Production of Indole acetic acid By Rhizobium, Azotobacter, and

Production of Indole acetic acid By Rhizobium,

Azotobacter, and Pseudomonas spp. Isolated from soil

A THESIS SUBMITTED IN PARTIAL FULFILLMENT OF THE

REQUIREMENTFOR THE AWARD OF MASTER OF SCIENCE

(BIOTECHNOLOGY)

BHAGWAN MAHAVIR COLLEGE OF M.Sc BIOTECHNOLOGY

(AFFILIATED TO VEER NARMAD SOUTH GUJARAT UNIVERSITY UNIVERSITY)

SURAT

2012

ACKNOWLEDGEMENT

I thank the almighty whose blessings have enabled me to accomplish my dissertation work successfully.

I am very much thankful to all my professors and my co-guidance Mr. Murtuza Hazoori in our institute who made us work hard, taught us how to manage everything skillfully and made us into confident individuals.

It is my pride and privilege to express my sincere thanks and deep sense of gratitude to my

Project guidance Miss.Priya Bande , Department of Biotechnology and Environmental Sciences,

MITCON, pune for her valuable advice, splendid supervision and constant patience through which this work was able to take the shape in which it has been presented. It was her valuable discussions and endless endeavors through which I have gained a lot. Her constant encouragement and confidence-imbibing attitude has always been a moral support for me.

My sincere thanks to Miss. Neha Vora and Mr. Chandrashekharkulkarni , Head Department of Biotechnology and Environmental Sciences, MITCON, pune for his immense concern throughout the project work.

I also wish to thank all my friends, for providing the mandatory scholastic inputs during my course venture.

Finally, I wish to extend a warm thanks to everybody involved directly or indirectly with my work.

The whole credit of my achievements goes to my parents and my brothers who were always there for me in my difficulties. It was their unshakable faith in me that has always helped me to proceed further

Abstract

List of figure

List of table

Introduction

Materials and method

Results and Discussion

Conclusion

Aknowlegement

References

Appendix

INDEX

LIST OF FIGURE

Figure No.

1

CONTENT

Fig no.1 Root nodules of Chick pea plant

2

5

6

7

3

4

8

9

Fig no.2: Rhizobium colonies on YEMA

Medium

Fig no.3: Gram’s staning of Rhizobium

Fig no.4: Detection of IAA Production by

Rhizobium

Fig no.5:Azotobacter colonies on

Ashbhy’s Medium

Fig no.6: Gram’s staning of Azotobacter.

Fig no. 7:Detection of IAA Production by

Azotobacter

Fig no.8: Pesudomonas colonies on nutrient agar medium

Fig no.9: Gram’s staning of

Pesudomonas

PAGE NO.

10

11

Fig no.10: Detection of IAA Production by Pesudomonas

Fig No.11: Thin layer chromatography for IAA

LIST OF GRAPH AND TABLE:

Gra ph No. CONTENT

1

2

3

Morphological Characters of isolates (

Rhizobium, Azotobacter, and Pseudomonas)

Biochemical tests of isolates ( Rhizobium,

Azotobacter, and Pseudomonas)

IAA assay for preparation of standard graph

4

5

6

Effect of Tryptophan on IAA production by Rhizobium

Effect of carbon sources on IAA production by Rhizobium

Effect of PH on IAA production by Rhizobium

7

8

Effect of Tryptophan on IAA production

By Azotobacter

Effect of Carbon source on IAA production by Azotobacter

Page No.

9

10

11

12

Effect of PH on IAA production by Azotobacter

Effect of Tryptophan on IAA production

By Pseudomonas

Effect of Carbon source on IAA production

By Pseudomonas

Effect of PH on IAA production

By Pseudomonas

1.

INTRODUCTION

1.1

What is indole?

Indole is an aromatic heterocyclic organic compound. It has a bicyclic structure, consisting of a six-membered benzene ring fused to a five-membered nitrogen-containing pyrrole ring.

Indole is a popular component of fragrances and the precursor to many pharmaceuticals.

Compounds that contain an indole ring are called indoles. The indolic amino acid tryptophan is the precursor of the neurotransmitter serotonin.

The name indole is a portmanteau of the words indigo and oleum, since indole was first isolated by treatment of the indigo dye with oleum.

1.2 General properties and occurrence

Indole is a solid at room temperature. Indole can be produced by bacteria as a degradation product of the amino acid tryptophan. It occurs naturally in human feces and has an intense fecal odor. At very low concentrations, however, it has a flowery smell, and is a constituent of many flower scents (such as orange blossoms) and perfumes. It also occurs in coal tar. The corresponding substituent is called indolyl.

Indole undergoes electrophilic substitution, mainly at position 3. Substituted indoles are structural elements of the tryptophan-derived tryptamine alkaloids like the neurotransmitter serotonin, and melatonin. Other indolic compounds include the plant hormone Auxin

(indolyl-3-acetic acid, IAA), the anti-inflammatory drug indomethacin, the betablocker pindolol, and the naturally occurring hallucinogen dimethyltryptamine (N,N-DMT).

1.2

History

Indole chemistry began to develop with the study of the dye indigo. Indigo can be converted to isatin and then to oxindole. Then, in 1866, Adolf von Baeyer reduced oxindole to indole using zinc dust In 1869, he proposed a formula for indole.

Certain indole derivatives were important dyestuffs until the end of the 19th century. In the

1930s, interest in indole intensified when it became known that the indole nucleus is present in many important alkaloids, as well as in tryptophan and auxins, and it remains an active area of research today.

