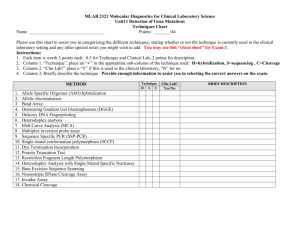

Training Checklist

advertisement

TRAINING CHECKLIST FOR MINI_VIDAS_MU_EN_99188_E This part should be completed by the TRAINEE TRAINEE NAME : DATE OF TRAINING STARTED: SECTION : Yes No Training Method Explanation Lectures Demonstration Practice Computer based Self study Training Materials SOP Manuals Package Inserts Lecture Hand outs Computer Program Handouts Videotape (s) Practice materials Yes No Read the following sections of the operator’s manual before starting training. Operator’s Manual Section/ Topic Date Completed Trainee Initials Minividas Procedures Manual Safety Symbols ….. Preface P. 2- 3 Safety Precautions ……. Preface P. 4- 6 Precautions on Use ……. Preface P. 7- 10 Analytical Methods Principles ……. Section 7.1 QC rules ……. Section 7.2.5 Calibration Methods ……7.2.3 Calculating the concentration of sample/control …..7.2.4 System Description …… Chapter 1 Basic Operations…… Chapter 3 Technical Specifications…. Appendix A.1 Environmental Requirements….. Appendix A.4 Training and Competency Assessment Program/ Training Effective Date: 21 August, 2011 Version 1 ULC/TCP/11F Page 1 of 7 Training Checklist Please Tick the appropriate box to the right Read & Understood Training Element Explained/ Discussed Observed 1. Intended use 2. 1. 2. 1. 2. 3. Analytical Methods Principles (Resource: operating Manual 7- 1 to 7-3) Qualitative mini VIDAS assays Analysis methods used for single reagent strip (P/S method and the P-S method) Analysis methods used for dual reagent strip (P/N method and the P-N method) Quantitative mini VIDAS assays Patient to standard ----- (Resource: Minividas Procedures Manual, Chapter 5) Patient to reference ----- (Resource: Minividas Procedures Manual, Chapter 5) Curve fitting equations - (Resource: Minividas Procedures Manual, Chapter 5) 1. QC rules Westgard Multi-rule Cumulative Sum Check 2. Twin-plot Calculation Method of ISE Unit 3. Specifications Technical Power Requirements EMC Environmental Requirements 4. System Description Hardware Reagent strip tray S PR® block Operating status light Microprocessor Incubators Strip preparation tray Detection system Central processing unit Keypad and screen Internal / External printer Rear panel components Bar code readers Software mini VIDAS menus Memory cards Contents of the assay kit single or dual reagent strips SPRs (Solid Phase Receptacle) control(s) standard(s) diluent package insert MLE card Training and Competency Assessment Program/ Training Effective Date: 21 August, 2011 Version 1 ULC/TCP/11F Page 2 of 7 Performed Proficiently Read & Understood Training Element Explained/ Discussed Observed 5. Basic Operations Starting up the analyzer Shutting down the analyzer Configuring the analyzer dose units Set up user ID the report header date and time display contrast Selecting the printer Defining the sample ID character sets Changing the key click volume Changing the beep volume Setting initial and final error beep volume Enabling display blinking Expired Standard warnings (Onscreen & Printed) Checks for expired calibrations (Any & Current Standard at Assay Startup) Check for master lot at assay startup LIS user options Creating normal ranges for assays Installing paper in the printer Routine Procedure Precautions for use of reagents Basic mini VIDAS work flow Type of run required Planning a run Assay compatibility Standards and controls Master lot data Assay requests Running Assays Starting a defined run Starting a load and go run Assigning a dilution factor Calibration and recalibration quantitative or qualitative Principles of calibration using the mini VIDAS Principles of recalibration using mini VIDAS Establishing the master curve Master Lot data How to calibrate Automatic and manual master lot data entry How to see the stored standards for a particular assay lot How to display the master lots for a particular assay procedure to stop the processing of one or both sections procedure to print a list of the mini VIDAS assays that have Master Lot Data loaded on your mini VIDAS. The assay report Printing and reprinting assay report assay report for qualitative assay assay report for quantitative assay Assay report errors messages Training and Competency Assessment Program/ Training Effective Date: 21 August, 2011 Version 1 ULC/TCP/11F Page 3 of 7 Performed Proficiently Training Element Read & Understood Explained/ Discussed Observed Validating LIS results Environmental requirements (Resource: Minividas Procedures Manual, Chapter 8, Appendix A) Temperature Control (Resource: Minividas Procedures Manual, Chapter 8, , Appendix A) Preparing for Analysis Starting Analysis Processing Results