Very Long…We`ll have to edit it. Let me know if you can

advertisement

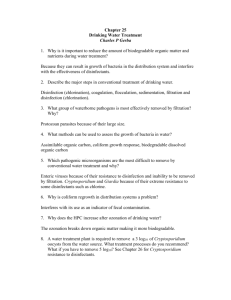

2014 GLPC Keynote Session “Regulatory Update” Presenter: J. Alan Roberson EPA’s Office of Groundwater and Drinking Water (OGWDW) continues to have a full regulatory agenda, however, several major regulations actions have been delayed somewhat. These delays are a result of the sequestration budget cuts in early 2014, as well as a decrease in the overall EPA budget in the latest omnibus appropriations bill. This presentation will summarize the regulatory actions that are expected in 2014 (the preliminary Third Regulatory Determination and the draft Fourth Contaminant Candidate List), as well as the proposed regulations that are expected to slip to 2015 (or beyond). Bio: J. Alan Roberson is AWWA’s director of federal relations in Washington, D.C. He has a bachelor’s degree in civil engineering from Georgia Institute of Technology in Atlanta and a master’s degree for the Virginia Polytechnic Institute and State Universit in Blacksburg. A recipient of the Archie Becher Award, which recognizes exemplary AWWA staff, Roberson has 23 years of experience at AWWA and 12 years of experience as a consulting engineer. “Tips to Support Microbiological Proficiency Testing” Presenter:? ? M. Blades, or R. Roemer, ERA (Still Waiting) ERA has received numerous inquiries concerning challenges with microbiological proficiency testing, especially relating to specific methods or products. In the process of tracking these inquiries, ERA has defined and acknowledged topics that are more likely to receive investigations of potential difficulties for laboratories. The ERA tips to support microbiological proficiency will reflect the topics that are more likely to require technical support from proficiency providers in the environmental industry. Areas of focus will include both drinking water and wastewater subject matter, as it relates to microbiological proficiency testing. The overall intention is to provide constructive material to support end users of proficiency testing, as well as provide administrators with a resource to refer new analysts or to be used as a refresher for experienced analysts. Bio: Keynote Session “Control Charting & Trending” Control Charting and Trending at the Division of Consolidated Laboratory Services Presenter: Kristen.Murphy@DGS.Virginia.gov Quality assurance in the environmental laboratory includes many different aspects including analyst capability, method validation, instrument performance, sample integrity, method performance, and document control just to name a few. The laboratory can employ various controls designed to monitor these aspects such as the use of method and field blanks, initial and continuing calibration verification samples, second source control samples, matrix spikes and matrix spike duplicates, and proficiency testing programs. The information gathered from these controls is evaluated to determine the effectiveness of the laboratory to routinely produce accurate results. Control charts are a tool that can be used to monitor the laboratory system and are useful for detecting potential problems which may support or discredit the data. Control charting is a process of evaluating the variability associated with the analysis. Variability may be expected or “natural-cause” indicating the system is in control, or variability may be “special-cause” indicating the system may be out of control. For each chemical environmental analysis, the Division of Consolidated Laboratory Services constructs Levey-Jennings style control charts, which serve as a visual process control tool designed to provide a synopsis of quality control data. Multi-Rules are applied to the data in the control charts to determine run acceptance/rejection and to monitor trends. Control charts also provide a means for the laboratory to demonstrate to regulators that their analytical system is in control. Control chart plotting and review protect the laboratory from liabilities which could result from the reporting of unsupported data. Bio: Keynote Session “Safe Laboratory Practices and Procedures” Presenter: Ashley Parker, M.S., CPSI Approximately 500,000 workers are employed in laboratories across the United States. Laboratory workers can be exposed to a variety of hazards including chemical, biological, physical and radiological hazards. This presentation is a general overview of safe laboratory practices and procedures as it relates to the General Industry OSHA standards. Topics covered include: general housekeeping, labeling and transfer of chemicals (hazard communication), bloodborne pathogens, engineering controls and PPE requirements. It is hoped that a better awareness of the hazards and risks associated with laboratories will enable workers to appreciate the importance of applicable OSHA standards as well as safety approaches provided through this session. Bio: Ashley Parker is co-owner of Commonwealth Environmental Solutions, LLC. Mrs. Parker has over 12 years of experience in health and safety for industry, construction and government performing audits, accident investigations, OSHA recordkeeping, development and implementation of safety programs and training, and more. She received her Master of Science degree in Occupational Safety and