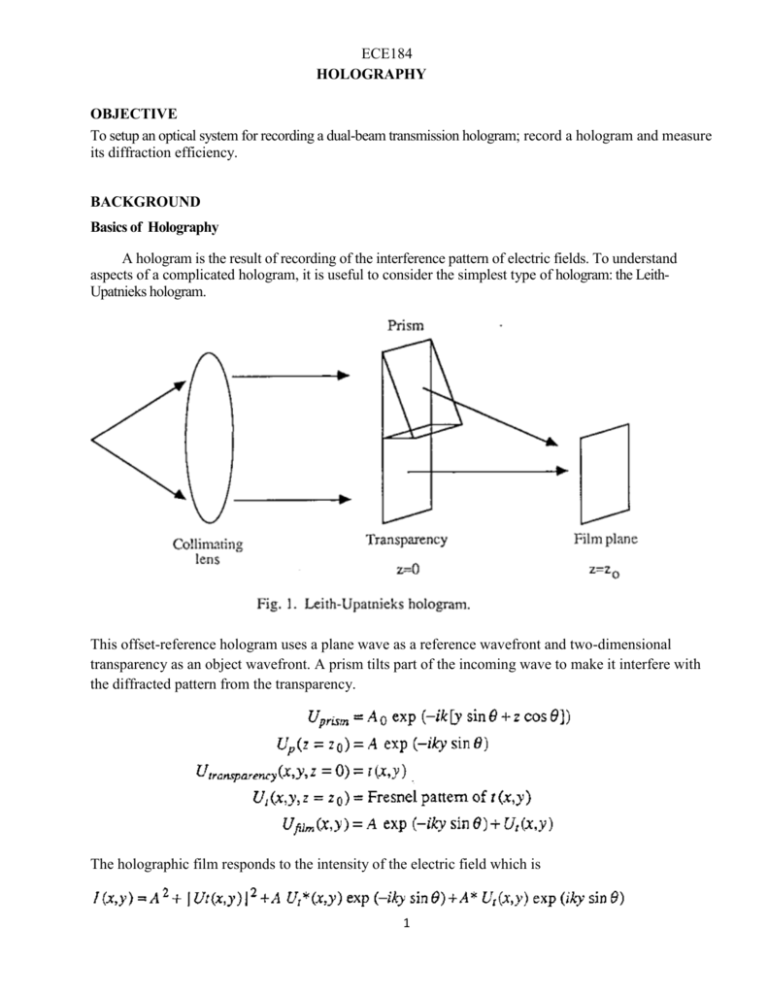

ECE184 HOLOGRAPHY OBJECTIVE To setup an optical system for recording a dual-beam transmission hologram; record a hologram and measure its diffraction efficiency. BACKGROUND Basics of Holography A hologram is the result of recording of the interference pattern of electric fields. To understand aspects of a complicated hologram, it is useful to consider the simplest type of hologram: the LeithUpatnieks hologram. This offset-reference hologram uses a plane wave as a reference wavefront and two-dimensional transparency as an object wavefront. A prism tilts part of the incoming wave to make it interfere with the diffracted pattern from the transparency. The holographic film responds to the intensity of the electric field which is 1 By knowing the characteristics of the transmission vs electric field response of the film, the exposure time can be calculated to occur on linear regime. The resulting amplitude transmittance of the film will be The bias transmittance of the film is tb and βˊ is the product of the exposure time and the slope of the amplitude transmittance-exposure curve at the bias point. Upon illumination of the film with a plane wave, the result is Analyzing each term separately Note that the angle between the object beam and the reference beam must be big enough to avoid viewing the real, virtual, and diffracted waves simultaneously. Coherence Length The coherence length of the source is extremely important. The path length difference between the reference and object beams must yield good fringe visibility and thus must be less than the coherence length of the laser to maximize the fringe contrast. 2 Stability of the Optical System Sufficient mechanical stability must be present in the optical recording system such that the motion of the film with respect to the optical pattern to be recorded is less than the spacing of the highest spatial frequency fringes formed by the interference pattern. A pictorial hologram will cause fringes of a variety of spacings to occur. As a result, in a pictorial hologram, the highest frequency will usually be determined by the response of the film, not the composition of the object. Reference to Object Beam Ratio Fringe visibility is also related to the ratio of reference to object beam intensities. The maximum fringe visibility and hence diffraction efficiency occurs when the ratio is equal. However, several factors indicate that this is not necessarily the best choice. The object beam will not be uniform in most cases. To prevent overexposing regions of the film, the ratio should be chosen with respect to the average object intensity with care in preventing overexposure from the peak object intensity. Linearly responding film such as PFG-1 usually exposed at 3:1 beam ratio for transmission hologram. Diffraction Efficiency of Amplitude Hologram To find diffraction efficiency of thin absorption hologram, consider the following intensity distribution at the film plane (two plane waves used): Assuming that the recording planes are equal and linear responsive film (β = 1/4a2) used, then If the hologram is illuminated with a plane wave, then Half of the amplitude passes through while only one quarter of amplitude is diffracted into each of the ±1orders. If U+1 = 0.25, then the total power in that order is I+1 = (0.25)2 =0.0625. Hence diffraction efficiency is only 6.25%. 3 Transmission and Reflection Holograms The main difference is the orientation of the interference fringes. Fig. 3. Transmission vs reflection holograms Note that the fringes are oriented along the bisector between the reference and object beams. The appropriate calculations show that the spacing of the fringes is much less in a reflection hologram, thus making these types of holograms more sensitive to vibration. Amplitude hologram and phase hologram Hologram encodes the phase information into intensity variation. In an amplitude hologram, the phase information is recorded as transmission variation (optical density variation). When the silverhalide film is exposed to light and developed, the grains of silver halides are changed into metallic silver and the transmittance of the film is altered. The amplitude transmittance varies spatially the same way as the exposure intensity. In a phase hologram, the phase information is recorded as index variation. Thus the amplitude transmittance has magnitude equals to 1 and a varying phase Bleaching is a chemical process that converts an amplitude hologram into a phase hologram, thereby increasing the efficiency. Standard silver halide films will respond to light by darkening through absorption of photons. The bleaching process converts the silver grains that have darkened into transparent silver halide grains. These grains have a different index of refraction than the surrounding emulsion gel. As the incident light waves travel through the bleached emulsion