APPENDIX 2 Example of test results sheet for one model of rice cooker

advertisement

Laboratory capacity and verification

testing report

Prepared for the

Vietnam Energy Efficiency Standards and Labelling (VEESL)

Program

Produced by

Chris Evans, Kevin Lane

399 Silbury Boulevard, Milton Keynes

MK9 2AH, United Kingdom

Email: enquiries@S2E4.com

Telephone: +44 (0)1908 303 600

www.S2E4.com

June 2014

Table of Contents

1

INTRODUCTION...................................................................................................................................... 7

2

EXISTING ACCREDITATION AND APPROVAL OF TESTING ORGANISATIONS ............................................ 9

2.1 ACCREDITATION BY THE BOA ..............................................................................................................................9

2.2 APPROVAL BY MOIT.........................................................................................................................................9

3

PROVISION OF EXPERT TRAINING ........................................................................................................ 10

3.1 ELECTRIC FANS ...............................................................................................................................................11

3.1.1 Report back to VEESL and MOIT from the electric fans expert ...........................................................11

3.2 RICE COOKERS ...............................................................................................................................................13

3.2.1 Report back to VEESL and MOIT from the rice cookers expert ...........................................................13

3.3 COMPACT FLUORESCENT LAMPS ........................................................................................................................14

3.3.1 Report back to VEESL and MOIT from the CFLs expert .......................................................................15

4

INTER-LABORATORY COMPARISON TESTS ........................................................................................... 17

4.1 RESULTS OF WITNESS TESTING ...........................................................................................................................17

4.2 RESULTS OF TESTING ELECTRIC FANS ...................................................................................................................18

4.2.1 Discussion of results of testing electric fans .......................................................................................21

4.3 RESULTS OF TESTING RICE COOKERS ....................................................................................................................23

4.3.1 Discussion of results of testing rice cookers .......................................................................................26

4.4 RESULTS OF TESTING CFLS ...............................................................................................................................28

4.4.1 Discussion of results of testing CFLs ...................................................................................................30

5

CONCLUSIONS AND RECOMMENDATIONS ........................................................................................... 33

5.1 PRODUCT TESTING RELATED ADVICE FOR EACH OF THE QUATEST LABORATORIES .......................................................33

5.2 RECOMMENDATIONS APPLICABLE TO ALL APPROVED TESTING ORGANISATIONS IN VIETNAM...........................................34

5.3 THE ACCREDITATION OPERATED BY THE VIETNAMESE BOARD OF ACCREDITATION (BOA) ..............................................34

5.4 SUPPORT FOR THE MOIT APPROVAL PROCESS ......................................................................................................34

5.5 RECASTING THRESHOLD FOR ENERGY LABEL BANDS ................................................................................................35

APPENDIX 1

EXAMPLE OF TEST RESULTS SHEET FOR ONE MODEL OF ELECTRIC FAN ............................... 36

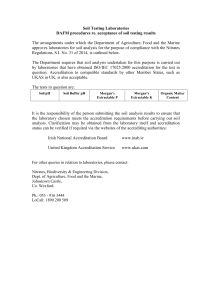

APPENDIX 2

EXAMPLE OF TEST RESULTS SHEET FOR ONE MODEL OF RICE COOKER ............................... 37

APPENDIX 3

EXAMPLE OF TEST RESULTS SHEET FOR ONE MODEL OF CFL ............................................... 38

2

List of Figures

Figure 1: Testing of electric fans with support from the expert ...............................................11

Figure 2: Testing of rice cookers with support from the expert ...............................................13

Figure 3: Testing of CFLs with support of the expert .............................................................15

Figure 4: Electric fan manufacturer label and the energy label ...............................................19

Figure 5: Star rating of the 20 fans as measured by the three laboratories ..............................20

Figure 6: Maximum-to-minimum star rating of the 20 fans as measured by the three laboratories

.....................................................................................................................................20

Figure 7: Reported minimum-to-maximum efficiency of the 20 fans, by three laboratories ........22

Figure 8: Rice cooker and its energy label ...........................................................................23

Figure 9: Star rating of the 20 rice cookers as measured by the three laboratories ...................25

Figure 10: Maximum-to-minimum star rating of the 20 rice cookers as measured by the three

laboratories .....................................................................................................................25

Figure 11: Reported average cooking efficiency (%) of the 20 models of rice cookers ...............26

Figure 12: Example of CFL label .........................................................................................29

Figure 13: Average efficacy (lm/W) measured for the 20 models of CFLs ................................30

Figure 14: Average measured power (W) of the 20 CFL models .............................................31

Figure 15: Measured/reported initial luminous flux (lm) of the 20 CFL models .........................32

List of Tables

Table 1: Summary of findings by electric fans testing expert .................................................12

Table 2: Summary of findings by rice cookers testing expert .................................................14

Table 3: Summary of findings by CFLs testing expert ...........................................................16

Table 4: Brand/model list of electric fans tested ...................................................................18

Table 5: Brand/model list of rice cookers tested ...................................................................24

Table 6: Energy efficiency bands given in TCVN 8252:2009 ...................................................27

Table 7: Brand/model/size list of CFLs tested ......................................................................28

Table 8: Difference between the average efficacies of the tested CFL lamps ............................30

Table 9: Example of test results sheet for one model of electric fan ........................................36

Table 10: Example of test results sheet for one model of rice cooker ......................................37

Table 11: Example of test results sheet for one model of CFL ................................................38

Disclaimer

The views and opinions expressed in this article are those of the authors and do not necessarily

reflect the official policy or position of any agency of the Australian Government.

The authors have made their best endeavours to ensure the accuracy and reliability of the data

used herein, however make no warranties as to the accuracy of data herein nor accept any

liability for any action taken or decision made based on the contents of this report.

3

Executive summary

The Australian Government Department of Industry (DoI) is providing assistance to Vietnam

through the Vietnam Energy Efficiency Standards and Labelling (VEESL) Program, funded by the

Australian Agency for International Development (AusAID).

This report has been compiled by consultants with extensive experience of product testing who are

providing direct assistance and advice to the VESSL Program. It provides results for that part of the

Program intended to help build laboratory testing capacity in three state-owned QUATEST

laboratories.

The work being reported was undertaken in partnership with Vietnam’s Ministry of Industry and

Trade (MOIT) and comprised of two main components:

Visits to the test laboratories, QUATEST 1, 2, 3, by experts in the energy efficiency

performance testing of electric fans, rice cookers and compact fluorescent lamps (CFLs).

