25 March 2015| REF: J/N 123192

Department of Economic Development,

Jobs, Transport and Resources

VEET Energy Saver Incentive Scheme

Business Sector Energy Efficiency

Modelling

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Project details

Department of Economic Development, Jobs,

Transport and Resources

Energetics Contact

Kathryn Lucas-Healey

Gordon Weiss

Description

Prepared By

Reviewed By

Approved By

Approval Date

Version 1: Initial Draft

Gordon Weiss

Emma Fagan

Gordon Weiss

23/02/2015

Version 2: Revised version

Emma Fagan

Gordon Weiss

Gordon Weiss

25/03/2015

About Energetics

Energetics is a specialist energy and carbon management consultancy. Our experts help clients to

Be leaders. Develop and implement strategy

Be informed. Make data-driven decisions

Be efficient. Drive business improvement and realise savings

Buy better. Leverage energy supply and carbon markets

2014

2013

Winners of BRW Client Choice

Awards: - Best Professional Services

Firm (revenue < $50M)

- Best Consulting Engineering Firm

(revenue < $50M)

- Best value

Finalists: BRW Client Choice Awards

for Best Client Service, Most Friendly

and Most Innovative

© Energetics Pty Ltd 2016

Finalist: BRW Client Choice Award for

Best Client Relationship Management

Finalist: Leading in Sustainability

Banksia Award

2011

2012

Winner: Australian Business Award

for Recommended Employer

Winner: Australian Business Award

for Service Excellence

123192\Documents\1948791\1

Winner: BRW Client Choice Award for

Best Value

Finalists: BRW Client Choice Awards

for

Exceptional

Service,

Most

Innovative, Outstanding Client Care

and Best Consulting Engineering Firm

(revenue <$50 Million)

ii

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Copyright

© 2015 Energetics. All rights reserved.

"Energetics" refers to Energetics Pty Ltd and any related entities.

This report is protected under the copyright laws of Australia and other countries as an unpublished work. This report contains

information that is proprietary and confidential to Energetics and subject to applicable Federal or State Freedom of Information

legislation, shall not be disclosed outside the recipient's company or duplicated, used or disclosed in whole or in part by the

recipient for any purpose other than for which the report was commissioned. Any other use or disclosure in whole or in part of

this information without the express written permission of Energetics is prohibited.

Disclaimer

The information contained in this document is of a general nature only and does not constitute personal financial product advice.

In preparing the advice no account was taken of the objectives, financial situation or needs of any particular person. Energetics

is authorised to provide financial product advice on derivatives to wholesale clients under the Corporations Act 2001 AFSL No:

329935. In providing information and advice to you, we rely on the accuracy of information provided by you and your company.

Therefore, before making any decision, readers should seek professional advice from a professional adviser to help you

consider the appropriateness of the advice with regard to your particular objectives, financial situation and needs.

Australian Financial Services License (AFSL # 329935).

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

iii

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Table of contents

TABLE OF CONTENTS

1.

Background ................................................................................................................................... 1

2.

Modelling the VEET scheme ........................................................................................................ 3

2.1.

Consideration of non-financial barriers ......................................................................................... 5

3.

Assumptions and parameters ....................................................................................................... 6

4.

Defining the measures .................................................................................................................. 9

4.1.

Large commercial and SME sectors ........................................................................................... 10

4.2.

Large industrial sector ................................................................................................................. 14

5.

Outcomes: Results of the modelling ........................................................................................... 17

5.1.

Business sector results ............................................................................................................... 17

5.2.

Results for certificate price scenarios ......................................................................................... 18

Appendix A.

Key assumptions ....................................................................................................... 25

Retail energy prices ........................................................................................................................... 25

Savings and cost of lighting upgrades ............................................................................................... 25

Payback thresholds ............................................................................................................................ 28

Appendix B.

Industrial and mining measures ................................................................................. 30

Appendix C.

Details of the measures ............................................................................................. 32

Contact details ..................................................................................................................................... 33

LIST OF FIGURES

Figure 1: Calculation of incentive level .................................................................................................... 3

Figure 2: Measure uptake for smaller measures – take up curves as a function of incentive percentage

................................................................................................................................................................. 4

Figure 3: Measure uptake for larger measures – take up curves as function of payback ...................... 4

Figure 4: Measures adopted.................................................................................................................... 4

Figure 5: Three year target with large business exclusion .................................................................... 17

Figure 6: Seven year target with large business exclusion ................................................................... 17

Figure 7: Seven year target without large business exclusion .............................................................. 18

Figure 8: Large commercial site energy consumption .......................................................................... 27

LIST OF TABLES

Table 1: Changes from previous VEET modelling .................................................................................. 2

Table 2: Key assumptions and parameters in the model ........................................................................ 6

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

iv

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Table 3: Parameters defining each measure .......................................................................................... 9

Table 4: Example of a measure .............................................................................................................. 9

Table 5: List of stationary energy savings measures by commercial market segment ......................... 12

Table 6: List of stationary energy savings measures by industrial market segment ............................. 14

Table 7: Extract from ClimateWorks database ...................................................................................... 16

Table 8: Three year scenario certificate prices ..................................................................................... 18

Table 9: Five year scenario certificate prices ........................................................................................ 19

Table 10: Certificates generated in the three year VEET scenario ....................................................... 19

Table 11: Certificates generated in five year VEET scenario ................................................................ 19

Table 12: Certificates generated by measure in 5.4 million certificates, five year VEET scenario ....... 20

Table 13: Model retail energy prices ..................................................................................................... 25

Table 14: Savings per lighting installation ............................................................................................. 26

Table 15: Energy consumption by building class .................................................................................. 27

Table 16: Derivation for commercial lighting upgrades in Victoria ........................................................ 28

Table 17: Industrial and mining measure parameters ........................................................................... 30

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

v

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

1.

Background

On 1 January 2009 the Victorian Energy Saver Incentive (ESI) scheme was launched to promote the

uptake of energy efficiency improvements in residential premises. The scheme is established in the

Victorian Energy Efficiency Target Act 2007 (the Act). The objectives of the Act are to:

•

reduce greenhouse gas (GHG) emissions

•

encourage the efficient use of electricity and gas

•

encourage investment, employment and technology development in industries that supply

goods and services which reduce the use of electricity and gas by consumers.

The scheme is based on three year phases.

Phase 1 had an annual target of reducing lifetime GHG emissions by 2.7 million tonnes per annum in

the residential sector, which was doubled to 5.4 million per annum for Phase 2 for the period to 2015,

and expanded to include business and other non-residential sectors.

This objective of this review is to develop an appropriate target for Phase 3 of the VEET scheme.

In 2013 Energetics developed modelling as well as a number of scenarios examining business sector

energy efficiency activities (as provided in VEET Energy Model Input Final Assumptions Report 1 [the

2013 Assumption Report] and related spreadsheets). Sustainability Victoria modelled the residential

sector energy efficiency activities.

