P0415/13A

Decision Document for Permit Number P0415/13A (Francis Horisk)

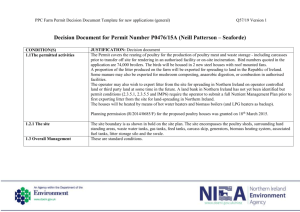

CONDITION(S)

1.1The permitted activities

1.2.1 The site

1.3 Overall Management

1.4 Pre-operation conditions

JUSTIFICATION

The Permit covers the rearing of poultry for the production of poultry meat and waste storage - including carcasses prior to transfer off site for rendering in an authorised facility. Bird numbers quoted in the application are 70,000 broilers. The birds will be housed in 2 new houses of steel construction with high speed roof mounted fans.

A proportion of the litter produced on the farm will be exported for spreading to land in the Republic of Ireland.

Some manure may also be exported for mushroom composting or combustion in authorised facilities.

The operator may also wish to land-spread litter in Northern Ireland at some time in the future. A land bank in

Northern Ireland has not yet been identified but permit conditions require the operator to submit a full Nutrient

Management Plan prior to first exporting litter for land-spreading in Northern Ireland.

The houses will be heated by means of hot water heaters and 2 LPG boilers. At some time in the future the operator may install biomass boilers and permit conditions have been included to control emissions from this activity.

The site boundary is as shown in bold on the site plan. The site encompasses the poultry sheds, surrounding hard standing areas, waste water tanks, gas tanks, feed tanks, carcass skip, generators & associated fuel tanks. The swale will be constructed just outside the site boundary. IMP7 requires an amended site plan to be submitted prior to installation of a biomass heating system.

These are standard conditions.

Condition 1.4.1 requires the operator to inform the Chief Inspector 14 days prior to the 40,000 bird capacity being exceeded and therefore the permit becoming effective. Pre-Operation Condition 1.4.2 requires a suitable wash water tank to be constructed prior to the installation being stocked above 40,000 birds. Pre-Operation Condition 1.4.3 has been added to ensure that a separate drainage system is provided to collect wash water from the houses and drain it directly to the waste water tanks without relying on a diverter. Pre-Operation Condition 1.4.4 has been added to ensure that the yard areas associated with the poultry houses are suitably designed and contained with all heavily contaminated yard drainage directed to waste water tank(s) and all lightly contaminated site drainage directed to swale. Pre-Operation Condition 1.4.5 requires the ventilation system for the proposed new poultry house 2 to be to a design that ensures the exhaust velocity from the fan vents matches that assumed in the air dispersion assessment

“Air Quality Impact Assessment – F. Horisk Facility – 28 March 2012” submitted with the application.

Condition 1.4.6 requires the operator to provide collision protection for LPG storage tanks. Condition 1.4.7 ensures that suitable bunding is provided for the generator and associated fuel storage. Condition 1.4.8 ensures that a suitable store is provided for pesticides and veterinary medicines and condition 1.4.9 ensures that there is sufficient metering

of all water used on the site. Condition 1.4.10 requires the operator to construct a swale to treat the lightly contaminated drainage from the site.

1.5 Off site conditions There are no off-site conditions.

1.6 Minor operational changes These are standard conditions.

2.1 Farm Management

Techniques

These are standard conditions. IMP4 has been added to ensure appropriate IPPC training is completed within 12 months of the effective date of the permit or as soon as a course becomes available.

2.2.1 – 2.2.3 Raw Materials and

Water

These are standard conditions. Pre-Operation Condition 1.4.9 requires water meters to be installed to enable water usage of specific activities to be monitored prior to the site exceeding 40,000 birds. Improvement Condition IMP1 has been added to ensure that an audit of water use is undertaken within 3 years of the effective date of the permit.

2.3.1 Feed delivery, milling and preparation

These are standard conditions. Feed will be blown into fully covered and sealed bins.

