end - Springer Static Content Server

advertisement

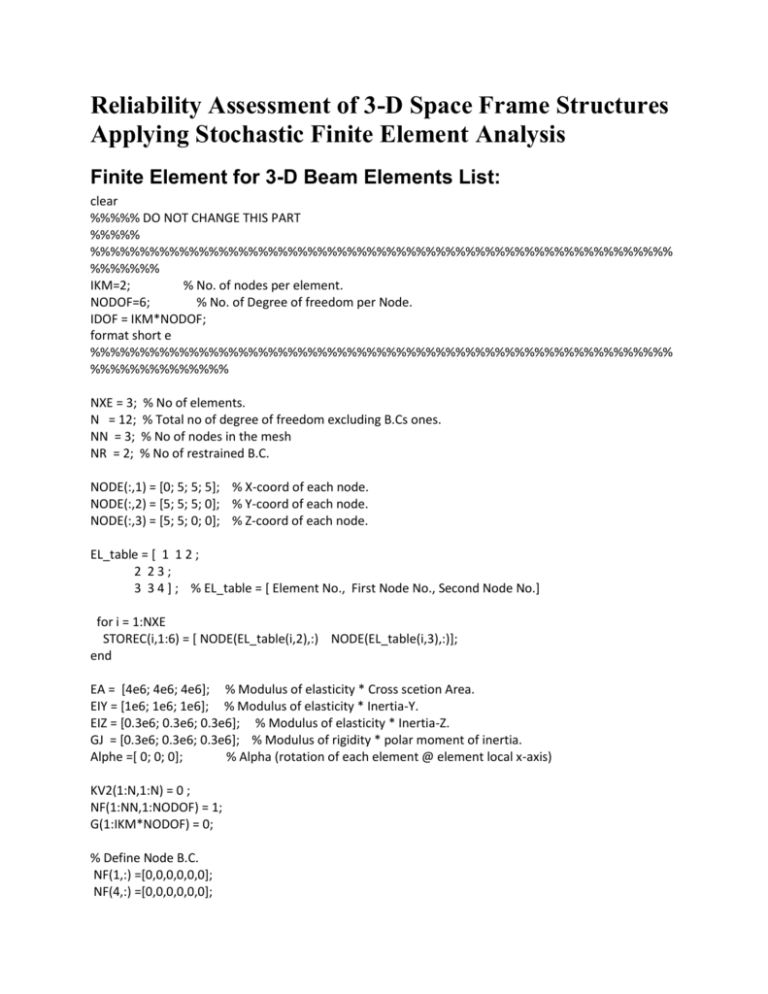

Reliability Assessment of 3-D Space Frame Structures

Applying Stochastic Finite Element Analysis

Finite Element for 3-D Beam Elements List:

clear

%%%%% DO NOT CHANGE THIS PART

%%%%%

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

%%%%%%%

IKM=2;

% No. of nodes per element.

NODOF=6;

% No. of Degree of freedom per Node.

IDOF = IKM*NODOF;

format short e

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

%%%%%%%%%%%%%%

NXE = 3; % No of elements.

N = 12; % Total no of degree of freedom excluding B.Cs ones.

NN = 3; % No of nodes in the mesh

NR = 2; % No of restrained B.C.

NODE(:,1) = [0; 5; 5; 5]; % X-coord of each node.

NODE(:,2) = [5; 5; 5; 0]; % Y-coord of each node.

NODE(:,3) = [5; 5; 0; 0]; % Z-coord of each node.

EL_table = [ 1 1 2 ;

2 23;

3 3 4 ] ; % EL_table = [ Element No., First Node No., Second Node No.]

for i = 1:NXE

STOREC(i,1:6) = [ NODE(EL_table(i,2),:) NODE(EL_table(i,3),:)];

end

EA = [4e6; 4e6; 4e6]; % Modulus of elasticity * Cross scetion Area.

EIY = [1e6; 1e6; 1e6]; % Modulus of elasticity * Inertia-Y.

EIZ = [0.3e6; 0.3e6; 0.3e6]; % Modulus of elasticity * Inertia-Z.

GJ = [0.3e6; 0.3e6; 0.3e6]; % Modulus of rigidity * polar moment of inertia.

Alphe =[ 0; 0; 0];

% Alpha (rotation of each element @ element local x-axis)

KV2(1:N,1:N) = 0 ;

NF(1:NN,1:NODOF) = 1;

G(1:IKM*NODOF) = 0;

% Define Node B.C.

