bit25153-sm-0002-SupData-S2

advertisement

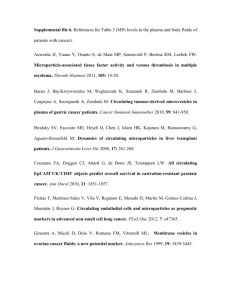

Supplemental Materials and Methods Protein adsorption to microparticles Spherical microparticles based on a melamine resin, 1 µm in diameter and fluorescentlylabeled with either Rhodamine B or Nile Blue were purchased from Sigma, and matrix proteins were physically adsorbed to the surface via the manufacturer’s instructions. Briefly, the microparticles were washed in borate buffer (pH=7.4) three times, and then mixed end-to-end overnight in borate buffer containing 80µg of either fibronectin (Human, BD Bioscences) or laminin from Engelbreth mouse sarcoma (BD Biosciences) per 5x109 microspheres. The protein-laden particles were then washed three additional times in sterile PBS containing 5% glycerol to prevent aggregation and 5% bovine serum albumin (BSA, Sigma) to stabilize the proteins for cell culture. Total protein adsorbed to the microparticles was quantified using a microBCA assay (Pierce) (Supplemental Information, Table SI); no BSA was added to the microparticles for this characterization. Briefly, to determine the total protein adsorbed to the microspheres and estimate protein delivery based on the number of incorporated microparticles, the adsorbed protein was first desorbed from the particles using a surfactant, sodium dodecyl sulfate (SDS, Sigma). The particles were incubated in 3% SDS overnight with constant rotation. The supernatant was collected and measured for total protein content using the microBCA assay kit per the manufacturer’s instructions. Standard curves of fibronectin and laminin were created using 3% SDS for determination of protein concentration. Microwell array and cell-particle aggregate formation Microwell arrays were formed as described previously19 using a 15 wt% poly (ethylene glycol) (PEG) macromer solution (25 mol% PEG-diacrylate – Mn~3000 Da (Sigma) synthesized as described in (Lin and Anseth, 2009b) – and 75 mol% PEG-monoacrylate – Mn~400 Da (Monomer-Polymer and Dajac Labs)) containing 0.5 wt% photoinitiator 4-(2- hydroxyethoxy)phenyl-(2-hydroxy-2-propyl)ketone (Irgacure 2959, Ciba), and Hanks Balanced Salt Solution (HBSS, Gibco). Glass slides were cut to fit within 6-well culture plates (CellStar) and cleaned with piranha solution (1:3 mixture by volume of hydrogen peroxide (30%, Macron Chemicals) and sulfuric acid (97%, Fisher)) for 45 minutes, rinsed with an excess of deionized (DI) water and dehydrated in acetone. The glass surfaces were then functionalized by chemical vapor deposition of (3-acryloxypropyl)-trimethoxysilane (Gelest) at 60°C under argon for at least three hours. Microwells were polymerized directly on to the treated glass surfaces by exposure of the PEG macromer solution to broad spectrum light (λ=350-500nm, 350 W Hg arc lamp) through chrome photomasks (Photosciences, Inc.). A schematic of the microwell formation is shown in Figure 1 A-C. Cell culture wells were fabricated with a fixed depth of 100 µm and square cross-sections of either 100 µm x 100 µm (w100) or 200 µm x 200 µm (w200). Microwell arrays were sterilized by quick immersion in 70% ethanol, followed by swelling in sterile HBSS containing 1% Pen Strep and 0.2% Fungizone under a germicidal UV light for at least 1 hour. MIN6 cells were removed from culture flasks by incubation in 0.5% Trypsin/EDTA (Gibco) for 4 minutes at 37°C. Suspended MIN6 cells were stained with 10 µM CellTracker Green CMFDA (Life Technologies) in serum-free, RPMI (Gibco) without phenol red for 45 minutes. Single cell suspensions of dyed MIN6, containing 5x106 cells for w100 devices or 10x106 cells for w200, were first pre-incubated overnight on an orbital shaker (35 rpm) in polypropylene Eppendorf tubes (VWR) with an appropriate number of microparticles to achieve a particle-to-cell ratio of 1:5 (i.e., 1 microparticle for every 5 cells), 1:1, or 5:1. After preincubation, the cells and particles were gently resuspended in 3 mL of media per 6-well devices (1.7 x 106 cells/mL for w100 devices and 3 x 106 cells/mL for w200 devices) and seeded into the microwell devices by centrifugation at 1200 rpm for 150 s (Figure 1 D-F) as described previously (Bernard et al., 2012; Kloxin et al., 2012; Ruiz and Chen, 2008). Unseeded cells and microparticles were gently resuspended and the centrifugation seeding step was repeated. The well plates were placed on an orbital shaker at 37°C and 5% CO2 for 2 hours, and then cultured statically for 5 days. After 5 days, the cell-microparticle aggregates were removed from the microwell device arrays by gentle rinsing with media and single cells and unincorporated microparticles were removed by separation via cell strainers (BD Falcon). Confocal microscopy and image analysis Cell-microparticle aggregates were imaged on a Zeiss LSM 710 NLO (Carl Zeiss) using λ=488 nm laser to visualize the cells (green), λ=541 nm laser to image the Rhodamine-labeled particles (red), and λ=633 nm laser to excite the Nile Blue-labeled particles (blue). Images were taken at 2 µm z increments and the images were compressed into 10 µm stacks (5 images per stack) for image analysis. MATLAB (MathWorks) was used to analyze the cell-aggregate composition by first creating a mask, or outline, of each aggregate (Supplemental Information, Figure S1). The number of pixels (red, green, and blue) contained within each mask was counted and tabulated for each stacked image (Supplemental Information, Figure S2). Each microparticle-laden cell aggregate was then characterized with respect to its particle content by dividing the number of red or blue pixels in an aggregate by the total number of red, blue, and green pixels. This percentage was calculated to determine the particle content in each 10 µm stack to give an indication of the particle distribution throughout the aggregate. This analysis yielded the fraction of the cross-sectional area at each z-position that was occupied by microparticles. The microparticle distribution throughout the aggregate was then evaluated by examining this particle fraction as a function of depth (i.e., analyzing the particle fraction in 10 µm stacks throughout the aggregate, Figure 2). The number of red or blue pixels was also summed over all the stacked images of an aggregate to determine the microparticle loading for the aggregate as a whole.