The purpose of the visits being to provide supplementary training to the already

experienced laboratory testing staff;

The inter-laboratory testing of 20 models of electric fans, rice cookers and CFLs (which

followed on from the visits by the experts).

Achieving accurate and consistent test results by these three laboratories is crucial for effective

standards and labelling in Vietnam. Methods for measuring declared values for energy

consumption and performance characteristics must be of sufficient accuracy to provide confidence

to governments, consumers and manufacturers. Any significant variations in the reproducibility1 of

results achieved by test laboratories could reduce the effectiveness of the implementation of the

MEPS and labelling regulations. It must be recognised that some variation in measurement is

unavoidable. This can be due to the variance of the product itself and to the measurement method

applied. While the first one is the responsibility of the manufacturer, the second one is the

responsibility of either or both the test laboratory(s) and the organisation publishing the test

standard.

The part of the Program reported here began with the supplementary training visits made to the

three QUATEST laboratories. In each case, the experts provided advice focussed on making

improvements to testing procedures - the precise application of testing methods, the use of

calibrated measuring equipment and the routine assessment of sources of errors of measurement.

1

reproducibility conditions

conditions where test results are obtained with the same method on identical test items in different laboratories with

different operators using different equipment

[IEC 61923:1997, 3.9]

4

The results of the inter-laboratory testing that then followed were mixed. Those of multiple

samples of the same models of CFLs showed, with the exception of consistently lower results from

one of the QUATESTs, good reproducibility – as should be expected.

The results of the testing of electric fans and rice cookers were much less reproducible with large

and inconsistent variations in performance measured for the same samples of some models. The

experts identified a number of reasons, which could have contributed to these variations, which

were the responsibility of the test laboratories:

Some inconsistencies in the precise application of techniques between the laboratories;

Some equipment not being as specified in the test standard;

Some equipment not being calibrated.

Additionally, in the case of the rice cookers, the expert identified that the published test method

needed amending as it could not be undertaken in ways that avoided significant errors of

measurement.

The challenges faced by laboratories when conducting performance tests on products should not

be underestimated. Relatively small changes in procedures or in the accuracy of measuring

instruments can have a significant impact on the energy efficiency ratings that are subsequently

calculated from the laboratory test results. Implementation of the advice that the experts gave to

each of the QUATEST laboratories was intended to have a positive impact on improving the

consistency of test results.

The authors of this report recommend further actions are taken. A multi-agency approach, in which

the Vietnam Board of Accreditation (BoA) takes part, should implement a programme to assist the

test laboratories to improve the suitability and calibration of their measuring equipment. In

addition, estimating and eliminating sources of measurement errors are also important actions to

be taken.

Some specific recommendations:

2

Amend the measurement standard TCVN 8252:2009 for rice cookers in order to improve its

repeatability2;

Assist the BoA to implement best practice when accrediting test laboratories to

ISO/IEC17025;

repeatability conditions

conditions where independent test results are obtained with the same method on identical test items in the same laboratory by the

same operator using the same equipment within short intervals of time

[IEC 61923:1997, 3.6]

5

Introduce a requirement that inter-laboratory trials are to be undertaken for each new test

standard to identify and resolve any inconsistencies in application of the test methodology

and so ensure that reproducible test results are consistently obtained;

Each QUATEST to implement a procedure under which uncertainties of measurement3 are

estimated for all the test programs they undertake.

Further and specific refinements to laboratory procedures should be made at each

QUATEST. The guidance provided by the testing experts and the comments presented in

this report are relevant to this.

Request the BoA to then undertake a re-accreditation program (which would normally be

undertaken annually) for the QUATEST laboratories;

3

The expression “uncertainties of measurement”, which is used frequently in this report, deals with assessing the variations in results

that can occur when making a measurement. Testing a product to measure its performance will always be affected by errors due to

instrumentation, methodology, presence of confounding effects and so on. Consequently, experimental uncertainty estimates need to

be undertaken by test laboratories to identify (and, where possible, reduce) the different sources of errors and to provide an assessment

of the confidence in the results.

It is a requirement of the international standard used for accrediting test laboratories, ISO/IEC 17025 General requirements for the

competence of testing and calibration laboratories, that testing laboratories have and apply procedures for estimating uncertainty of

measurement.

6

1

Introduction

The Government of Vietnam has introduced legislation to implement Minimum Energy

Performance Standards (MEPS) for appliances and equipment alongside a program of Energy

Labelling. The Australian Government is supporting the Vietnam Energy Efficiency Standards and

Labelling (VEESL) Program, using funds supplied by the Australian Agency for International

Development (AusAID) and the Australian Department of Industry (DoI). These funds have been

used to employ consultants with extensive experience in this area who are providing direct

assistance and advice to the Australian and Vietnamese Government officials managing VESSL.

The aim of the VEESL Program is to improve prosperity in Vietnam while increasing energy security

and reducing carbon emissions. This will be achieved through a range of activities designed to build

sustainable capacity within Vietnam to set and enforce appliance and equipment energy standards,

and monitor and evaluate the MEPS and Energy Labelling Program. Two of the main activities,

within the scope of this report, are to:

Support the monitoring of compliance through verification testing;

Support the development of local test capacity and technical and commercial skills in

laboratories through training, and through inter-laboratory (round robin) testing.

The legislation to implement MEPS and Energy Labelling for appliances and equipment became

effective during 2013. This has required new products to meet MEPS levels and, in many cases,

being required to display an energy label at the point of sale. All affected products must be

compliant with the legally imposed performance requirements.

Though the responsibility for this lies with the product supplier, the Vietnamese market

surveillance authorities also have a responsibility for checking that these products are in

compliance with these requirements. Some checks, such as whether a label is being correctly

displayed, can be made at the point of sale4 but the technical performance of the product can only

be checked through tests conducted by a suitably skilled and equipped testing organisation.

Since the results of these check tests may be used as evidence for enforcement action, it is vital

that tests are conducted accurately according to the specified test methodology, and that the

results are sufficiently repeatable and reproducible. Much of the current responsibility for

conducting compliance tests is likely to be with the state testing organisations, Quality Assurance

and Testing Centre (QUATEST) 1, 2 & 3, and a program was developed on behalf of VEESL to

support these organisations.

