List of Tables

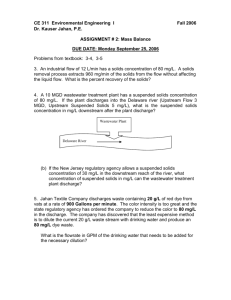

advertisement