Cryogenics and Refrigeration-Proceedings of ICCR2013 Paper ID

advertisement

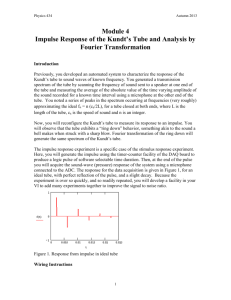

Cryogenics and Refrigeration-Proceedings of ICCR2013 Paper ID: A-1-08 [Four line space] Novel Configuration of Three-stage Pulse Tube Refrigerator for Temperature Below 4 K [Two line space] 1 Matsubara Y. and Gao J. L. 2 [One line space] Atomic Energy Research Institute, Nihon University, 7-24-1 Narashinodai, Funabaishi, Chiba 274, Japan. 2 Cryogenics Laboratory, Zhejiang University, Hangzhou 310027, China. 1 [Three line space] ABSTRACT [One line space] A novel multiple staging configuration for the pulse tube refrigerator is described for increasing its performance and simplicity. To decrease both the regenerator loss and pulse tube loss, a regenerative tube was developed for operating the pulse tube from room temperature to liquid helium temperature. With this configuration a lowest temperature of 3.6 K and a cooling capacity of 119mW at 4.9 K were achieved by a three-stage pulse tube refrigerator. The test results and refrigerator performance of this refrigerator are also presented. [One line space] KEYWORDS [One line space] Pulse Tube, Refrigerator, Optimization, Experiment [Two line space] INTRODUCTION [One line space] The need for reliable, simple and efficient cryocoolers has recently increased, especially in space applications. Pulse tube refrigerator is one of the attractive methods for producing a reliable and simple cryocooler. The performance of the pulse tube refrigerator is greatly increased by improvement of the phase shifter located at the pulse tube hot end [2-4]. Here the term “phase shifter” is used to describe a device which delays the mass flow by pressure oscillation. [Two line space] MULTIPLE-STAGING CONFIGURAITON FOR PULSE TUBE [One line space] The previous multiple-stage for the pulse tube refrigerator [1,5,6] is shown in Figure 1. In this configuration, both the pulse tube and regenerator of each stage were operated in the same temperature region. The hot end of the lower stage pulse tube is thermally attached to the cold end of the upper stage, and the lower stage regenerator is added below the upper stage, with some gas passing through it to the lower stage. [One line space] Thermodynamics Equations Base on the first law of thermodynamics, the energy balance at the cold end of the first stage pulse tube in Figure 1 is given by Cryogenics and Refrigeration-Proceedings of ICCR2013 Paper ID: A-1-08 [One line space] Q A1 H1 Q R1 QPTL1 H R2 H D2 QO2 (1) [One line space] where: Q A1 is the actual cooling power at the first stage. [One line space] [One line space] Figure 1Schematic of three-stage pulse tube refrigerator 1: compressor; 2: rotary valve; 3: reservoir; 4: orifice valve; 5: double-inlet valve; 6: first stage regenerator; 7: second stage regenerator; 8: third stage regenerator; 9: first stage pulse tube; 10: second stage pulse tube; 11: third stage pulse tube; 12: first stage cooled head; 13: second stage cooled head; 14: third stage cooled head; 15: regenerative tube; 16: radiation shield 17: vacuum chamber [Two line space] Table 1 Description of regenerators of three-stage pulse tube refrigerator [One line space] Component Materials Size (mm) First stage regenerator Second stage regenerator Third stage regenerator Stainless steel tube filled with No. 250 bronze mesh Stainless steel tube filled with lead shot Stainless steel tube filled with Er3Ni shot and lead shot(half and half) [Two line space] 60×0.5×130 48×0.5×50 20×0.5×200 CONCLUSION [One line space] Optimization of the pulse tube size at each sage, plus amending the regenerative tube construction and the operating conditions, such as mean pressure, pressure ration and frequency, has not been carried out: however, a lowest temperature of 3.6 K and a cooling capacity of 119 mV at 4.9 K were achieved by a three-stage pulse tube refrigerator, complete with a regenerative tube for the third stage pulse tube. Cryogenics and Refrigeration-Proceedings of ICCR2013 Paper ID: A-1-08 [Two line space] ACKNOWLEDGEMENT [One line space] This work is supported by the Chinese National Natural Science Foundations (Foundation No. 50876095 and 50890184). [Two line space] REFERENCES [One line space] [1] Radebough R., Zimmerman J., Smith D. R. and Louis B. A comparison of three types of pulse tube refrigerator: new methods for reaching 60 K. Adv. Cryog. Eng., 1986, 31:40-51. [2] Zhu S., Wu P. and Chen Z. Double inlet pulse tube refrigerator: an important improvement. Cryogenics, 1990, 30(5):514-520. [3] Alpheev V. N., Brodiansky V. M. Nikolsky V. A., et al. Refrigerant for a cryogenic throttling unit. Great British Patent, 1,336,892 (1973) [4] Wang Q., Chen G. M. Analysis of features of J-T refrigeration cycles using mixed refrigerants with an infinite low temperature heat reservoir. Proceedings of ICCR’2003, Hangzhou, China, 2003:327-330