Auxins were the first plant hormones discovered. Charles Darwin was among the first scientists to dabble in plant hormone research. In his book "The Power of Movement in

Plants".

It was in 1885 that Salkowski discovered indole-3-acetic acid (IAA) in fermentation media

(Salkowski, 1885). The isolation of the same product from plant tissues would not be found in plant tissues for almost 50 years. IAA is the major auxin involved in many of the physiological processes in plants (Arteca, 1996).

1.3

Indole Acetic Acid

IDENTIFICATION OF IAA

IUPAC NAME

Molecular formula

Molar mass

Physical state

2-(1 H -indol-3-yl)acetic acid

C

10

H

9

NO

2

175.184

Off white crystal

Melting point

Solubility in water

PH

Vapor density

Stability

Other name

168-170 ( 441-443K)

Very slightly in water

< 7.0

5

Stable under ordinary condition ( light sensitive )

Indole 3-Acetic acid. Indolylacetic acid , 1-H

Indole 3-acetic acid,Indole acetic acid,Heteroauxin,IAA

Indole-3-acetic acid, also known as IAA, is a heterocyclic compound that is a phytohormone called auxin. This colourless solid is native plant compound, potent and the most important auxin. The molecule is derived from indole, containing a carboxymethyl group (acetic acid).

Structure of Indole 3-Acetic Acid

The phytohormone auxins play a central role in plant growth and development as a regulator of numerous biological processes, from cell division, elongation and differentiation to tropic responses, fruit development and senescence. Auxins are employed to induce rooting, callus formation, flowering, parthenocarpy and so on. They can also prevent abscission of leaves,

flowers and fruits. The action and interaction of some growth regulators like auxins regulate most of the physiological activities and growth in plants. Naturally occurring substances with indole nucleus possessing growth-promoting activity are referred to as auxins, chemically it is Indole acetic acid. (IAA) Not only plants but also microorganisms can synthesize auxins and cytokinins. The ability to synthesize phytohormone is widely distributed among plantassociated bacteria. 80% of the bacteria isolated from plant rhizosphere produce IAA. Many bacteria are known to produce IAA.

1.4

Biosynthesis and biological activity of IAA

Biochemical pathway of IAA

IAA is chemically similar to the amino acid tryptophan which is generally accepted to be the molecule from which IAA is derived. Three mechanisms have been suggested to explain this conversion:

Tryptophan is converted to indolepyruvic acid through a transamination reaction.

Indolepyruvic acid is then converted to indoleacetaldehyde by a decarboxylation reaction.

The final step involves oxidation of indoleacetaldehyde resulting in indoleacetic acid.

Tryptophan undergoes decarboxylation resulting in tryptamine. Tryptamine is then oxidized and deaminated to produce indoleacetaldehyde. This molecule is further oxidized to produce indoleacetic acid

.

As recently as 1991, this 3rd mechanism has evolved. IAA can be produced via a tryptophanindependent mechanism. This mechanism is poorly understood, but has been proven using trp(-) mutants. Other experiments have shown that, in some plants, this mechanism is actually the preferred mechanism of IAA biosynthesis.

The enzymes responsible for the biosynthesis of IAA are most active in young tissues such as shoot apical meristems and growing leaves and fruits. The same tissues are the locations where the highest concentrations of IAA are found. One way plants can control the amount of IAA present in tissues at a particular time is by controlling the biosynthesis of the hormone. Another control mechanism involves the production of conjugates which are,simple terms, molecules which resemble the hormone but are inactive

.

1.4.1

Synthesis

Chemically, it can be synthesized by the reaction of indole with glycolic acid in the presence of base at 250 °C.

Many methods for its synthesis have been developed since its original synthesis from indole-3-acetonitrile.

1.5

Functions of Indole Acetic acid ( Auxin )

Stimulates cell elongation

Stimulates cell division in the cambium and, in combination with cytokinins in tissue culture

Stimulates differentiation of phloem and xylem

Stimulates root initiation on stem cuttings and lateral root development in tissue culture

Mediates the tropistic response of bending in response to gravity and light

The auxin supply from the apical bud suppresses growth of lateral buds

Delays leaf senescence

Can inhibit or promote (via ethylene stimulation) leaf and fruit abscission

Can induce fruit setting and growth in some plants

Involved in assimilate movement toward auxin possibly by an effect on phloem transport

Delays fruit ripening

Promotes flowering in Bromeliads

Stimulates growth of flower parts

Promotes (via ethylene production) femaleness in dioecious flowers

Stimulates the production of ethylene at high concentrations

1.6

Indole Acetic Acid Producing Bacteria

1.6.1

Rhizobium spp.

These are gram negative soil bacteria. The root nodulating bacteria invented by hellriegal and wilfarth (1988) was first isolated and named radicola by beijerinck in 1988. The generic name

was changed later to Rhizobium . Rhizobium is one of the important nitrogen-fixing bacteria.

They form a symbiotic association with leguminous plants to form nodules in the roots of host plant. These nodules are the sites of nitrogen fixation. Active nodules contain a red pigment called leghaemoglobin .

1.6.1.1 Classification

Rhizobium

Family : Rhizobiaceae.

Genus : Azorhizobium for stem nodulation ( Sesbania rostrata )

Bradyrhizobium (soyabean, lupin, cowpea miscellany i.e. cowpea, green gram, red gram, chickpea, groundnut)

Rhizobium (pea, lentil, bean, lathyrus, berseem, lotus).