In this report, Energetics updates the modelling of business sector energy efficiency activities to

ensure that it is accurate and current. We also present a number of target scenarios to incorporate into

a model of the energy market, including energy efficiency measures pursued by the parts of the

Victorian business sector that buy energy from energy retailers rather than the wholesale market.

Constraints and limitations

There are a number of factors that may influence the growth of the VEET scheme in Victoria that have

not been included in this model. Non-market barriers such as split incentives and limited knowledge

and access to information about the benefits of energy efficiency activities, cannot be modelled

accurately.

There are also policies in Australia that may impact the pool of opportunities potentially taken up under

the VEET, particularly the Emissions Reduction Fund (ERF). While the influence of the ERF is

difficult to estimate before it begins, we see possible outcomes where engagement with the VEET

scheme is preferred. One such example arises where ERF assessment methodologies overlap with

the VEET. Project proponents may choose the VEET scheme as payment for emissions reductions is

made up front unlike the delivery model offered under the ERF. The lack of entry-level abatement

thresholds in the VEET may also make the scheme more attractive.

Ultimately market conditions and the price of both ACCUs and VEECs will determine how the pool of

opportunities offered under the VEET, may be impacted by the ERF.

1

“VEET Energy Model Input: Final assumptions report”, Energetics, 18 November 2013

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

1

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Changes from the 2013 model

The business sector energy efficiency modelling described in this report built on work done for the

2013 Assumption Report. A number of changes have been made to the earlier model and these are

outlined in Table 1 below.

Table 1: Changes from previous VEET modelling

Changes

Reference in this report

Measures for the large industrial sector are included

Section 4.2

A number of measures pertaining to the large

commercial and SME sectors have been removed or

combined

Section 4.1

Several measures pertaining to the large commercial

and SME sectors have been amended

Table 5

The electricity and natural gas prices are updated

Appendix A

The year by year decay of the savings due to a

measure has been changed

The value was changed from 0% to 3%.

Discount rate

The value for project based assessment (PBA)

measures was changed from 20% to 10%.

Detail in Section 2.

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

2

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

2.

Modelling the VEET scheme

This report focuses on commercial energy efficiency measures and the assumptions used to model

their impact. The following section provides an overview of the functionality of the model.

Figure 1 to Figure 4 outline the process used to determine the number of certificates created for

different certificate prices. Each energy efficiency measure was defined according to adjustable

parameters such as the total pool of efficiency opportunities, the costs of implementation and the

average electricity and gas savings that will result. The model also includes adjustable parameters.

Examples include a certificate price ($/certificate2), a greenhouse gas (GHG) emissions factor and any

administrative fees associated with the creation of certificates.

The total number of certificates created depends on the annual GHG emissions savings, the duration

of the energy efficiency measure and the GHG emissions factor applied.

The incentive for participants is a function of the number of certificates created, multiplied by the value

of each certificate. The latter is net of any fees associated with the administration of the scheme.

The model calculates the uptake of measures based on the incentive to participate. One of two

approaches is used. For the less costly measures most suited to SME markets, the uptake is

calculated based on a simple relationship between the size of the incentive and the cost of the energy

efficiency measure. Figure 2 shows the uptake of simpler measures such as replacing an old

appliance. There is a default take-up curve plus one for low cost appliances and one for new

technologies (where there can be resistance to early adoption).

Incentive level

Annual energy

saving

Certificates

created

×

×(

Measure

life

×

VEET GHG

coefficients

Certificate

price

-

Administration

fees

=

Certificates

created

)=

Consumer

incentive

Figure 1: Calculation of incentive level

The 5% fee used within the model reflects the observed administrative cost reported in the

assessment of the ACT Government EEIS.

In determining the deemed savings for a project, the calculated emissions savings are discounted by

10% for each year of a project’s life up to 10 years. This differs from the 20% discount rate used in

prior VEET modelling. This discount provides a balance between what is an adequate incentive for

project proponents to drive energy saving measures and the need to ensure that certificates are only

created for genuine savings. The change in the discount rate is material and has resulted in an

effective project life of 5.5 years when generating VEECs as opposed to three years when using a

20% discount rate. It also results in a savings persistence of ten years rather than five.

The treatment of $0 certificate prices and the impact of the results are discussed in detail in section

2.1.

2

One certificate is intended to be equivalent to 1 tonne of lifetime greenhouse gas abatement.

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

3

Measure uptake – Take up curves

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Consumer

incentive

÷

Cost of

measure

Incentive as % of

additional cost

=

Incentive as % of

additional cost

Uptake rate

function

=

Annual uptake

rate

Figure 2: Measure uptake for smaller measures – take up curves as a function of incentive percentage

If the commercial GHG emissions abatement measure is more costly and generally applicable to

larger businesses then it is more appropriate to use an approach based on the payback. Figure 3

shows the calculation. The payback threshold, which establishes when the energy efficiency measure

will be taken up, is a distribution function that reflects the range of thresholds for different participants.

Measure uptake – Payback

(

Cost of

measure

-

Payback

Consumer

incentive

)÷

Payback

threshold

Annual energy

saving

=

=

Payback

Annual uptake

rate

Measure uptake – Take up curves

Figure 3: Measure uptake for larger measures – take up curves as function of payback

Finally, the actual number of instances that the energy efficiency measure is adopted is expressed as

the uptake rate times the total pool of opportunity. Total uptake figures are managed by a constraint

that limits the maximum annual uptake to reflect the fact that the market has limited capacity to deliver

any one measure within a fixed period of time. See Figure 4 for an overview on how this functionality

works.

Annual uptake

rate

Maximum limit

on uptake

<×

Pool of

opportunity

=

Measures

adopted

Figure 4: Measures adopted

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

4

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

2.1.

Consideration of non-financial barriers

Note that the assessments of payback periods within the model were undertaken on a purely financial

basis. There are a range of non-financial barriers that may also limit the interest in energy efficiency

projects. The impact of non-financial barriers is modelled through the use of payback periods that

have actually been seen in the market, rather than payback periods that would be implied by realistic

financial returns. As discussed in Section 3, the actual paybacks required by the market are as low as

1.75 years whereas projects with paybacks as high as 10 years would show a positive financial return.

The data that defines the take-up of a measure comes from a number of independent sources –

observed take-up of measures, reported costs to implement energy efficiency measures, savings

based on a basket of specific activities within a broad measure and forecasts of energy prices. For

instance, the measure “lighting upgrade” covers a broad range of potential activities that depend upon

the existing form of lighting and the replacement technology. It is possible that some measures will be

cost effective to some participants even if no incentive is in place. This is best considered as a

component of the business-as-usual case.

The business-as-usual take-up that is predicted by the model was deducted from the take-up at

various positive incentives (external to the VEET program) in order to give a true indication of the takeup driven by the incentive. As an example, if a measure saw 500 certificates generated at a $0

certificate price, and 10,000 generated a $15 certificate price, these 500 certificates are deducted from

the 10,000 certificates to give the actual impact of the incentive.

