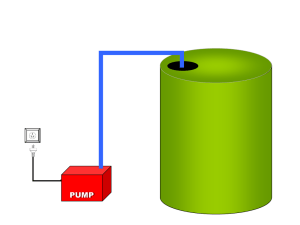

2014-655 MiniPumper specs addendum[Icon]

advertisement

![2014-655 MiniPumper specs addendum[Icon]](http://s3.studylib.net/store/data/006674424_1-e593600490caebf79a014e3ef27dd134-768x994.png)