The VEESL program reported here was undertaken in partnership with the Vietnam Ministry of

Industry and Trade (MOIT). It consisted of the following components:

4

Survey of Energy Efficiency Labelling of Appliances in Vietnam was published by VEESL in April 2014

7

Providing supplementary training for laboratory staff undertaking the testing of electric

fans, rice cookers and compact fluorescent lamps (CFLs);

Witnessing of the testing of these products by the experts that had provided the training;

Production of testing methodological guides for electric fans and rice cookers;

Inter-laboratory testing of 20 models of electric fans, rice cookers and CFLs.

Products were purchased from the Vietnamese market for testing. The results of testing were

intended to enable the program to achieve the following:

An exploration of whether the standard test procedures, their regulated performance

levels and the testing being conducted were sufficient to deliver the performance

standards required by the Vietnamese authorities; and, if so,

A check on whether these products were compliant with their regulatory requirements and

performed as claimed on their energy labels.

8

2

Existing accreditation and approval of testing organisations

There are two official accreditation or approval programs that are applicable to testing

organisations in Vietnam. Both have been applied to the QUATEST laboratories. The first is based

on the accreditation process managed by the Bureau of Accreditation Vietnam (BoA). The second,

approval to undertake the tests required by the standards and labelling regulations, is undertaken

by MOIT.

2.1 Accreditation by the BoA

The BoA is the official body in Vietnam responsible for accrediting certification bodies under the

ISO/IEC Guide 65 and specifically for accrediting test laboratories in accordance with ISO/IEC 17025.

The BoA has international recognition as the Vietnamese member of the International

Accreditation Forum (IAF), Asia Pacific Laboratory Accreditation Cooperation (APLAC), International

Laboratory Accreditation Cooperation (ILAC) and the Pacific Accreditation Cooperation (PAC).

QUATEST laboratories 1, 2 & 3 each have a generic accreditation certificate for ISO/IEC 17025

issued by the BoA. These certificates do not state which specific TCVN standards that the

laboratories have been accredited for (accreditation under ISO/IEC 17025 is specific to identified

standards; it cannot be applied generically to the laboratory). Examination of the content of the

BoA’s website, in which detailed schedules of accredited tests are displayed for each organisation,

reveals that the detailed lists they publish are not up to date. Enquiries are on-going, but currently

it has not been possible to confirm whether each QUATEST has been specifically accredited to

ISO/IEC 17025 for testing the energy efficiency of electric fans, rice cookers and CFLs.

2.2 Approval by MOIT

An approval process of testing organisations is undertaken by MOIT. This is undertaken separately

to the ISO/IEC based accreditation process undertaken by the BoA.

The VEESL program has previously provided guidance to MOIT that was intended to assist them to

conduct audits of testing organisations. This guidance was prepared to ensure the quality systems

operated by approved testing organisations extended beyond the minimum requirements required

by ISO/IEC standards.

9

3

Provision of expert training

The QUATEST laboratories were already able to test electric fans, rice cookers and CFLs so were

seeking expert guidance to help them further refine their expertise. International experts for each

product group were commissioned to support the VEESL program. The role the experts were asked

to adopt was one of providing support and training rather than one of critique and supervision.

To do this, each expert separately spent three days in November 2013 at each QUATEST and

undertook a similar program based on the following framework:

•

Inspect the current test arrangements and compare with those required by the applicable

TCVN standard. Make note of any deficiencies and, where practicable, assist the staff to

remedy them. Where possible, assist the staff to improve these to best practice standards.

•

Check the samples to be witnessed tested by the laboratories. These should have been

selected in advance by MOIT and consist of a minimum of three different models taken

from the retail market.

•

Assist the staff to conduct tests and record results, providing guidance and training to

correct any deficient practice wherever possible.

•

Formally witness the testing (i.e. post-training) of the three models. Note any deficiencies

in the tests carried out and take a record of the results obtained.

•

Throughout the period spent at each laboratory, note any other aspects of laboratory

management that fall short of best practice and which may in some way prevent the

laboratory achieving consistent results in the testing it does on the other product

categories. Provide briefings to laboratory management where improvements could be

made.

•

At the completion of testing at the first laboratory, supervise the packing of the three

models tested5 and ensure arrangements have been made to immediately ship these

samples to the next laboratory to be visited.

•

Provide report backs to the laboratory management using a Laboratory Report Template.

This report must also be provided in a verbal briefing to senior laboratory management at

the end of each training visit.

•

Provide a training mission report back to VEESL and MOIT using a Training Mission Report

Template.

•

Use, where appropriate, materials from the laboratories’ existing testing guidance manuals,

to produce a test guidance manual for the product under review. This document is

intended to replace the individual guides currently being used and so ensure that all

laboratory staff followed the same guidance in future. (This requirement applied to electric

fans and rice cookers only.)

5

For rice cookers and electric fans; three separate batches of the same model were provided to each

laboratory for CFLs

10

3.1 Electric fans

The expert engaged to provide support and training was:

Johnny Chow

Technical Manager

Intertek-Consumer & Commercial Electrical

Hong Kong

Training was focussed on the requirements of the applicable Vietnamese national standards TCVN

7826, and TCVN 7827.

Figure 1: Testing of electric fans with support from the expert

3.1.1 Report back to VEESL and MOIT from the electric fans expert

In addition to supplying an individual verbal and written report back to the managers of each

QUATEST laboratory, Mr Chow submitted a written report of his key findings to VEESL. A summary

of the content of each of these reports is provided in Table 1. These summaries cover whether the

conditions for undertaking the test were as required by the relevant test standard, whether the

measuring equipment had been calibrated (i.e. checked for accuracy), whether the staff were

evaluating and estimating the applicable uncertainties of measurement and whether the test was

being conducted exactly as required. All of these must be undertaken correctly in order to achieve

repeatable and reproducible test measurements.

11

Table 1: Summary of findings by electric fans testing expert

QUERIES

QUATEST1

QUATEST2

QUATEST3

Were all the

No. Significant defects

No. Significant defects

No. Significant defects

conditions specified in

were found

were found

were found

No

Yes

Yes

No

No

No

Were significant

Yes. Most

Yes. Most

Yes. Most

improvements in

improvements that

improvements that

improvements that

undertaking the test

were possible to make

were possible to make

were possible to make

procedures achieved

in the time available

in the time available

in the time available

during the visit of the

were to improve the

were to improve the

were to improve the

expert?

alignment of the test

alignment of the test

alignment of the test

fan with the

fan with the

fan with the

positioning of the

positioning of the

positioning of the

measuring instrument.

measuring instrument.

measuring instrument.

the test method for

undertaking the tests

found to be

satisfactory when

expert arrived?