Note though that in the ‘real world’, factors such as an un-modelled increase in energy prices or a

significant drop in implementation cost will result in the measure becoming more cost effective and

therefore we would see take-up without any incentive. Similarly, a fall in energy prices or increase in

implementation costs will mean that measures are less attractive.

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

5

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

3.

Assumptions and parameters

Table 2 outlines a number of key assumptions and parameters that define the overall properties of the

model. Some of these assumptions and parameters relate to the structure of the model and others

relate to the performance of the abatement measures.

Table 2: Key assumptions and parameters in the model

Item

Details

Business-asusual

Where activities involve the upgrade of equipment at the point of replacement (e.g. installing

a high efficiency motor at the time the motor needs replacing), the business–as-usual (BAU)

case assumes that a unit compliant with the Minimum Energy Performance Standards

(MEPS) is installed.

In other cases, the savings associated with the measure represent a weighted average of

savings for measures reported in the Commonwealth Energy Efficiency Opportunities (EEO)

program and other energy audits.

In confidence, commercial data has also been used to derive installation costs and savings

potentials for some measures, most notably commercial lighting.

Averaging

different items

Energy savings for each measure where the averages of a number of uses of the measure

are reported in EEO and other energy assessments. The aggregation of different instances of

the measure will include the use of different pieces of equipment. The extensive, publicly

available EEO dataset, which was used to derive the average savings for an energy

efficiency measure, was assumed to be representative of the total pool of opportunities in the

wider economy.

Average annual

energy savings

(MJ/yr)

Commercial buildings and SMEs: An average was calculated for annual energy savings for

commercial buildings and SMEs, based on the fraction of the total energy used by the

building or facility resulting from the implementation of the energy efficiency measure.

The baseline and measures developed for the modelling of the National Energy Savings

Initiative [the NESI dataset] also included the average amount of energy used by each type

of building. The product of these two values gives the average annual energy savings.

Industrial facilities: We used the “Percentage of total energy used by a facility that is saved

by the measure” reported in the industrial component of the NESI dataset.3

Measure life

(Years)

This is the estimated length in years that the measure is expected to deliver energy savings

once installed. Sources included the Carbon Trust persistence factor data base, the Low

Carbon Australia persistence factor data base, EES residential baseline study, RIS: NAEEEC

Report 2003/10 Minimum Energy Performance Standards and Alternative Strategies for

Linear Fluorescent Lamps, the BIS Shrapnel Household Appliances 2006 and Energetics

commercial in-confidence figures.

VEET GHG

coefficients

Provided by the Victorian Government and used consistently across all VEET modelling, the

values applied were 0.963 tCO2-e/MWh for electricity and 0.0573 tCO2-e/GJ for natural gas.

Pool of

opportunities

The following approach was used to estimate the number of opportunities for large

commercial and SME buildings:

The total energy consumption for each type of building or SME facility was estimated

using the energy reported by ANZSIC sector, measures of building size and activity as

reported to the ABS (e.g. employee numbers, sales volume, patient numbers, student

numbers) and measures of energy intensity within various types of buildings.

3

Inputs to Energy Savings Initiative modelling from Industrial Energy Efficiency Data Analysis Project:

http://www.industry.gov.au/Energy/Documents/energy-efficiency/energysavings/consultant/Industrial_data_subsector_grouping_level_dataset.xls (Accessed March 2015)

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

6

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Item

Details

The average energy used by each type of building or facility was assessed by either:

o

aggregating a set of representative assessments of a specific building type to

directly estimate the average, or

o

estimating the total number of buildings in a specific category and then dividing

the total energy used by those buildings by the total number of buildings.

Using our estimate for the total energy used by each type of building in Victoria, and our

estimate of the average energy used by a building, we estimated the number of buildings

of each type in Victoria.

Using our estimate for the fraction of all buildings or facilities where a measure was

applicable (eg an upgrade to a boiler is only applicable to a building with a boiler) and

our estimate for the fraction of buildings where a particular measure has already been

adopted, we adjusted the estimate of each type of building or facility in Victoria to give

the number of buildings or facilities where a particular measure is still able to be

implemented. This is the pool of opportunities.

The modelling of measures applicable to the large industrial sector used a different approach.

The large industrial sector covered mining and industry excluding non-ferrous metals. The

latter were excluded as non-ferrous metal production is dominated by metal (aluminium)

smelting which takes its electricity directly from the wholesale market. The pool of opportunity

for the industrial measures covers the energy used by the large industrial sector as

determined during the modelling of the national energy savings initiative. This basically

covered the entities that were obligated under the NGER program.

More detail on calculating the pool of opportunity can be found in the report on the

Commercial and SME Energy Efficiency Data on the NESI Consultants Reports webpage.4

Maximum uptake

rate/year

Where a measure is only applicable at the point of replacement of the equipment, the

maximum uptake rate is the total pool of opportunity divided by the life of the equipment ie

the turnover of stock.

In other cases, it was based on our estimate of what is achievable and reasonable. This is

the part of the model where there is the greatest uncertainty

Note that where measures were assessed using a project based method, the maximum takeup in the first year was set to zero to account for the time needed to undertake the

assessment and the internal processes to approve and then implement the measure.

Discount rate

In determining the average number of certificates for a project, the calculated emissions

savings are discounted by 10% for each year of a project’s life up to 10 years. This differs

from the 20% discount rate used in prior VEET modelling.

Average number

of certificates

Where a commercial measure uses a default abatement factor5 to determine the number of

certificates, the number of certificates is equal to the energy savings times the emissions

factors times the measure lifetime.

For measures that are assessed by a project based methodology, the number of certificates

is equal to the energy savings times the emissions factors times 5.5. The latter term

represents 100% of the emissions savings in the first year plus 90% of the emissions savings

in the second year plus 80% of the emissions savings in the third year, and so on.

Additionality

The measures have accounted for regulatory additionally though the definition of the energy

savings due to the measure e.g. the savings due to the installation of an appliance subject to

4

http://www.industry.gov.au/Energy/Documents/energy-efficiency/energysavings/consultant/Commercial_and_SME_EnergyEfficiencyDataReport.pdf (Accessed March 2015)

5

Default abatement factors are used to calculate the number of abatement certificates that may be created from the installation

of common equipment such as compact fluorescent lamps, refrigerated display cabinets and certain electric motors. Calculation

of certificates using default abatement factors is simple as the number of certificates is linked to the size of the appliance and

not the characteristic of the particular installation.

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

7

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Item

Details

minimum energy performance standards (MEPS) is taken to be the savings above the MEPS

level not the market average energy performance (assuming the latter is the lower).

Rebound

Rebound in this instance refers to the implementation of a more energy efficient technology

driving a slight increase in the use of the more efficient equipment compared to the previous,

less efficient technology (generally related to the energy cost saving differential). With

deemed abatement this may result in slightly less GHG abatement than anticipated.