NF(1,:) =[0,0,0,0,0,0];

NF(4,:) =[0,0,0,0,0,0];

%Define Loads

NL = 1 ; % no of loaded degree of freedom

LOADS(1:N) = 0;

LOADS(2) = -100;

Main Program Body

% INPUT SECTION C

clear

input3d;

% NODE FREEDOM DATA

NF = READNF(NN,NODOF,NR,NF) ;

% GLOBAL STIFFNESS MATRIX ASSEMBLY

for IP=1:NXE

KM = BMCOL3(EA,EIY,EIZ,GJ,Alphe,IP,STOREC);

G = GSTRNG(EL_table,IP,NODOF,NF) ;

STOREG(IP,:) = G;

[KV2] = FORMKV(KV2,KM,IKM,G,N,NR,IDOF);

end

KV2

Disp2 = inv(KV2)*LOADS';

Disp2

%RETRIEVE ELEMENT END FORCES AND MOMENTS

for IP=1:NXE

[KM] = BMCOL3(EA,EIY,EIZ,GJ,Alphe,IP,STOREC);

for i=1:IDOF

if (STOREG(IP,i)==0)

Edisp(i)=0;

else

Edisp(i) = Disp2(STOREG(IP,i));

end

end

Efor = KM*Edisp';

Eforce(IP,1:IDOF) = Efor';

end

Eforce

function [G1] =GSTRNG(EL_table,IP,NODOF,NF)

Node(1) = IP;

Node(2) = IP + 1;

L1=0;

for i1=1:2

for j1= 1:NODOF

L1 = L1+1

EL_table(L1) = NF(Node(i1),j1)

end

end

Subroutine to Calculate Element Stiffness Matrix

function [KMF] = BMCOL3(EA1,EIY1,EIZ1,GJ1,Alphe1,IP,COORD)

%THIS SUBROUTINE FORMS THE STIFFNESS MATRIX OF AN INCLINED 2-D BEAM-COLUMN ELEMENT

EA = EA1(IP); EIY = EIY1(IP); EIZ = EIZ1(IP); GJ = GJ1(IP); alph = Alphe1(IP)*(pi/180);

X1=COORD(IP,1); Y1=COORD(IP,2); Z1 = COORD(IP,3);

X2=COORD(IP,4); Y2=COORD(IP,5); Z2 = COORD(IP,6);

ELL=sqrt( (Y2-Y1)^2 + (X2-X1)^2 + (Z2-Z1)^2 )

CX = (X2-X1)/ELL; CY = (Y2-Y1)/ELL; CZ = (Z2-Z1)/ELL;

CXZ = sqrt( CX^2 + CZ^2 );

KM(1:12,1:12) = 0;

KM(1,1) = EA/ELL; KM(1,7) = -EA/ELL;

KM(2,2) = 12*EIZ/(ELL^3); KM(2,6) = 6*EIZ/(ELL^2); KM(2,8) = -12*EIZ/(ELL^3); KM(2,12) =

6*EIZ/(ELL^2);

KM(3,3) = 12*EIY/(ELL^3); KM(3,5) = -6*EIY/(ELL^2); KM(3,9) = -12*EIY/(ELL^3); KM(3,11) = 6*EIY/(ELL^2);

KM(4,4) = GJ/ELL; KM(4,10) = -GJ/ELL;

KM(5,3) = KM(3,5); KM(5,5) = 4*EIY/(ELL); KM(5,9) = 6*EIY/(ELL^2); KM(5,11) = 2*EIY/(ELL);

KM(6,2) = KM(2,6); KM(6,6) = 4*EIZ/(ELL); KM(6,8) = -6*EIZ/(ELL^2); KM(6,12) = 2*EIZ/(ELL);

KM(7,1) = KM(1,7); KM(7,7) = EA/ELL;

KM(8,2) = KM(2,8); KM(8,6) = KM(6,8); KM(8,8) = 12*EIZ/(ELL^3); KM(8,12) = -6*EIZ/(ELL^2);

KM(9,3) = KM(3,9); KM(9,5) = KM(5,9); KM(9,9) = 12*EIY/(ELL^3); KM(9,11) = 6*EIY/(ELL^2);

KM(10,4) = KM(4,10); KM(10,10) = GJ/ELL;

KM(11,3) = KM(3,11); KM(11,5) = KM(5,11); KM(11,9) = KM(9,11); KM(11,11) = 4*EIY/(ELL);

KM(12,2) = KM(2,12); KM(12,6) = KM(6,12); KM(12,8) = KM(8,12); KM(12,12) = 4*EIZ/(ELL);

if CXZ==0

Alph = [ 0

CY

0;

-CY*cos(alph) 0 sin(alph);

CY*sin(alph) 0 cos(alph) ];

else

Alph = [ CX

CY

(-CX*CY*cos(alph)-CZ*sin(alph))/CXZ

CY*CZ*cos(alph)+CX*sin(alph))/CXZ;

