aeronautics 085

advertisement

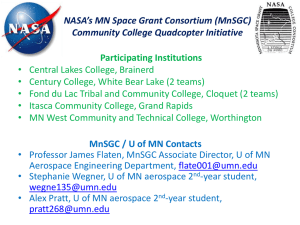

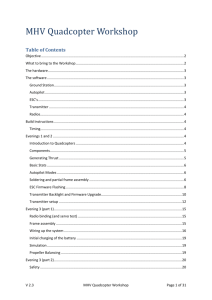

Senior Project Report Quadrotor Unmanned Aerial CopterCam System (Q.U.A.C.S.) Jeff Ramos Joshua Olds Nelson Mankey IT Crowd College of Engineering and Information Sciences DeVry University, Fremont 1 Title: QUACS: The Standalone Quadcopter Solution (This document contains 53 sheets including this title page) Design Team: Jeff Ramos Name Electronics Engineering Technology Program Signature Joshua Olds Name Computer Engineering Technology Program Signature Nelson Mankey Name Electronics Engineering Technology Program Signature Submittal Date: 6-17-2013 2 Contents Executive Summary 7 Introduction 8 Statement of Problem 9 Design Objectives 10 Technical Approach Identifying Needs of Customers Identifying Target Specifications Generating Design Concepts Selecting Design Concepts 11 12 13 14 15 Design Alternatives 16 Test Plan Flight Duration Test R/C Range Test Video Transmission Range Test Base Station Solar Charge Rate Base Station Results Quadcopter Results Testing Results 18 22 23 23 23 24 24 24 Risk Analysis 27 Project Management Deliverables Budget Communication and Coordination with Sponsor Team Qualifications 29 29 31 32 33 Conclusion 33 Product Revisions 33 3 Appendices 36 References 48 Resumes of Team Members Jeff Ramos Joshua Olds Nelson Mankey 49 49 51 52 Photo Gallery (Eye Candy) 54 4 List of Figures Fig. 1—Three quadcopters shown for size comparison and appearance. 6 Fig. 2 – Altair UAV 8 Fig. 3 Charger to Battery Voltage Chart 25 Fig. 4 Charger to Battery Voltage Grid 25 Fig. 5 – Base Station Load Voltage Chart 1 26 Fig. 6 – Base Station Load Voltage Grid 1 26 Fig. 7 – Base Station Load Voltage Chart 2 27 Fig. 8 – Base Station Load Voltage Grid 2 27 Fig. 9— Project Gantt Chart 30 Fig. 10— Quadcopter Cost Breakdown 31 Fig. 11– Base Station Cost Breakdown 32 Fig. 12 – Revised Gantt Chart 35 5 Appendices Atmel ATmega 2560-16AU Specifications 36 BMA180 Digital Triaxial Acceleration Sensor Specifications 37 BMP085 Barometric Pressure Sensor Specifications 38 Turnigy Plush 40A Electronic Speed Control Specifications 39 Hobbyking 900Mhz 500mW Video TX/RX Specifications 40 HMC5883L Triple Axis Magnetometer Specifications 41 ITG3205 Triple Axis Gyro Specifications 42 Turnigy D3536/9 910KV Brushless DC Motor Specifications 43 DX6i 6-Channel Full Range 2.4Ghz Radio Transmitter Specifications 44 MultiWii PID Block Diagram 45 LiPo Battery Voltage vs. Discharge Rate Graph 46 Base Station Charging/Regulating Schematic 47 6 Executive Summary Of the multitude of Unmanned Aerial Vehicles (UAV’s) available on the market today, none manage to surpass the affordability or accessibility of the Quadrotored Helicopter, or “quadcopter” for short. The typical quadcopter consists of a cross shaped frame with four independently controlled rotors, one on each of its 4 arms (Fig. 1). The onboard flight controllers rely on a programmed microcontroller in serial with Electronic Speed Controllers (ESC’s) to determine thrust, direction, yaw and pitch. In aeronautics terms, the quadcopter is classified as a Verticle Take Off and Landing (VTOL) craft and warrants the ability to hover indefinitely in place. Fig. 1—Three quadcopters shown for size comparison and appearance. To the general population, the quadcopter is highly favorable to its UAV predecesors due to its compact size, signifcant affordability, and precise manuverabilty (Suh 2003). One aspect that makes this device so accessible to consumers is the huge advantages derived from the flight controller coding being widely open source. Therefore, one does not have to generate and develop their own diffrencial equation-based algorithms in order to get a consistent flying 7 behavior. Professionals and hobbyists worldwide have submitted their workable code based on unique testing environments and purposes. This allows even a novice programmer access to participate in this open source conglomorate. It is no surprise that the quadcopter has gained so much popularity. The scope of this project is to continue the deleopment and prosperity of these devices. We have accomplished this by contributing a utilitarian resource for quadcopters. We aim to achieve a standalone quad copter support system, designed completely around customer need. Our plan includes a customization Graphical User Interface (GUI) for informed component selection and performance calculator that will output a quadcopter built to the exact specifications. We then pair that quadcopter with a solar powered deployable base that will provide charging capability to additional batteries, and powered accessories. Introduction The conquest of flight is a triumph that humanity has enjoyed now for over a century. Flight is something we now experience in a plethora of shapes and forms ranging from commercial 747's on down to the flying squirrel suits (aka Wing Suits) developed by diehard base-jumpers. However, in this modern age, it is possible we are glimpsing what may be the final days of manned flight. With the advent of the unmanned aerial vehicle (UAV) enormous potential has been created towards the preservation of human lives. As its namesake suggests, a UAV requires no onboard pilot and can be remotely This Altair UAV has a wingspan of 86 feet, can reach altitudes over 55,000 feet, and can stay airborne for up to 44 hours. 8 piloted via remote control or strictly autonomous programming—having no pilot whatsoever. Currently, UAV's serve in a wide range of capacities including combat duty, land surveying, air quality control, disaster relief, and not to Fig. 2 – Altair UAV mention just for pure recreation (Freedman, 2012). However, it is not too modest to consider the number of practical applications to be almost without limit. In actuality, the do-it-yourself UAV market has exploded in recent years. For a meager investment by today’s standards, one can purchase their own flying platform and put it to use as they see fit—for work or for pleasure. Mary Cummings, an MIT Aeronautics Professor and former F/A-18 pilot, was quoted “[Ongoing UAV development] is the best thing to happen since the space race…a technology with low cost of entry that anyone with a cell phone can use.” Very soon, experts predict the capabilities of a “refrigerator-size, multi-tens-of-thousands-of-dollars drone…will be doable soon with a shoebox-size, multi-hundred-dollar version” (Freedman, 2012). With this news, one can imagine the myriad of potential the average consumer might find beneficial from owning such a craft. Statement of Problem The industry has already proven that the quadcopter platform is extremely versatile and capable of solving a multitude of problems creatively and affordably. One of the most popular uses of a quadcopter platform is for the purpose of streaming aerial video. However, this