Health from Columbia Southern University. Also, she is an OSHA authorized General Industry 10 and 30-hour trainer. Mrs. Parker is a member of The American Society of Safety Engineers (ASSE). She currently resides in Henrico County, VA with her husband Michael and 6-year old son Trenton. She can be contacted at parker.commonwealth@gmail.com. Drinking Water Session #1 “Introduction to Disinfection: From CT to UV” Presenter: Erick Rosenfeldt, PhD, PE, Hazen and Sawyer Protection of public health from pathogens is the primary function of water treatment, and drinking water utilities rely upon disinfection as one of the basic options for providing this protection. Disinfection is defined as the process of killing pathogenic organisms or rendering them inert, and is one of the two main tools at the disposal of utilities for pathogen protection. The history of disinfection in drinking water is long, and has been heralded one of the greatest achievements of mankind. However, it must be recognized that disinfection in water treatment is not sterilization, so several key concepts must be fully understood to ensure adequate disinfection and public health protection. This presentation will provide an overview of key concepts for effective disinfection in water treatment, including mechanisms of disinfection, conventional and advanced disinfection techniques (chlorine, ozone, chlorine dioxide, UV), dosing concepts such as CT, and the need for and options for residual disinfection in distribution systems. Attendees will learn how to “talk the talk” of disinfection in water treatment, prepared for more in-depth discussions of disinfection with a firm understanding of basic vocabulary and understanding of key disinfection concepts. Bio: Dr. Erik Rosenfeldt has over 14 years’ experience in drinking water process and design, research, and teaching. He received his BS in Chemical Engineering from Washington University in St. Louis, and his MS and PhD in Civil and Environmental Engineering from Duke University, where he studied treatment of emerging contaminants in water. Upon graduation, Dr. Rosenfeldt took a job as an assistant professor of Environmental Engineering at the University of Massachusetts, where his teaching and research interests focused on environmental engineering and chemistry concepts, and physical and chemical treatment processes. He joined Hazen and Sawyer in 2010, where he is involved in the water process and applied research groups. While at Hazen and Sawyer, he has worked on a myriad of projects, from optimization of coagulation for TOC removal and DBP reduction to evaluations of aeration and mixing in distribution system tanks, along with performing cutting edge research ranging from understanding presence of emerging contaminants in source waters to evaluating fundamental rate constants of hydroxyl radicals with natural organic material. Drinking Water Session #1 Slicing and Dicing UCMR3 Results Andy Eaton, PhD, BCES Unregulated Contaminant Monitoring Rule 3 (UCMR3) took effect in January 2013. Although this monitoring can be conducted anywhere within the 3 year time window from 2013-2105, many utilities chose to start monitoring the first year. Eurofins Eaton Analytical (EEA) has provided results for more than 400 PWS across the country (including many from Virginia) and therefore has a robust database to assess both occurrence and some of the factors influencing that occurrence. Additionally, in October 2013, EPA provided the first public release of data under UCMR3, representing nearly 1,000 PWS and up to 6,000 samples. EPA is expected to update that database on a quarterly basis going forward. The public database makes it very easy to examine UCMR3 data and determine trends, such as differences between groundwater and surface water sources for contaminants, the influence of disinfection practice on occurrence of various contaminants such as chlorate or hexavalent chromium and any obvious geographic trends in the data. UCMR3 also provides an interesting data set because it is the first time that EPA has based monitoring on the method sensitivities and not on health reference levels, which results in a much greater frequency of detections. It also involves the use of field blanks, which demonstrate the extent to which utilities are able to control contamination, and also the extent to which they follow instructions for collection. Examples of the material to be presented are shown below. This presentation will discuss some of the QC issues that we have seen in incoming samples with respect to field blank handling and recommendations for utilities that have as yet to do their monitoring. More importantly we will discuss the occurrence patterns based on publicly released data to date. Several anthropogenic compounds, 1,4-dioxane and chlorate, are both showing up at relatively high frequencies and some of the patterns are intriguing. 