(CX*CY*sin(alph)-CZ*cos(alph))/CXZ

];

CXZ*cos(alph)

-CXZ*sin(alph)

CZ;

((CY*CZ*sin(alph)+CX*cos(alph))/CXZ

end

GAMM (1:12,1:12) = 0;

GAMM(1:3,1:3) = Alph;

GAMM(4:6,4:6) = Alph;

GAMM(7:9,7:9) = Alph;

GAMM(10:12,10:12) = Alph;

KM1 = GAMM'*KM;

KMF = KM1*GAMM;

Subroutine to Calculate Global Stiffness Matrix

function [BK2] = FORMKV(BK2,KM,IKM,G,N,NR,IDOF)

% C C THIS SUBROUTINE FORMS THE GLOBAL STIFFNESS MATRIX C STORING THE UPPER TRIANGLE AS A

VECTOR BK(N*(IW+l))

for I =1:IDOF

if (G(I) == 0) ,continue ,end

for J =1:IDOF

if (G(J) == 0) ,continue ,end

BK2(G(I),G(J)) = BK2(G(I),G(J)) + KM(I,J);

end

end

Subroutine to extract ANSYS file to MATLAB

echo off

%

ext56uxuyuz.m

extraction of ux, uy and uz dof's only

%

10-13-00

clear all;

%

bring up a window with the file names of defined extension to choose from

filename=uigetfile('*.lis','Select ELEMENT Input file from list - ELIST')

fid = fopen(filename,'rt'); %% Open in read mode as text.

if fid == -1

error('Error opening the file')

end

ic=1;

while 1

nextline = fgetl(fid);

%

read a line

%

end of the file

if nextline == -1, break, end

if ext56chk(nextline, ' ELEM') & ext56chk(nextline, 'MAT')

emp = 0;

while 1

nextline = fgetl(fid);

c = sscanf(nextline,' %f');

if isempty(c),

emp = emp+1;

if emp > 1, break, end;

continue;

end

array(ic,:) = c';

ic = ic + 1;

end

end

end

fclose(fid);

filename=uigetfile('*.lis','Select NODES Input file from list - NLIST')

fid = fopen(filename,'rt'); %% Open in read mode as text.

if fid == -1

error('Error opening the file')

end

ic = 1;

while 1

nextline = fgetl(fid);

read a line

if nextline == -1, break, end;

end of the file

if ext56chk(nextline, ' X') & ext56chk(nextline, ' Y')

emp=0;

while 1

nextline = fgetl(fid);

c2 = sscanf(nextline,' %f');

%

if isempty(c2),

emp = emp+1;

if emp > 0, break, end;

continue;

end

%

array2(ic,:) = c2';

ic = ic + 1;

end

end

end

fclose(fid);

NE = size(array(:,1));

filename=uigetfile('*.lis','Select TEMP Input file from list - BFLIST')

fid = fopen(filename,'rt'); %% Open in read mode as text.

TEMP = [];

if fid == -1

error('Error opening the file')

end

ipe=1;

while 1

nextline = fgetl(fid);

%

read a line

if ~isstr(nextline), break, end;

end of the file

%

if ext56chk(nextline, ' ELEMENT=') & ext56chk(nextline, ' TEMPERATURES')

disp(nextline);

EL(ipe) = sscanf(nextline, ' ELEMENT=

%f ');

nextline = fgetl(fid);

c3 = sscanf(nextline,' %f');

TEMP(ipe,:) = [EL(ipe) c3(1,1)];

ipe = ipe+1;

%if ip > NE, break,end;

end

end

fclose(fid);

filename=uigetfile('*.lis','Select NODES FORCES Input file from list - FLIST')

fid = fopen(filename,'rt'); %% Open in read mode as text.

FORC_E = [];

if fid == -1

error('Error opening the file')

end

while 1

nextline = fgetl(fid);

%

read a line

if ~isstr(nextline), break, end

end of the file

if ext56chk(nextline, ' NODE') & ext56chk(nextline, ' IMAG')

%

ic2=1;

while 1

nextline = fgetl(fid);

fc = sscanf(nextline,'

%i %s %f')

if isempty(fc), break, end;

FORC_E(ic2,1:6) = [fc(1) fc(2) fc(3) fc(4) fc(5) fc(6)];

ic2 = ic2 + 1;

end

end

end

fclose(fid);

Subroutine to Input Parameters (mean and covariance)

%%% Verify with ANSYS file 'beam4.db' with no Temp. - 'beam3.db' with Temp

%%%%%%%%%%%%%%%%%%%%

extract;

%pack;

format short e

%%%%%%% DO NOT CHANGE THIS PART

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%5

IKM =2; % No. of nodes in each Element

NODOF=6; % No. of Degree of Freedom at each node.