The model accounts for rebound by reducing the savings due to an implemented measure

from year to year.6 Our default factor, based on Energetics experience is to reduce the

energy savings by 3% each year and this value was used in the model of the VEET scheme.

Average payback

The average payback is calculated by the model, taking into account the capital cost,

incentive payments and the energy savings.

Payback

installation hurdle

Our default payback thresholds are to include any measure that offers a payback within three

years for measures in large businesses and 1.75 years for the SME sector. Where the takeup is assessed using the payback threshold, 50% of the available instances of the measure

will be taken up when the average payback is equal to the threshold.

Lifetime energy

saved

The lifetime savings for a particular instance of a measure is equal to the sum of annual

savings over the lifetime of the measure.

The total energy saved is the aggregate of energy saved for each instance of each measure,

taking into account the calendar year when the instance was implemented. Discounts to

these savings are applied to measures incentivised using project based assessment

methodologies (see Maximum uptake rate/year).

Annual GHG

emissions saved

This model used an emissions factor equivalent to the VEET GHG coefficient to calculate

annual GHG emissions reduction on a measure by measure basis and in totality.

Lifetime GHG

emissions saved

This is the sum of annual GHG savings across all measures and all years. Lifetime GHG

emissions reductions are also calculated using an emissions factor equivalent to the VEET

GHG coefficient.

Certificate

administrative fee

A further 5% of the certificate price is deducted to account for the cost incurred by the

Accredited Person or third party involved in installing a measure.

Note that costs incurred for the undertaking of a feasibility study prior to implementing the

measure are included in the implementation cost of the measure.

Average cost

The average cost is equal to the cost of applying the measure to the entire building or facility

(equipment + installation + feasibility studies).

The average costs for large commercial and SME measures were derived from the NESI

dataset, unless otherwise indicated in Table 5. Large industrial measures were derived from

the industrial component of the NESI dataset.3

Uptake rate

function

The uptake of a measure is determined by the ratio of the size of the incentive and the cost of

the measure. See Figure 2 for an illustration of an uptake rate function.

6

Note that the year by year reduction in energy savings is independent of the discounting of calculated emissions savings when

determining the number of certificates for project based measures.

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

8

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

4.

Defining the measures

The energy efficiency measures that were included in the modelling of the extension of the VEET

scheme are based on opportunities in the large industrial, large commercial and SME sectors. They

were developed with reference to Australian and international literature, as well as Energetics’

extensive field experience in conducting energy audits nationwide across most building types.

Each measure was defined by a collection of parameters. Table 3 and Table 4provide details of those

parameters and an example of one activity. Measures were also split between industrial facilities,

commercial buildings and buildings appropriate to the SME sector.

Table 3: Parameters defining each measure

Item

Meaning

Measure name

A descriptive name for the measure.

Building type or sector

Ten types of large commercial buildings, four types of small buildings, industrial

facility. mining facility

Size of opportunity

Number of nominal buildings or nominal facilities where the opportunity exists

Lifetime

Estimate of a particular opportunity useful lifetime

Installed cost

Average cost to implement all instances of the opportunity in the building type or

the facility

Electricity savings

(GJ/p.a.)

Average annual savings from implementing all instances of the opportunity in the

building type or facility

Gas savings (GJ/p.a.)

Average annual savings from implementing all instances of the opportunity in the

building type or facility

T/U function

Used to determine the uptake of a measure, the options were one of three

potential take-up functions or the use of payback in years. There is a default take

up curve plus one for low cost appliances and one for new technologies (where

there can be resistance to early adoption).

T/U rate % size year 1, 2,

3 and 4 and beyond

Maximum limit on uptake: maximum percentage of buildings or facilities that can

be upgraded in any year of the program

P/B Threshold

Three years for large buildings, the industrial sector and the mining sector. 1.75

for the SME sector.

Incentive method

Default abatement factor or project based assessment

Table 4: Example of a measure

Item

Measure Name

ID

© Energetics Pty Ltd 2016

Meaning

Lighting upgrade

18

123192\Documents\1948791\1

9

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Item

Meaning

Sector

SME industrial

End use

Lighting

Measure type

Size of opportunity (units)

SME-existing

126300

Units

Buildings

Applicable energy tariff

Franchise

Lifetime of abatement savings (years)

10

Total Installed cost ($/unit)

4509.855

Electricity savings (GJ/unit p.a.)

25.67172

Mains Gas savings (GJ/unit p.a.)

0

T/U function

Payback

T/U rate % size year 1

0.15

T/U rate % size year 2

0.15

T/U rate % size year 3

0.15

T/U rate % size year 4 onwards

0.15

Payback Threshold

1.75

Payback SD

Incentive method

4.1.

0.291667

DAF

Large commercial and SME sectors

A number of considerations were taken into account in calculating potential energy savings

attributable to each measure for each building type:

7

The lifetime of a measure: Lifespan estimates were made for each measure with reference

to industry sources7, complemented by Energetics’ industry knowledge.

The minimum energy performance standards (MEPS) applicable to equipment or typical

baseline energy use by equipment in the sample base.

The energy consumed by high efficiency (HE) alternative technologies to existing

installations.

See Table 2.

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

10

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

The energy use baseline per building type.

The energy savings potential for each of the measures was expressed as a percentage of the total

energy use by the building type. The marginal or incremental cost per measure relative to the

energy usage of the building type was also calculated based on the capital and implementation cost

estimates from the audit datasets.

The savings potential was assessed for individual measures that were intended as input into the NESI

dataset. We did not take into account the interaction of measures8 nor mutually exclusive measures9.

However, there were only limited instances identified where measures interact with other measures.

The energy efficiency measures included in the model were derived from a similar data set used for

the modelling of the NESI dataset. For commercial and SME applications 38 different measures

across twelve broad classes were modelled. Each measure applied to one or more of ten types of

large commercial building and four types of small to medium enterprises. Types of buildings within the

model include commercial offices, schools, large and small retail outlet, hotels and restaurants.

The list of potential energy savings opportunities in the commercial and SME sectors was supported

with reference to Australian and international literature, as well as Energetics’ extensive field

experience in conducting energy audits nationwide across most building types.

Certain adjustments were made to the list of measures from the earlier work. The key adjustments are

outlined below:

Measures covered by Schedule 1 to Schedule 30 of the VEET Regulations were removed as

they will be covered by the modelling of the residential sector.

Several groups of measures involved the same improvement implemented in different

building types. Further, these measures had the same implementation cost per MJ. These

measured were combined into one measure spanning all buildings covered by the separate

measures with no change in the overall result but with the benefit of less complexity.

With the exception of certain forms of window treatment, building shell measures are not

cost effective. Window treatments are covered by the residential component of the VEET

scheme and so applying treatments on SME premises has been transferred to the residential

model. We validated the remaining window treatment measures that applied to large

commercial buildings. These measures were combined into a single measure applicable to

large commercial buildings. These changes have made no material impact on the results

generated by the model.