2.3.2 Storage of agricultural fuel oils and other materials

These are standard conditions. Pre-Operation condition 1.4.6 has been added to ensure that suitable collision protection is provided for any gas tanks on site. Pre-Operation condition 1.4.7 has been added to ensure that the generator installation and any fuel tanks associated with the generator are suitably bunded to contain any potential leaks or spills of fuel, coolant or lubricant. Pre-Operation condition 1.4.8 has been added to ensure that all chemicals are correctly stored.

2.3.3 Minimising emissions from housing

2.3.4 Litter storage

2.3.5 Litter spreading

Pre-Operation Condition 1.4.10 requires a swale to be constructed for the treatment of lightly contaminated site runoff. Pre-Operation Condition 1.4.2 requires an underground tank to be installed to collect poultry house wash water and heavily contaminated site run-off associated with the new poultry house. Pre-Operation Condition 1.4.3 has been added to ensure that a separate drainage system is provided to collect wash water from the houses and drain it directly to the waste water tanks without relying on a diverter. Pre-Operation Condition 1.4.4 has been added to ensure that the yard areas associated with the two poultry houses are contained with all heavily contaminated yard drainage directed to waste water tank(s) and all lightly contaminated site drainage directed to swale.

Litter will be loaded directly from the poultry sheds onto covered trailers and removed from site for export to the

Republic of Ireland for land-spreading, mushroom composting, for combustion in an authorised facility or landspreading in Northern Ireland in accordance with a nutrient management plan.

Litter will be exported from the site for use in mushroom composting, combustion in authorised facilities or landspreading in the Republic of Ireland. The relevant regulatory authority (Department of Agriculture, Food and

Marine, DAFM) in the ROI has been notified in writing of the proposed export of litter from the poultry farm.

Relevant legislation (Animal Veterinary Health Certificates, TRACES etc) and record requirements will be complied

with.

The operator may also wish to land-spread litter in Northern Ireland at some time in the future. A land bank in

Northern Ireland has not yet been identified but permit conditions (2.3.5.1 and IMP6) require the operator to submit a full Nutrient Management Plan prior to first exporting litter for land-spreading in Northern Ireland.

The operator estimates the litter produced on the site to be up to 590T per year.

2.3.6 Odour These are standard conditions.

The closest third party dwelling is approximately 230m east of the poultry site. The independent odour assessment submitted with the application indicates that the current odour guideline value of 3OU/m3 98 th percentile 1 hour value (as set out in the Environment Agency H4 Odour Management Guidance, March 2011) is not expected to be exceeded at any of the closest existing 3 rd party dwellings. Check odour screening carried out by NIEA indicates that the odour guideline value of 3 OU/m3 is unlikely to be breached at any of the third party dwellings in the area.

The installation and operation of biomass boilers should help improve the quality of the litter and reduce emissions from the houses (ammonia, odour). The biomass heating system is an indirect heating system (hot water) which will reduce production of CO

2

and water vapour within the houses.

Measures described in the odour management plan provided with the application shall be implemented. A satisfactory complaints procedure was submitted with the odour management plan. It is considered that people should not be unduly affected by odour emissions from the poultry unit provided the conditions set out in the permit are strictly adhered to.

2.3.7 Operation of biomass boiler The poultry houses will be heated by mean of hot water heaters. The hot water will initially be provided by means of

LPG boilers. However, at sometime in the future the operator may install a biomass heating system. In preparation for this conditions (2.3.7.1 to 2.3.7.5) and improvement items (IMP7 and IMP8) have been added requiring the operator to submit details of the proposals to install a biomass heating system and to ensure correct installation, maintenance and operation of the boilers and that appropriate biomass fuel is used.

The installation and operation of biomass boilers should help improve the quality of the litter and reduce emissions from the houses (ammonia, odour). The biomass heating system is an indirect heating system (hot water) which will reduce production of CO

2

and water vapour within the houses.