IDOF= IKM*NODOF; % No. of Degree of Freedom for each element.

% X - Axis = is Horizontal and from left to right.

% Y - Axis = is Vertical and from down to up.

% Theta_Z = is counter clockwise.

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

%%%%%%%%%

%%%%%%% Define FE Mesh %%%%%%%%%%%%%%%%%%%%%%%%%%%%%

a11 = size(array(:,1)); NXE = a11(1); % No of elements.

a22 = size(array2(:,1)); NN = a22(1); % No of nodes in the mesh

NF(1:NN,1:NODOF) = -1;

G(1:IKM*NODOF) = 0;

%%%%%%%%%%%%%%%%%% Enter Node (x1,y1) Location & Element Node Numbering

NODE(:,1:4) = array2(:,1:4); % [ Node No., X, Y, Z] location of each node.

%%%%%% EL_table = [Element No., First Node No., Second Node No., Real_Constants No,

Material_Constants No. ]

EL_table(:,1) = array(:,1); EL_table(:,2:3) = array(:,7:8); EL_table(:,4) = array(:,4); EL_table(:,5) =

array(:,2);

%%%%%%%%%%%%%%%%%%%%% Define Real constants of the cross section properties of the 2-D

BEAMS %%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

% %% You can define any No. of Real_Constants Sets according to your problem

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

% Enter Dist. Type of each variable %%%%%%%%%%%%%%%%%%%%%%

% 0 = Normal.

% 1 = Lognormal.

% 2 = Type-I.

% Real_Constants[Set No.] = [Ty_mean,Ty_COV, Tz_mean,Tz_COV, Dist_ty, Dist_tz, Alphe]

NREAL = 6; % No. of real constants sets

Real_Constants(1,1:7) = [ 25 0.05 15 0.05 1 1 0];

Real_Constants(2,1:7) = [ 20 0.05 12 0.05 1 1 0];

Real_Constants(3,1:7) = [ 15 0.05 10 0.05 1 1 0];

Real_Constants(4,1:7) = [ 12 0.05 6 0.05 1 1 0];

Real_Constants(5,1:7) = [ 11 0.05 5 0.05 1 1 0];

Real_Constants(6,1:7) = [ 10 0.05 5 0.05 1 1 0];

% You can define any No. of Real_Constants Sets

%%%%%%%%%%%%%%%% Define Sets of Material Properties

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

%%%%%%%%%%%%%%%%

% Material_Properties[Set. no.] = [E_mean, E_COV, Fy_mean, Fy_COV, Density_mean, Density_cov,

Thermal-exp_mean, Thermal-exp_cov, Dist_E, Dist_Fy,

%

Dist_density, Dist_thermal_exp]

NM = 1; % No of Material Properties Sets.

Material_Properties(1,1:12) = [ 72e6 0.06 150e3 0.11 2.63e-6 0 23e-6 0 1 1 1 1];

T_ref = 20;

%Material_Properties(1,1:9) = [ 29e3 0.06 39.6 0.11 0 0 0 0 0];

%Material_Properties(2,1:9) = [ 39e3 0 30 0 0 0 0 0 0];

%%%%%%%%%%% DO NOT CHANGE THIS PART %%%%%%%%

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

%%%%

for i = 1:NXE

STOREC(i,1:NODOF) = [ NODE(EL_table(i,2),2:4) NODE(EL_table(i,3),2:4)];

end

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

% Define Node B.C. , 0 = fixed , 1 = free

NF(78,:) =[0,0,0,0,0,0];

NF(79,:) =[0,0,0,0,0,0];

NF(80,:) =[0,0,0,0,0,0];

NF(81,:) =[0,0,0,0,0,0];

NR = 4; % No of restrained B.C.

N = (NN - NR)*6; % Total no of degree of freedom excluding B.Cs ones.

%%%%%%% Define Loads Sets

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

%%%%%%%%%%%%%%%

% Loads_Set[Set No.] = [Key, Value_mean, Value_COV, Distribution Type, Dir-X, Dir_Y, Dir_Z, Node No.(if

%concentrated load) OR No. of Element(NE)

% (Thermal Load), Element No. OR Element No.1 (Thermal Load) , Angle between Load and the Beam OR

%Element No.2 (thermal load), Element No. 3, .... % ......., Elemnt no. NE ];

%[Dir-X, Dir-Y, Dir-Z] = for distributed load, define the plane of working load, i.e. x-y plane = [ 1 1 0]; i.e.

%x-z plane = [0 1 1]; x-y-z are

%the element coord. system

%[Dir-X, Dir-Y, Dir-Z] = for concentrated load are the Global Coord. system

% Key = 0 - Concentrated Load.