Had all measuring

equipment been

calibrated?

Were uncertainties of

measurement being

estimated?

What are the main

further actions

recommended for the

Test rooms must be draught-free and of the correct dimensions; all

substantial gaps in the wall fabric need to be eliminated.

laboratories to take?

The accuracy of the test result is dependent on the alignment of the

test fan with the positioning of the measuring instrument. The

current inaccurate alignment marking on the floors of the chambers

need to be removed and laser pointers used to obtain and constantly

check the necessary precision of alignment.

The wind speed meters used must meet the requirements given in

the test standard.

The laboratories must apply measurement uncertainties procedures

and so identify and, where possible, reduce sources of measurement

error. This is a requirement of the accreditation standard

ISO/IEC17025.

12

3.2 Rice cookers

The expert engaged to provide support and training was:

Michael Cheng

Technical Manager

Intertek-Consumer & Commercial Electrical

Hong Kong

Training was focussed on the requirements of the applicable Vietnamese national standard TCVN

8252.

Figure 2: Testing of rice cookers with support from the expert

3.2.1 Report back to VEESL and MOIT from the rice cookers expert

In addition to supplying an individual verbal and written report back to the managers of each

QUATEST laboratory, Mr Cheng submitted a written report of his key findings to VEESL. A summary

of the content of each of these reports is provided in Table 2. These summaries cover whether the

conditions for undertaking the test were as required by the relevant test standard, whether the

measuring equipment had been calibrated (i.e. checked for accuracy), whether the staff were

evaluating and estimating the applicable uncertainties of measurement and whether the test was

being conducted exactly as required. All of these must be undertaken correctly in order to achieve

repeatable and reproducible test measurements.

13

Table 2: Summary of findings by rice cookers testing expert

QUERIES

QUATEST1

QUATEST2

QUATEST3

Were all the

No. Significant defects

No. Significant defects

Yes

conditions specified in

were found.

were found.

No

No

Yes

No

No

No

Were significant

Yes.

Yes.

Yes.

improvements in test

Primarily to the

Primarily to the

Primarily to the

procedures achieved

detailed application of

detailed application of

detailed application of

during the visit of the

test method.

test method.

test method.

the test method for

undertaking the tests

found to be

satisfactory when

expert arrived?

Had all measuring

equipment been

calibrated?

Were uncertainties of

measurement being

estimated?

expert?

What are the main

The accuracy of the test result is dependent on temperature

further actions

measurement and the way in which stirring (of the contents of the

recommended for the

rice cooker) needs to be undertaken to achieve a uniform

laboratories to take?

temperature. The expert has developed test guidance for all the

laboratories to follow in order to achieve this in a more consistent

way.

The testing needs to take place in substantially draught-free areas.

The weighing equipment needs to be upgraded.

The laboratories must apply measurement uncertainties procedures

and so identify and, where possible, reduce sources of measurement

error. This is a requirement of the accreditation standard

ISO/IEC17025.

3.3 Compact fluorescent lamps

The expert engaged to provide support and training was:

Shuming Hua

Chief Executive

Global Efficient Lighting Centre

Beijing

14

Training was focussed on the requirements of the applicable Vietnamese national standard TCVN

7896.

Figure 3: Testing of CFLs with support of the expert

3.3.1 Report back to VEESL and MOIT from the CFLs expert

In addition to supplying an individual verbal and written report back to the managers of each

QUATEST, Mr Hua submitted a written report of his key findings to VEESL. A summary of the

content of his report is provided in

15

Table 3. These summaries cover whether the conditions for undertaking the test were as required

by the relevant test standard, whether the measuring equipment had been calibrated (i.e. checked

for accuracy), whether the staff were evaluating and estimating the applicable uncertainties of

measurement and whether the test was being conducted exactly as required. All of these must be

undertaken correctly in order to achieve repeatable and reproducible test measurements.

16

Table 3: Summary of findings by CFLs testing expert

QUERIES

QUATEST1

QUATEST2

QUATEST3

Were all the

No. Significant defects

No. Significant defects

No. Significant defects

conditions specified in

were found.

were found.

were found.

No

No

No

No

No

No

Were significant

Yes.

Yes.

Yes.

improvements in test

Primarily because the

Primarily because the

Primarily because the

procedures achieved

testers had not

testers had not

testers had not

during the visit of the

previously received

previously received

previously received

expert?

sufficient training for

sufficient training for

sufficient training for

testing lamps.

testing lamps.

testing lamps.

the test method for

undertaking the tests

found to be

satisfactory when

expert arrived?

Had all measuring

equipment been

calibrated?

Were uncertainties of

measurement being

estimated?

What are the main

Staff to receive more training for testing lamps and (in some

further actions

laboratories) to conduct testing more frequently in order to build

recommended for the

experience and maintain skills.

laboratories to take?

Test equipment needs to be managed better, it needs to be

calibrated and included within a test instrument quality system.

Some of the test equipment should be updated.

The laboratories must apply measurement uncertainties procedures

and so identify and, where possible, reduce sources of measurement

error. This is a requirement of the accreditation standard

ISO/IEC17025.

17

4

Inter-laboratory comparison tests

The three QUATEST laboratories undertook inter-laboratory comparisons. Each tested the same

samples of 20 different models of electric fans and rice cookers. Testing of CFLs was undertaken on

30 samples of 20 different models requiring a total of 600 CFLs to be obtained. For each of the 20

models, the 30 samples were subdivided into three batches of 10 samples; one batch went to each

QUATEST laboratory.

The main purposes of these trials were to provide:

A measure of the extent of the variation and uncertainty of results;

An understanding of the cause of these variations in order to…

Be able to advise MOIT and the laboratories on steps that could be taken to minimise these

variations and so achieve repeatable and reproducible results.

The first, of two, phases of the inter-laboratory comparison tests was initiated when the expert

trainers were present at the QUATEST laboratories. Part of their role was to witness the initial tests

being undertaken. These tests were performed after the experts had provided some

training/guidance and had assisted the testing staff to achieve the best possible set-up using the

test equipment available at the time.