2.4 Discharges to Groundwater No emissions from the permitted installation shall give rise to the introduction into groundwater of any hazardous substance or non hazardous pollutants.

2.5 Waste minimisation These are standard conditions. IMP2 has been added to ensure a waste minimisation audit is undertaken within 3

2.5.2 Disposal of carcasses years of the effective date of the permit.

These are standard conditions. Carcasses will be disposed of to an approved rendering plant. On site incineration in a

2.6 Energy Use

DARD approved incinerator is also included an option.

These are standard conditions. A number of features have been incorporated into the design of the poultry houses to reduce the energy consumption e.g. high levels of insulation in the walls and roof. The operator does not participate in a Climate Change Levy Agreement. Therefore, IMP3 has been added to ensure an Energy Audit is carried out within 3 years of the effective date of the permit.

These are standard conditions. The plan provided with the application was considered satisfactory.

2.7 Accident Prevention and

Management

2.8 Noise and vibration

2.9.1 Recording

These are standard conditions. A satisfactory noise management plan including complaints procedure was provided with the application. The closest third party dwelling is approximately 230m east of the poultry site.

Significant noise impacts are not considered likely from this installation at these distances provided permit conditions are adhered to. Permit condition 2.8.2 requires deliveries of feed, apart from emergencies, to be restricted to between the hours of 0700 and 2200 Monday to Saturday, or as otherwise agreed in writing with the Chief

Inspector.

These are standard conditions stating the requirements for recording and monitoring

2.9.2 Emissions and Monitoring No specific controls are required on either emissions to air or water.

2.10 Decommissioning

IMPROVEMENT

PROGRAMME

CONSULTEE COMMENTS

Public Health Agency

These are standard conditions. A satisfactory site closure plan was submitted with the application.

IMP1 has been added to reinforce the need for a water audit to be undertaken within 36 months of the effective date of the permit. IMP2 requires a waste minimisation audit to be undertaken within 36 months of the effective date of the permit. IMP3 ensures that the operator will either become part of a CCLA or submit an energy audit within 36 months. IMP4 will ensure that the operator, or another responsible person working on the installation, will complete training in Pollution Prevention and Control. IMP5 requires the operator to carry out and submit a review of the site drainage plan after the site is constructed. IMP6 requires the operator to submit a Nutrient Management Plan for land-spreading on any land in Northern Ireland at least 1 month prior to land-spreading. IMP7 and IMP8 control the emissions from biomass boilers which may be installed at some time in the future. IMP9 requires the operator to submit evidence that the incinerator complies with the Animal By-Product requirements.

Comments and measures in permit where applicable

No concerns were raised by The Public Health Agency.

District Council No concerns were raised by Omagh District Council. No further conditions are considered necessary.

Food Standards Agency (FSA) The FSA states that a well managed poultry production facility should present a very low risk of compromising the safety of the food chain and concludes that provided the operator complies with relevant technical guidance it is unlikely there will be any unacceptable effects on the human food chain as a result of the operations at the facility.

NIEA Conservation,

Designations and Protection

(NIEA-CDP)

In their response NIEA-CDP stated that the development is unlikely to significantly affect the features of any designated site within 7.5Km of the installation. The closest habitat is Deroran Bog SAC, ASSI at 1.2 Kms.

The Air Quality and Odour Study submitted with the application predicts that the ammonia impact from the proposed farm on the Deroran Bog SAC habitat will be 5.9% of the critical level for that habitats. Use of the

IMPACTS ON THE

ENVIRONMENT

AQMAU Ammonia Screening Tool (v4) agrees with these predictions. This impact is above the threshold (4%) above which an in-combination assessment would be required with other PPC installations in the area (as set out in the Environment Agency guidance document “Assessing the impact of ammonia releases from new and expanding intensive farms on nature conservation sites” – August 2013). When this in-combination assessment is carried out to include another proposed PPC poultry farm in the area the total impact is predicted to be 12% of the critical level which is not considered significant (i.e. less than 20% process contribution from the poultry farms).