% Key = 1 - Distributed Load.

% Key = 2 - Thermal Load.

% Key = 3 - Acceleration.

% Enter Dist. Type of each variable %%%%%%%%%%%%%%%%%%%%%%

% 0 = Normal.

% 1 = Lognormal.

% 2 = Type-I.

NLS = 1;

% No. of Load Sets.

Loads_Set(1,1:10) = [ 3 10e4 0.1 2 0 1 0 0 0 0];

if ~isempty(FORC_E)

a22 = size(FORC_E(:,1)); n3 = a22(1);

for i3 = 1:n3

NLS = NLS + 1;

Loads_Set(NLS,1) = 0;

Loads_Set(NLS,2) = FORC_E(i3,4);

Loads_Set(NLS,3) = 0.1;

% Coefficient of Variation

Loads_Set(NLS,8) = FORC_E(i3,1);

if FORC_E(i3,3) == 88

Loads_Set(NLS,5:7) = [1 0 0];

elseif FORC_E(i3,3) == 89

Loads_Set(NLS,5:7) = [0 1 0];

elseif FORC_E(i3,3) == 90

Loads_Set(NLS,5:7) = [0 0 1];

end

end

end

if ~isempty(TEMP)

[TEMP2,I2] = sort(TEMP(:,2)); ik=1;

while 1

NLS = NLS + 1; ik2=1;

while 1

Loads_Set(NLS,1) = 2; % Key for Thermal Load

Loads_Set(NLS,2) = TEMP2(ik); Loads_Set(NLS,3) = 0.05;

Loads_Set(NLS,9+(ik2-1)) = I2(ik);

Loads_Set(NLS,8) = ik2;

ik2 = ik2+1;

if ik < (ipe-1)

if TEMP2(ik+1) ~= TEMP2(ik)

ik = ik+1;

break;

end

end

ik = ik + 1;

if ik > (ipe-1) , break, end;

end

if ik > (ipe-1), break, end;

end

end

%Loads_Set(2,1:11) = [ 2

%Loads_Set(3,1:11) = [ 2

%Loads_Set(4,1:11) = [ 2

%Loads_Set(2,1:10) = [ 3

50 0.1 2

40 0.1 2

-10 0.1 2

20e4 0.1 2

0 0 0 3 1 2 3 ];

0 0 0 3 4 5 6 ];

0 0 0 3 7 8 9 ];

0 1 0 0 3 0];

%%%%%%%%%%%%%%%%%%% DO NOT change this part %%%%%%%%%%%%%%%%%%%%%%%

DVn = 0;

for iL=1:NLS % No of Load sets

if Loads_Set(iL,3) ~= 0

DVn = DVn + 1; dist(DVn) = Loads_Set(iL,4);

Xs(1,DVn) = Loads_Set(iL,2); % Mean value

Xs(2,DVn) = Loads_Set(iL,3); % COV value

end

end

for ir = 1:NREAL

if Real_Constants(ir,2)~= 0

DVn = DVn + 1; dist(DVn) = Real_Constants(ir,5);

Xs(1,DVn) = Real_Constants(ir,1); % Mean value

Xs(2,DVn) = Real_Constants(ir,2); % COV value

end

if Real_Constants(ir,4)~= 0

DVn = DVn + 1; dist(DVn) = Real_Constants(ir,6);

Xs(1,DVn) = Real_Constants(ir,3); % Mean value

Xs(2,DVn) = Real_Constants(ir,4); % COV value

end

end

for im = 1:NM

if Material_Properties(im,2)~= 0

DVn = DVn + 1; dist(DVn) = Material_Properties(im,9);

Xs(1,DVn) = Material_Properties(im,1); % Mean value

Xs(2,DVn) = Material_Properties(im,2); % COV value

end

if Material_Properties(im,4)~= 0

DVn = DVn + 1; dist(DVn) = Material_Properties(im,10);

Xs(1,DVn) = Material_Properties(im,3); % Mean value

Xs(2,DVn) = Material_Properties(im,4); % COV value

end

if Material_Properties(im,6)~= 0

DVn = DVn + 1; dist(DVn) = Material_Properties(im,11);

Xs(1,DVn) = Material_Properties(im,5); % Mean value

Xs(2,DVn) = Material_Properties(im,6); % COV value

end

if Material_Properties(im,8)~= 0

DVn = DVn + 1; dist(DVn) = Material_Properties(im,12);

Xs(1,DVn) = Material_Properties(im,7); % Mean value

Xs(2,DVn) = Material_Properties(im,8); % COV value

end

end

DVn

Xs

Subroutine to Calculate Displacement and Forces in Frame Structure

function [Disp2,Eforce,STOREG,NF] =

Beam3D(IKM,IDOF,NODOF,NXE,N,NN,NR,E,Iy,Iz,A,Alphr,STOREC,NF,EL_table,LOADS,T_ref,Loads_Set,Alp

ha_T,NLS)