application is very limited due to two major setbacks in the quadcopter design. The first downfall of the quadcopter platform is that it is notorious for short flight times, mainly due to the delicate balance between battery capacity, flight performance, and weight. Second, for a quadcopter to be 9 piloted using streaming aerial video, the pilot must use a base station equipped with a receiver and display for viewing the video stream. The conventional quadcopter must obey the laws of physics, including thrust to weight ratios, just as any other aircraft would. This being said, there are not many options for improving the flight time of the platform. If you increase the battery capacity, you proportionately increase the weight, netting you no additional flight time. Conversely, if you strip the quadcopter of all accessory components to optimize weight, you diminish the ability for it to complete useful tasks. Additionally the industry has already optimized structural weight to a degree that leaves little room for design improvement. At the absolute minimum, a base station needs to provide the pilot with a live video display and clear video reception. However, the need for this base station inherently limits the quadcopter’s mobility by requiring additional equipment and power sources. The need for an external power source can be alleviated with the use of battery packs. Unfortunately, this places another limiting factor on the system’s run time. This leads us to the conclusion that we cannot fundamentally optimize the quadcopter for longer flight times, nor can we simply eliminate the need of a base station due to the need for live video support. Design Objectives 1. Create an affordable, efficient, flying camera platform that is capable of recording highdefinition video in flight, as well as transmitting a live video feed up to 100 meters. 10 2. Build a regenerative mobile base station capable of receiving a live video stream and powering all the components and accessories needed without an external source. 3. Build a system that unites the quadcopter platform with a modular base station design that is capable of extending the quadcopter’s flight time. Technical Approach To create a reliable flight platform that meets the design objectives we have set above, we will be using a quad-rotor helicopter design. This design is comprised of a central body and four arms extending in an ‘X’ pattern from the body. The central body will house the electronics for the platform, as well as the camera recording equipment. The arms will support four electronically controlled brushless motors. These motors will drive 10 inch propellers to provide thrust for the platform. The electronics will consist of a flight control board, four electronic speed controllers (ESC’s), a camera system, a radio receiver, a video transmitter, and a battery. The flight control board will utilize an onboard gyroscope and accelerometer to gather the position and acceleration of the platform. It will then use this data to calculate the thrust needed from each motor to level the platform. The flight control board then sends this data to the ESC’s. The ESC’s will use this data to control the speed of the motors, and thus level the platform. This flight leveling system will ensure that the platform is stable for the video recording; however, it still requires a user to operate the platform. To do this, a user will be equipped with a 2.4 GHz radio transmitter that will transmit a control signal to the onboard receiver. The receiver 11 will send the transmitted data to the flight control board which will then adjust the automated flight leveling data to provide the user with stabilized control. We will also include a toggle able ‘Manual Mode’ that will allow the user to take full control of the platform, effectively shutting of the flight leveling system. We will also be designing a portable self-sufficient base station to go along with the quadcopter platform. This base station will consist of a video receiver, LCD display, solar panels, and a battery. The video receiver will be running at the same frequency as the quadcopter platform’s transmitter. This will allow us to receive the live video from the quadcopter. The small LCD screen will then be used to display the live video. The solar panels will be attached to the battery through a charging circuit allowing us to charge the battery when the platform is not in use, as well as to provide some extra power to take the load off of the battery when the platform is active. The base station will also have a built in charging circuit for charging the quadcopter platform’s flight batteries when connected to an external source. This charging circuit will be design with the ability to simultaneously charge multiple batteries for less down time between flights. This will eliminate the need for any external hardware besides the base station and the quadcopter platform itself. The quadcopter platform in combination with our custom base station will give users a platform that meets all of our design objectives. Identifying Customer Needs We identified the needs of the customers by observing the current procedures for those seeking to acquire a video feed in locations that were previously inaccessible to the average consumer. We observed that there are no cost-effective ways of getting aerial video and photography shots without the use of complicated professional systems or aerial vehicles. We then looked into the market for solutions to this problem and saw that there are products for 12 aerial photography, but none that are affordable to the average user while still fulfilling the consumer’s needs. Our product will offer a solution that is not only affordable, but reliable and reusable as well. The consumer will need a way to see first-hand what their aerial vehicle is recording. This is because many applications will require the user to control their quadcopter without being within line of sight. The consumer will also need easy mobility since many applications require one person to be complete a task in a remote location. Without a complimentary system the quadcopter’s downfalls would surpass its benefits and it would not be able to accomplish the user’s needs. Identifying Target Specifications The first major specification that we decided the platform must fulfill is that the quadcopter must be stable enough in its design to allow for a clear video feed. If the platform is unstable or has too many vibrations, the video recording will not be clear enough for use in most applications. If the platform meets this specification, it will also be stable enough to allow for easy control. This, in turn, will help reduce the skill required to pilot the platform, and will make it more accessible to consumers. The flight platform must also have the ability to transmit a live video feed up to 100 