1.6.1.2 Morphology

Unicellular, cell size less then 2µ wide. Short rod, polymorphic, motile with peritricus flagella,

Gram negative,

Accumulate poly B-hydroxyl butyrate granules.

1.6.1.3 Physiology

Nature : Chemohetrotrophic, Symbiotic with legume,

C – Source : Supplied by legume through photosynthates,

Monosaccharide, Disaccharide.

N – Source : Fixed from atmosphere

Respiration : Aerobic

Growth : Fast ( Rhizobium ), slow ( Bradyrhizobium ).

Doubling time : Fast growers (2 - 4 hours)

Slow growers (6 - 12 hours)

Growth media : YEM/YEMA(Fred).

1.6.1.4 Recommended for Legumes

Pulses : Chickpea, pea, lentil, cowpea, greengram, blackgram, pigeonpea.

Oil seeds : Soyabean, Groundnut.

Fodders : Berseem (egyption clover), lucern.

Increase in Yield : 10-35%

1.6.1.5 Fast and Slow Growers

Generally Rhizobium spp. fall into two distinct categories based on growth characteristics.

Rhizobium meliloti, R. trifolii, R. phaseoli, R. leguminosarum, and rhizobia isolated from nodules

on sesbania, birdsfoot, chickpea, and others are considered "Fast Growers." When incubated at

28°C on a solid medium such as yeast extract mannitol (YMA), visible colonies develop 4 to 5 days. In contrast, the "Slow Growers", Bradyrhizobium japonicum and others, require 6 to 8 days to produce visible colonies when incubated under the same conditions. However, within these two general groups, strains of rhizobia vary in their growth rates in culture; the division into slow- and fast-growers on the basis of time required to develop visible colonies is not fix

COMMON NAME OF CROPS RHIZOBIUM SPP.

(with cross inoculation group)

FAST GROWING RHIZOBIUM

Lucerne, fenugreek

Egyptain, clover,

Khesri(lathyrus), lentil, pea, common vetch

Bean, kidney bean, French bean

Chickpea, subabul

Rhizobium meliloti

R. trifolii

R. leguminosarum

R. phaseoli

Rhizobium spp.

SLOW GROWING RHIZOBIUM

White lupines, lupines R. lupines

Soybean Bradyrhizobium japonicum

Sun hemp, green gram, black gram, cowpea, peanut, Rhizobium moth bean

Table :- Fast grower and slow grower Rhizobium strains

1.6.2 Azotobacter

Azotobacter is a genus of usually motile, oval or spherical bacteria that form thick-walled cysts and may produce large quantities of capsular slime. They are aerobic, free-living soil microbes

which play an important role in the nitrogen cycle in nature, binding atmospheric nitrogen, which is inaccessible to plants, and releasing it in the form of ammonium ions into the soil. Apart from being a model organism, it is used by humans for the production of biofertilizers, food additives and some biopolymers. The first representative of the genus, Azotobacter chroococcum , was discovered and described in 1901 by the Dutch microbiologist and botanist Martinus Beijerinck.

Azotobacter are Gram-negative bacteria. They are found in neutral and alkaline soils, in water and in association with some plant.

1.6.2.1 Classification:

Domain: Bacteria

Kingdom: Bacteria

Phylum: Proteobacteria

Class: Gammaproteobacteria

Order: Pseudomonadales

Family: Pseudomonadaceae/Azotobacteraceae

Genus: Azotobacter

Number of species : Seven (A. beijerinckii, A. chroococcum, A.paspali, A.vinelandii,

A.agilis, A.azomonas, A.mactroytogenes

).

Azotobacter

1.6.2.2 Morphology :

Cell size : Large ovoid cells, Size ranging from 2.0-7.0 x 1.0-2.5 µ

Cell character : Polymorphic

Gram reaction : Negative

Accumulate poly B-hydroxybutyrate granules

1.6.2.3 Physiology

Nature : Chemoheterotrophic, Free living.

Carbon source : A variety of carbon sources(mono, di & certain polysacharide) organic acids.

Nitrogen source : N

2

through fixation, amino acids, N

2

, NH

4

+ , NO

3

-

Respiration : Aerobic

Growth media : Ashby/Jensen’s medium

Doubling time : 3 hours

1.6.3 Pseudomonas

Pseudomonas is a genus of gammaproteobacteria, belonging to the family Pseudomonadaceae containing 191 validly described species. Like most bacteria genera the pseudomonad last common ancestor lived hundreds of million years ago, however they were classified by humans at the end of the 19th century. Because of their widespread occurrence in water and in plant seeds such as dicots, the pseudomonads were observed early in the history of microbiology. The generic name Pseudomonas created for these organisms was defined in rather vague terms by

Walter Migula in 1894 and 1900 as a genus of Gram-negative, rod-shaped and polar-flagella bacteria with some sporulating species.

1.6.3.1Classification

Domain: Bacteria

Phylum: Proteobacteria

Class: Gammaproteobacteria

Order: Pseudomonadales

Family: Pseudomonadaceae

Genus: Pseudomonas

1.6.3.2 Morphology

Pseudomonas aeruginosa is a gram-negative, rod-shaped, asporogenous, and monoflagellated bacterium that has an incredible nutritional versatility. It is a rod about 1-5 µm long and 0.5-1.0

µm wide. P. aeruginosa is an obligate respirer, using aerobic respiration (with oxygen) as its optimal metabolism although can also respire anaerobically on nitrate or other alternative electron acceptors. P. aeruginosa can catabolize a wide range of organic molecules, including organic compounds such as benzoate. This, then, makes P. aeruginosa a very ubiquitous

microorganism, for it has been found in environments such as soil, water, humans, animals, plants, sewage, and hospitals.