% NODE FREEDOM DATA

T_t(1:NXE) = T_ref;

NF = READNF(NODOF,NXE,EL_table,NF);

%%%%% IW = subtract minimum DOF from maximum DOF for each element, then take the largest

number among all elements.

for i= 1:NXE

G = GSTRNG(EL_table,i,NODOF,NF);

STOREG(i,:) = G;

if ( min(STOREG(i,:)) == 0), continue, end;

%IW_array(i) = max(STOREG(i,:)) - min(STOREG(i,:));

end

%IW = max(IW_array);

%IW

%KV2(1:N*(IW+1))=0;

KV2(1:N,1:N) = 0;

% GLOBAL STIFFNESS MATRIX ASSEMBLY

for IP=1:NXE

[KM,KMe,Gam] = BMCOL3(E,A,Iy,Iz,Alphr,IP,STOREC); % Ke is the KM-without rotation

G = STOREG(IP,:);

[KV2] = FORMKV(KV2,KM,IKM,G,N,NR,IDOF);

% [KV2] = FORMKV2(KV2,KM,IKM,G,N,NR,IDOF);

end

%[KV2] = BANRED(KV2,N,IW);

%[Disp2] = BACSUB(KV2,LOADS,N,IW);

Disp2 = inv(KV2)*LOADS';

%RETRIEVE ELEMENT END FORCES AND MOMENTS

for IP=1:NXE

[KM,KMe,Gam] = BMCOL3(E,A,Iy,Iz,Alphr,IP,STOREC); % Calcluate Orginal KM-element

for i=1:IDOF

if (STOREG(IP,i)==0)

Edisp(i)=0;

else

Edisp(i) = Disp2(STOREG(IP,i)); % Displacement of element nodes in Global-Coord

end

end

X1=STOREC(IP,1); Y1=STOREC(IP,2); Z1 = STOREC(IP,3);

X2=STOREC(IP,4); Y2=STOREC(IP,5); Z2 = STOREC(IP,6); alph = Alphr(IP)*(pi/180);

ELL=sqrt( (Y2-Y1)^2 + (X2-X1)^2 + (Z2-Z1)^2 );

CX = (X2-X1)/ELL; CY = (Y2-Y1)/ELL; CZ = (Z2-Z1)/ELL;

CXZ = sqrt( CX^2 + CZ^2 );

if CXZ==0

Alph = [ 0

CY

0;

-CY*cos(alph) 0 sin(alph);

CY*sin(alph) 0 cos(alph) ];

else

Alph = [ CX

CY

CZ;

(-CX*CY*cos(alph)-CZ*sin(alph))/CXZ

CY*CZ*cos(alph)+CX*sin(alph))/CXZ;

(CX*CY*sin(alph)-CZ*cos(alph))/CXZ

];

CXZ*cos(alph)

(-

-CXZ*sin(alph)

(CY*CZ*sin(alph)+CX*cos(alph))/CXZ

end

Pm(1:12,1:12) = 0;

Pm(1:3,1:3) = Alph;

Pm(4:6,4:6) = Alph;

Pm(7:9,7:9) = Alph;

Pm(10:12,10:12) = Alph;

%%%% Define each element Temperature from Load Sets

for IL=1:NLS

ch = Loads_Set(IL,1);

if ch == 2

NE = Loads_Set(IL,8);

for IT = 1:NE

IE = Loads_Set(IL,9+(IT-1));

T_t(IE) = Loads_Set(IL,2);

end

end

end

LTe = E(IP)*A(IP)*Alpha_T(IP)*(T_t(IP)-T_ref)*[-1;0;0;0;0;0;1;0;0;0;0;0];

Edispe = Pm*Edisp';

Efor = KMe*Edispe - LTe;

Eforce(IP,1:IDOF) = Efor';

end

Subroutine to Apply FORM Method for 3-D Frames

% FORM Method-2

% Step-1: Define Random variables parameters [mean - std - distribution

% type & FE Mesh

clear all

format short e

Input3R

% Step-2: Define initial design point xo

xm0(1:DVn) = Xs(1,1:DVn); cov0(1:DVn) = Xs(2,1:DVn);

for i1=1:DVn

std0(i1) = cov0(i1) * xm0(i1);

end

xstar(1:DVn) = xm0(1:DVn);

Beta_old=0;

for k=1:100

% Calculate response parameters and g-value for the current random variables.