meters. This is imperative as it allows the platform to be used for numerous applications that would be otherwise impossible. This greatly increases the versatility of the platform and opens the product to a much larger market. In addition to having stable flight and clear video, the platform must be capable of long flight times and cannot sacrifice mobility or affordability to meet this specification. While we cannot extend the capacity of the batteries on the flight platform, we can design the base station to include extra batteries for quick on-field replacement. The base station must be designed with 13 the ability to carry enough extra batteries for one hour’s flight time while still being mobile enough to use in the field. The base station must also be able to charge multiple flight batteries when connected to an external source. This will allow for less down time between flights, and also makes the base station a comprehensive system. This will eliminate the need for any external hardware. Finally, the base station must not be a limiting factor on the flight time of the system. This means that the base station must never run out of power before the quadcopter does. This is imperative as the base station will provide a display for the quadcopter’s live video feed. It must also be able to play back recorded video after flights without worrying about battery life. Generating Design Concepts Based on our design objectives, we know that we would need a platform capable of stable flight and live video streaming. There are many designs that would meet these objectives, and all of them are based on a multi-rotor helicopter platform. It would be possible to use quad, hexa, or even octacopter designs. These designs utilize four, six, and eight propellers respectively. The design could also be made of a variety of materials such as balsa wood, aluminum and even carbon fiber. These material choices all have different strength to weight ratios and will have a profound effect on the performance and battery life of our design. Any of these designs would be able to lift the equipment required for first person video, and would be stable enough to suit our needs. In addition, we know we require the use of a base station for playback of the live video and to support the quadcopter platform. Base stations can vary in complexity and design, from expensive setups with multiple long range directional antennas, to cheap pocket stations consisting of only a receiver and screen. The video playback can also be approached in many 14 ways. It is possible to use first-person view goggles that connect directly to the video receiver. These goggles would even eliminate viewing interferences like sun glare. Any of these base stations would be sufficient for basic viewing purposes. Selecting Design Concept All of the design concepts that we described above are very flexible and have their uses in different applications, however, only our final platform fully meets our design objectives. We decided on a system that combines the use of both a lightweight and efficient quadcopter platform with the utility of a comprehensive base station. We chose to use a quadcopter design over hexa or octacopter designs due to the fact that a quadcopter is simpler and more efficient. The quadcopter design is inherently lighter due to having a lesser number of arms and motors than the larger models. It is also much cheaper and easier to maintain because there are less parts involved in the system. It would have cost us up to 40% more to use a hexacopter design and up to 80% more to use an octacopter design. Even with the smaller number of arms and motors, it is still able to carry the load we require while maintaining its stability. We also chose to use carbon fiber for the frame as it has a strength to weight ratio five times that of balsa wood, and nearly ten times that of aluminum. This will ensure that our design is as light as possible while still maintaining a structure strong enough to withstand the forces created while in flight. We decided to use a comprehensive base station to help us neutralize the problems inherent in the quadcopter design. The biggest limitation we saw was that quadcopters do not have long flight times. We knew that we could not solve this problem beyond optimizing the quadcopter’s weight, so we looked to the base station for a solution. By including room for multiple extra batteries and a charging system capable of charging multiple batteries 15 simultaneously, we were able to curb the drawbacks of the short flight time. The use of a small LCD screen instead of goggles allows us to reduce costs and allow other people to view your live video stream. We also wanted to prevent any occurrence of the base station being the limiting factor on flight time. To solve this, we included a solar panel charging system to charge the base station’s battery as well as to prevent the system failing while in flight. This also allows the system to playback your recorded video once the flight is complete without having to worry about battery life. Our design, however, is not without its delimitations. The choice of a quadcopter design leaves us with no motor redundancy. In a hexacopter or octacopter design, one or more motors can fail and the platform can still stay airborne. If any motors on our platform fail, the quadcopter will not be able to continue flying. However, this design choice was necessary to keep costs at an affordable level and flight times at a maximum. The LCD screen on our base station is also a delimiting factor. The use of an LCD screen makes our base station susceptible to sun glare and other external factors that could make it hard to view the video feed. This was necessary to allow other observers to view the live video, and again to ensure we kept costs down. Design Alternatives Based on our design objectives outlined previously, we know that we would need a platform capable of stable flight and live video streaming. That is the most basic requirement of our project. While we highly favor our proposed choice of design, there are many designs that would meet these objectives, and all of them are based on a multi-rotor helicopter platform. It would be possible to use quad, hexa, or even octacopter design and accomplish this goal. These designs utilize four, six, and eight propellers respectively. The design could also be made of a 16 variety of materials such as balsa wood, aluminum and even carbon fiber. These material choices all have different strength to weight ratios and will have a profound effect on the performance and battery life of our design. Any of these designs would be able to lift the equipment required for first person video, and would be stable enough to suit our needs. In addition, we know we require the use of a base station for playback of the live video and to support the