Immunofluidics_NIH DEBUT COMPETITON

advertisement

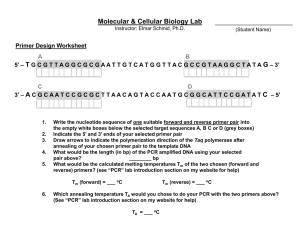

A Novel Microfluidic PCR Platform for Rapid Tissue Typing Immunofluidics NAME Brandon Wong Philip Chao Irfanali S. Kermalli Jay Le Pere Daniel Lorey UCI SCHOOL/ OTHER AFFILIATION Henry Samueli School of Engineering Henry Samueli School of Engineering Henry Samueli School of Engineering Henry Samueli School of Engineering Henry Samueli School of Engineering GRADUATE/UNDER- MAJOR/MINOR GRADUATE FIELD OF STUDY EMAIL ID Undergraduate BME brandogw@uci.edu Undergraduate BME/Materials Minor pchao@uci.edu Undergraduate BME/Management Minor ikermall@uci.edu Undergraduate BME jlepere@uci.edu Undergraduate BME/Materials Minor dlorey@uci.edu Division: Diagnostic Devices/Methods Page 1 Abstract The ImmunoFluidics Chip is a device that leverages cutting edge diagnostic technologies to assist doctors in finding a donor-recipient match during organ transplantations. Tissue matching has been proven to make a significant difference on survival rate in organ transplant recipients. However, due to the urgent nature of these transplantations, there is not enough time for tissue typing to be done. Consequently, surgeons choose to put a healthy organ into a patient rather than taking the time to match the organ, potentially lowering its viability. The ImmunoFluidics Chip leverages microfluidic technology to be able to perform rapid tissue typing. By performing tissue typing faster, more information about the organ can be determined, letting surgeons make a better decision before transplantation of the organ. Background and Clinical Need Every year, organ transplantation saves the lives of thousands of patients. In 2009, records show that roughly 30 thousand organ transplantations were performed in the United States alone1. Even though this procedure has been prevalent in clinical practice for many decades, there are still areas of improvement that can result in higher patient survival rate2. Specifically, tissue typing has been proven to make a significant difference on reducing the amount of immunosuppressant drugs used, shortening the recovery time after transplantation, and increasing the probability of survival post-implantation2. However, due to the urgent nature of these procedures, there is not enough time for tissue typing to be done. Though tissue matching is proven to increase survival rate of the patient, quickly transferring a healthy organ to the recipient is more important. Considering that over 75% of organ donations come from cadavers, time is an important limitation that determines whether an organ remains viable for implantation. Certain organs, like the heart and the lung, remain viable only 4-6 hours after blood stops circulating3. Traditional technologies to perform tissue typing include serological, cellular, and molecular tests. Current tissue typing takes around three hours and requires the expertise of trained lab technician, meaning the process cannot be started until the organ has arrived at the laboratory. The (1) inconvenient location of the lab and (2) time needed for the diagnostics test make tissue typing techniques impractical for most organs, two limitations ImmunoFluidics overcomes. Patient-Donor Matching during Organ Transplantation - Issues: Currently impractical due to time needed to tissue type organ Incorrect typing contributes to $1.5 billion dollars in cost every year Limited to diagnostic tests available in central laboratories Need expensive laboratory expertise Currently only practiced on kidney (longer explanted survival time) and bone marrow transplant (live patient) ImmunoFluidics directly competes with other platforms available to perform PCR based diagnostics tests. Current microfluidic PCR technologies enable different applications of PCR techniques; however, these platforms still employ inefficient, bulky external heating elements. ImmunoFluidics relies on novel microfluidic technologies to maintain a sustainable competitive edge. Page 2 Competitive Edge ImmunoFluidics vs. Traditional PCR: Advantages of Microfluidic Diagnostic Technology: Combines faster reaction times with decreased reagent usage. Allows portability for point-of-care or point-of-application diagnostics Requires minimal expertise due to on-chip automation Provides faster reaction times due to high surface area to volume ratio in the micro scale Less thermal mass for heating and cooling during biological diagnostic techniques Ability to multiplex reactions. Competition Competition with ImmunoFluidics would come from other companies attempting to create microfluidic PCR devices. The following are top companies involved with this technology: 1. RainDance Materials: PDMS Chip, pipette tips, drive oil, carrier oil, stabilizer/destabilizer reagents Pros: 4,000 regions per sample, highly accurate, no valves or moving parts on chip, disposable chip, requires