3. MATERIALS AND METHOD

3.1 MATERIALS REQUIRED

3.1.1 GLASSWARE

Sterile Petri dishes, Glass slides, Glass beakers, Cover slips, Media bottles, Conical flasks,

Pipette,Media bottles, Test tubes, Micro pipette, Beake , Measuring cylinder,Cavity Slides

Sterile wire loop ,Sterile centrifuge tube, Stirror ,Glass spreader.

3.1.2

EQUIPMENT

V ortex ( cyclo mixture )

Magnetic stirrer ( REMI )

Colony counter ( DBK-instrument interlink )

Microscop ( Labomed )

Laminar air flow ( Micro filt india )

Incubater ( REMI )

Incubater with shaker ( REMI )

Refrigerater

Autoclave ( Meta instrument mumbai )

Centrifuge ( REMI )

Hot air oven ( Meta instrument mumbai )

Water bath ( NEOLAB )

Weighing machine ( ATCO, CITIZEN )

PH meter ( control dynamics )

Uv-visibal spectrophotometer ( Milton roy company )

3.1.3

MATERIAL AND MEDIA

Sterile distilled water

yeast extract mannitol agar ( YEMA)

Congo red

Nutrient agar

Ashbhy’s agar medium

Alcohol (70%)

3.1.4 METHOD

3.1.4.1 SAMPLE COLLECTION:

The rhizopheric soil is used for isolation of microorganism. Soil Sample was collected from sugarcane and wheat field near by agricultural college,pune

3.1.4.2

ISOLATION OF MICROORGANISM

A.

Rhizobium Spp.

For isolation of Rhizobia from root nodules of leguminous plants following method was used

REQUIREMENTS:

Root nodules of chick pea plant

1. Recently rooted out leguminous plant roots with nodules

2. Yeast extract mannitol (YEMA) agar plate with congo red

3. 1:1000 aqueous solution of Hgcl

2 soluton (1g Hgcl

2 dissoled in 1000 ml of distill water).

4. Ethanol (95%)

5.

Sterile petri dishes, forceps, scalpel and slides

PROCEDURE: o Healthy root nodules were selected, washed with tap water and surface sterilized by 1:1000 H g

Cl

2

, o washed with sterile distilled water several times. o These nodules were crushed in a drop of sterile water, inoculated on sterile yeast extract mannitol agar with Congo red Plates were incubated at room temperature for 48 hrs.

o Typical rhizobial colonies on YEMA were opaque, white and mucoid. Colony characters of a well-isolated colony were studied. Gram staining and motility was carried out.

B .Azotobacter spp.

REQUIREMENTS:

1. Fertile soil sample having slight reaction.

2. 100 ml Ashby’s mannitol broth in 500-ml flask.

3. Ashby’s mannitol agar medium.

4. Sterile distilled water tubes ( 10 ml ).

5. Spatula

PROCEDUER: o Inoculate the Flask of Ashby’s mannitol broth with 2g of soil o Incubate the flask at 25

0 c ( room temp.) , until a pellical forms on the surface. This may require 1-2 weeks of incubation. o Do not disturb the pellicle once it has been formed. o Steak a loopful of pellical over the Ashby’s mannitol agar plate, and incubate the plate at

25 0 c ( room temp.) for 5-7 days. o Observe plates for a typical mucoid , dew drops colony’s of Azotobacter. o Perform Gram’s staning and examine under oil immersion objective. o Record the results and draw conclusion.

C. Pseudomonas Spp.

Requirements:

1. sterile petri dishes

2. Nutrient agar

3. soil sample

4. distille water

5. Ethanol ( 95%)

PROCEDURE: o 1g of soil sample on 9 ml of Sterile distille water tubes and mix well. o After few minutes take 1ml of sample and transfer the another tues with 9ml distille water. o Prepare a diution like 10

-1

,10

-2

,10

-4

,10

-6 ….. o And take a 0.1 ml sample on nutrient agar plate and sprading with glass sprader and incubate the plate at 37 0 c for 24 hs.

o Record the results and draw conclusion.

3.1.5 Gram’s Staning

REQUIREMENTS:

1.

Yong culture of microorganism

2.

Crystal violets

3.

Gram’s iodine

4.

Alcohol

5.

Distill water

6.

Saffranin

PROCEDURE:

1.

Prepare a heat fixed smear of the culture.

2.

Cover the smear with crystal stain for 1 minutes.

3.

Add Gram’s iodine to wash off crystal violet stain and cover it with iodine till the smear turns coffee brown in color ( approximately 1 min.)

4.

Rinse the slide in running water.

5.

Add decolorizing solution drop wise at upper end of slides held in inclined position till the violet color fails to from the smear for normal smear 10-15 seconds are enough.

6.

Rinse the smear with water.

3.1.6 BIOCHEMICAL TEST:

3.1.6.1 CARBOHYDRATES FERMENTATION TEST

REQUIREMENTS:

1.

Test culture

2.

Nutrient sugur broth

PROCEDURE:

1.