they are refracted instead of absorbed. The disadvantage to bleaching is often a noisier hologram. Holographic plates and development. We will use Slavich PFG-01 holographic film which can resolve more than 3000 lines per millimeter. For developing the film the JD-2 chemical processing kit will be used. 4 Object selection The film plate is 4" x 5". The hologram will be like a small window for viewing the object. The coherence length of the laser will determine the depth of view. Objects should reflect the illuminating laser light. Choose an object that is bright and looks good due to its contrast and shape rather than its color. Pick object with hard surface: metal, ceramic or rigid plastic. Soft and furry objects like paper, thin flexible plastics, stuffed animals, and plants will often move a wavelength or more during the exposure time. EXPERIMENTAL SETUP Fig.4. Optical setup for transmission hologram recording. PROCEDURE 1. Set up the optical system follow Fig.4. Adjust the object stage so that the object and film plate will be about the same height. Look through the film holder to get an idea of the windowing effect. Adjust the object beam MOs for optimum illumination of the object. Set up the reference beam spatial filter centering the illumination spot in middle of the film plate (make reference beam width at least 50% more than object beams). Path length difference between the reference and object beams to the plate should be near zero. Place the film plate holder at about 30° to the reference beam. Make sure all components are locked down properly. 2. Measure and record object and reference beam intensities with a detector in the film plane. Point the detector directly at the illumination source; take measurements at different points across the beam spot and calculate average power (the detector area is about 1cm2). Set the reference beam intensity about 3:1 to the sum of the object beams. 3. Using total light intensity falling on the film plane, calculate exposure time to obtain exposure of 250 µJ/cm2. Set this time on the shutter control unit. 5 4. Practice in the dark placing and removing dummy plate in the film holder and "recording" the hologram. Pay attention to do not move the object. After the plate is placed in the holder nobody should touch the optical table to prevent the vibrations. Wait for about 20 seconds to allow the holographic plate to settle before the exposure. 5. In the sink pour the developing solution into the tray, and distilled water into another tray. 6. Check the developing procedure below. Set the developing time on the timer. Both developing and soaking in the water will be done in the dark. (The holographic plate is sensitive to the red light, so a small amount of green light can be used.) Processing Procedure for Transmission Holograms (PFG-01 holographic plates and JD-2 processing kit) 1. Develop in the processing solution (part A + part B) for two minutes. 2. Wash in water for two minutes. 3*. Bleach (if needed) until the hologram is transparent, less than two minutes. 4*. Wash in water for two minutes. 5. The hologram can be quick-dried by holding it vertically and blow warm air across it with a hair dryer. 7. A light-tight box with a plate inside will be provided. Either side of the plate can face the object, though preferable to place the emulsion side facing the object. Handle plate by the edges only. 8. When ready for the actual exposures turn off the light. Check that recording beams are not obstructed. 9. In the dark take the holographic plate out of the box and carefully place it in the holder. Expose and develop the plate follow the procedure. (For faster drying the plate, the hairdryer can be used, but hold it from the distance to prevent melting the emulsion.) 10. Visually analyze developed plate: check the transmittance level, recorded spot size, etc. 11. Place p1ate back into the optical setup and block the object beams. Compare the image to the actual object before dismantling the system to verify that the hologram was properly recorded. 12. Analyze the virtual image: angle of view, depth, resolution, clarity; rotate the plate to analyze the effect of deviating from the original reference illumination direction. 13. Rotate plate 180° and analyze the real image on a white screen. In addition to the original illumination, use a straight laser beam and observe the output. Scan the beam onto different parts of the plate and note the results. 14. Measure diffraction efficiency by using this beam type illumination: scan for the brightest output image, and measure the output image power (be sure the image fills the detector as much as possible). Measure the input power and calculate the diffraction efficiency. 15. Pour the bleach solution into the tray and bleach the hologram. 16. Place hologram back in the holder. Repeat your observations and measurement of the diffraction efficiency. 6