The second phase of the inter-laboratory comparison testing took place after the experts had

departed. The laboratory staff then tested all the products using their existing knowledge

supplemented by the expert training.

4.1 Results of witness testing

Each expert was required to formally observe (“witness”) the testing of a selection of products that

they had trained the laboratory staff to test. This had two purposes:

To enable the experts to review how well the tests were being conducted and so note

whether the advice and training they had been given previously had improved the ways in

which the tests were performed; and

To establish the organisation of the inter-laboratory comparison tests that would continue

to take place after their departure.

Each expert submitted detailed report test sheets to VEESL of the test results he witnessed being

measured. An example of one of the result sheets for each of the three product types is given in

Appendices 1-3.

The content of the experts’ reports, which mainly deal with sources of measurement uncertainty

i.e. the reasons for variations in results obtained from reproduced tests of the same product, are

discussed later in this report. The measurements obtained in the tests that were witnessed have

not been reported here since they have been superseded by those that were subsequently

repeated by the three QUATEST laboratories following them making further improvements to their

testing procedures.

18

4.2 Results of testing electric fans

Twenty different models of electric fan were tested, after the expert training had been provided.

The brand and model identifications are listed on Table 4.

Table 4: Brand/model list of electric fans tested

Reference number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Fan name

ĐIỆN CƠ TICO: B300

CHING HAI: BF168

LIOA: QB-409K

CHING HAI: HS802

SHARP: PJT1621V

ĐIỆN CƠ TICO: B400

VINAWIND: QĐ400-MS

LIOA: QT-409KLG

VINA ASIA: L16003

ĐIỆN CƠ HD: HĐ-450 (treo)

SANAKY: SK-16C

ĐIỆN CƠ 91: QB-450 (dung)

VINAWIND: QĐ450-ĐM

DAIICHI: DC-SF525

DAIICHI: DC-SF535

HOTOFAN: QĐC400

DAIICHI: DC-SF650

LIOA, MODEL: Q-409K

ĐIỆN CƠ TICO: B300

ĐIỆN CƠ 91: QĐ-CN450P

They were a mixture of table top and pedestal fans; there was one wall fan. Blade diameters

ranged from 300-450mm; input powers were in the range 35-65W (example shown in Figure 4).

19

Figure 4: Electric fan manufacturer label and the energy label

Each sample was measured in accordance with TCVN 7827:2007, the official test method for

measuring the airflow performance of these types of product.

The results obtained were then used in combination with TCVN 7826:2007, which provides the

levels of energy efficiency of the fan (k) and the corresponding energy label star rating. Figure 5

gives the reported level of energy efficiency or star rating (based on R6) of the 20 fans by the three

laboratories.

6

TCVN 7826 and TCVN 7827 use “k” and “R” to mean the same thing (ratio of measured efficiency to minimum requirement), which

some users may find confusing.

20

Figure 5: Star rating of the 20 fans as measured by the three laboratories

There is clearly a difference between the star ratings measured by the laboratories for some of the

fans. This may be more clearly seen if the measured star range for each fan is only plotted as a line.

Figure 6: Maximum-to-minimum star rating of the 20 fans as measured by the three laboratories

21

4.2.1 Discussion of results of testing electric fans

The variation in results for the star rating for the label, reported in Figures 5 & 6 is very large for

some of the models tested. Since the tests were conducted on the same samples, using the same

test procedure and the same guidance manual was available to follow, the following may have

contributed to the variation:

1. Large measurement uncertainties being caused by the test method not being reproduced

in exactly the same way by each of the three QUATESTs;

2. Large measurement uncertainties being caused by the test method because it is not

possible to repeat it in a consistent way;

3. The threshold values for the energy label levels, the star values, are too compressed with

the consequence that small differences in performance measurements are increased

through being multiplied in the labelling calculation, which results in having the effect of

exaggerating the real difference in energy efficiency.

Examining each of these in turn:

Large measurement uncertainties being caused by the test method not being reproduced in exactly

the same way by each of the three QUATESTs

The training expert identified this as the most significant factor at the time when the very first tests

were being conducted. The following causes of measurement uncertainties were reported:

The wind speed measuring instrument was not being accurately aligned with the wind flow

from the fan under test;

None of the test chambers at the three QUATESTs were fully correct as they did not

completely eliminate draughts from external sources and, in one case, the chamber was of

incorrect dimensions;

The wind speed test instruments used by two of the QUATESTs did not meet the

specification given in TCVN 7827;

Some equipment had not been calibrated;

Some wind flow readings had to be taken from the wind speed measuring instrument

manually which meant that test personnel had to be in the vicinity of the wind flow being

measured, a factor that could interfere with the wind flow being measured.

All of these factors, which were possibly contributing to increasing the level of measurement

uncertainties, were fully identified to the QUATEST staff prior to them conducting the performance

tests that are reported in Figure 5 & 6.

At the time of writing this report, it was not known to what extent remedial actions had been

undertaken by any of the three QUATESTs in the period following the departure of the training

expert and prior to them conducting the main set of tests.

22

Large measurement uncertainties being caused by the test method because it is not possible to

repeat it in a consistent way

The opinion of the training expert was that this was not a significant factor. However, the wind flow

from the sample under test has to be meticulously measured under precisely maintained

conditions. The laboratory testing staff must understand that this test procedure has to be

undertaken using methods requiring a high level of precision. The only enhancement

recommended for the basic test methodology was for a guidance note to be added to TCVN 7827

to draw the attention of testing staff to the importance of accurately aligning the wind flow

measuring instrument with the fan being tested and the importance of ensuring nobody is standing

in the vicinity of the air flow when it is being measured. Given the sensitivity of the measurement

process, an additional precaution would be to require the test to be conducted under repeatability

conditions to ensure that the results being obtained are consistent.

The banding scales for levels of energy efficiency are too compressed with the consequence that

small differences in performance measurements are accounting for large (exaggerated) differences

in the levels of energy efficiency

The average difference in the k values between the minimum and maximum values for each fan is

0.4 (Figure 7). Since the current labelling scale has increments of 0.1 i.e. a 10% increase in efficiency

at each level, the variation in test results from the three laboratories is, on average, spanning four

levels of efficiency. It is clear from this variation, that the results of inter-laboratory tests were not

sufficiently reproducible to support the current energy label.