European sites

The closest third party dwelling is approximately 230m east of the poultry site.

At these distances, significant impacts from odour and dust emissions from a poultry site of this size are not expected. The results of independent and NIEA in-house air impact assessments indicate that odour impacts from the site will be acceptable at all existing 3 dwellings. rd party dwellings and that dust impacts will be acceptable at all existing

The closest European sites is Deroran Bog SAC at 1.2 Kms. The independent ammonia impact assessment submitted with the application indicates that the annual mean NH3 concentration from the farm at this distance is predicted to be approx. 0.059ug/m3 i.e. approx. 5.9% of the annual mean critical level for this habitat. Therefore, as the impacts are predicted to be greater than 4% of the critical level for the habitat an in-combination assessment would be required with other PPC installations in the area (as set out in the Environment Agency guidance document

“Assessing the impact of ammonia releases from new and expanding intensive farms on nature conservation sites”).

When this in-combination assessment is carried out the total impact is predicted to be 12% of the critical level which is not considered significant (i.e. less than 20% process contribution from the poultry farms). The independent

ASSIs results submitted are backed up by in-house ammonia assessment carried out by IPRI using the AQMAU Ammonia

Screening Tool (V4).

The installation and operation of biomass boilers should help improve the quality of the litter and reduce emissions from the houses (ammonia, odour). The biomass heating system is an indirect heating system (hot water) which will reduce production of CO

2

and water vapour within the houses.

The closest ASSI is Deroran Bog ASSI at 1.2 Kms as discussed above.

Other environmental receptors Pre Operation Conditions have been included to ensure that all heavily contaminated yard drainage is diverted to waste water tanks to be disposed of in accordance with DARD CoGAP and that a swale is constructed to treat all lightly contaminated site drainage to minimise potential for pollution of ground and surface waters (pre-operation

1.4.10). Pre-Operation Conditions also require gas tanks and feed bins to be protected from collision; fuel to be adequately contained to minimise potential for surface or ground water pollution and chemicals to be adequately contained within a suitable store. All litter is removed from the installation in covered trailers for combustion, mushroom composting at authorised facilities or land-spreading. All carcasses are removed from the site for rendering at an approved rendering facility.

People Odour, Dust or Noise impacts are not expected to be significant at any existing dwellings provided permit conditions are adhered to. Satisfactory Noise and Odour Management Plans, including complaints procedures, were provided with the application. Noise, dust or odour concerns were not raised in any of the consultation responses received.

The closest third party dwelling is approximately 230m east of the poultry site. The independent odour assessment submitted with the application indicates that the current odour guideline value of 3OU/m3 98 th percentile 1 hour value (as set out in the Environment Agency H4 Odour Management Guidance, March 2011) is not expected to be exceeded at any of the closest existing 3 rd party dwellings. Check odour screening carried out by NIEA indicates that the odour guideline value of 3 OU/m3 is unlikely to be exceeded at any of the third party dwellings in the area.

People should therefore not be unduly affected by emissions from the poultry unit provided the conditions set out in the permit are strictly adhered to.

The installation and operation of biomass boilers should help improve the quality of the litter and reduce emissions from the houses (ammonia, odour). The biomass heating system is an indirect heating system (hot water) which will reduce production of CO

2

and water vapour within the houses.

Overall BAT demonstration. The application and additional information submitted indicates that appropriate measures have been taken to control the risk of pollution of waterways and that procedures are in place for the control of the handling/storage of waste materials on the site. The site is designed with a high level of containment. The releases to air from the poultry farm are predicted to be low. The installation is not a major energy user and is not likely to give reasonable cause for

Completed by

Date annoyance due to noise. The combination of measures proposed in the application and required by the permit is considered to represent the Best Available Techniques for an installation of this nature.

The determination of this application (P0415/13A) is that a permit should be granted.

NIEA – Industrial Pollution & Radiochemical Inspectorate

05 January 2015