Inoculate a loopful of culture into the sugar broth and incubate 37

0 c for overnight

2.

Observe the tube for acid and gas production

3.1.6.2 METHYL RED (M-R) TEST

REQUIREMENTS:

1.

Glucose phosphate broth (GPB) , methyl red indicator.

2.

Test culture

PROCEDURE:

1.

Inoculate GPB with the test culture and incubate the broth at 37

0 c for 48-72 hr.

2.

After incubation add about 5 drops of methyl red indicator to the medium

3.

Observe for development of the red color

3.1.6.3

VOGES-PROSKAUER (V-P) TEST

REQUIREMENTS:

1.

Glucose phosphate broth (GPB)

2.

5% alcoholic alfa napthol and 40% KOH solution.

3.

Test culture

PROCEDURE:

1.

Inoculate the medium (GPB) with culture and incubate the medium at 37

0 c for 24-48 hr.

2.

After incubation add 0.6 ml of alfa nephthol and 0.2 ml of KOH solution per ml of culture broth

3.

Shake well after addition of each reagent and slope the tube to increase the aeration. Read results after 15-60 minutes.

3.1.6.4 CITRATE UTILIZATION TEST

REQUIREMENTS:

1.

Simmon’s citrate agar slant

2.

Test culture

PROCEDURE:

1.

Streak heavily on the surface of agar slant and incubate the slant at 37

0 c for 24-48 hr.

2.

Record the color change of the slant after incubation

3.1.6.5 INDOL PRODUCTION TEST

REQUIREMENTS:

1.

1% Tryptone broth and Erlich’s or Kovac’s reagent

2.

Test culture.

PROCEDURE:

1.

Incubate the tryptone broth with of test culture and incubate at 37

0 c for 24 hr.

2.

After incubation add 3-4 drops of xylene in the medium and shake it vigorously.

3.

Allow the two layers to seprate.

3.1.6.6 HYDROGEN SULPHIDE PRODUCTION TEST

REQUIREMENTS:

1.

Standard thiosulphate iron agar stab medium

2.

Test cultur

PROCEDURE:

1.

Stab the medium with the test culture and incubate the medium at 37

0 c for 24hr.

2.

After incubation look for the black color in the lower portion of the stab agar medium.

3.1.6.7 UREA HYDROLYSIS TEST

REQUIREMENTS:

1.

Stuart’s urea broth

2.

Test culture.

PROCEDURE:

1.

Inoculate a loopful of test culture in urea broth add incubate at 37 o c for 24 hr.

2.

Observe for the change in color of the after incubation

3.1.6.8 NIRATE REDUCTION TEST

REQUIREMENTS:

1.

Peptone nitrate broth (PNB).

2.

Test culture

3.

Zinc dust

4.

α-napthylamine reagent (reagent A)

5.

Sulphanilic acid reagent (reagent B)

PROCEDURE;

1.

Inoculate PNB with a loopful of test culture and incubate the medium at 37

0 c.

2.

Add 0.5 ml of the reagent A and B each to the test medium in this order.

3.

Observe the development of color within 30 seconds after adding test reagent.

4.

If no color develops add a pinch of Zinc dust mix them well and observe the development of red color.

3.1.5.9

GELATIN HYDROLYSIS TEST

REQUIREMENTS

1.

Two nutrient gelatin agar tube

2.

Test culture

3.

Refrigerator

PROCEDURE:

1.

Inoculate a loopful of test culture into one of the tube and the second tube is left uninoculated incubate both the tubes at 37

0 c for 24-72 hr.

2.

After incubation place both the at 5-10

0 c either in refrigerator or in ice water bath for

30-60 min.

3.

After refrigeration slightly tilt tubes so as to check the liquefaction of gelatin.

3.1.5.9 CATALASE TEST

REQUIREMENTS:

1.

Microscopic glass slide

2.

3% H

2

O

2

3.

Test culture

PROCEDURE:

1.

Place one or two drops of hydrogen peroxide solution on a glass microscopic slide.

2.

With a nicrome wire loop pick up cells from the of a well isolated colony of the test.

3.

Observe for the production of the gas bubbles of effervescence.

3.1.5.11 OXIDASE TEST

REQUIREMENTS:

1.

Nutrient agar plate

2.

Filter paper, platinum wire loop

3.

Test culture

4.

1% tetramethyl-p-phenylenediamine dihydrochloride solution

PROCEDURE:

1.

Grow the test organism under aerobic condition on nutrient agar medium for 18-24 h.

2.

Take a filter paper strip and moisten it with 3-4 drops of tetramethyl-pphenylenediamine dihydrochloride solution

3.

With the help of platinum wire pick up a colony and make a compact smear on moistened filter paper.

4.

Wait for 10-15 seconds and observe for formation of violet color.

3.1.5.12 TRIPAL SUGAR IRON ( TSI ) AGAR TEST

REQUIREMENTS:

1.

TSI agar slant

2.

Test culture

PROCEDURE:

1.

Streak a loopful of test culture on slant and stab the same culture into butt of the slant.

2.

Incubate the TSI slant at 37

0 c for 24 hr.

3.

After incubation observe the medium for presence of acid/gas/H

2

S in butt as well in the slant.