Figure 7: Reported minimum-to-maximum efficiency of the 20 fans, by three laboratories

23

Furthermore, most of fans comfortably exceed the best performance requirements required in the

energy labelling regulations as can be seen from the test results of the samples displayed in Figure

7. An examination of the MOIT registration database for electric fans confirms that almost all the

fans listed have 5 stars.

It is clear that the thresholds need to be recast if they are to provide any meaningful signals to the

market, and be useful to policy makers. The re-grading of the energy label should be done using

other available evidence, e.g. examination of the latest registration database, examination of other

countries regulations on electric fans, and finding best-practice products. Ideally, this re-grading

process would be done after the laboratories have succeeded in improving the level of

reproducibility and so further reduce the level of test result differences between themselves.

4.3 Results of testing rice cookers

Twenty different models of rice cookers were tested. All were table top designs with capacities

ranging from 1 – 3 litres; input powers ranging from 350-1000W (an example is shown in Figure 8).

Figure 8: Rice cooker and its energy label

The brand and model identifications of the twenty models tested are listed in Table 5.

24

Table 5: Brand/model list of rice cookers tested

Reference number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Rice cooker name

SHARP KSH-211

HIỆP HƯNG: HH105

SUPOR: CFXB50YB5B-70

SUPO VIET: SP-30R

GOLDSUN: ARC-G18CP1

ELECPOR: SR-P1C

HONEY’S: H0901-M22D

SUPO VIET: SP-22R

GOLDSUN: ARC-GDF18C2

DAEWOO: DFC-5018

COMET: CM8018

SHARP: KSH-219V

AIDI: MR-SM07J

SUPO VIET: RC-18SB

DAELUX: DXR50J-G

CARIBBEAN: CRC-182

SHARP: KSH-222

KANGAROO: KG376

SUPO VIET: SP-12R

MIDEA: MR-CM18SD

Each sample was measured in accordance with TCVN 8252:2009, the official test method for

measuring the energy efficiency performance (K) of these types of product.

Figure 9 gives the reported energy efficiency grade or star rating (based on the Energy Efficiency

Index, K) of the 20 rice cookers by the three laboratories.

25

Figure 9: Star rating of the 20 rice cookers as measured by the three laboratories

There is clearly a difference between the laboratories for some of the rice cookers. This may be

more clearly seen if the measured star range for each rice cooker is only plotted as a line (Figure

10).

Figure 10: Maximum-to-minimum star rating of the 20 rice cookers as measured by the three

laboratories

26

The large variation in the star rating is mainly due to the large variation in the measured cooking

efficiency.

NOTE: the efficiency reported by QUATEST2 as exceeding 100% is assumed to be an error.

Figure 11: Reported average cooking efficiency (%) of the 20 models of rice cookers

4.3.1 Discussion of results of testing rice cookers

The variation in results for the star rating for the label, reported in Figure 9 and Figure 10, is very

large for some of the models tested. Since the tests were conducted on the same samples using the

same test procedure and the same guidance manual was available to follow, the causes for the

variation are expected to be one or some of the following:

1. Large measurement uncertainties being caused by the test method not being reproduced

in exactly the same way by each of the three QUATESTs;

2. Large measurement uncertainties being caused by the test method because it is not

possible to repeat it in a consistent way;

3. The threshold values for the energy label levels, the star values, are too compressed with

the consequence that small differences in performance measurements are increased

through being multiplied in the labelling calculation, which results in having the effect of

exaggerating the real difference in energy efficiency.

Examining each of these in turn:

27

Large measurement uncertainties being caused by the test method not being reproduced in exactly

the same way by each of the three QUATESTs;

The training expert identified this as one of the two most significant factors at the time when the

very first tests were being conducted. The main cause of the measurement uncertainties being that

the accuracy of the test result is dependent on temperature measurement. The stirring of the

contents of the rice cooker in a thorough and consistent way in order to achieve a uniform

temperature distribution is crucial to this and, perhaps not surprisingly, different laboratory staff

undertake this manual activity in slightly different ways.

Large measurement uncertainties being caused by the test method because it is not possible to

repeat it in a consistent way

The training expert confirmed that this was the other significant factor. For example, the

measurement uncertainty of 0.5oC permitted by the existing standard already accounts for one

label grade. Furthermore, the standard needs to be changed to make it less sensitive to

temperature measurement. This could be achieved by using a longer heating time in order to make

the temperature rise larger. This would ensure that the label grade calculation becomes less

sensitive to the temperatures being measured. Alternatively, the test method could be changed to

measuring the energy required to raise the water temperature in the rice cooker for a larger fixed

value, say 50K.

The banding scales for the energy efficiency grades are too compressed with the consequence that

small differences in performance measurements are accounting for large (exaggerated) differences

in the final energy efficiency grade

The current grade performance thresholds given in TCVN 8252 appear very compressed, see Table

6 below. The impact of this is significant since a change in measured temperature as small as 0.5oC

results in a change of label grade.

Table 6: Energy efficiency bands given in TCVN 8252:2009

Grade

Energy Efficiency Index

K

1

≥ 1,00

2

≥ 1,05

3

≥ 1,10

4

≥ 1,15

5

≥ 1,20

However, examination of the MOIT registration database for rice cookers shows a wide spread of

ratings from 1 through to 5 stars i.e. most rice cookers do not exceed the best performance

requirements required in the energy labelling regulations.

28

Consequently, from a marketplace perspective, there is no requirement yet to recast the

thresholds and this leads to the conclusion that expanding the banding scales would not provide a

practicable solution for dealing with the spread of performance results reported by the three

QUATEST laboratories.

4.4 Results of testing CFLs

Twenty different models of CFLs were tested, with each of the three laboratories having 10 of each

model to test from the same purchased batch of 30 samples. The lamps were not transferred

between three QUATEST laboratories. Brand and model identifications are listed on Table 7. Rated

powers were in the range 5-23W. Some models claimed to have high efficiency performance and so

were qualified to display the endorsement energy label.