quadcopter platform. Base stations can vary in complexity and design, from expensive setups with multiple long range directional antennas, to cheap “pocket” stations consisting of only a receiver and screen. The video playback can also be approached in many ways. It is possible to use first-person view goggles that connect directly to the video receiver. These goggles would even eliminate viewing interferences like sun glare. Any of these base stations would be sufficient for basic viewing purposes. We chose to use a quadcopter design over hexa or octacopter designs due to the fact that a quadcopter is simpler and more efficient. The quadcopter design is inherently lighter due to having a lesser number of arms and motors than the larger models. It is also much cheaper and easier to maintain because there are less parts involved in the system. It would have cost us up to 40% more to use a hexacopter design and up to 80% more to use an octacopter design. Even with the smaller number of arms and motors, it is still able to carry the load we require while maintaining its stability. We also chose to use carbon fiber for the frame as it has a strength-toweight-ratio five times that of balsa wood, and nearly ten times that of aluminum. This will ensure that our design is as light as possible while still maintaining a structure strong enough to withstand the forces created while in flight. We decided to use a comprehensive base station to help us neutralize the problems inherent in the quadcopter design. The biggest limitation we saw was that quadcopters do not 17 have long flight times. We knew that we could not solve this problem beyond optimizing the quadcopter’s weight, so we looked to the base station for a solution. By including room for multiple extra batteries and a charging system capable of charging multiple batteries simultaneously, we were able to curb the drawbacks of the short flight time. The use of a small LCD screen instead of goggles allows us to reduce costs and allow other people to view your live video stream. We also wanted to prevent any occurrence of the base station being the limiting factor on flight time. To solve this, we included a solar panel charging system to charge the base station’s battery as well as to prevent the system failing while in flight. This also allows the system to playback your recorded video once the flight is complete without having to worry about battery life. Our design, however, is not without its delimitations. The choice of a quadcopter design leaves us with no motor redundancy. In a hexacopter or octacopter design, one or more motors can fail and the platform can still stay airborne. If any motors on our platform fail, the quadcopter will not be able to continue flying. However, this design choice was necessary to keep costs at an affordable level and flight times at a maximum. The LCD screen on our base station is also a delimiting factor. The use of an LCD screen makes our base station susceptible to sun glare and other external factors that could make it hard to view the video feed. This was necessary to allow other observers to view the live video, and again to ensure we kept costs down. Test Plan This document describes a test plan for conducting a test during the development of the Q.U.A.C.S. System. The goals of testing include establishing a baseline of system performance, establishing and validating user performance measures, and identifying potential design 18 concerns to be addressed in order to improve the efficiency, productivity, and end-user satisfaction. The Q.U.A.C.S. system is comprised of two major sub-systems that work in unison to complete the unit. The first sub-system is the quadcopter aircraft itself. This aircraft has many requirements that must be met in order to meet the testing criteria laid out in this document, as well as our design objectives. The second sub-system is the base station. The base station also has some criteria that must be met to ensure that the system works together in unison. The primary function of the quadcopter aircraft that we will be analyzing is the flight characteristics. We need to be able to determine if the aircraft is capable of stable flight and that it is able to fulfill our design objectives. We will be breaking down this analysis into two parts; a hardware analysis of the aircraft’s body and components, and a software analysis of the flight control software and the PID loop. The primary functions of the base station that we will be analyzing are its portability and power output. We must ensure that the base station is able to power all of its components for an extended period of time, as well as have enough excess power to charge the flight battery of the quadcopter. We also will test the system’s portability to ensure that it is usable by a single person in a field position. To test the flight characteristics of the quadcopter, we need an ideal testing platform where we can actively monitor the output from the onboard sensors and physically monitor the vehicle for stability. This platform must allow us to test the results of various software and PID changes and collect accurate data regarding those changes. This platform should also allow us 19 to test the system when introduced to various unknown factors, such as artificial wind and physical contact. We will use this testing platform at regular intervals to test the stability of the system after any hardware or software changes. We have created a testing platform that has allowed us to be able to test the quadcopter on many levels. We have been able to monitor all of the sensor outputs as well as the stability of the system as a whole. We have implemented a test using this platform after every hardware or software change to the system. The objective of this test was to ensure that the system is stable enough to meet our design objectives. We have also designed a set of test criteria for the base station to ensure that it meets our design objectives. The first test platform consisted of running a constant monitor over the circuit to see the ability and limitations of the circuit. The second test platform was be an ideal range test of the wireless video transmission. We will choose a specific location that is free of visual obstructions and relatively free of wireless interference. We will ensure that we use the same location for each test. Both the base station tests will take place in the both indoor and outdoor environment. We used the multimeter equipment to measure the voltage and amperage coming from the solar panel to the base station as well as from the base station to the batteries and finally from the base station to the onboard peripherals. This information allowed us to see how efficient our circuit was as well as determine the limitations. In addition to that there were temperature readings to make sure that the circuit would not over heat. We have also ensured that the base station is capable of powering all of the peripherals as well as charge the quadcopter. 