Measures involving the installation of evaporative air conditioners were removed as the

commercial sector has seen a steady decline in the installation of evaporative air

conditioners10. This amendment also had no material impact on the results generated by the

model.

8

This refers to a situation where the effectiveness of one measure is impacted by the adoption of a second or third measure.

For example, the replacement of inefficient lighting in an office could lead to increased energy use for heating due to more heat

being lost in the ambient atmosphere by the inefficient lighting.

9

This refers to a situation where the implementation of one measure, precludes the adoption of another.

Institute for Sustainable Systems and Technologies, “ Technical research on evaporative air conditioners and feasibility of

rating their energy performance”, (accessed March 2015)

10

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

11

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Based on experiences with other energy efficiency trading schemes (e.g. the ESS),

upgrades to commercial lighting are expected to be one of the measures that has a large

take-up. Therefore have a robust description for this measure is highly desirable in this

Report. The lighting measures outlined in the 2013 Assumption Report were taken from the

NESI dataset. Better data regarding the savings and costs of commercial lighting upgrades

is now available. This was used to validate and revise the lighting measures. In particular, all

lighting measures were combined into two aggregated measures: one for large commercial

buildings and one for SME buildings. These amendments have resulted in a more accurate

calculation of the likely certificates to be generated under the lighting upgrade measure. A

more comprehensive description of the lighting measures can be found in Appendix A.

There has been almost no take-up of high efficiency (HE) motors in the ESS. The technical

potential for the measure “HE motors in small offices” in the NESI dataset is much higher

than can be justified as small offices do not use pumps other than small pumps in generally

packaged HVAC systems. Based on revised assessment for the HE motor market in the

commercial business sector in Victoria this measure was removed from the current model.

This removal does not impact on the treatment of HE motors in other business sectors such

as warehouses, shopping centres and universities.

The list of measures for energy savings for the large commercial and SME sectors is presented in

Table 5. In several cases the capital costs from the earlier modelling were increased by 15% to

capture the cost of the feasibility study. Previously this was included in the administration fee. This is

described as “the 15% loading” in the table.

Table 5: List of stationary energy savings measures by commercial market segment

DAF/PBA11

Measure Name

Sector

Basis and comments

Air Compressors:

Improved operation

of compressed air

systems

The measure was taken from the NESI SME dataset.

There was some take-up of air compressor measures in

the ESS. The need for a relatively high certificate price

will limit actual take-up.

PBA

SME Industrial

PBA

Appliances &

Equipment: Variable

speed drives (VSDs)

SME Industrial

The measure was taken from the NESI SME dataset.

Several similar VSD measures applicable to the SME

sector were included in the earlier modelling. Further,

some related measures are included in the current

dataset. Therefore as VSDs are largely an industrial

piece of equipment, this measure is restricted to just the

industrial SME sector.

The poor take-up of these apparently cost effective

measures appears to be because take-up was

modelled by an uptake curve rather than payback.

Payback is used in the current modelling.

Appliances &

Equipment: Replace

a MEPS compliant

motor with a HE

motor

These were derived from the NESI dataset. The 15%

loading has been applied.

DAF

Shopping

Centre

11

Note that there has been almost no take-up of high

efficiency motors in the ESS.

DAF means a default abatement factor. PBA means project based assessment.

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

12

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Measure Name

Sector

Basis and comments

DAF/PBA11

Appliances &

Equipment: Replace

a MEPS compliant

motor with a HE

motor

DAF

Warehouse

(NR)

HVAC: Replace a

MEPS compliant

motor with a HE

motor

University /

TAFE

Boilers, Furnaces &

Ovens: Upgrade

Hospitality

The measure was taken from the NESI large

commercial dataset.

PBA

Boilers, furnaces and

ovens: Replace boiler

Large

commercial

This combined measure was derived from the NESI

large commercial dataset. The 15% loading has been

applied.

PBA

Building shell:

Window treatment

Large

commercial

The treatment of building shell measures was

discussed above.

PBA

HVAC: HVAC

controls

Hospitality

DAF

PBA

The measures were taken from the NESI datasets.

HVAC: HVAC

controls

PBA

SME Industrial

The measure was derived from the NSEI SME dataset.

The large installation cost of these measures suggests

that they would be better modelled using payback to

determine take-up. A 5% loading was added to the

installation cost to allow for any feasibility studies.

DAF

HVAC: High

efficiency standalone

AC

SME

HVAC: High

efficiency standalone

AC

Large office

HVAC: High

efficiency standalone

AC

Shopping

Centre

Large

commercial

A review of data from sources available to Energetics

suggested that the indicated installation cost per GJ of

electricity saved was too low, and should be at least

$150/GJ. The 15% loading has been applied.

PBA

HVAC: HVAC

controls

HVAC: Replace

cooling tower

Large office

The measure was taken from the NESI large

commercial dataset.

PBA

HVAC: Upgrade

chiller

Large

commercial

This measure was derived from the NESI large

commercial dataset. The 15% loading has been

applied.

PBA

HVAC: Variable

speed drives and

control for fans

Large

commercial

This measure was derived from the NESI large

commercial dataset. The 15% loading has been

applied.

PBA

Lighting upgrade

SME Industrial

Lighting upgrade

Large

commercial

© Energetics Pty Ltd 2016

DAF

The measures were taken from the NESI large

commercial dataset. The test for take-up was changed

to the payback as it better reflects the type of measure

and the large installed cost. A 5% allowance for the

feasibility study has been added.

DAF

DAF

Lighting measures were discussed above.

123192\Documents\1948791\1

DAF

13

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Measure Name

Sector

Pumps: Upgrade to

HE pumps

Hospitality

DAF/PBA11

Basis and comments

DAF

The measures were taken from the NESI datasets.

Pumps: Upgrade to

HE pumps

SME Industrial

Pumps: Variable

speed drives for

pumps

Hospital

DAF

PBA

The measures were taken from the NESI datasets.

Pumps: Variable

speed drives for

pumps

4.2.

PBA

SME Industrial

Large industrial sector

In addition to the calculation of potential energy savings from the commercial and SME sectors,

additional work was undertaken to calculate energy savings (electricity and natural gas savings) from

the large industrial sector in Victoria. These sites have been included following the sunsetting of the

Environment and Resource Efficiency Plans (EREP) program. To date large industrial and commercial

sites had been excluded from the coverage of the VEET scheme due to the operation of the EREP

scheme.

In total 26 measures were considered covering both the broad industrial sector and the mining sector.

Note that all measures are based on a PBA assessment of savings.