1,4-dioxane is showing up in more than 5% of PWS at levels exceeding the health reference level and appears to be in both surface waters and groundwaters; both of these findings are somewhat in contrast to what was expected initially. Chlorate is found over the health reference level in more than 15% of PWS and there are some trends in concentration depending on whether a utility is using onsite generation of hypochlorite (OSG) or bulk hypochlorite. Both scenarios may result in excess levels of chlorate as demonstrated by Stanford et al, but the UCMR3 database suggests that bulk hypo degradation is a more important source. Metals are much more prevalent in groundwater sources than in surface waters, and there are generally no trends with respect to increases in the distribution system, although some individual systems do show increases. It will require additional data releases for us to be able to evaluate any differences between Virginia utilities and others, but if sufficient data are available before the conference we will present that data also. Bio: Dr. Eaton is the Technical Director at Eurofins Eaton Analytical, Inc. He has a PhD from Harvard University in geochemistry and did post-doctoral work at CalTech. He has been in the drinking water industry for more than 30 years and was involved in specialized drinking water monitoring programs such as the Information Collection Rule and each of the Unregulated Contaminant Monitoring Rules. His laboratory was the first commercial lab to pass all of the UCMR3 proficiency tests and supports several hundred utilities across the country with their UCMR3 monitoring. Drinking Water Session #1 “Automated Technology Applied to the Enumeration of Heterotrophic Plate Count (HPC)” Presenter: Annamarie Miller, City of Newport News Heterotrophic Plate Count (HPC) is an enumeration procedure for estimating the number of heterotrophic bacteria in water. HPC is used to evaluate the effectiveness of a disinfectant in the water treatment plant processes and in the distribution system. Under the Surface Water Treatment Rule (SWTR), drinking water utilities must demonstrate a detectable disinfectant residual or HPC results of < 500 colonies in 95% of monthly distribution samples. Manual counting of HPC plates is tedious, subjective, and time consuming. Automation of the enumeration of the HPC can be accomplished by automated colony counters that utilize imaging technology and plate counting software. This presentation will provide an overview of the technology of automated colony counters, comparison studies performed by the Newport News Waterworks laboratory and the laboratory’s perspective of utilizing automated colony counters in routine HPC monitoring. Bio: Anna-Maria Miller graduated from Christopher Newport University in 2012, with a master’s degree in environmental science. She is currently employed as a Laboratory Technician at Newport News Waterworks. Improving Drinking Water Quality and Demonstrating Competence in Laboratories and Field Activities by TNI NELAP and NEFAP Accreditation Presenter: Nilda Cox, Eurofins Eaton Analytical, Inc. The drinking water regulation under the Safe Drinking Water Act (SDWA) have established requirements for laboratory Certification by EPA or States to be eligible to analyze compliance samples, but did not require certification for field sampling and measurements organizations (FSMO) which may result in lack of documented procedures, weak quality systems and weak ethic/data integrity program in the field. The NELAC Institute (TNI) National Environmental Field Activities Program (NEFAP) have developed national field accreditation, adopted ISO/IEC 17025 requirements for competency and ISO/IEC 17011 Standards to recognize Accrediting Bodies (AB). TNI National Environmental Laboratory Accreditation Program (NELAP) have developed a national accreditation program that adopted ISO/IEC 17025 requirements for competency and ISO/IEC 17011 standards for accrediting bodies, and added specified technical requirements for US environmental testing laboratories. Both NEFAP and NELAP programs added the ethics/data integrity program requirements to generate true, authentic, and of known documented data quality. In 2008, EPA published Supplement I to the Fifth Edition of the EPA Manual for the Certification of Laboratories Analyzing Drinking Water to encourage laboratories the adoption of a formal documented Quality Management System particularly ISO/IEC 17025 Standards, have an ethics policy and implement a fraud detection and deterrence policy/program. The TNI NEFAP and NELAP accreditations provide an opportunity for field samplers and laboratories to improve data quality, generate reliable and legally defensible data through improved traceability, implement data integrity program and demonstrate competency. Purpose The presentation will discuss the benefits of National Lab and Field Accreditation Programs to drinking water labs and its field activities, demonstrating competence and generating reliable Bio: Ms. Cox is the Quality Manager of Eurofins Eaton Analytical. She has over 20 years of environmental experience in Quality Assurance/Quality Control including hazardous waste management and safety compliance in the laboratory. Her experience also includes eight years as senior chemist and supervisor of chemistry QA/QC Methods Development Group, and in-charge of the Industrial Hygiene Monitoring Program for a medical device company. Additional experience includes six years in Research and Development in the field of agriculture. Ms. Cox is responsible for providing QA solutions to Eurofins Eaton Analytical's clients. In addition to supporting internal QA/QC, Ms. Cox serves as a resource for