20 The quadcopter test has been implemented in an indoor location that is large enough to house our testing platform and is free of obstacles. Our testing platform has been made up of two structural bodies about four to five feet above the ground and about five feet apart. These bodies were attached to the ground and immovable. We then placed the quadcopter between those two bodies, and suspend it in the air by tying it between the two bodies. We tied it in a way that it will be able to rotate forward and backwards freely, but not move more than a foot in any direction. The quadcopter was connected to a laptop via a FTDI cable that will allow us to monitor the sensor readings from the flight control board. This setup allowed us to test the response of the PID settings in a controlled environment. We were able to view the response to various control inputs, in addition to how well the system stabilizes after different movements. We also were able to test how the system responds to various external stimuli, such as being shoved or shaken by wind. As this test is taking place, we were able to monitor the output of the sensors in real time and log the data. This allowed us to both scientifically and practically test the system. The information we collected from these tests will allow us to adapt the software and hardware to fit our needs and design objectives. Most importantly, they will provide us with a stable platform to adjust our PID software settings and ensure that everything is working as efficiently as possible. As described in section 4 of this document, we have two major scientific tests; one regarding the quadcopter, the other regarding the base station. The base station test will be implemented whenever we change the base station hardware. We will need to determine if our 21 changes affected the power output or the video transmission. When moving to a new flight area, it will also be necessary to do a quick video range test to ensure that there is no abnormal interference that could disrupt the video. The quadcopter test will be implemented whenever we make a hardware change to the body of the quadcopter, or whenever we make a software change to the flight control. This will be to verify that the PID loop is still functioning properly and that the frame can withstand the forces induced during normal flight. The time required for this test is ~1 hour. This is due to the setup time required to mount the quadcopter in the testing rig, as well as the data logging time. Once the previous two tests have been conducted and the system has been determined to be stable. We will do a live flight test. This test can be recorded on video; however, we do not have the means to record the sensor data during the live flight test. With the implementation of Bluetooth transmission, we could monitor this data in real time while in close proximity. However, due to the range that a test flight involves, this is not an option that we plan to implement at this time. Flight Duration Test The flight duration test will be conducted on a windless day, using a fully charged 5000mAh 4S battery pack. The quadcopter will be ‘fully loaded’ carrying all of the final equipment necessary for a full-featured flight. The quadcopter will be brought to a hover at least 3 meters from the ground to ensure there is no prop blowback. The quadcopter will be made to hover in this position until the battery no longer has enough power to sustain hover. 22 The time recorded from the hover position being achieved to landing is the operational flight duration. R/C Radio Range Test The R/C radio range will be determined by powering on the quadcopter and radio as for normal operation. The quadcopter will then be transported away from the radio on flat ground while maintaining line of sight. The radio operator will continually send commands to the quadcopter as the platform is being moved away. Once the quadcopter is no longer able to receive the radio signal, the distance traveled will be noted. This is the maximum line of sight radio range. Video Transmission Range Test The video transmission range will be tested in a fashion similar to the R/C radio range test. The video transmitter and receiver will both be powered on as per normal operation. The transmitter will then be transported away from the receiver along flat ground while maintaining line of sight. The transmitter and receiver antennas will be oriented so that the gain is greatest. Once the receiver loses more than 50% of the signal, the distance traveled will be noted. This is the maximum operational video transmission distance. Base Station Solar Charge Rate The base station requires a constant monitoring during testing of various measurements. To do this we used the multimeter equipment to measure the voltage and amperage coming from the solar panel to the base station as well as from the base station to 23 the batteries and finally from the base station to the onboard peripherals. The information we receive from that, allows us to see how efficient our circuit was as well as determine the limitations. In addition to that there were temperature readings to make sure that the circuit would not over heat. Testing Results Our results for this system have exceeded our expectations. The quadcopter and the base station complement each other in more ways than one. Our results clearly show that this product has fulfilled our design objectives with no issues. Quadcopter Results The quadcopter has met or exceeded all of our design objectives. It is able to fly stable enough for our camera to capture clear video. It is also able to transmit this video to the base station at up to 1400 feet. The average flight time on a fully charged flight battery is 10 to 12 minutes, depending on how aggressively you fly. All of these flight characteristics come together to make a perfect flight system. Base Station Results The base station does not only power the peripherals from both the solar panels and/or the batteries but it also charges the quadcopter at a faster rate than we can from an outlet. It does all of this while still being able to fit in a suitcase for mobility. This circuit is capable of outputting over 7 amps at 16 volts for a total of over 112 watts. 