Table 7: Brand/model/size list of CFLs tested

Reference number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

CFL name

Rạng Đông 5W

Rạng Đông 11W

Rạng Đông 15W

Rạng Đông 20W

Rạng Đông 40W

PHILIPS, GENIE 5W

PHILIPS, GENIE 11W

PHILIPS, GENIE 14W

PHILIPS, Essential 18W

PHILIPS, Essential 23W

Điện quang 5W

Điện quang 8W

Điện quang 14W

Điện quang 18W

Điện quang 26W

OSRAM DULUXSTAR COMPACT 8W

OSRAM DULUXSTAR COMPACT 11W

OSRAM DULUXSTAR COMPACT 14W

OSRAM DULUXSTAR COMPACT 20W

OSRAM DULUXSTAR COMPACT 23W

An example of one of the CFLs tested with its energy label marking is shown in Figure 12.

29

Figure 12: Example of CFL label

Each sample was measured in accordance with TCVN7896:2008, the official test method for

measuring the energy efficiency performance of these types of product.

The initial luminous flux (lm) and the power (W) were measured, and the ratio reported (lm/W).

The results for this (as the average of the 10 samples tested for each model) from each of the three

QUATEST laboratories are shown in Figure 13.

30

Figure 13: Average efficacy (lm/W) measured for the 20 models of CFLs

4.4.1 Discussion of results of testing CFLs

These results from the three QUATEST laboratories are, when compared to those obtained for

electric fans and rice cookers much more consistent. All models appeared to be compliant in

respect of efficacy (lm/W), which was the only compliance parameter monitored in this testing

program.

The results reported by QUATEST3 showed consistently lower values, a few per cent lower than the

other two laboratories on average – see Table 8, below.

Table 8: Difference between the average efficacies of the tested CFL lamps

Declared*

Q1

Q2

Q3

(lm/W)

56.24

56.97

56.87

54.50

Q3=100%

103%

105%

104%

100%

Average efficacy

* average of 17 lamps

The cause of this variation could be due to variations in the measurement of input power or

variations in measuring the light output. A further examination of the input power recorded by

each laboratory for each was made to determine whether this was the factor responsible.

The average power for each model by each laboratory is given in Figure 14.

31

Figure 14: Average measured power (W) of the 20 CFL models

These data show that the measured input powers are very close to each so are not causing the

variation in reported efficacy. The variation is therefore coming from the measurement of light

output (Figure 15). An examination of the remarks made by the expert trainer suggests that the

failure to calibrate the standard (calibration) lamps used by each of the three QUATEST laboratories

to the same national (reference) standard lamp is most likely to be the cause of the consistent

variation in initial luminous flux measurements.

The following figures shows the reported initial luminous flux, which clearly shows that QUATEST 3

is reporting lower figures than the other two laboratories, especially for the larger CFLs.

32

Figure 15: Measured/reported initial luminous flux (lm) of the 20 CFL models

NOTE: In the figure above, the display of most of the results from QUATEST 1 are hidden by the nearly identical results

from QUATEST 2.

33

5

Conclusions and recommendations

Vietnam has a number of testing laboratories that have the ability and potential to undertake the

testing required to support the appliance MEPS and energy labelling testing regime. The state

owned QUATEST laboratories, for which this program from VEESL provided support, were already

able to test electric fans, rice cookers and CFLs so were seeking expert guidance to help them

further refine their expertise.

The results obtained by the inter-laboratory testing of electric fans and rice cookers will need

careful examination by MOIT in order to identify whether any can be used for enforcement

purposes. Many, though, appear too variable to be used for this purpose.

The results for CFLs are much more consistent and could have been used for enforcement purposes

if any had performed below the minimum permitted performance level. None did.

The main finding of this report is that the variability in test results for two of the three product

sectors (rice cookers and electric fans) is very large for some models. Examination of the test

methodologies used, the procedures followed and the data recorded by the test laboratories has

identified that the following are likely to be the main reasons for the variability:

Not all measurements are being reproduced in a consistent way by each of the three

laboratories;

The specification and calibration of measuring instrumentation needs to be improved in

some cases;

The published test method for rice cookers needs to be amended to enable it to be

consistently reproduced by different test laboratories;

Thresholds for energy label bands for electric fans are too narrowly defined.

These reasons are covered in the discussions below. Actions have been recommended that should

enable the results of laboratory testing to become sufficiently accurate to provide confidence to

the Government, consumers and manufacturers.

5.1 Product testing related advice for each of the QUATEST laboratories

The deployment of testing experts to provide training and guidance to testing staff at the QUATEST

laboratories has been beneficial since they have identified where further refinements can be made.

The results of the inter-laboratory testing show that, if not done already, the following needs to be

done at each laboratory:

Upgrade and calibrate testing equipment as already recommended by the experts directly

to each of the QUATEST laboratories;

34

Implement a program to apply measurement uncertainties procedures and so identify and,

where possible, reduce sources of measurement error;

Implement the use of the guidance manuals for testing electric fans and rice cookers.

Note: the use of these and the routine estimation of uncertainties of measurement should

support the continuing development of a performance testing culture at the QUATEST

laboratories – one in which performance testing is always undertaken in a meticulous way;

5.2 Recommendations applicable to all approved testing organisations in Vietnam

Poor reproducibility of test results between testing organisations is not uncommon. It has

previously been found in similar programs conducted in other countries. As a result of these, a

number of processes have been developed to improve the repeatability and reproducibility of

testing at different locations, and these are recommended by the authors of this report:

Use of common testing manuals (or shared interpretation sheets) for all products impacted

by the standards and labelling regulations;

Undertaking of regular inter-laboratory trials to check that the test results being obtained

are reproduced consistently and, where not, to have the test laboratories to work

cooperatively together to establish and eliminate the causes of poor reproducibility;

Feed the experiences of using the test methodology standards by the laboratories back to

the standards development body (VSQI, for Vietnam) in order to support the continuing

development (to improve the repeatability and, hence, the reproducibility) of those test

methods.

5.3 The accreditation operated by the Vietnamese Board of Accreditation (BoA)

The reports from each of the experts suggest that the QUATEST laboratories do not fully match the

minimum standards that are required of laboratories that have been accredited to the

requirements of ISO/IEC 17025. For example, uncalibrated or incorrect measuring equipment was

sometimes used and none of the laboratories were routinely estimating uncertainties of

measurement.

This is a matter that the BoA can assist the QUATEST laboratories with. The BoA can advise the

QUATEST laboratories of the detailed requirements in the ISO/IEC17025 standard and can make a

detailed examination of these at their next accreditation visits to the laboratories.

This is particularly important as the accreditation process is there to provide the assurance to all

stakeholders that testing is being carried out properly, and with sufficient accuracy.