[No_r,No_m,Ty,Tz,A,Iy,Iz,Alphe,E,Fy,Density,Alpha_T] =

Properties(NXE,EL_table,Real_Constants,Material_Properties);

for j1=1:1e4 % Loop to increase value of Load to make 'g( ) < 0.7' for convergence reason. done for

the first loop only.

[LOADS,DLOADS] =

LOADS1(IDOF,NN,NR,N,NXE,NLS,DVn,NODOF,EL_table,NF,Loads_Set,Alphe,STOREC,E,A,Alpha_T,T_ref,D

ensity);

[Disp2,Eforce,STOREG,NF] =

Beam3D(IKM,IDOF,NODOF,NXE,N,NN,NR,E,Iy,Iz,A,Alphe,STOREC,NF,EL_table,LOADS,T_ref,Loads_Set,Alp

ha_T,NLS);

[S,Rel_E_N,Stress,S_DIR] = Smatrix(Eforce,EL_table,NXE,A,Iy,Iz,Ty,Tz);

[gvalue] = performance_function(S,xstar,Rel_E_N,STOREC,Fy);

gvalue

if (abs(gvalue) < 0.75) | (k > 1) , break, end;

DVnL=0;

for iL=1:NLS % No of Load sets

if Loads_Set(iL,3) ~= 0

DVnL = DVnL + 1;

Loads_Set(DVnL,2) = 1.25*Loads_Set(DVnL,2); % Mean value

xm0(DVnL) = Loads_Set(DVnL,2); std0(DVnL) = cov0(DVnL) * xm0(DVnL);

xstar(DVnL) = xm0(DVnL);

end

end

end

S

Rel_E_N

gvalue

% Step-3: Define mean and std of the equivalent normal dist. And evaluate

% the equivalent normal variables

[xm,std] = meanstd(DVn,xstar,xm0,std0,dist);

Bmatrix(1:DVn,1:DVn) = 0;

for i2=1:DVn

Bmatrix(i2,i2) = 1/std(i2);

end

for i=1:DVn

xstar_dash(i) = (xstar(i) - xm(i))/std(i);

end

% Step-4: Compute partial derivative at design point x_star

%[dgdx] =

Dperformance_function(IKM,IDOF,NODOF,NXE,N,NR,STOREG,S,xstar,Disp2,DLOADS,Rel_E_N,EL_table,S

TOREC,E,Iy,Iz,A,Zy,Zz,Fy,Alphe,NLS,NREAL,NM,Loads_Set,Real_Constants,Material_Properties);

for i3=1:DVn

Xv = xstar;

dx = std0(i3)/10;

Xv(i3) = xstar(i3) + dx;

[Loads_Set,Real_Constants,Material_Properties] =

Convert(NLS,NREAL,NM,Xv,Loads_Set,Real_Constants,Material_Properties);

[No_r,No_m,Ty,Tz,A,Iy,Iz,Alphe,E,Fy,Density,Alpha_T] =

Properties(NXE,EL_table,Real_Constants,Material_Properties);

[LOADS,DLOADS] =

LOADS1(IDOF,NN,NR,N,NXE,NLS,DVn,NODOF,EL_table,NF,Loads_Set,Alphe,STOREC,E,A,Alpha_T,T_ref,D

ensity);

[Disp2,Eforce,STOREG] =

Beam3D(IKM,IDOF,NODOF,NXE,N,NN,NR,E,Iy,Iz,A,Alphe,STOREC,NF,EL_table,LOADS,T_ref,Loads_Set,Alp

ha_T,NLS);

[S2,Rel_E_N] = Smatrix(Eforce,EL_table,NXE,A,Iy,Iz,Ty,Tz);

[gvalue2] = performance_function(S2,xstar,Rel_E_N,STOREC,Fy);

dgdx(i3) = (gvalue2-gvalue)/dx;

[Loads_Set,Real_Constants,Material_Properties] =

Convert(NLS,NREAL,NM,xstar,Loads_Set,Real_Constants,Material_Properties);

end

dgdx

[NLS]=sensitivity(NLS,NREAL,NM,Xs,Loads_Set,Real_Constants,Material_Properties,dgdx)

% Step-5: Compute partial derivative in the equivalent normal space

dgdxstar_dash = [inv(Bmatrix)] * dgdx';

alpha1 = dgdxstar_dash/norm(dgdxstar_dash)

% Step-6: Evaluate coordinates of the new design point in the equivalent

% normal space using eqn 3.48

xstar_dash_new = (1/norm(dgdxstar_dash))^2 * ( DOT(dgdxstar_dash,xstar_dash) - gvalue

)*dgdxstar_dash;

% Step-7: Evaluate Beta - distance to the new design values

Beta = norm(xstar_dash_new);

delta_Beta = abs(Beta - Beta_old);

Beta_old = Beta;