24 Comprised below is a series of charts and data that are excerpts from our testing to show exactly how successful the base station has become. Below is information from 1 ½ hour charge. Charger to battery voltage 14.6 14.5 14.4 14.3 Voltage 14.2 14.1 14 13.9 13.8 13.7 13.6 Charger to battery voltage Time 1:55 PM 2:07 2:34 3:00 3:20 13.9 14 14.2 14.2 14.3 14.5 2:07 2:34 3:00 3:20 4:00 18.7 18.9 18.3 18.4 18.9 410 14 400 95 102.2 400 14.2 395 90.4 107.3 375 14.2 370 92.3 109.8 365 14.3 360 95.5 107.5 345 14.5 335 107.6 106.5 Fig. 3 – Charger to Battery Voltage Chart Time Beginning voltage Solar panel to charger voltage Solar panel to charger amperage Charger to battery voltage Charger to battery amperage Charger temp 1 Charger temp 2 1:55 PM 10.33 18.8 410 13.9 410 64.2 65.6 25 Fig. 4 – Charger to Battery Voltage Grid As you can see the voltage increases at a reasonable rate while maintaining good efficiency. The next figure shows how once the batteries are reaching maximum capacity that the charging circuit begins to let give less current to the batteries until they become full where is completely stops charging the batteries until they drop below that voltage again. 25 20 Voltage 15 10 5 0 Time 2:08 PM 2:19:00 PM 2:27:00 PM 2:47:00 PM 3:06:00 PM Solar panel to charger voltage 18.75 18.88 18.8 19.28 20.1 20.3 Charger to battery voltage 15.01 15.17 15.35 15.38 15.39 15.4 Fig. 5 – Base Station Load Voltage Chart 1 Time Beginning voltage Solar panel to charger voltage Solar panel to charger amperage Charger to battery voltage Charger to battery amperage Charger temp 3 2:08 PM 11.12 18.75 2:19:00 PM 2:47:00 PM 3:06:00 PM 3:20:00 PM 18.88 2:27:00 PM 11.53 18.8 19.28 20.1 20.3 970 15.01 930 116.9 990 15.17 860 137.6 810 15.35 620 93.8 610 15.38 460 121 335 15.39 200 96.8 280 15.4 180 92.3 Fig. 6 – Base Station Load Voltage Grid 1 The next set of information clearly shows that just running off of the batteries we will be able to sustain the video peripherals for up to 10 hours. In the next figure you can see how in over 1 hour of the video perpherials being on the batteries had only dropped 300 mV. It is also important to know during this we pulled 650 mA. 26 Load Voltage 14.2 14.15 14.1 14.05 14 13.95 13.9 13.85 13.8 13.75 13.7 13.65 Load Voltage 9:22:00 9:26:00 9:35:00 9:55:00 10:15:00 10:35:00 AM AM AM AM AM AM Fig. 7 – Base Station Load Voltage Chart 2 Time: Load Voltage Receiver temperature 9:22:00 AM 14.15 80 9:26:00 AM 14.1 86.8 9:35:00 AM 14.08 92.8 9:55:00 AM 14.02 98.2 10:15:00 AM 13.94 99.8 10:35:00 AM 13.84 100.1 Fig. 8 – Base Station Load Voltage Grid 2 Risk Analysis Like any product on the market, there are risks associated with using the platform in an incorrect manner. This is especially true for our system since the quadcopter uses high speed spinning blades as well as high output batteries. This could be potentially dangerous to both the consumer as well as other people or objects around the quadcopter. This will be dealt with by 27 having a clear manual that states the directions for use to help the user clearly understand how to operate in a safe manner. It will also include information regarding the operational conditions. This will include, but is not limited to operating temperature, humidity, gale, lighting, and surroundings. This product is designed for specific application under a particular environment to operate safely. There is also a risk in the user’s ability to safely control the quadcopter. This is why it is important to make sure that the user can safely control the quadcopter by practicing in line of sight before using in applications. The quadcopter will also have a first person view on the base station for ease of control. The platform will be equipped with a microcontroller that is capable of keeping the quadcopter stable. Transmission from the user to the quadcopter offers a risk of loss in communication when the device is too far from the controller. This was solved by making sure the first person view transmission range was much shorter than transmission range of the controller signal. By doing this the user will know when he/she is going out of range when the live video feed starts breaking up. Finally the base station is a charging unit and we run the risk of the battery over charging. This will be solved by using a latching circuit to stop charging the battery once it has reached its full capacity. As specified early all of these risks will be addressed in the user manual. In addition to these physical risks, there are a few legal risks we must take into account. To provide the live video feed at the range designated in our design objectives, our transmitter must have a power that exceeds FCC limits for unlicensed use (FCC Part 15). This means that our platform, when using the FPV view, must be operated by a used with an amateur radio license. This makes the platform less accessible to some consumers; however, the platform can still be used by everyone as long as the FPV transmitter is not activated. The FAA also states that unmanned aerial vehicles cannot exceed an altitude of 400 feet above ground level in 28 unrestricted airspace. This is not as big of a problem, as this is about the same range that our live video will support. Project Management With the input of the rest of the group the Project Manager will assign to each group member tasks in order to make the most progress on the project. These deadlines must be met, if any member feels that they won’t be able to meet the deadline, they must make sure that they ask for help from a fellow group member. If we are ahead of or behind schedule, tasks will be adjusted accordingly. When any task is completed, it will be documented in the team log, as well as delivered to the rest of the team in a timely manner. These tasks will be assigned while following the logical layout described in the deliverables below. Deliverables Focus and organization is needed to stay on schedule. This is done not just by planning, but with organization throughout the group. This way everyone knows what needs to be done, as well as what is done, since certain sections of the project rely on the completion of other sections before they can start. Keeping logs of work in progress and completed will let us know who worked on what if we need to go back and refer to their work. We have also set up a way to share our files through the internet that can be accessed at any computer so that we will always be able to reach and see the updated files of the project. Constant updates of the project are vital as it gives a constant reading of our level of completion. We can always know if what we are completing is on time if we compare what we have done with the Gantt chart. The following 29 Gantt chart (Fig. 2) shows how we have devised a plan from the planning process all the way to testing and revising. Gantt Chart: Fig. 9— Project Gantt Chart 30 Bill of Materials: When planning for parts there were strict requirements for performance to meet the consumer’s use while keeping the price as low as posssible. This involved a large amount research as well as calculations to get the best performance while keeping the price at a minimum. The following (Fig. 3) shows a breakdown of our expenses and how we came up with a grand total of approximately $920 for our variable costs. Quadcopter Cost