Experiment No.2 Hydraulic Jump

advertisement

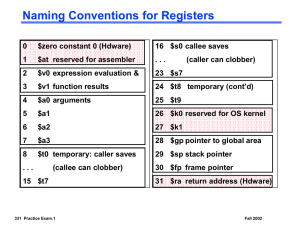

Experiment No.2 Hydraulic Jump A hydraulic jump is a phenomenon in the science of hydraulics which is frequently observed in open channel flow such as rivers and spillways. When liquid at high velocity discharges into a zone of lower velocity, a rather abrupt rise occurs in the liquid surface. The rapidly flowing liquid is abruptly slowed and increases in height, converting some of the flow's initial kinetic energy into an increase in potential energy, with some energy irreversibly lost through turbulence to heat. In an open channel flow, this manifests as the fast flow rapidly slowing and piling up on top of itself similar to how a shockwave forms. The phenomenon is dependent upon the initial fluid speed. If the initial speed of the fluid is below the critical speed, then no jump is possible. For initial flow speeds which are not significantly above the critical speed, the transition appears as an undulating wave. As the initial flow speed increases further, the transition becomes more abrupt, until at high enough speeds, the transition front will break and curl back upon itself. When this happens, the jump can be accompanied by violent turbulence, eddying, air entrainment, and surface undulations, or waves. 1Objective 1.1 To observe the characteristics of hydraulic jump and verify of flow. 1.2 To study and observe the relationship between the conjugate depths and Froude number. 2 Experimental apparatus The experiment apparatus includes of depth gauge, stop watch and sluice gate. Figure3.14 Depth gauge Figure3.15 Stop watch Figure3.16 Sluice gate 3 Theory The Hydraulic Jump is a phenomenon which occurs where the water flows from the super critical flow region to the sub-critical flow region that show as Figure 1. Figure1 Hydraulic Jump Phenomenon (Macmillan, 1966) Supercritical Flow ; Froude Number > 1 Critical Flow ; Froude Number = 1 Subcritical Flow ; Froude Number < 1 3.1 Basic principles The basic principles behind the momentum function are: Conservation of Momentum which states that the total momentum of a closed system of objects (which has no interactions with external agents) is constant. And Newton's laws of motion stating that the sum of the forces in a particular direction is equal to the mass times acceleration in that direction. ∑ 𝐹𝑥 = ∆(𝑚𝑎𝑥 ) ∑ 𝐹𝑥 = ∆𝑚 × (1) 𝑑𝑦 𝑑𝑡 (2) change in mass × change in velocity Moment = mv (3) 𝑑𝑦 𝑑𝑡 ∆𝑚𝑣 = ∆𝑚 × change in mass × change in velocity ∑ 𝐹𝑥 = ∆(𝑚𝑣𝑥 ) (4) (5) The following derivation is for the momentum function of a simple momentum conserving hydraulic jump in a rectangular channel with constant width. Change in momentum ∆(𝑚𝑣)(𝑤) =𝜌(𝑄)(𝑣2 − 𝑣1 ) (6) Divide through by w to obtain q. Change in momentum per unit width. ∆(𝑚𝑣) = 𝜌𝑞 (𝑣2 − 𝑣1 ) (7) Sum of Forces in the direction of flow. ∑𝐹 = 𝑃1 − 𝑃2 − 𝐹𝑑 Where (8) 𝛾𝑦2 2 P = The sum of forces is equal to the momentum change. 𝛾𝑦2 1 2 2 − 𝛾𝑦2 2 − 𝐹𝑑 = 𝜌𝑞(𝑣2 − 𝑣1 ) (9) Divide by 𝛾 𝑦2 1 2 1 𝑔 2 − 𝑦22 − 𝐹𝛾𝑑= 𝜌 ×𝑞 ×(𝑣2 −𝑣1 ) 𝛾 Recall that 𝜌 =𝛾 𝑦2 1 2 + 𝑞𝑣1 𝑔 (10) (11) = 𝑦2 2 2 to obtain the equation for M. + 𝑞𝑣2 𝑔 (12) Recall that V = 𝑞 𝑦 M = 𝑦2 1 2 𝑞 + 𝑔𝑦 1 M = 𝑦2 2 2 𝑞 + 𝑔𝑦 2 2 2 (13) (14) (15) Figure2 Specific Force (Momentum Function) (Macmillan, 1966.) A specific force diagram plots the specific force as a function of the channel depth (y versus M). The minimum momentum function (Mmin) corresponds to critical flow (i.e., Fr = 1), and the corresponding channel depth is referred to as the critical depth (yc). For a given momentum function, two different channel depths (ysub and ysup) are possible, and they are referred to as the sequent or conjugate depths. The top and bottom portions of the specific force curve correspond to subcritical and supercritical flows, respectively. 