The bulk of the data used to derive the measures applicable to the large industrial sector has been

extracted from work done by ClimateWorks as part of the modelling of the NESI12. The list of

measures as included in the VEET model is shown in Table 6:

Table 6: List of stationary energy savings measures by industrial market segment

Measure

Industry

Mining

Measures that save electricity

Upgrade: Co-generation or Tri-generation

Upgrade: Comminution (crushing and grinding) and blasting systems

Upgrade: Compressed air systems

Upgrade: Conveyors

Upgrade: Furnace/Kilns

Upgrade: Gas compression equipment

Upgrade: IT, communications and other electronic equipment

Upgrade: Lighting systems

“Inputs to the Energy Savings Initiative modelling from the Industrial Energy Efficiency Data Analysis Project”, ClimateWorks

Australia, July 2012

12

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

14

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Measure

Industry

Mining

Upgrade: Non-transport machinery

Upgrade: Other Building services

Upgrade: Other equipment

Upgrade: Pumping systems

Upgrade: Refrigeration

Upgrade: Stationary materials handling systems

Upgrade: Various industrial systems

Upgrade: Ventilation systems, fans and blowers

Upgrade: Waste treatment, disposal and remediation

Measures that save natural gas

Upgrade: Boiler systems

Upgrade: Conveyors

Upgrade: Dryers

Upgrade: Furnace/Kilns

Upgrade: Gas compression equipment

Upgrade: Other process heating equipment

Upgrade: Ovens

Upgrade: Thermal electricity generation

Upgrade: Various industrial systems

The data for individual measures was aggregated by “Technology/ process” and “Fuel category”

across the major industry classifications – “Mining” and “Industry”. Subsector groupings associated

with manufacturing of metals was excluded as they largely reflect energy used by the aluminium

smelters which is not covered by the VEET. The final set of aggregated measures described the

expected savings as a percentage of total electricity or gas used at a facility and the average capital

cost per GJ of energy saved for particular technology or process. The aggregation did not include

measures with paybacks in the 0-2 year range as reported by ClimateWorks as they are likely to be

taken up by businesses without any additional incentives afforded through the VEET.

The model also estimated the energy used by the large industrial sector. Information on energy use in

Australian categorised by fuel type and by ANZSIC sector is available from the Office of the Chief

Economist13. The energy used in Victoria for each ANZSIC sector was estimated by assuming the

13

2014 energy statistics data (http://www.industry.gov.au/industry/Office-of-the-Chief-Economist/Publications/Pages/Australianenergy-statistics.aspx#)

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

15

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

fraction of energy used by each ANZIC sector in Victoria is the same as the corresponding national

fraction. The electricity and natural gas consumed by Victoria was also available in the 2014 energy

statistics.

Work on the NESI yielded the fraction of each fuel type used by large and SME business. This data

was used to estimate the electricity and gas used by large industry and large mining in Victoria. These

values were within 10% of the reported EREP amounts, which suggests that the majority of facilities

obligated under the EREP program are also the sites that report under NGER. The requirement to

report under NGER was the criteria to separate large businesses from SMEs in the NESI dataset

modelling.

An example of a specific measure by sub-sector and fuel type is outlined below in Table 7.

Table 7: Extract from ClimateWorks database

Item

Typical value

Subsector grouping

C11 - Food Product Manufacturing

Technology/ process

Dryers

Fuel category

Gas

Payback range

>4 years

Energy savings (% subsector

grouping - fuel category energy use)

4.23%

Capital costs ($/GJ)

$41.60

Appendix A provides additional information about the industrial measures including the amount of

energy they save and the cost to implement the measures.

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

16

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

5.

Outcomes: Results of the modelling

5.1.

Business sector results

Figure 5 to Figure 7 below show the results of the modelling of the business sector of the VEET

scheme. It considers three or five year timeframes of the VEET scheme, and forecasts the take-up of

certificates at varying certificate prices. Note that neither Figure 5 nor Figure 6 include the possible

generation of certificates from large business (as outlined in section 4.2).

Figure 5: Three year target with large business exclusion

Figure 6: Five year target with large business exclusion

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

17

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Figure 7 below includes large business in the modelling of total certificates created leading to the

higher level of certificates created, particularly in years 2018 and 2019. The approach taken to include

large industrial sector energy users is outlined further in section 4.2.

Figure 7: Five year target without large business exclusion

As demonstrated in both Figure 6 and Figure 7 some drop off is assumed at a higher certificate price.

This results from a higher certificate price driving increased participation in the earlier years, and

limiting the pool of opportunity for participation in the later years. This is particularly so where large

business’ are excluded. As Figure 6 demonstrates there is a levelling off after a certain certificate

price.

5.2.

Results for certificate price scenarios

The generation of certificates for each specific measure was based on two different scenarios – a

three year scenario and a five year scenario – with yearly certificate prices modelled against three

different VEET targets. Table 8 and Table 9 below consider the certificate prices that were used to

model the results in each scenario against each certificate target.

Table 8: Three year scenario certificate prices

Certificate Target

2016

2017

2018

5,400,000

19.53

30.73

27.04

5,800,000

23.30

37.04

28.56

6,200,000

30.77

44.15

30.26

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

18

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Table 9: Five year scenario certificate prices

Certificate Target

2016

2017

2018

2019

2020

5,400,000

19.53

30.73

27.04

25.86

51.30

5,800,000

23.30

37.04

28.56

28.41

54.47

6,200,000

30.77

44.15

30.26

30.75

57.65

Based on these certificates the following total certificate prices were generated. These totals

incorporate all measures and assumptions outlined within this Report.

Table 10 provides an overview of the total certificates created at each certificate target over the three

year VEET scenario.

Table 10: Certificates generated in the three year VEET scenario

Certificate Target

2016

2017

2018

5,400,000

1,139,016

2,257,823

2,937,394

5,800,000

1,169,056

2,400,504

3,335,132

6,200,000

1,195,707

2,582,105

3,402,405

Table 11 provides an overview of the total certificates created at each certificate target over the five

year VEET scenario. Note that the remainder of the certificates generated in each of the scenarios

outlined in Table 10 and Table 11 arise from the residential sector.

Table 11: Certificates generated in five year VEET scenario

Certificate Target

2016

2017

2018

2019

2020

5,400,000

1,139,016

2,257,823

2,937,394

3,136,295

4,074,539

5,800,000

1,169,056

2,400,504

3,335,132

3,581,499

3,533,575

6,200,000

1,195,707

2,582,105

3,402,405

3,699,273

3,767,856

Table 12 gives a complete breakdown of certificated generated for each measure over the five year

period for an indicative target of 5.4 million certificates.