numerous outside entities, providing consulting services in the area of QA/QC to assist them in the development of their own in-house QA Programs. Waste Water Session #2 Automating Manual Sample Preparation with FIA Presenter: Lynn Egan. Lachat Instruments- A Hach Company Brand For some analytes, automating the chemistry is the easy part; it's automation of sample preparation that has real potential to increase laboratory productivity. Flow Injection Analyzers (unlike discretes) are well-suited not only for the automation of common manual chemistry methods, but also to automate sample preparation, prior to the analysis. And, for many labs, this automation can also provide benefits beyond increased throughput and labor cost savings. These advantages include better data quality, more reproducible results, the ability to perform multiple analyses on each sample simultaneously, simplified data management, and data integrity and an audit trail. The promulgation of the last two Method Update Rules (the most recent on May 18th, 2012) has greatly expanded the possibilities available for regulated wastewater labs to include automated sample preparation techniques. In the past, these methods had been available only to research facilities. Among other allowed changes, EPA has revised the language at (b)(4)(T) be more specific with respect to the use of gas diffusion across a hydrophobic semi-permeable membrane, to separate the analyte of interest from the sample matrix in place of manual or automated distillation for the analysis of certain analytes. In-line sample preparation utilizing gas diffusion is an acceptable change to an approved method for the following analytes: ammonia, cyanide, TKN, and Total Phenolics. In-line digestion is also allowed for analytes like total phosphorus. Examples of in-line sample methods currently possible for digestion and/or distillation are: Digestion: Distillation : TN (Total Nitrogen) TP (Total Phosphorus) Cyanide, Ammonia, TKN Phenol Bio: Ms. Eagan has a degree in Microbiology from the University of Wisconsin, Oshkosh. While in school, she completed 32 credits of chemistry along with her microbiology courses. She was very fortunate to be able to do collaborative research between the Chemistry and Biology departments. She researched the binding of metals to polysaccharides purified from Microcystis aeruginosa. She also spent some time working with the hepatatoxin produced by this cyanobacterium, microcystin, as well as immobilization of the polysaccharide in alginate beads and gels. She has worked with Lachat Instruments since 1998. These days, most of her job is centered on inorganic chemistry. She supports the Lachat products globally. Her job includes method development across all markets, working with EPA to get methods approved and to be sure Lachat meets the EPA criteria, as well as support of customers, technical support, manufacturing, and the sales team. For fun, she has a flower garden, has 1 dog, 4 cats and a parrot. Waste Water Session #2 “What is Standard Methods for Water & Wastewater from a Microbiological Perspective” Presenter: Gil Dichter, IDEXX laboratories As a chair, co-chair and committee member for many microbiological standards in Section 9000, I wanted to understand how this water “bible” came about; what it takes to obtain approval for new methods and update existing methods as well as to volunteer my time and knowledge for microbiological methods. Water and Wastewater dates back to the late 1880s with the first edition published in 1905. It bears little resemblance to the present edition of Standard Methods. My presentation will consist of: 1. The history of Standard Methods 2. Structure of Standard Methods – Joint Editorial Board, Parts Coordinators, JTG Chairs 3. Compare the printed edition vs. the on-line edition 4. Process for approving a new method 5. Process for updating an existing method every 4-6 years 6. How to volunteer 7. Q&A Bio: Gil Dichter is a Technical Support Manager with IDESS Labs. He has: B.A. in Chemistry, MBA in Management 15+ years experience –Pharmaceutical & Clinical Industry Past 20 + years experience -water microbiology. Chair of ASTM D19-24 Water Microbiology Standard Methods for Water &Wastewater-Microbiology Quality Systems Committee- NELAC Several publications Organizations: AWWA, WEF, ASM, ACS, ASTM Waste Water Session #2 “CRM's and how they relate to ISO 17025 Accreditation outcomes” Presenter: Thomas Widera, ERA This presentation will discuss the use of Certified Reference Materials to meet the technical requirements of ISO/IEC 17025 aimed at ensuring the accuracy and reliability of measurements performed in the laboratory. Specifically, the presenter will examine the characteristics and production of Certified Reference Materials, the significance of traceability and method uncertainty in the ISO/IEC 17025:2005 standard and practical use of suitable traceable reference materials in the laboratory’s quality control program to ensure the accuracy and reliability of analytical data. Bio: Thomas is a chemist with 26 years of experience in the environmental testing industry. He obtained his Bachelors degree in Chemistry from the State University of New York at Potsdam. His studies focused on inorganic and analytical chemistry. Thomas has been a principal scientist