picoliter samples Cons: Off-chip heating, $225,000 for instrumentation, of-chip preparation, manual loading of multiple wells 2. Fluidigm Materials: Chip created from multiple layers of fused rubber Pros: 48 regions for each of 48 samples, computerized loading device for fewer liquid handling steps, requires nanoliter samples Cons: Off-chip heating, 4 hours from start to finish, $79,000 for instrumentation 3. HaloPlex Materials: Biotinylated probes Pros: Custom designs of probes up to 500 Kb, great specificity, uniformity and high sensitivity Cons: 6 hours for amplification, 96 samples, 480 reactions Competitors demonstrate complex microfluidic function and manipulation for PCR diagnostics; however, there are limitations to many of their technologies that ImmunoFluidics will address. Device Design Technological developments in the industry have focused on sensitivity and size of PCR devices. Simply put, PCR is a technique that uses cyclic heating for controlled amplification of genomic information. Critical aspects of PCR devices are (1) heating control/speed, (2) sample loading and (3) DNA analysis. Our device presents novel technologies in heating as well as loading. Further DNA analysis will rely on using previously developed platforms provided by collaborating companies. Figure 1 represents the general design of our device as well as a picture of our prototype. Page 3 Figure 1: general design of our device (left), finished prototype (right) Design Specifications Design Decision Electrode Composition Electrode Shape Composition of Base/Electrode Layer Specification Gold – Sputter Coat Oven Heating Coil Concept Polystyrene – “Shrinky Dink” Concept Loading Layer Composition Polyolefin Flow Layer Design Sealing Layer Simple Loading of Wells Polyolefin Well Number Chip Size Rationale - High conductivity and well characterized resistivity curves - Sputter and shrink technology allows for no clean room -Consistent localized heating achievable -Best material properties, chemically inert -Ability to create complex designs – Allow easy prototyping, fabrication (no clean room), and scalability -Low cost, easy to fabricate, adhesive nature makes for easy manipulation -Fast and easy fabrication allows for scalable loading -Low cost, easy to fabricate layer prevents crosscontamination and evaporation during thermocycling 4-5 -Basic design for proof of concept - Plan to upscale later on Roughly 3cm by - Increased portability 2.5 cm Prototype Device Our prototype device will be loaded by a single syringe with positive pressure. Furthermore, our device will be powered by an external power source connected directly to the electrode contact pads. Specific device operation can be seen in Figure 2. Page 4 Figure 2: Device Functionality and Operation Device Novelty ImmunoFluidics directly competes with other platforms available to perform PCR based diagnostics tests. Current microfluidic PCR technologies enable different applications of PCR techniques; however, these platforms still employ inefficient, bulky external heating elements. ImmunoFluidics relies on novel microfluidic technologies to maintain a sustainable competitive edge. ImmunoFluidics leverages novel patented fabrication techniques, developed in labs at the University of California at Irvine, to provide unparalleled reaction speeds on a platform that is biocompatible, cheap, and easily manufactured. This novel manufacturing is patented and owned by our mentor, Dr. Michelle Khine as well as by the University of California, Irvine. From our collaboration with other diagnostic companies, we will be able to license and use preexisting patents from our collaborators at very low costs if any. Page 5 Sustainable Competitive Technological Highlights Our device has been optimized and tested for functionality through finite element modeling and a series of reiterations. Initial testing and has shown promising results that our device can surpass the competition. Initial electrode heating capabilities have been identified through IR camera imaging as seen in figure 3. Further analysis and data needs to be gathered to support the complete validity of our device. We expect full PCR capabilities within the next few weeks. Page 6 Figure 3: thermal map (top), temperature over time (bottom References [1] Bentley, T. Scott and Steven G. Hanson. “2011 U.S. Organ and tissue transplant cost estimates and discussion.” Millman Research Report. April 2011 [2] S. J. Lee, J. Klein, M. Haagenson, L. A. Baxter-Lowe, D. L. Confer, M. Eapen, M. Fernandez-Vina, N. Flomenberg, M. Horowitz, C. K. Hurley, H. Noreen, M. Oudshoorn, E. Petersdorf, M. Setterholm, S. Spellman, D. Weisdorf, T. M. Williams and C. Anasetti, Blood, 2007, 110, 4576-4583. [3] Abdulla K. Salahudeen, Naeem Haider and Warren May. “Cold ischemia and the reduced long-term survival of cadaveric renal allografts.” Kidney International (2004) 65, 713–718