Finishing Analysis 6. Advanced Operations (the operating software of analyzer) Sample Sample Information dialog box Request Delete dialog box Change Sample Position dialog box Requesting Samples or Modifying Information Scan Sample Barcode Download Sample Information Probe Analysis Current Results (Rerun sample tests) Historical Results QC Request Start Stop Results Replace the cuvettes Relog the operating software Exit the operating software Reagent Setup screen Calibration Calibration Screen Calibrator screen ISE screen Calibration Request screen Request Calibration Reset Position of a Calibrator Calibration Results Calibration Curve Calibration Reaction Curve Reagent Blank Trend Curve Calibration Data To Recalculate or Modify Calibration Parameters parameters on the screen. Modify Calibrator Information parameters on the screen Search ISE Calibration Results Training and Competency Assessment Program/ Training Effective Date: 21 August, 2011 Version 1 ULC/TCP/11F Page 4 of 7 Performed Proficiently Training Element QC screen Status screen Statistics screen Parameters screen Setup System screen Hospital Screen User screen Print screen Read & Understood Explained/ Discussed Observed Real-time QC screen Daily QC screen (QC Reaction Curve) Day to Day QC screen QC Summary screen Control screen Modification of Control Information Sample Disk screen Reagent Disk screen Reaction Disk screen Worklist screen Results screen (Search dialog box) Workload screen Charges screen Conditions dialog box Set Cost and Price Test Screen parameters screen Reference ranges screen Calibration screen QC Rules screen QC Screen ISE screen Profile screen Calculation screen Off-system screen Carryover screen Basic ISE Bar Code LIS Dictionary General Template Maintenance screen Daily Maintenance screen ISE maintenance Daily maintenance screen screen Maintenance Record screen Log screen Import/Export screen System Screen Alignment Motion screen screen Training and Competency Assessment Program/ Training Effective Date: 21 August, 2011 Version 1 ULC/TCP/11F Page 5 of 7 Performed Proficiently Training Element Read & Understood Explained/ Discussed Observed 7. Maintenance Daily Maintenance ISE Unit Maintenance Weekly Maintenance Monthly Maintenance Maintenance Every Six Months Irregular Maintenance Checking Remaining Deionized Water Emptying Waste Tank Checking Connection of Deionized Water Checking Connection of Wastewater Checking Syringe Checking Probe Checking Mixing Bar Daily Cleaning Pump Calibration Cleaning Probe Cleaning Mixing Bar Washing Deionized Water Tank Washing Waste Tank Cleaning Sample/Reagent Compartment and Barcode Reader Cleaning Panel of Analyzing Unit Cleaning Wash Well of Probe Cleaning Wash Well of Mixing Bar Washing Dust Screens Replacing Filter Assembly Unclogging Probe Replacing Probe Replacing Mixing Bar Replacing Plunger Assembly of Syringe 8. Removing Air Bubbles Replacing Lamp Replacing ISE Components Replacing Reagent Pack Replacing Electrodes ISE Unit Storage (optional) Maintenance Log Troubleshooting process to determine alarm status help system 9. Safety Safety Symbols Safety Precautions Precautions on Use 12. Running the Following Assays 1. Troponin 2. Estradiol Training and Competency Assessment Program/ Training Effective Date: 21 August, 2011 Version 1 ULC/TCP/11F Page 6 of 7 Performed Proficiently 3. 4. 5. LH FSH Progesterone 6. 7. 8. CK- mb H. pylori HCG Level of achievement Date/ Trainer Initials: Level of achievement defined: Discussed- Process/ procedure has been discussed; principles, procedures, processes, have been explained and demonstrated by the trainer. The trainee has observed demonstration and asked questions Observed- Trainee has practiced the procedure/ process under the direction of the trainer with guided instruction. Performed Proficiently- Trainee can accurately complete the task with minimal supervision and evaluates results or troubleshoots problems when indicated. Completes the procedure entirely according to written SOP Trainee Performance Evaluation This part should be completed by the TRAINER Please Tick the appropriate box to the right Yes Evaluation Method Result Of Evaluation Un Satisfactory Satisfactory Oral evaluation Direct observation competency (If yes, complete the form) Written competency Unknown samples (If yes, include a copy of the result) Other Corrective Action If Needed DATE OF TRAINING COMPLETED TRAINEE SIGNATURE TRAINER SIGNATURE SUPERVISOR SIGNATURE DATE : …………………………… : …………………………….. : …………………………….. : …………………………….. : …………………………….. Training and Competency Assessment Program/ Training Effective Date: 21 August, 2011 Version 1 ULC/TCP/11F Page 7 of 7 No