Electrical Boxes

advertisement

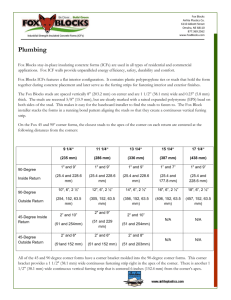

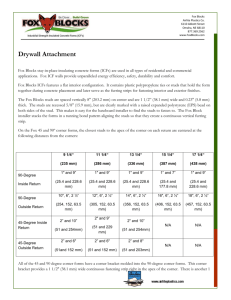

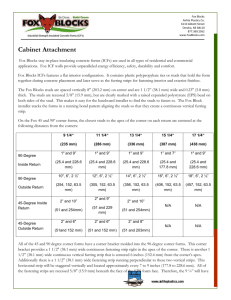

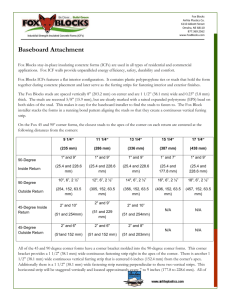

Fox Blocks Airlite Plastics Co. 6110 Abbott Street Omaha, NE 68110 877.369.2562 www.FoxBlocks.com Electrical Fox Blocks stay-in-place insulating concrete forms (ICFs) are used in all types of residential and commercial applications. Fox ICF walls provide unparalleled energy efficiency, safety, durability and comfort. Fox Blocks ICFs features a flat interior configuration. It contains plastic polypropylene ties or studs that hold the form together during concrete placement and later serve as the furring strips for fastening interior and exterior finishes. The Fox Blocks studs are spaced vertically 8" (203.2 mm) on center and are 1 1/2” (38.1 mm) wide and 0.23" (5.8 mm) thick. The studs are recessed 5/8" (15.9 mm), but are clearly marked with a raised expanded polystyrene (EPS) bead on both sides of the stud. This makes it easy for the baseboard installer to find the studs to fasten to. The Fox Block installer stacks the forms in a running bond pattern aligning the studs so that they create a continuous vertical furring strip. On the Fox 45 and 90º corner forms, the closest studs to the apex of the corner on each return are centered at the following distances from the corners: 90-Degree Inside Return 90-Degree Outside Return 45-Degree Inside Return 45-Degree Outside Return 9 1/4" 11 1/4" 13 1/4" 15 1/4" 17 1/4" (235 mm) (286 mm) (336 mm) (387 mm) (438 mm) 1" and 9” 1" and 9” 1" and 9” 1” and 7” 1" and 9” (25.4 and 228.6 mm) (25.4 and 228.6 mm) (25.4 and 228.6 mm) (25.4 and 177.8 mm) (25.4 and 228.6 mm) 10", 6”, 2 ½” 12", 6”, 2 ½” 14", 6”, 2 ½” 16", 6”, 2 ½” 18", 6”, 2 ½” (254, 152, 63.5 mm) (305, 152, 63.5 mm) (356, 152, 63.5 mm) (406, 152, 63.5 mm) (457, 152, 63.5 mm) N/A N/A N/A N/A 2” and 10” 2" and 9” 2" and 10” (51 and 254mm) (51 and 229 mm) (51 and 254mm) 2” and 6" 2” and 6" 2” and 8" (51and 152 mm) (51 and 152 mm) (51 and 203mm) All of the 45 and 90 degree corner forms have a corner bracket molded into the 90-degree corner forms. This corner bracket provides a 1 1/2" (38.1 mm) wide continuous fastening strip right in the apex of the corner. There is another 1 1/2" (38.1 mm) wide continuous vertical furring strip that is centered 6 inches (152.4 mm) from the corner’s apex. Additionally there is a 1 1/2" (38.1 mm) wide fastening strip running perpendicular to these two vertical strips. This Fox Blocks Airlite Plastics Co. 6110 Abbott Street Omaha, NE 68110 877.369.2562 www.FoxBlocks.com horizontal strip will be staggered vertically and located approximately every 7 to 9 inches (177.8 to 228.6 mm). All of the fastening strips are recessed 5/8" (15.9 mm) beneath the face of the EPS foam face. Therefore, the 9 ¼” will have continuous fastening strips located 2 1/2 inches, 6 inches and 10 inches (63.5, 152.4, and 254 mm) from the outside corner, the 11 1/4" will have continuous vertical fastening located 2 ½” inch, 6 inches and 12 inches (63.5, 152.4. and 305 mm) from the outside corner, the 13 1/4" iForm will have a fastening strip located 2 ½” inch, 6 inches and 14 inches (63.5, 152.4. and 356 mm) from the outside corner, the 15 1/4” will have a fastening strip located 2 ½” inch, 6 inches, and 16 inches (63.5, 152.4, and 406.4 mm), and the 17 1/4” will have a fastening strip located 2 ½” inch, 6 inches, and 18 inches (63.5, 152.4. and 431.8 mm). 15-Minute Thermal Barrier Requirement. All model building codes require that the interior face of the foam insulated wall for all buildings be finished with an approved 15-minute thermal (fire) barrier, such as minimum ½" (12.7 mm) thick regular gypsum wallboard attached to the plastic studs. This requirement includes unfinished basement areas and some crawl spaces. Other building materials documenting the ASTM E-119 fire index rating of 15 would be acceptable. Electrical Wall Penetration Sleeves Install wall penetration sleeves that run from the exterior to the interior of the Fox Block walls prior to concrete placement. Installing the penetrations prior to pouring is important to avoid the expense of drilling a hole through the reinforced concrete wall Lay-out and mark the location of any