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

19

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Table 12: Certificates generated by measure in 5.4 million certificates, five year VEET scenario14

Measure Name

Sector

End use

2016

2017

2018

2019

2020

Air Compressors: Improved operation of

compressed air systems

SME Industrial

Air Compressors

0

0

0

0

0

Appliances & Equipment: Variable speed drives

SME Industrial

Appliances and equipment

2,930

8,723

6,791

9,197

179,859

Appliances & Equipment: Replace a MEPS

compliant motor with a HE motor

Shopping Centre

Appliances and equipment

3,793

3,793

3,793

3,793

3,793

Appliances & Equipment: Replace a MEPS

compliant motor with a HE motor

Warehouse (NR)

Appliances and equipment

2,630

2,630

2,630

2,630

2,630

Boilers, Furnaces & Ovens: Upgrade

Hospitality

Boilers, furnaces and ovens

0

319

246

359

11,482

Boilers, furnaces and ovens: Replace boiler

Large commercial

Boilers, furnaces and ovens

52,354

56,867

51,282

13,263

0

Building shell: Window treatment

Large commercial

Building shell upgrade

1

1

2

4

331

HVAC: HVAC controls

Hospitality

HVAC

0

0

0

0

0

HVAC: HVAC controls

SME Industrial

HVAC

0

0

0

0

0

HVAC: High efficiency stand alone AC

SME

HVAC

0

0

0

0

0

HVAC: High efficiency stand alone AC

Large office

HVAC

0

0

0

0

0

HVAC: High efficiency stand alone AC

Shopping Centre

HVAC

0

0

0

0

0

HVAC: HVAC controls

Large commercial

HVAC

0

27,334

35,821

17,783

0

14

In the context of this Report “small offices” and “small trade” captures tenancies in large commercial buildings and large shopping centres

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

20

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Measure Name

Sector

End use

2016

2017

2018

2019

2020

HVAC: Replace a MEPS compliant motor with a

HE motor

University / TAFE

HVAC

2,926

2,926

2,926

2,926

2,926

HVAC: Replace cooling tower

Large office

HVAC

0

0

0

0

0

HVAC: Upgrade chiller

Large commercial

HVAC

0

0

0

0

0

HVAC: Variable speed drives and control for fans

Large commercial

HVAC

37,466

124,038

120,934

28,948

0

Lighting upgrade

SME

Lighting

748,040

1,513,131

1,918,612

1,958,276

1,392,327

Lighting upgrade

Large commercial

Lighting

0

0

0

0

0

Pumps: Upgrade to HE pumps

Hospitality

Pumps

0

9,761

9,337

7,351

9,761

Pumps: Upgrade to HE pumps

SME Industrial

Pumps

133,575

133,575

133,575

133,575

133,575

Pumps: Variable speed drives for pumps

Hospital

Pumps

0

0

0

0

0

Pumps: Variable speed drives for pumps

SME Industrial

Pumps

77,181

158,295

132,213

141,710

158,953

Refrigeration: RDC upgrade

Hospitality

Refrigeration

21,120

21,120

21,120

21,120

21,120

Refrigeration: RDC upgrade

Small trade

Refrigeration

32,871

32,871

32,871

32,871

32,871

Refrigeration: HE commercial refrigeration

Large retail (R)

Refrigeration

5,576

8,254

7,193

4,855

2,126

Refrigeration: HE commercial refrigeration

SME Industrial

Refrigeration

6,574

11,324

10,333

14,745

51,917

Refrigeration: Replace a low efficiency fan motor

with an electronically commutated motor

Large retail (R)

Refrigeration

11,979

24,062

40,173

3,818

0

Ventilation / fans: Car park ventilation control

Large office

Ventilation and fans

0

0

0

0

0

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

21

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Measure Name

Sector

End use

2016

2017

2018

2019

2020

Ventilation / Fans: Improve fan efficiency

SME

Ventilation and fans

0

0

0

0

0

Water heating: Solar or heat pump water heater

Hospital

Water heating

0

2

1

3

1,711

Water heating: Solar or heat pump water heater

Large retail (R)

Water heating

0

1

0

1

595

Upgrade: Co-generation or Tri-generation

Industry

Co-generation or Tri-generation

0

0

0

0

0

Upgrade: Compressed air systems

Industry

Compressed air systems

0

0

0

0

0

Upgrade: Conveyors

Industry

Conveyors

0

0

7

20

16

Upgrade: Furnace/Kilns

Industry

Furnace/Kilns

0

0

6

53

0

Upgrade: Gas compression equipment

Industry

Gas compression equipment

0

0

0

6,147

0

Upgrade: IT, communications and other

electronic equipment

Industry

IT, communications and other

electronic equipment

0

0

0

0

3

Upgrade: Lighting systems

Industry

Lighting systems

0

0

0

0

0

Upgrade: Non-transport machinery

Industry

Non-transport machinery

0

7

7

13

268

Upgrade: Other Building services

Industry

Other Building services

0

9,922

55,158

138,227

68,859

Upgrade: Other equipment

Industry

Other equipment

0

9

57

64

147

Upgrade: Pumping systems

Industry

Pumping systems

0

4,766

19,257

21,719

61,626

Upgrade: Refrigeration

Industry

Refrigeration

0

7

7

18

1,313

Upgrade: Stationary materials handling systems

Industry

Stationary materials handling

systems

0

0

0

0

0

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

22

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Measure Name

Sector

End use

2016

2017

2018

2019

2020

Upgrade: Various industrial systems

Industry

Various industrial systems

0

40,998

38,147

60,835

855,519

Upgrade: Ventilation systems, fans and blowers

Industry

Ventilation systems, fans and

blowers

0

523

6,409

10,152

14,660

Upgrade: Waste treatment, disposal and

remediation

Industry

Waste treatment, disposal and

remediation

0

8

8

11

107

Upgrade: Comminution (crushing and grinding)

and blasting systems

Mining

Comminution (crushing and

grinding) and blasting systems

0

0

0

4,026

0

Upgrade: Compressed air systems

Mining

Compressed air systems

0

0

0

4,015

0

Upgrade: Conveyors

Mining

Conveyors

0

5

5

12

265

Upgrade: Lighting systems

Mining

Lighting systems

0

9

35

45

85

Upgrade: Other Building services

Mining

Other Building services

0

7,108

29,528

35,558

73,519

Upgrade: Other equipment

Mining

Other equipment

0

0

0

0

0

Upgrade: Pumping systems

Mining

Pumping systems

0

0

0

0

0

Upgrade: Stationary materials handling systems

Mining

Stationary materials handling

systems

0

0

0

0

0

Upgrade: Boiler systems

Industry

Boiler systems

0

0

155,370

395,601

838,602

Upgrade: Dryers

Industry

Dryers

0

19,353

58,171

39,633

94,291

Upgrade: Furnace/Kilns

Industry

Furnace/Kilns

0

0

0

0

0

Upgrade: Other process heating equipment

Industry

Other process heating

equipment

0

0

0

0

0

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

23

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Measure Name

Sector

End use

2016

2017

2018

2019

2020

Upgrade: Ovens

Industry

Ovens

0

0

0

0

0

Upgrade: Various industrial systems

Industry

Various industrial systems

0

36,060

45,336

22,905

59,248

Upgrade: Boiler systems

Mining

Boiler systems

0

0

0

0

0

Upgrade: Conveyors

Mining

Conveyors

0

0

0

0

0

Upgrade: Furnace/Kilns

Mining

Furnace/Kilns

0

22

32

13

34

Upgrade: Gas compression equipment

Mining

Gas compression equipment

0

0

0

0

0

Upgrade: Other process heating equipment

Mining

Other process heating

equipment

0

0

0

0

0

Upgrade: Thermal electricity generation

Mining

Thermal electricity generation

0

0

0

0

0

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

24

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Appendix A.