3.1.5

PRODUCTION OF IAA FROM BACTERIA:

3.1.5.1

SCREENING OF IAA PRODUCTION :

All the test strains of Rhizobium ,Azotobacter and Pseudomonas spp. were screened for

IAA production . Briefly, test bacterial culture was inoculated in the respective medium

(YEMB /Ashby’s broth/nutrient broth) with tryptophan ( 2 and 5 mg/ml) or without tryptophan incubated at 28 ± 2 0C for 1week for rhizobium ,15 days for Azotobacter and 1 week for Pseudomonas spp.

Cultures were centrifuged at 3000 rpm for 30 min.

Two milliliters of the supernatant was mixed with 2 drops of orthophosphoric acid and 4 ml of Solawaski’s reagent (50 ml, 35% perchloric acid, or HCL , 1 ml 0.5 M FeCl3).

3.1.6.2 PREPARATION OF INOCULUM

Inoculum were used in order to obtain maximum production of IAA and best inoculum was used for further studies. Inoculum was prepared by a loopful organism into 5 ml Normal saline or nutrient broth and incubated at 28

0 c for 48hr. and transfer a 2 ml of old culture into respective fermentation broth .

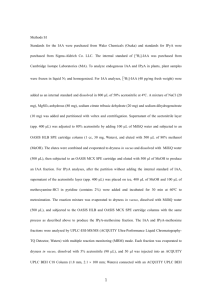

3.1.6.3 PREPARSTION OF STANDARD GRAPH

Standard graph of IAA was prepared as mentioned by Different IAA concentrations are prepared as aqueous solution of IAA ranging from 10 microgram/ml to 100 micrograms/ml. To each 1 ml of the standard, 2ml of 0.5 M FeCl3 in 35% perchloric acid or HCL i.e. Salkowaski reagent is added and readings are taken after 25 minutes at 530 nm by UV Visibl Espectrophotometer(

Milton Roy company). Standard graph is prepared by plotting concentration of IAA in micrograms/ml Vs Optical Density at 530 nm.

3.1.6.4

EFFECT OF CARBON SOURCES ON IAA PRODUCTION

IAA production was detected on different carbon source like glucose, sucrose, lactose, and mannitol 1% w/v. supplemented with 2 mg/ml of tryptophan. IAA production was studied by using Salkowaski reagent after 24, 48 and 72 hrs. for Rhizobium, and pseudomonas. Azotobacter

IAA production studied at 5,10 and 15 days after incubation period.Cultures selected for the

study i.e.

Rhizobium isolated from chickpea plant and Azotobacter, pseudomonas from wheat soil in near agicultural field.

3.1.6.5

EFFECT OF PH ON IAA PRODUCTION

To study the extent of IAA produced by the different isolates at different pH, on YEMB

,Ashby’s broth , nutrient broth with 2 mg/ml of tryptophan is adjusted to different pH as 5, 7, and 9. Media were inoculated with 1% inoculum of O.D.600 1.0 and incubated at 28 0 c for 24 hrs. IAA production was studied by using Salkowaski reagent.

3.1.6.6

EXTRACTION OF CRUDE IAA

A proper inoculam of Pseudomonas spp. inoculated in 100 ml of nutrient broth and strains of

Azotobacter was inoculated in 100 ml of Ashbhy’s broth amended with 2 and 5 mg/ml of tryptophan and incubated at 28 ± 2oC for 1 week on a shaker incubator. Bacterial cells were separated from the supernatant by centrifugation at 10,000 rpm for 30 min. The supernatant was acidified to pH 2.5 to 3.0 with 1 N HCl and extracted twice with ethyl acetate at double the volume of the supernatant. Extracted ethyl acetate fraction was evaporated to dryness in a rotator evaporator at 40 o

C. The extract was dissolved in 0.5 ml of methanol and kept at -20 o

C.

3.1.6.7

CONFIRMATION OF IAA BY USING TLC

After incubation period broth was centrifuged at 10000 rpm for 10 minutes. pH of broth brought to 3.0 using HCL. 4:1 aliquots of liquid portion of centrifuged sample were extracted three times with ethyl acetate. The organic phase was concentrated to dryness and then diluted with 0.5 ml methanol. This solution along with the standard IAA was applied on silica gel G plate and TLC was run by using a solvent system chloroform: Ethyl acetate: Formic acid in 5:3:2 proportion or benzene : n-butanol 17.5 :6.25 ml and developed by using Salkowaski reagent. Red colour spots were developed. Rf value of the standard and IAA produced by the selected isolates was calculated.

3.1.6.8

THIN LAYER CHROMATOGRAPHY

COMPONENTS:

1.

TLC Plate ( Silica gel G, Distiile water )

2.

TLC chamber ( Solvent Benzene: n-butanol )

3.

Solvent system or mobile phase :

This comprises of a solvent or solvent mixture recommended for the purpose. The mobile phase used should be particulate free and of highest purity for proper development of TLC spots. The solvents recommended are chemically inert with the sample, stationary phase.

4.

Spreyer ( Solawaski’s reagent or ehman’s reagent )

5.

Hot air oven

PROCEDURE o The stationary phase is applied onto the plate uniformly and then allowed to dry and stabilize. But now a days ready made plates are preferred. o A thin mark is made at the bottom of the plate with a capillary to apply the sample spots .

o Then samples solutions are applied on the spots marked on the line at equal distances. o The mobile phase is poured into the TLC chamber to a level few centimeters above the chamber bottom. A filter paper moistened in mobile phase is placed on the inner wall of the chamber to maintain equal humidity in the entire chamber. o Then the plate prepared with sample spotting is placed in TLC chamber such that the side of the plate with sample line is towards the mobile phase .