5.4 Support for the MOIT approval process

Currently, MOIT manage a separate approval process to the accreditation process operated by the

BoA. Such approval processes are not unusual as many regimes recognise that the formal

accreditation process has some limitations and so wish to impose further conditions.

35

MOIT may wish to review the procedures it follows in its approval process once it is satisfied that

repeat accreditation visits by the BoA have resulted in further improvements being implemented

by the QUATEST laboratories.

5.5 Recasting threshold for energy label bands

The evaluation of results reported in section 4.2.1 suggests that the thresholds for the energy

label bands for electric fans would benefit from being re-cast. The evaluation identified that the

market is already saturated with 5 star products and most of the fans tested easily exceeded the

energy efficiency requirements for 5 stars.

NOTE: further work relating to this topic of recasting thresholds is covered by another part of the

VEESL Program.

36

APPENDIX 1 Example of test results sheet for one model of electric fan

Table 9: Example of test results sheet for one model of electric fan

Measurement Radius

Power

point

consumption

(at the

highest

Setting with

Osc)

(I/D)

( r)

(P)

Wind speed

(at the

highest

Setting)

Average

of Wind

speed

Left

V = (Vl +

Vr )/2

Right

Check

point

Cross sec. of

donuts

Wind flow

blowing

through the

donuts

S=

Qn = V.S =

2*(PI)*r*b*10- (m2)*(m/min)

6

1

2

3

4

5

6

7

8

9

10

11

(mm)

(W)

20

60

100

140

180

220

260

300

340

380

420

47.80

47.80

47.80

47.80

47.80

47.80

47.80

47.80

47.80

47.80

47.80

(m/min)

162.6

197.4

205.2

184.8

156.0

142.8

111.0

99.6

80.4

60.6

40.2

202.2

208.2

212.4

167.4

153.0

108.6

99.6

56.4

26.4

0.0

0.0

(m/min)

182.40

202.80

208.80

176.10

154.50

125.70

105.30

78.00

53.40

30.30

20.10

Go

Go

Go

Go

Go

Go

Go

Go

Go

Go

Stop

(m2)

(m3/min)

0.005

0.015

0.025

0.035

0.045

0.055

0.065

0.075

0.085

0.096

0.106

0.917

3.058

5.248

6.196

6.989

6.950

6.881

5.881

4.563

2.894

2.122

Total

wind

flow

blowing

through

the

donuts

Energy

Efficiency

Coefficient

Level of

Energy

Efficiency

of Fans

(stable,

stand,

wall)

Q = sum

(Q1

…Qn)

EER do =

Q/P

R = EER do

/ EER min

Level

(m3/min) (m3/min.W)

0.917

3.975

9.223

15.419

22.408

29.359

36.239

42.120

46.684

49.577

51.699

0.019

0.083

0.193

0.323

0.469

0.614

0.758

0.881

0.977

1.037

1.082

0.02

0.10

0.24

0.40

0.59

0.77

0.95

1.10

1.22

1.30

1.35

0

0

0

0

0

0

0

2

3

3

4

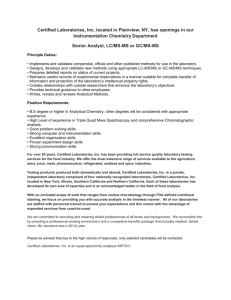

APPENDIX 2 Example of test results sheet for one model of rice cooker

Table 10: Example of test results sheet for one model of rice cooker

Witness test results for Energy Efficiency test of Rice cookers TCVN8252:2009

Sample 4

Product description:

Rice Cooker Model #4

Model No.:

Ratings

220V 50Hz

Actual Power

Cooker weight:

Aluminium, W g1 (g)

304 Staninless steel, W g2 (g)

CP1 (cal/g K)

0.22 CP2 (cal/g K)

700W

Test staff:

666W

0

0.12

Formal witness test

Ambient temperature 20.6 ~ 21.8°C

Relative humidity

52% ~ 72%

Test date:

22 Nov & 25 Nov-2013

Test voltage

219.8V

Frequency

50Hz

Cooker mode:

Cook

Test

T1 (ºC)

T2 (ºC)

ΔT (ºC)

Water volume (g)

Energy consumption, Ec (Wh)

Initial test

19.2

31.0

11.8

2648

44.9

Trail 1

19.2

30.8

11.6

2648

44.9

Trail 2

19.4

31.2

11.8

2648

44.9

Trail 3

19.4

31.2

11.8

2648

44.9

Average of trails 1,2,3

19.3

31.1

11.7

2648.0

44.9

Rd%

Energy Efficiency Index, K

{ΔT x [Q + (W g1 x CP1) + (W g2 x CP2)] x 100} / (0,24 x Ec x 3600)

Rd/Rmin

1.03

82.11910478

label grade 1

38

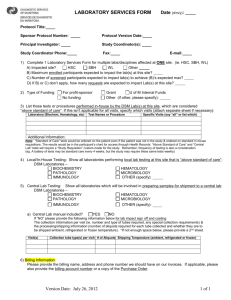

APPENDIX 3 Example of test results sheet for one model of CFL

Table 11: Example of test results sheet for one model of CFL

Witness test results for Energy Efficiency test of CFL TCVN 7896

Lamp model Information

Identifier

VEESL-DR11-22

VEESL-DR11-25

VEESL-DR11-26

VEESL-DR11-28

VEESL-DR11-29

Average

non-uniformity factor

Brand A, 11W

Voltage (V)

Current (A)

220.0

220.0

220.0

220.0

220.0

220.0

/

0.074

0.074

0.076

0.075

0.074

0.075

2.68%

Power

(W)

9.6

9.6

9.9

9.8

9.7

9.7

3.09%

PF

0.593

0.591

0.591

0.592

0.592

0.592

0.002

Flux (lm)

Efficacy

(lm/W)

529.0

531.7

547.0

552.4

532.2

538.5

4.35%

55.10

55.39

55.25

56.37

54.87

55.40

2.71%

Colour coordinate

x

y

0.3164

0.3469

0.3160

0.3443

0.3173

0.3476

0.3155

0.3450

0.3170

0.3473

0.3164

0.3462

0.0018

0.0033

CCT

6199

6231

6157

6252

6170

6202

95

CRI

81.9

81.5

82.0

81.4

82.0

81.8

0.6

39