Key assumptions

Retail energy prices

These feed directly into the payback calculation that determines the take-up of measures, and a small

change in the retail price can have a significant impact on the cost effectiveness of measures e.g. a

10% change in the electricity price to SMEs is roughly equivalent to a change in certificate price of

$20/tonne. The electricity prices must be marginal prices, representing the cost of the electricity that is

actually saved due to the measures.

The retail prices out to 2024 in the model are in Table 13.

Table 13: Model retail energy prices

Sector and fuel

2016

2017

2018

2019

2020

2021

2022

2023

2024

Franchise (SME) customers

Electricity ($/MWh)

207.22

200.63

203.88

209.36

214.39

210.79

214.28

217.49

221.29

Natural gas ($/GJ)

11.17

11.98

12.42

11.95

11.07

10.27

9.55

9.59

9.62

Contract (large) customers

Electricity ($/MWh)

158.52

151.90

154.85

159.95

164.63

160.91

164.08

166.98

170.45

Natural gas ($/GJ)

10.77

11.58

12.02

11.55

10.67

9.87

9.15

9.19

9.22

Savings and cost of lighting upgrades

These are expected to be the measures with the highest uptake in the SME and commercial sectors,

and so accurate modelling of these measures will increase confidence in the outcomes of the

modelling. Key data items are the cost of implementation per unit of energy saved, savings per

instance of a measure and the number of measures that can be implemented.

Implementation costs

Energetics analysed the actual implementation cost and savings achieved for a large number of

commercial lighting upgrades for confidential and non-confidential sources. We found that

implementation costs ranged from $32/GJ saved up to $278/GJ saved. Averages, weighted by the

number and size of projects were $175/GJ for the SME sector and $135/GJ for the large commercial

sector. These results reflected a typical basket of lighting measures that are actually being

implemented in the respective sectors.

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

25

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

For comparison, the simple average of lighting measures in the earlier VEET modelling was $156/GJ.

The NSW OEH recently published a technology report on energy efficient lighting 15. This report

included typical savings and costs for commercial lighting upgrades. The cost of various low cost

upgrades ranged for $64/GJ (replacing a 60W dichroic halogen lamp with a 25W IRC lamp) through to

$237/GJ (replacing a twin 36 W T8 recessed linear fluorescent luminaire with a single 36 W T8

reflector). The simple average of these lighting upgrades was around $150/GJ.

These comparisons suggest that using values of $175/GJ for the SME sector and $135/GJ for the

large commercial sector is not unreasonable.

Savings per instance of a measure

The savings per instance of a measure is required to determine the number of instances that can be

implemented. The average savings per installation across a range of actual lighting upgrades in our

databases is in Table 14.

Table 14: Savings per lighting installation

Sector

Large commercial

SME

Average use per

site (MWh)

Savings as % of site

consumption

Savings/instance

(MWh)

5000

2.71%

136

86

8.33%

7.1

The OEH technology report on energy efficient lighting quotes the annual energy savings for the

upgrading of 100 lights of different types, with the annual savings ranging from 5.2 MWh to 80 MWh.

Lighting upgrades typical of SMEs saved the order of 10 MWh per 100 lights. The figure of 7.1 MWh

per instance in the table implies that a typical SME lighting upgrade involves around 70 to 100 lights.

This seems reasonable.

The figure of 5000 MWh for large commercial sites was derived from values reported in the NESI

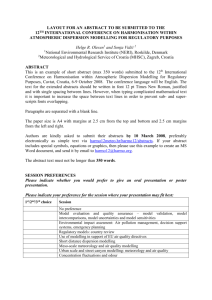

dataset. The following chart was taken from the NESI Consultants Report Webpage16 (refer Figure 8).

15

http://www.environment.nsw.gov.au/resources/business/140017-energy-efficient-lighting-tech-rpt.pdf (Accessed March 2015)

16

http://www.industry.gov.au/Energy/Documents/energy-efficiency/energysavings/consultant/Commercial_and_SME_EnergyEfficiencyDataReport.pdf (Accessed March 2015).

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

26

16,000

14,000

13,676

12,000

10,000

8,479

8,000

5,439

6,000

5,265

5,179

3,440

4,000

3,161

2,729

1,908

2,000

1,045

0

School

Large retail

(NR)

Shopping centre

Warehouse

(NR)

Large retail (R)

Warehouse (R)

Large office

CBD Hotel / SA

Hospital

University /

Tertiary

Annual electricity consumption (MWh)

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Figure 8: Large commercial site energy consumption

Potential instances of lighting upgrades

The potential number of instances of lighting upgrades comes from a consideration of the energy used

by the SME and large commercial sectors. Estimates of the energy used by these sectors come from

the NESI dataset modelling, refer Table 15.

Table 15: Energy consumption by building class

Energetics Building Class

Electricity consumption by

building class in Victoria (PJ)

Sector

CBD Hotel / SA

0.76

Large Com

School

0.98

Large Com

University / Tertiary

2.70

Large Com

Hospital

1.39

Large Com

Large retail (R)

3.57

Large Com

Large Retail (NR)

1.25

Large Com

Warehouse (R)

0.49

Large Com

Warehouse (NR)

2.13

Large Com

Large office

3.96

Large Com

Shopping Centre

2.75

Large Com

Street lighting

1.24

Large Com

© Energetics Pty Ltd 2016

123192\Documents\1948791\1

27

BUSINESS SECTOR ENERGY EFFICIENCY MODELLING

Energetics Building Class

Electricity consumption by

building class in Victoria (PJ)

Sector

Non-CBD hotel/hostel/resort

2.05

SME

Restaurant

5.53

SME

Small retailing facilities

8.13

SME

Small office

17.81

SME

SME Manufacturing

22.12

SME

0

SME

SME Industrial (other / NMF)

Knowing the energy used by the sectors in Victoria and the average energy used per site means that

the number of potential sites can be estimated. Many of the sites will already have undertaken lighting

upgrades and so must be removed from the set of potential sites. Based on analysis done during the

NESI dataset modelling, we estimated that 40% of large buildings and 30% of small buildings already

had upgraded lights.

The derivation of the potential for commercial lighting upgrades in Victoria is in Table 16.

Table 16: Derivation for commercial lighting upgrades in Victoria

Sector

Total electricity

use in Victoria

(GWh)

Average

use per site

(MWh)

Estimated

penetration to

date

Technical

potential

(Instances)

Potential

certificates

Large commercial

5,893

5000

40%

710

966,000

SME

15,455

86

30%

126300

9,016,000

The final column in the figure is the number of certificates that would be generated if all possible

measures were implemented. It assumes a 10 year lifetime for the measures. The uptake of

commercial lighting in the ESS generated around 1 million certificates in the first year, rising to 3

million in the third year. Assuming that the market in Victoria is similar to that in NSW, we constrained

the uptake in the first three years of the modelled scheme to 10%, 20% and 30% of the maximum.