3.2 M-y curve locations The M-y Diagram is a graphical representation of the conservation of momentum and can be applied over a hydraulic jump to find the upstream and downstream depths. We can see from the above example that the flow approaches super critically at a depth of y1. The critical point represents the minimum value of the momentum function available for that particular flow per unit width, q. An increase in q would cause the M function to move to the right and slightly up, giving the flow access to more momentum at its critical point. It follows that a decrease in the q value would move the M function down and to the left, decreasing the momentum available to the flow at its critical value. This is shown graphically figure3.19 below. Figure3 Effect of increasing q on depth up- and down-stream of hydraulic jump (Chanson.H 2012) From Figure3.20, it can also be seen what effect increasing the flow rate, q, will have on the depth up- and down-stream of the jump. Increasing the incoming flow rate (from q = 10 ft2/s to 30 ft2/s in Figure3.19) will result in an increase in the supercritical approach depth and a decrease in the subcritical depth post-jump. 3.3 Energy Loss Although momentum is conserved throughout the hydraulic jump, the energy is not. There is an initial loss of energy when the flow jumps from supercritical to subcritical depths. The resulting loss of energy is equal to the change in specific energy across the jump and is given by the equation for ΔE below. The equation below is based on the condition that y1 and y2are conjugate depths. ∆𝐸 = 𝐸1 − 𝐸2 = (𝑦1 + 𝑞2 2𝑔𝑦2 1 ) − (𝑦2 + 𝑞2 2𝑔𝑦2 2 ) (𝑦2 −𝑦1 )3 4𝑦1 𝑦2 = (16) When looking at the critical points on the M-y diagram and what their locations tell us about the nature of the hydraulic jump, we mentioned that an increase in q would affect the energy lost in the jump. From Figure3.19 we see that increasing the flow rate decreases the difference in the upstream and downstream depth of the jump (y2 – y1). From this we can infer that if the momentum is held to be constant, there will be a decrease in the energy lost in the jump if the flow rate is increased. The efficiency of the jump is determined by the dimensionless parameter E2/E1 which tells us how much of the original energy is remaining after the jump is complete. The equation for the energy efficiency is given below and shows the heavy dependence that the efficiency has on the Froude number of the upstream flow. 𝐸2 𝐸1 = 3 2 (8𝐹𝑟2 ) 1 2 −4𝐹𝑟1 + 1 2 8𝐹𝑟2 1 (2+𝐹𝑟1 ) (17) 3.4 Momentum Formula Consider the occurrence of a hydraulic jump in prismatic channel with a horizontal bed. The depth before jump D1 is called the initial depth and the depth after the jump D2 is called the sequent depth. The corresponding total pressures per unit width and velocities are P1, P2 and V1, V2 respectively. Figure4Hydraulic jump interpreted by specific-energy and specific-force curves In the short length of the jump the energy loss due to friction is neglected. The continuity equation is: q = 𝑉1 𝐷1 = 𝑉1 𝐷1 (18) 𝛾 Change of momentum per second/unit width = 𝑔(V1-V2) Difference of forces/ unit width 1 = 2𝛾 (𝐷22 -𝐷12 ) (19) (20) Due to Newton’s second law of motion the change of momentum per unit time in a flowing channel is equal to the result of all external force acting on the body of the flow. 1 2 𝛾 (V1-V2)q 𝑔 𝛾(𝐷22 − 𝐷12 ) = 𝑞 Substituting 𝐷 for V = (21) 1 2 𝛾 (𝐷22-𝐷12 ) We obtain; 𝐷22 -𝐷12 = 2𝑞 𝑞 𝑔 𝐷1 ( 𝐷22 -𝐷12 = 𝐷22 -𝐷12 𝐷2 𝐷1 = = - 𝐷𝑞2) (22) 2𝑞2 𝐷2 −𝐷1 ( ) 𝑞 𝐷1 𝐷2 (23) 𝛾 (𝑉 −𝑉2 )𝑞 𝑔 1 (24) 1 (√1 + 8𝐹12 -1) 2 (25) Or 𝐷2 + 𝐷1 = 2𝑞2 𝑔𝐷1 𝐷2 (D2+D1)(D2+D1) = (26) 2𝑞2 𝑔 (27) By substituting VD for q, Eq. (3.8) can be written as 𝐷1 𝐷2 (𝐷1 + 𝐷2 ) = 2 2 2 𝑉 𝐷 𝑔 1 1 (28) 𝐷22 + 𝐷1 𝐷2 = 2 2 2 𝑉 𝐷 𝑔 1 1 (29) 2 2 2 𝑉 𝐷 𝑔 1 1 𝐷22 + 𝐷1 𝐷2 + 14𝐷12 = 𝐷2 + 𝐷2 1 𝐷 2 1 = Alternatively = 1 −2𝐷1 1 + 4𝐷12 2 √𝑔𝑉12 𝐷1 + 14𝐷21 + 1 𝐷 2 1 (30) (31) 2 8𝑉1 √𝑔𝐷 +1 1 (32) 𝐷1 𝐷2 = 1 (√1 + 8𝐹12 -1) 2 (33) Where, F1 and F2 are incoming and out coming flow Froude numbers respectively. Energy Loss Energy loss = ∆𝐸 = 𝐸1 − 𝐸2 Where E1= Energy of flow before the jump. E2= Energy of flow after the jump. 𝐻𝐿 = (𝐷1 + 𝑉2 1 2𝑔 ) − (𝐷2 + 𝐻𝐿 = (𝐷1 − 𝐷2 ) + 𝐻𝐿 = (D1-D2) + 1 (𝑉 2 2𝑔 1 𝑞2 1 ( 2𝑔 𝐷2 1 𝑉2 2 2𝑔 ) (34) − v22 ) (35) - 𝐷12) (36) 2 we obtain HL = (𝐷2 −𝐷1 )3 4𝐷1 𝐷2 (37) 3.5 Types of Jumps on Horizontal Floor For F1 =1, the flow is critical and no jump can form. For F1 =1-1.7, water surface shows undulation and the jump is called “undular jump”. Figure5 Undular jump For F1 =1.7-2.5, a series of small rollers on the surface of the jump develop, but the downstream water surface remain smooth. The energy loss is low. The jump is called “weak jump”. Figure6 Weak jump For F1 =2.5-4.5, there is an oscillating jet entering the jump bottom to surface and back again with no periodicity. Each oscillation produces a large wave of irregular period which can travel for large distances doing unlimited damage to earth banks and ripraps. This jump is called “oscillating jump” Figure7 Oscillating jump