Breakdown $160.00 $140.00 $120.00 $100.00 $80.00 $60.00 $40.00 $20.00 $- Fig. 10— Quadcopter Cost Breakdown 31 Base Station Cost Breakdown $70.00 $60.00 $50.00 $40.00 $30.00 $20.00 $10.00 $- Fig. 11 – Base Station Cost Breakdown Communication and Coordination with Sponsor: Professor Singh is our project sponsor and must be kept up to date with weekly logs. This information is just as useful to him as it is to our group, as it helps ensure that we are on task. There are a few ways that we are able to keep this communication with him, but the best is via email. This is because we are able to attach documents, have time stamped responses, as well as have the ability to go back and review what anyone said for further clarification. To even further avoid complications for the future we will be in contact personally as a team with Professor Singh on at least a monthly basis. During these meetings we can let Professor Singh know our plans and status as well as get feedback on our status. These meetings are also great for questions on anything related to the project. 32 Team Qualifications: This project entails a fairly large amount of work and planning in order to be completed on time. Our team consists of extremely competent members that are more than capable of completing complex problems in an organized and timely manner. This is clearly shown by past and current work completed from each member. The IT Crowd is not just a group of students but a team of capable pupils that have strengths that complement each member in way to make a complete team. In the Appendix we list our exact qualifications via our resumes. Conclusion After extensive research and the creation of this proposal, we are confident that we will be able to successfully design this system and meet or exceed our design objectives. We feel that we have all the necessary experience, both technical and managerial, to complete this project in the time specified. We genuinely believe that this system will greatly benefit the industry by providing a creative solution to many problems. We feel that this system is easily accessible and can help solve many issues pertinent to modern industries. We are very excited to see this project come to fruition. ECET 492 Product Development Plan Revisions Upon ordering parts for our quadcopter, we had to completely redo our parts list due to most of our previously selected parts being out of stock. We ended up going with a slightly smaller and lighter body, the cheaper version 1 of our original choice. This was not as ideal as it has less space to store our electronics and battery and it is not as strong of a platform. We were also forced to buy larger 45A ESCs due to the 35A ones being out of stock. However, this choice proved to be for the better as our motors have pulled close to 40A at max throttle. We also had to go with a different flight controller, but we still managed to find an Arduino based system with 33 open-source software. These alternate part choices were a minor setback, but we were still able to find parts that satisfied our design objectives. We also had major scheduling issues that threw our project off course. The first setback was that our parts supplier HobbyKing.com did not ship our order. They held our order for ‘processing’ for a week before we verified with them that the order was indeed valid. However, after this time, our propellers had gone out of stock. We were able to replace them with comparable propellers of a different color. Even with these setbacks, we were still able to catch up to our Gantt Chart schedule. We utilized the time lost waiting for parts to ship by working on our solar panel base station. As of our last flight test on December 9, 2012, our quadcopter platform lost power during flight and crashed. This was due to a bad connection between the battery and our wiring harness. This crash resulted in a broken carbon fiber arm, and possibly other electronics that we have yet to determine. This will set us back a considerable amount of time as we will need to order a replacement arm and reconstruct the entire body. However, the system performed admirably before the power loss, and we are confident that after rebuilding the system it will meet our design specifications. The impact of these setbacks can be seen below. Our time frame is approximately one and a half to two weeks behind out proposed outline, but we are confident we can make up the time in the next phase since we will be much more prepared resource-wise. 34 Fig. 12 – Revised Gantt Chart 35 Atmel ATmega2560-16AU Specifications Manufacturer: Atmel Product Category: 8-bit Microcontrollers - MCU RoHS: Details Core: AVR Data Bus Width: 8 bit Maximum Clock Frequency: 16 MHz Program Memory Size: 256 KB Data RAM Size: 8 KB On-Chip ADC: Yes Operating Supply Voltage: 4.5 V to 5.5 V Maximum Operating Temperature: + 85 C Package / Case: TQFP-100 Mounting Style: SMD/SMT A/D Bit Size: 10 bit A/D Channels Available: 16 Data ROM Size: 4 KB Interface Type: 2-Wire, SPI, USART Minimum Operating Temperature: - 40 C Number of Programmable I/Os: 86 Number of Timers: 6 Processor Series: ATMEGA256x Program Memory Type: Flash Factory Pack Quantity: 90 Supply Voltage - Max: 5.5 V Supply Voltage - Min: 4.5 V Datasheet: http://www.atmel.com/images/doc2549.pdf 36 BMA180 Digital Triaxial Acceleration Sensor Specifications BMA180 specifications: measurement ranges: +- 1g, 1.5g, 2g, 3g, 4g, 8g lub 16g 12- or 14-bit internal DACs 2 selectable I2C addresses for minimizing address collision risk Self-Test capability sleep mode internal interrupts: o wake up o low-g detection o high-g detection o slope detection (interrupt after any movement) o tap sensing (interrupt after two subsequent slope detections in a short time) Datasheet: http://www.spezial.cz/pdf/BST-BMA180-DS000-03.pdf 37 BMP085 Barometric Pressure Sensor Specifications Digital two wire (I2C) interface Wide barometric pressure range (300 – 1100 hPa, -500m to +9000m) Flexible supply voltage range Ultra-low power consumption Low noise measurement Fully calibrated Temperature measurement included Ultra-flat, small footprint Dimensions: 0.65 x 0.65" (16.5 x 16.5 mm) Datasheet: http://www.adafruit.com/datasheets/BMP085_DataSheet_Rev.1.0_01July2008.pdf 38 Turnigy Plush 40A Electronic Speed Control Specifications Cont Current: 40A Burst Current: 55A BEC Mode: Linear BEC : 5v / 3A Lipo Cells: 2-6 NiMH : 5-18 Weight: 33g Size: 55x28x13mm 39 900MHZ 500mW Video Tx/Rx Specifications Channel: 4-Ch, AV synchronization Power: 500mW Input voltage: 12V Weight: 18g Size: 31 x 88 x 8mm Frequency: 0.9G 0.910G,0.980G,1.010G,1.040G 40 HMC5883L Triple Axis Magnetometer Specifications Simple I2C interface 2.16-3.6VDC supply range Low current draw 5 milli-gauss resolution Datasheet: http://dlnmh9ip6v2uc.cloudfront.net/datasheets/Sensors/Magneto/HMC5883L-FDS.pdf 41 ITG3205 Triple Axis