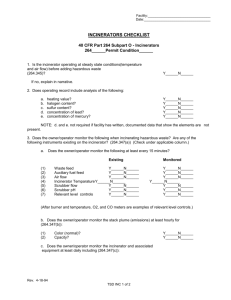

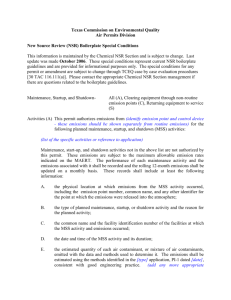

Detailed description of requirements new EPA requirements

advertisement