Standard Calibration Procedure

advertisement

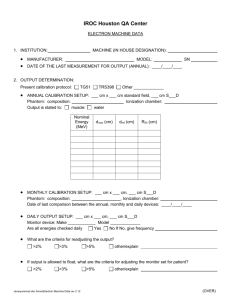

Standard Calibration Procedure Test Subject: API Plug and Ring Procedure #: QSCP-95 Revision #: 2.0 Date: 5/13/2012 Approval: James Cagle 1.0 Purpose 1.1 2.0 3.0 4.0 To establish a standard procedure for calibration of API Plugs and Rings. Requirements 2.1 The calibration laboratory shall be furnished with all items of equipment (including reference materials) required for the correct performance of calibrations and tests. In those cases where the laboratory needs to use equipment outside its permanent control, it shall ensure that the relevant requirements of this section are met. 2.2 All measuring and testing equipment having an effect on the accuracy or validity of calibrations or tests shall be calibrated and/or verified before being put into service. The laboratory shall have an established program for the calibration and verification of its measuring and test equipment. The program will ensure the recall or removal from service of any standard or equipment that has exceeded its calibration interval or is otherwise judged to be unreliable. 2.3 The laboratory shall use appropriate methods and procedures for all calibrations and tests and related activities within its responsibility (including sampling, handling, transport and storage, preparation of items, estimation of uncertainty of measurement and analysis of calibration and/or test data). They shall be consistent with the accuracy required and with any standard specifications relevant to the calibrations or tests concerned. 2.4 The laboratory shall have documented instructions on the use and operation of all relevant equipment, on the handling and preparation of items, and for calibration and/or testing, where the absence of such instructions could jeopardize the calibrations or tests. All instructions, standards, manuals and reference data relevant to the work of the laboratory shall be maintained up-to-date and be readily available to the staff. Referenced Documents 3.1 ISO 17025 3.2 NIST Handbook 150 3.3 NIST Technical Note 1297 3.4 ANSI/NCSL Z540-1 3.5 ANSI/API Spec 7-2, First Edition Materials Required 4.1 Cleaned and inspected Master Gages. Page 1 of 4 QualiCal, LLC Quality Management System Calibration Procedures Standard Calibration Procedure Test Subject: API Plug and Ring Procedure #: QSCP-95 Revision #: 2.0 Date: 5/13/2012 Approval: James Cagle 4.2 4.3 4.4 4.5 4.6 4.7 4.8 4.9 4.10 4.11 5.0 Lubricating Oil Thinner Zep ID Cleaning Solution Lint free cloths Hi-Cal 150 Height Gage for measuring standoff. Granite Surface Plate Torque Hammer and Weights Vice/Sleeve and securing peg Laboratory Form QAF-022, Rev. 2.0 Gagemaker Certifi Software Tolerance / Measurement Range / Measurement Uncertainties 5.1 Tolerance will be as per API Gaging Practice Handbook, and OEM Technical Brief Doc 100 REV. B. and ANSI/API Specification 7-2, First Edition. See following; o o o o Master Ring mated to Master Plug Master Ring mated to Working Plug Master Plug mated to Working Ring Working Ring mated to Working Plug = +0.0005 / -0.003 = +0.004 / -0.004 = +0.004 / -0.004 = +0.0005 / -0.003 For EUE (UPTBG) gages the tolerances will be as per API Specification 5B, see following: o o o o 5.2 Master Ring mated to Master Plug Master Ring mated to Working Plug Master Plug mated to Working Ring Working Ring mated to Working Plug Torque Hammer Weight Selection: Hammer Weight 2lb 3lb 4lb 6.0 = Reference Only = +0.025 / -0.025 = +0.025 / -0.025 = +0.0125 / -0.0195 Size 2 3/8” 2 7/8” 3 ½” 4” 4 ½” 6 5/8” Thread REG, EUE EUE, REG, IF EUE, REG, IF IF REG, IF REG, FH Procedure 6.1 6.2 Working Gages shall be placed in thinner for a period of no less than 2 hours to help with removal of any oils and grime build up. Once removed, they will be cleaned using a lint free cloth and ZEP ID cleaning solution, cleaning between each and every thread. Page 2 of 4 QualiCal, LLC Quality Management System Calibration Procedures Standard Calibration Procedure Test Subject: API Plug and Ring Procedure #: QSCP-95 Revision #: 2.0 Date: 5/13/2012 Approval: James Cagle 6.3 6.4 6.5 6.6 6.7 6.8 6.9 6.10 6.11 6.12 6.13 6.14 7.0 Records 7.1 8.0 Apply a small amount of light oil to the inside of the ring and turn the ring to evenly coat the inside. Make up the gages, hand tight and sit on granite block for at least 1 hour. After the 1 hour period insert the made up gage handle into appropriate sleeve/vise and insert securing peg through hole of handle. Gage should not move. Choose appropriate weight for the torque hammer (use the above table in 5.2). Insert the torque hammer into hole on ring and allow the weight to drop (using gravity for force only), for 12 drops. Remove gages from vise. Sit gages on granite block and using the height gage measure the working plug’s standoff from the working ring. Do this in 4 places around the gage and Record results, working out the “mean” value of the 4 readings. Do the same procedure using mated master gages, then master plug mated with master ring and so on until the form is complete. Check results against allowable tolerances. If a pass is recorded continue with documentation. If a fail is recorded work will have to be conducted on the gages (either shimming or grinding face plate). Clean Masters and store in Lab. Print all documentation, and prepare Calibration Certificate in CERTIFI. A copy of the master gage’s Calibration Certificate needs to be included with QualiCal certificate. QA Manager to review all documentation. Place Calibration sticker on equipment. Prepare all collection/shipment documents and contact customer. Place M&TE in outgoing area with customer name clearly visible. The records for item requiring calibration shall include an individual record of calibration or verification, or other means of control. This record shall provide a description or identification of the item, calibration interval, date calibrated, identification of the calibration source, calibration results (data and/or condition status) and calibration action taken (adjusted, repaired, new value assigned, de-rated, etc.). Calibration Status 8.1 Item shall be labeled to indicate calibration or verification status. The label shall identify specific date calibrated (date, month, year, Julian date, or equivalent) and the specific calibration due date or usage equivalent. Items not calibrated to their full capability or which have other limitations of use, shall be labeled or otherwise identified as to the limitations. When it is impractical to apply a label directly to an item, the label may be affixed to the instrument container or some other suitable means may be used to reflect calibration status. Tamper resistant seals are affixed to operator accessible controls or adjustments, which if moved will invalidate the calibration. The quality system shall provide instructions for disposition of equipment with broken tamper resistant seals. Page 3 of 4 QualiCal, LLC Quality Management System Calibration Procedures Standard Calibration Procedure Test Subject: API Plug and Ring Procedure #: QSCP-95 Revision #: 2.0 Date: 5/13/2012 Approval: James Cagle 9.0 Storage and Handling 9.1 Items shall be handled, stored, and transported in a manner which shall not adversely affect the calibration or condition of the equipment. Page 4 of 4 QualiCal, LLC Quality Management System Calibration Procedures