Then the chamber is closed with a lid. o The plate is immersed such that sample spots are well above the level of mobile phase but not immersed in the solvent. o Allow sufficient time for development of spots .

Then the plates are removed and allowed to dry. The sample spots are visualized in suitable UV light chamber or any other methods as recommended for the said sample.

The Rf value can be calculated as:

Rf = distance of sopt traveled

Distance of solvent traveld

Solvent traveled

TLC plate

RESULT AND DISSCUTION

PLATE COLONY OF RHIZOBIUM Spp.

Fig No.3 Rhizobium colonies on YEMA with congo red

3

4

Sr. no.

1

2

COLONY CHARACTER

Size

Shape

Colour

Margin

MORPHOLOGICAL CHARACTERISTIC

RHIZOBIUM CHARACTER

Small

Circular

White

Entire

5

6

7

8

9

Elevation

Consistency

Opasity

Motility

Remark

Convex

Mucoid translucent

Motile

Nil

GRAM’S STANING OF RHIZOBIUM

After performing Gram’s staning Gram negative short rod bacteria are observed

Fig No.4 Gram’s staning of Rhizobium

BIOCHEMICAL TEST RESULT OF RHIZOBIUM

BIO CHEMICAL TEST

Oxidase test

RESULT

Positive (+)

Catalase test

Voges– Proskauer’S Test

H2s Production Test

Triple Iron Sugar( TSI ) Slant

Positive (+)

Negative (-)

Negative (-)

Positive (+)

Nitrate Reduction Test

Methyl red ( M-R) Test

Citrate Utilization Test

Negative (-)

Negative (-)

Positive (+)

Indole Production Test

Urea Hydrolysis Test

Gelatin Hydrolysis Test

CARBOHYDRATE UTILIZATION TEST

Glucose

Sucrose

Lactose

Xylose

Mannitol

Positive (+)

Negative (-)

Negative (-)

Negative (-)

Negative (-)

Negative (-)

Positive (+)

Negative (-)

Carbohydrate utilization test Oxidase test

H

2

S Reduction test

Simmon’s Citrate utilization test

Triple Sugar Iron Test

PRODUCTION OF IAA BY RHIZOBIUM Spp.

Catalase Test

Production of IAA by Rhizobium in different Tryptophan concentration

Production of IAA by Rhizobium in different carbon source

Production of IAA by Rhizobium in different PH

PLATE COLONY OF AZOTOBACTER Spp.

7

8

9

4

5

6

Azotobacter colony on Ashby’s Mannitol Agar

MORPHOLOGICAL CHARACTER OF AZOTOBACTER

Sr. no.

1

COLONY CHARACTER

Size

AZOTOBACETR CHARACTER

Small

2

3

Shape surface

Circular

Smooth

Colour

Margin

Elevation

Consistency

Opasity consistancy

White

Entire

Convex

Mucoid translucent

Moist

10

11

Motility

Remark

GRAM’S STAINING OF AZOTOBACTER

Motile

Nil

Gram’s staining of Azotobacter

BIOCHEMICAL TEST OF AZOTOBACTER

BIO CHEMICAL TEST

Oxidase test

RESULT

Positive (+)

Catalase test

Voges– Proskauer’S Test

H2s Production Test

Triple Iron Sugar( TSI ) Slant

Positive (+)

Positive (+)

Negative (-)

Positive (+)

Nitrate Reduction Test

Methyl red ( M-R) Test

Citrate Utilization Test

Indole Production Test

Urea Hydrolysis Test

Negative (-)

Positive (+)

Positive (+)

Positive (+)

Negative (-)

Gelatin Hydrolysis Test Negative (-)

CARBOHYDRATE UTILIZATION TEST

Glucose

Sucrose

Lactose

Xylose

Mannitol

Positive (+)

Positive (+)

Negative (-)

Positive (+)

Negative (-)

Carbohydrate utilization Test Catalase Test

Simmon’s Citrate utilization Test

PRODUCTION OF IAA BY AZOTOBACTER

Production of IAA by Azotobacter in different Tryptophan concentration

Production of IAA by Azotobacter in different carbon source

Production of IAA by Azotobacter in different PH

PLATE COLONY OF PSEUDOMONAS Spp.

Pseudomonas colony on Nutrient agar medium

3

4

5

6

7

1

2

Sr. no.

MORPHOLOGICAL CHARACTER OF PSEUDOMONAS

COLONY CHARACTER AZOTOBACETR CHARACTER

Size

Shape

Small

Rod surface

Colour

Margin

Elevation

Consistency

Smooth

Green

Entire

Convex

Mucoid

8

9

10

Opasity consistancy

Motility

11 Remark

GRAM’S STAINING OF PSEUDOMONAS translucent

Moist

Motile

Nil

BIOCHEMICAL OF PSEUDOMONAS

BIO CHEMICAL TEST RESULT

Oxidase test

Catalase test

Voges– Proskauer’S Test

H2s Production Test

Triple Iron Sugar( TSI ) Slant

Nitrate Reduction Test

Methyl red ( M-R) Test

Citrate Utilization Test

Indole Production Test

Urea Hydrolysis Test

Gelatin Hydrolysis Test

CARBOHYDRATE UTILIZATION TEST

Glucose

Sucrose

Lactose

Xylose

Mannitol

Positive (+)

Positive (+)

Negative (-)

Positive (+)

Negative (-)

Positive (+)

Positive (+)

Negative (-)

Negative (-)

Negative (-)

Negative (-)

Positive (+)

Positive (+)

Positive (+)

Negative (-)

Negative (-)

Simmon’s Citrate utilization test

Carbohydrate utilization Test glucose, sucrose, xylose

Oxidase test Catalase Test

H

2 s Reduction Test

STANDARD GRAPH OF IAA

TSI Slant

Straight-line graph indicates direct proportion between concentrations of IAA and the extent of red colour developed. Hence production of IAA by the organisms was confirmed.