For F1 =4.5-9, the downstream extremity of the surface roller and the point at which the high velocity jet tends to leave the flow occur at practically at the same vertical section. This jump is least sensitive to variation in tail water depth. The energy dissipation ranges from 45% to 70%, this jump is called “steady jump”. Figure8 Steady jump For F1 =9 and greater, the high velocity jet grabs large slugs of water rolling down the front face of the jump generating waves downstream and a rough surface can prevail. The energy dissipation may reach 85%. The jump is called a “strong jump”. Figure9 Strong jump 3.6 Jump as Energy Dissipater Case 1: Represents the pattern in which tail water depth (Tw) equals sequent depth (D2). In this case values of F1, D1 and D2 will satisfy the general equation of hydraulic jump (Eq.3.10) and the jump will occur on a solid apron. For scour protection, this is an ideal case. Figure10 Tail water depth (Tw) equals sequent depth (D2) Case 2: Represents the pattern in which the tail water depth is less than sequent depth D2, this means that the tail water in Case 1 is deceased. As a result, the jump will move downstream to a point where Eq.(3.10) is again satisfied. This case must be avoided because the jump is taken place on a loose rubble bed or unprotected channel resulting severe erosion. The purpose of design is to increase Tw to insure a jump within the protected apron. Figure11 Tail water depth is less than sequent depth D2 Case 3: Represents the pattern in which the tail water depth Tw > sequent depth D2 as a result the jump will be forced upstream and may finally be drowned out at the source (structure), becoming a submerged jump this is the safest case in the design because the position of the submerged jump can be fixed but the design is not efficient because only little energy will be dissipated. Figure12 Tail water depth Tw > sequent depth D2 3.7 Tail water conditions Class 1: Jump height rating curve is always above tail water rating curve. In this class, the depth of in the river is insufficient for all discharges for the formation of a jump at the toe of the structure. The jump will form at certain place for downstream (Case 2). The energy dissipation can be achieved in any of the following ways which are lowering the floor level downstream of the dam in order to make the tail water depth in the stilling basin equal to the jump height for all discharges, stilling basin with baffles or sills at bed level, stilling basin with a low secondary dam downstream. And bucket type energy dissipaters (ski-jump). Class 2: The jump height curve is always below tail water rating curve. This means that Case 3 occurs at all times and the jump will move upstream consequently, little energy will be dissipated. A method of energy dissipation can be achieved by sloping apron and roller bucket type energy dissipater. Class 3: Jump height curve is above tail water rating curve at low discharges and below at higher discharges. An effective method of dissipating energy is by stilling basin for forming a jump at low discharges and to combine with the basin a sloping apron for developing a satisfactory jump at high discharge and stilling basin with baffle piers or dentate sill. Class 4: Jump height curve is below tail water curve at low discharges and above at high discharges. An effective method to insure a jump is to increase the tail water depth sufficiently high by providing stilling pool (basin), this forming a jump at high discharges. Figure13 Classification of tail water conditions for the design of scour- protection works.(Department of civil engineering in the University of Duhok , 2010) 4 Experimental Procedure 4.1 Open the sluice gate opening for the width of 15 mm. 4.2 Turn on the water pump and then open the valve 4.3 Wait until the water level does not change. Adjust the weir on downstream of the flume until the hydraulic jump occurs. Keep adjusting it until the hydraulic jump occurs right next to the vena contracta. 4.4 Measure 𝑦1 and 𝑦2 at the starting point and the ending point of hydraulic jump, respectively. Also measure the 𝐿𝑗 and 𝐿𝑟𝑗 . 4.5 Measure the discharge by the notched-weir 4.6 Increase the sluice gate opening for the width of 25mm. 4.7 Repeat step number 3.2.4.3-3.2.4.4 again 4.8 Increase the water discharge by adjusting the valve. 4.9 Repeat step number 3.2.4.1 – 3.2.4.6 again. Use totally 4 discharge.