in the environmental field with vast experience in analytical chemistry. He has also worked with the EPA Region 1 ESAT team focusing on data validation, analytical chemistry, laboratory auditing, and emergency response. Thomas is currently a Product Line Manager, focusing on Inorganic Chemistry and Air & Emissions at Environmental Resource Associates in Arvada, Colorado. Thomas has also been providing full day training courses relating to the EPA DMRQA study for the past 8 years. These courses have been approved in many states to provide Continuing Education Units (CEUs). Waste Water Session #2 Automated methods for Methylene Blue Active Substances (MBAS) Presenter: Lynn Egan. Lachat Instruments- A Hach Company MBAS is a method that estimates mainly the amount of surfactants in a sample. Methylene blue reacts with anionic surfactants, both ABS and LAS, to form a blue-colored dye complex. The complex is extracted in chloroform, and the methylene blue active substances are then determined spectrophotometrically. The manual determination of surfactants, (MBAS) includes an extremely complex, time-consuming and error prone extraction method which also involves extended exposures to chloroform. The Lachat in-line method automates both the extraction and colorimetric determination while maintaining the chloroform in a closed system to minimize exposure for the operator. It also requires 25.0 ml of chloroform or more per sample. Two automated in-line extraction methods are currently available. The manifolds share the following characteristics: Parallel channels through membrane-based phase separator use a single membrane for high efficiency, micro-channel design for minimal dispersion, and a flow-cell bypass valve for easy method start-up and shut down In both methods, the chloroform is mixed in-line with the aqueous phase, with the chloroform being separated through a hydrophobic membrane after mixing. These methods improve precision and accuracy as every sample and standard is treated in the same manner. In the double extraction method, f example, for 10 replicates at 0.5 mg SDS/L, a %RSD of 0.86% was obtained. One of the methods utilizes a single extraction, and meets the requirements under the MUR for NPDES. 30 samples and standards per hour can be analyzed using this method. There is also a double extraction method, which greatly reduces interferences by MBAS materials other than surfactants. This method allows the analysis of 24 samples and standards per hour. Bio: : Ms. Eagan has a degree in Microbiology from the University of Wisconsin, Oshkosh. While in school, she completed 32 credits of chemistry along with her microbiology courses. She was very fortunate to be able to do collaborative research between the Chemistry and Biology departments. She researched the binding of metals to polysaccharides purified from Microcystis aeruginosa. She also spent some time working with the hepatatoxin produced by this cyanobacterium, microcystin, as well as immobilization of the polysaccharide in alginate beads and gels. She has worked with Lachat Instruments since 1998. These days, most of her job is centered on inorganic chemistry. She supports the Lachat products globally. Her job includes method development across all markets, working with EPA to get methods approved and to be sure Lachat meets the EPA criteria, as well as support of customers, technical support, manufacturing, and the sales team. For fun, she has a flower garden, has 1 dog, 4 cats and a parrot. Management Session #3 “Expedited Test Method Development for Emergency Response” Presenter: Clarence L. Haile, Ph.D., REI Consultants, Inc., On Thursday, January 9, 2014, it was reported that approximately 10,000 gallons of an industrial chemical was released into the Elk River near Charleston, WV, just upstream from a regional drinking water plant intake. The release resulted in use restrictions impacting roughly 300,000 residents. The chemical was identified as a crude mixture, largely 4methylcyclohexanemethanol (MCHM) with percent level quantities of propyleneglycolphenyl ether (PPH) and dipropyleneglycolphenyl ether (DiPPH). An emergency water testing program for these chemicals was required to confirm the effectiveness of remedial actions and dilution on drinking water quality. Unfortunately, no approved analytical methods were available for these compounds. This presentation will describe the expedited method development and analysis processes that facilitated rapid response to these critical testing requirements. Within 48 hours of initial notification, part per million level testing was initiated for MCHM. Shortly thereafter, the method was enhanced to achieve low part per billion testing for MCHM, PPH, and DiPPH. Over the following few weeks, more than 2000 samples were analyzed, most within 24 hours of receipt. clhresum1210.pdf Bio: Very Long…We’ll have to edit it. Let me know if you can’t open it. Management Session #3 Key Elements of a TNI-Compliant Quality Management System Abstract: Many states, such as Virginia, are going to a laboratory certification program based on standards published by The NELAC Institute (TNI). Laboratories that are successful in developing a Quality Management System (QMS) in compliance with TNI standards produce analytical and toxicological data that are