0,07

0,06

0,05

0,04

0,03

0,02

0,01

0

0,004

0,01

0,016

0,024

0,032

0,035

0,04

0,046

0,05

0,06

20 40 60 80 100 120 140 160 180 200

Concentration (µg/ml)

Series 1

6

7

8

4

5

1

2

3

Observation table

Assay of IAA

Sr.no IAA std.sol

n

(ml)

IAA conc.(µg/ml)

Distille water

(ml)

20 1.8 0.2

0.4

0.6

40

60

1.6

1.4

0.8

1.0

1.2

1.4

1.6

9 1.8

10 2.0

80

100

120

140

160

180

200

1.2

1.0

0.8

0.6

0.4

0.2

0.0

4

4

4

4

4

4

4

4

4

4

Solawaski’s reagent

(ml)

Optical density

(530nm)

0.004

0.010

0.020

25 min in 0.024 room 0.032 temp.

0.035

0.040

0.046

0.050

0.060

Standard IAA for preparation of standard graph.

IAA production by Rhizobium Spp.

Effect of tryptophane concentration

Most of the organisms produce IAA in presence of tryptophan. In present study it was observed that as the concentration of tryptophan in the medium increases, the amount of IAA produced increased and also study the IAA production in 72 hr.and 5 days incubation period. In 72hr the

IAA production is (10µg/ml,150µg/ml,323µg/ml) ) IAA production was found to be decreased in 5 days incubation.

350

300

250

200

150

100

150

323

Series 1

50

0

10

0 2

Concentration of tryptophane (mg/ml)

5

Effect of Carbon source on production of IAA

For finding out the most favourable carbon source giving maximum IAA production mannitol from YEMB is replaced by different sugars. maximum IAA production in presence of glucose followed by sucrose, mannitol, and lactose in descending order. A reported 1% glucose as a preferred carbon source for IAA production. In glucose was a best carbon source for production of IAA. Glucose as a carbon source production of IAA was 466 µg/ml.

500

450

400

350 320

466

300

250

Series 1

200

150

150

100

50

70

0 lactose mannitol sucrose glucose

Effect of PH on IAA production

To decide the optimum pH for IAA production, the isolates are inoculated in YEMB amended with 2.0 mg/ml of tryptophan having different pH such as 5, 7, 9. A rhizobium showed little amount of IAA production at pH 5 whereas maximum production found at pH 7. IAA production decreased at pH 9.

185

180

175

170

165

160

155

150

145

140

135

150

180

160

Series 1

5 7

PH

9

6

7

8

4

5

Observation table

Sr no.

1

Different parameter

2

Without tryptophan

2 mg/ml

3

(try.)

5 mg/ml

(try.)

Glucose

Sucrose

Lactose

Ph-5

Ph-9

Supernatant of broth (ml)

2

2

2

2

2

2

2

2 4

4

4

4

Solawaski’s reagent(ml)

4

4

4

4

O.D

0.004

Incubation

0.042

Two drops of orthophospharic temp. for acid in room

25min

0.097

0.140

0.096

0.024

0.045

0.050

Production of IAA by Azotobacter Spp.

Effect of tryptophan concentration on IAA production

Tryptophan is a induced the IAA production in fermentation broth. In Azotobacter spp. In

Ashby’s broth with different tryptophan concentration showed the different concentration IAA was produced.The incubation

50

40

30

20

10

0

100

90

80

70

60

5 days

5 10 tryptophan conc.( µg/ml)

15

1.0 Abstract

The phytohormone auxins play a central role in plant growth and development as a regulator of numerous biological processes, from cell division, elongation and differentiation to tropic responses, fruit development and senescenc. Chemically auxins is a indole acetic acid A bacterial(Rhizobium,azotobacter,pseudomonas Spp.) were isolated from rhizospheric soils was collected from sugarcane and wheat field near agicultural college,pune These isolates were identify by Gram’s staning,motility and Biochemical test. the production of indole acetic acid (IAA) in a medium with 0, 1, 2 and 5 mg/ml of tryptophan. A low amount of IAA production was recorded by Azotobacter,Rhizobium and pseudomonas strains without tryptophan addition. Azotobacter isolates showed high level (7.3 to 32.8 mg/ml) production of IAA at 5 mg/ml of tryptophan while at 1 and 2 mg/ml the production was in the range of

1.47 to 11.88 and 5.99 to 24.8 mg/ml, respectively. Production of IAA in fluorescent

Pseudomonas isolates increased with an increase in tryptophan concentration from 1 to5 mg/ml.Azotobacter and Rhizobium were production of high amount IAA in glucose as a carbon source and PH-7.IAA was detect by solawaski’s reagent and subsequent TLC analysis. A specific spot from the extracted IAA preparation was found corresponding with the standard spot of IAA with same Rf value.Among studies on diffrenent isolates like pseudomonas,Rhizobium, and azotobacter using tryptophan as inducer Azotobacter showed the highest IAA production ability.