Mike Yang February 26, 2011 Nifty Lifting Machine Project As a part

advertisement

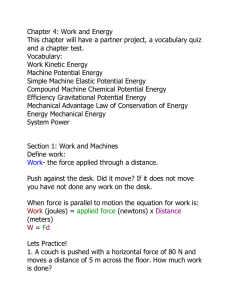

Mike Yang February 26, 2011 Nifty Lifting Machine Project As a part of our studies on the physics unit of work and machines, we’ve been required to create a compound machine and document the process of its creation. Our machine had to incorporate at least two of the six simple machines we’ve studied in the unit, and it had to be able to lift an object of 600 grams five centimeters off the ground using as little force as possible. For the past few weeks, we’ve been planning and building our device, called our Nifty Lifting machine. Our initial design featured an inclined plane, a block and tackle pulley, two wheels and axles, and a fixed pulley. By combining a large number of simple machines, we believed that our machine could achieve a high mechanical advantage. The output weight (600 grams) is attached to the block and tackle pulley, which is tied to a stand attached to the inclined plane. The string that joins together the two pulleys that make up our block and tackle pulley runs through our wheels and axles and fixed pulley. When the input weight is attached to the end of the string, the weight will pull down on it, rotating the wheels and axles and pulling the block and tackle pulley and the output weight up the inclined plane. After building the components that made up our compound machine, we made measurements that were necessary to calculate the mechanical advantage of our machine. Our inclined plane had a height of 15 cm and a length of 33 cm (MA = 33/15 = 2.2). The radius of each wheel of our wheels and axles was 2 cm, while the radius of each axle was 0.15 cm (MA = 2(2/0.15) = 26.66). The combined mechanical advantages of our block and tackle and fixed pulleys would be 3 (3 x 1 = 3). The ideal mechanical advantage of our entire machine would have been: 2.2 x 26.66 x 3 = 175.956 Although our machine probably would have been able to achieve an incredibly high mechanical advantage (even after we factor in the amount of friction), we soon realized that it couldn’t be completed due to lack of adequate material. The material that comprised our wheels and axle was too weak (we used mainly cardboard) and probably couldn't have supported the weight of 600 grams. Also, the way we were required to set up our machine and join it all together (using string) was a little complicated. Getting it to function properly probably would have required better material. Eventually, we decided to factor out the wheels and axles and the fixed pulley and make do with the inclined plane and block and tackle pulley. Now, we attach our input weight to a piece of string that runs through the block and tackle pulley, and it pulls up the output weight just like before. To increase the mechanical advantage of this second design, we lowered the height of our inclined plane to 10 cm (MA = 33/10 = 3.3) and increased the number of rope sections that support our block and tackle pulley to four (we did this by looping the string through each pulley multiple times). We also tried to reduce the amount of friction between our output weight and inclined plane by wrapping two pieces of string around the output weight, so that when it’s pulled up the inclined plane, it will roll up instead, turning it into a makeshift wheel. We thought that we could decrease the amount of force required to lift the weight by converting the sliding friction between it and the inclined plane into rolling friction. But since this is not technically a part of our machine, it was not included in our calculations (we wouldn’t have known what to calculate anyway). The ideal mechanical advantage of our entire machine is now: 3.3 x 4 = 13.2 After performing some tests, we found that an input weight of 100 grams was required to lift the output weight of 600 grams. So, our actual mechanical advantage would be: 600/100 = 6 The efficiency of our machine would then be: 6/13.2 x 100 = 45.4545% Our machine was not very efficient, considering that our actual mechanical advantage wasn’t even 50% of our ideal mechanical advantage. Most of our work was probably wasted overcoming the friction between our output weight and the inclined plane. Our rolling system wasn’t as effective as we had hoped it would be, but mostly it depended on the material we used. Our inclined plane was made out of cardboard, so its surface wasn’t particularly smooth. If we had used something a smoother surface, the efficiency of our machine might have been greater. There was, perhaps, some friction between the string sections of our block and tackle pulley. We wanted to compensate for the simplification of our machine by increasing the mechanical advantage of each component, but by looping the string multiple times around the pulley, we were introducing more friction between each string section.