traceable, defendable, and reliable for use in compliance monitoring. Though beneficial, the process of creating a TNI-compliant QMS can be daunting. This presentation will provide an overview of lessons learned during the last 14 years of NELAC compliance. Notes: It is our intention to make this presentation applicable to large and small wastewater and water testing laboratories. We are willing to share our approach to the development of a QMS, as well as how we have implemented some of the requirements. We can make this presentation very basic, or more advanced if you believe that the majority of laboratories have already successfully implemented the basic NELAC standards. Beth Thompson Quality Manager and Special Projects Manager Shealy Consulting, LLC. 603 South Lake Drive Lexington, SC 29072 (803) 447-8471 bthompson@shealyconsulting.net Bio: Beth is a graduate of the University of South Carolina, and is still a loyal Gamecock! She is currently the Technical Director of Shealy Consulting, LLC, where she has also held positions as Senior Aquatic Toxicologist, Quality Manager, Special Projects Manager, and Radiation Safety Officer. Beth has performed toxicity testing and Toxicity Identification Evaluations for over 19 years. She has also assisted over sixty facilities throughout South Carolina and Virginia with site-specific metal limit development. She has maintained certification of the toxicity laboratory with the State of South Carolina, NELAC, Virginia, North Carolina and Georgia. She has also designed a toxicity program with approval to test samples from sites regulated by the U.S. Department of Energy. Beth lives in Lexington, South Carolina, with her husband and two teenagers. Management Session #3 “Streamlining Laboratory Weekend Operations” Presenter: Theresa Narkinsky, Prince William County Service Authority To comply with permit requirements and operational needs, the Water Quality Laboratory (WQL) is a 7 days a week regular working hours operation serving the water reclamation plant and drinking water transmission and distribution. Personnel working weekends are afforded 2 regular days off during weekdays, which result in short staffing during the regular work week. In an effort to evaluate staff assigned to weekend work, the WQL researched methods that would allow staffing weekends with one person in a safe manner, without reducing the level of service provided to water reclamation operators. Prior to making changes to weekends’ staffing, a consultant was hired to conduct a WQL weekend safety evaluation to determine if a one person schedule was possible. The most pressing concern identified was the TKN/TP strong acid digestion for water reclamation analyses with the Lachat Quikchem Spectrophotometer. Other minor safety concerns were quickly resolved. WQL staff’s research identified the TKN/TP HACH method as substantially reducing the use of strong acid making them ideal alternatives for weekend work. In addition to other HACH nutrients methods, a side-byside evaluation of HACH Method # 10242 Nitrogen, Simplified TKN and HACH Method # 8190 Phosphorous, Total versus the TP/TKN Lachat procedure was performed. The results of the side-by-side evaluation showed excellent agreement between methods resolving the pressing concern identified by the safety evaluation. A one person weekend schedule combined with a buddy system (with weekend reclamation staff) is in place at the WQL. The complete paper and presentation will include detailed results of the safety evaluation, the side-by-side methods comparison and the benefits of implementing the HACH tests to the WQL, water reclamation and drinking water operations. Bio: Theresa is currently a Laboratory Supervisor at the Prince William County Service Authority. She has held this position since December 2013. Prior to her role as Supervisor Theresa was employed as a Laboratory Specialist at the Service Authority since February 2002. In her role as a Specialist, Theresa was responsible for the analysis and quality control of the GC/MS. In addition to her many other duties Theresa took part in many of the lab’s special projects. In 2011, Theresa responded to the needs of the laboratory and began investigating methods to maximize the number of samples and tests conducted in the lab on the weekends while minimizing workforce. “Where to Start When Writing an SOP” Presenter: Stacie Splinter, Universal Laboratories Abstract: This presentation will teach you where to start when writing an SOP. You will learn all the details that are required within the SOP and an effective way to know where the details are found and how to conveniently place them within the SOP. We will work through writing an SOP for Total Suspended Solids (TSS) to show participants an easy way to work through a tedious task. Participants will receive an SOP template to help them get started. Bio: Stacie has worked in the environmental industry for over 11 years. She obtained her bachelor’s degree in Biology from the University of Tennessee at Martin. She began in the laboratory performing BOD analysis. Within her first 3 years, she mastered Microbiology, Wet Chemistry, and Metals and had a basic understanding for Organics. Stacie became the Quality Director for Universal Laboratories and has maintained that role for the last 8 years.