penetrations on the interior and exterior face of the wall, using the sleeve as a template to mark the location. Then cut the hole using a keyhole saw so that the sleeve will be snug tight. If an oversized hole is cut, use expanding foam to fill in any gaps to prevent air infiltration leaks. Before placing the concrete in the Fox wall, insert a metal or PVC sleeve, which is the length of the overall thickness of the Fox Block form. Some builders like to have the length of the sleeve sticking out the interior and exterior sides of the wall and cut off the extra length after placing the concrete. The sleeve should be water sealed with compatible foam caulk or seal. Insert the sleeve at a slight angle so that the exterior side of the sleeve is slightly lower than the interior side of the sleeve. Electrical Wiring and Conduit You can install electrical wiring directly into the EPS foam surface after the concrete is placed in the Fox Block walls. Mark a layout of the path that the electrical wire will follow on the wall with a chalk line or marker. Once the layout is complete, create a groove or chase in the foam for running the wire. Most installers use an electrical hot knife o router for this purpose. The hot knife should come with a depth stop, so it can be adjusted to the required depth. A router may also be used, but it does not provide the clean and professional results that a hot knife does. To avoid the necessity of cutting chases behind the interior framed walls, Fox Blocks recommends that you cut the wire chases in the foam prior to framing the interior walls. The chase should be approximately 1" wide by 1 ½" (25.4 by 31.7 mm) deep. The Fox Block form has a consistent 2 5/8" (66.7 mm) thickness of foam on the interior and exterior face of the wall. Preferably, run the chases between the horizontal joints of two Fox Blocks form courses to minimize the amount cutting through the plastic furring strips that are located vertically 8" (203 mm) on center. To run the wire to the electrical box, run the chase up or down between the plastic ties. Run Romex type wire in the chases that you have cut into the foam. If the chase is too wide to snug fit the wire, use expanding foam or scraps of foam wedged into the chase to hold the wire in place. Electrical wiring routed in conduit Fox Blocks Airlite Plastics Co. 6110 Abbott Street Omaha, NE 68110 877.369.2562 www.FoxBlocks.com can be installed in a similar fashion. You may find it quicker and easier to run wiring along the floor and ceiling cavities whenever possible. Electrical Boxes Both metal and plastic boxes can be placed in Fox Blocks walls. Again, use a hot knife or router for cutting the foam cutout, and secure the electrical box to the wall by one of the following three methods: 1. Fastening the box to the plastic ties 2. Using expanding foam glue to secure the box within the cutout 3. Fastening the box to the concrete When anchoring the back of the box to the concrete wall, run the wires into the box first, and use concrete fasteners—either screws or nails. The size of electrical boxes is based upon the volume within the box. The electrical code will determine the size of the electrical box based upon the size and quantity of wire. Carlon Electrical Boxes B118B-UPC, B232B-UPC, B344AB, B455A-UPC, B418A-UPC Standard 2"x2"x3" (50.8 x 50.8 x 76.2 mm) Electrical Box This electrical box can be placed anywhere the Fox Block wall. 4"x4"x1 ⅜" (101.6 x 101.6 x 34.9 mm) Electrical Box This electrical box is wider and shallower than the standard box. It is only 1 ⅜" (34.9 mm) deep and can be placed anywhere along either the Fox wall. You can use a mud ring to reduce a larger switch box to a one-gang switch box. Main Electrical Panel When permissible it is best to mount the main electrical panel to an interior wall. When mounting the main electrical panel flush to a Fox Block wall, build a wood buck with a wood backer embedded in the wall. The Fox Block wall should be properly reinforced as if this were a window buck. Another option is to fur out the Fox wall. Fasten the exterior meter enclosure panel to the concrete using galvanized screws or concrete fasteners. Usually a 4" (101.6 mm) or 6" (152.4 mm) sleeve is required to run the wires outside. Follow the above procedures for this penetration.