Gyro Specifications Features: • Digital-output X-, Y-, and Z-Axis angular rate sensors (gyros) on one integrated circuit • Digitally-programmable low-pass filter • Low 6.5mA operating current consumption for long battery life • Wide VDD supply voltage range of 2.1V to 3.6V • Standby current: 5μA • Digital-output temperature sensor • Fast Mode I2C (400kHz) serial interface • Optional external clock inputs of 32.768kHz or 19.2MHz to synchronize with system clock • Pins broken out to a breadboard friendly 7-pin 0.1" pitch header • Dimensions: 17.8x14mm • Weight: 0.8g Datasheet: http://www.kamami.pl/dl/itg3205.pdf 42 Turnigy D3536/9 910KV Brushless Outrunner Motor Specifications Battery: 2~4 Cell /7.4~14.8V RPM: 910kv Max current: 25.5A No load current: 1.5A Max power: 370W Internal resistance: 0.063 ohm Weight: 102g (including connectors) Diameter of shaft: 5mm Dimensions: 35x36m Prop size: 7.4V/12x5 14.8V/10x7 Max thrust: 1050g 43 DX6i 6-Channel Full Range 2.4Ghz Radio Transmitter Specifications Modulation: Band: DSM2 2.4GHz Receiver: AR6200 Programming Features: Model Memory: Modes: Helicopter & Airplane 10 Mode 2 Transmitter (Tx) Battery Type: Charger: AA NiMH 1500mAh batteries (included) 4-cell 150mAh wall charger (included) Experience Level: Is Assembly Required: Intermediate No 44 MultiWii PID Diagram 45 LiPo Battery Voltage vs. Discharge Rate 46 Base Station Charging/Regulating Schematic 47 References FAA Makes Progress with UAS Integration. (n.d.). FAA: Home. Retrieved October 10, 2012, from http://www.faa.gov/news/updates/?newsId=68004 FREEDMAN, D. H. (2012). Attack of the Drones. Discover, 33(8), 28-29. Marks, P. (2012). The droneliness of the long-distance runner. New Scientist, 214(2868), 24. Part 15 - Radio Frequency Devices. (n.d.). American Radio Relay League | ARRL - The national association for AMATEUR RADIO. Retrieved October 10, 2012, from http://www.arrl.org/part-15-radio-frequency-devices Shachtman, N. (2012). 5 Drones At Work. Wired, 20(7), 104. Suh, Y. (2003). Robust control of a quad-rotor aerial vehicle. International Journal Of Applied Electromagnetics & Mechanics, 18(1-3), 103-114. 48 Resumes of Team Members Jeff Ramos 34793 Ardentech Court, Fremont, CA 94555 Contact Number: (510) 461-6731 Jeffr2010@yahoo.com HIGHLIGHTS OF QUALIFICATIONS Current GPA : 3.97 Received Herman DeVry Scholarship IT Background Over 2 years of customer service PROFESSIONAL EXPERIENCE DeVry Fremont Library, CA (2010 to 2011) Contact Number: (510) 574-1200 Front Desk Manager Greet customers and provide information. Answer phones and provide customer service. Check out/Order reading materials for customers. Work with Microsoft Office software Handle cash box Keep library organized and clean DeVry Fremont ASC, CA (2011) Contact Number: (510) 574-1200 Electronics Engineering Technology Tutor Specialized in Math tutoring. Assisted teachers in class with struggling students. Maintained regular clients. Organized and logged data. Assisted in Front Desk Duties. DeVry IT Department, CA (2011 to current) Contact Number: (510) 574-1240 Helpdesk Worker Greet customers and provide with information and assistance. Answer/Make phone calls to provide customer assistance. Handle software and hardware based problems. Assess situations and devise a solution. Ability to figure out problems by using general knowledge Work with deadlines 49 EDUCATION Corning Union High School; Corning, CA (2006 to 2010) DeVry University; Fremont, CA (2010 to Present) Major: Electronics Engineering Technology 50 51 Nelson Mankey 26381 Whitman Street #27 Hayward, CA 94544 559.430.5395 nelsonmankey@hotmail.com Objective Statement Seeking a fulfilling and challenging career opportunity to utilize my skills and creativity. Qualifications & Strengths Certified interpersonal and public communicator Dedicated and determined worker—task-oriented and thorough Optimistic and charismatic personality regardless of environment Extensive computer software literacy—experience includes MatLab, LabView, MS Office Suite, Solidworks, and AutoCAD Versed in all things Mathematic and Scientific—Calculus, Chemistry, Physics, and Electronics Technology Proven leadership qualities in work environments as well as among peers Capable and impassioned engineer—studied beyond required coursework to build a greater skill set Adept problem solver and critical thinker Education DEVRY UNIVERSITY, FREMONT, CA Class of 2013 Bachelor of Science, Electronics Engineering and Technology COLLEGE OF THE SEQUOIAS, VISALIA, CA Fall 2006—Fall 2009 70 Undergraduate and GE units completed Certificate in Communication Studies Work Experience OUTREACH SERVICES, DEVRY UNIVERSITY, Fremont, CA………………………………………………………………………….February 2010—Present Student Associate Aided with the design and implementation of event signage and promotion; developing visual presentations and flyers that directly impacted local schools and communities. TAYLOR RESIDENCE HALL, Fremont, CA…………………………………………………………………………………………….….October 2010—June 2011 Resident Assistant Supervised a floor of 40 residents, organized floor programs, and advised residents on personal and academic issues. Trained new staff members. Promoted from Assistant Resident Advisor. ME ‘N ED’S PIZZERIA, Hanford, CA…………………………………………………………………………………………………..October 2007—October 2009 Delivery Driver Outside the parlor: Navigated the greater Kings County area—Exemplary driving record required. Inside the parlor: Answered telephones, managed food orders, stocked supplies, and washed dishes. Kitchen Employee Worked the front cash register; Handled money transactions and food orders. Maintained great customer service for all guests; worked cooperatively with fellow coworkers. MICHAEL’S ARTS AND CRAFTS, Hanford, CA………………………………………………………………………………………October 2006–January 2007 Framing Associate Assigned as the only seasonal framing technician; became quickly adept with color coordinating, frame arrangement, and dimensional manipulation. • 52 Responsible for the framing counter register; Aptly assisted customers with craft supply related shopping as well as typical restocking and cleaning. HANFORD HIGH SCHOOL, Hanford, CA………………………………………………………………………………………………….August—November 2006 Marching Instructor Peer recommended for this position for both my skill and experience in the area. Responsible for the instruction and implementation of basic to complex marching techniques needed to succeed in the very competitive sport of marching band. Activities & Hobbies MUSIC Symphony, Jazz, Marching Band and Small band. Instruments: Piano (12+ years), Trumpet (8 years), Guitar, French Horn, Saxophone ATHLETICS Tennis (6+ years), Marching band (6 years), Ultimate Frisbee (Always). GLOBAL SERVICE PROJECTS 2003 - 2008: Cuernavaca, México; Los Angeles, CA; San Francisco, CA; Seattle, WA; and Pana Jachel, Guatemala. 53 Mark I 54 Mark II 55 Mark III 56 Gen. I Base Station 57