% Step-8: Evaluate new design values in the orginal space

for i=1:DVn

xstar(i) = xm(i) + std(i)*xstar_dash_new(i);

end

[Loads_Set,Real_Constants,Material_Properties] =

Convert(NLS,NREAL,NM,xstar,Loads_Set,Real_Constants,Material_Properties);

xstar_dash_k(:,k) = xstar_dash';

xstar_dash_new_k(:,k) = xstar_dash_new;

xm_k(:,k) = xm';

std_k(:,k) = std';

dgdx_k(:,k) = dgdx';

dgdxstar_dash_k(:,k) = dgdxstar_dash;

gvalue_k(k) = gvalue;

Beta_k(k) = Beta;

xstar_k(:,k) = xstar';

if (abs(gvalue) < 0.0001) & (delta_Beta < 0.001)

break

end

end

Subroutine to Assemble Load Vector

function [LV2] = FORMLV(LV2,LM,G,N,IDOF)

% C C THIS SUBROUTINE FORMS THE GLOBAL STIFFNESS MATRIX

for J =1:IDOF

if (G(J) == 0) ,continue ,end

LV2(G(J)) = LV2(G(J)) + LM(J);

end

Subroutine to Calculate Performance function

function [gv] = performance_function(S,X,Rel_E_N,COORD,Fy)

IP = Rel_E_N(1);

X1=COORD(IP,1); Y1=COORD(IP,2); Z1 = COORD(IP,3);

X2=COORD(IP,4); Y2=COORD(IP,5); Z2 = COORD(IP,6);

L=sqrt( (Y2-Y1)^2 + (X2-X1)^2 + (Z2-Z1)^2 );

gv = 1 - (S / Fy(IP));

Subroutine to Calculate extract Statistical Parameters from Input File

function [Loads_Set,Real_Constants,Material_Properties] =

Convert(NLS,NREAL,NM,Xs,Loads_Set,Real_Constants,Material_Properties)

DVn=0;

for iL=1:NLS % No of Load sets

if Loads_Set(iL,3) ~= 0

DVn = DVn + 1;

Loads_Set(iL,2)=Xs(DVn); % Mean value

end

end

for ir = 1:NREAL

if Real_Constants(ir,2)~= 0

DVn = DVn + 1;

Real_Constants(ir,1)=Xs(DVn); % Mean value

end

if Real_Constants(ir,4)~= 0

DVn = DVn + 1;

Real_Constants(ir,3)=Xs(DVn); % Mean value

end

end

for im = 1:NM

if Material_Properties(im,2)~= 0

DVn = DVn + 1;

Material_Properties(im,1)=Xs(DVn); % Mean value

end

if Material_Properties(im,4)~= 0

DVn = DVn + 1;

Material_Properties(im,3)=Xs(DVn); % Mean value

end

if Material_Properties(im,6)~= 0

DVn = DVn + 1;

Material_Properties(im,5)=Xs(DVn); % Mean value

end

if Material_Properties(im,8)~= 0

DVn = DVn + 1;

Material_Properties(im,7)=Xs(DVn); % Mean value

end

end

Subroutine to Calculate sensitivity of performance function to

random variables

function [NLS] = sensitivity(NLS,NREAL,NM,Xs,Loads_Set,Real_Constants,Material_Properties,dgdx)

DVn = 0;

for iL=1:NLS % No of Load sets

if Loads_Set(iL,3) ~= 0

DVn = DVn + 1;

fprintf(1,'Sensitivity of performance function w.r.t Load Set %i = %f \n', iL,dgdx(DVn))

end

end

for ir = 1:NREAL

if Real_Constants(ir,2)~= 0

DVn = DVn + 1;

fprintf(1,'Sensitivity of performance function w.r.t Ty of real constant set %i = %f \n',

ir,dgdx(DVn))

end

if Real_Constants(ir,4)~= 0

DVn = DVn + 1;

fprintf(1,'Sensitivity of performance function w.r.t Tz of real constant set %i = %f \n',

ir,dgdx(DVn))

end

end

for im = 1:NM

if Material_Properties(im,2)~= 0

DVn = DVn + 1;

fprintf(1,'Sensitivity of performance function w.r.t E of Material set %i = %f \n', im,dgdx(DVn))

end

if Material_Properties(im,4)~= 0

DVn = DVn + 1;

fprintf(1,'Sensitivity of performance function w.r.t Fy of Material set %i = %f \n', im,dgdx(DVn))

end

if Material_Properties(im,6)~= 0

DVn = DVn + 1;

fprintf(1,'Sensitivity of performance function w.r.t Density of Material set %i = %f \n',

im,dgdx(DVn))

end

if Material_Properties(im,8)~= 0

DVn = DVn + 1;

fprintf(1,'Sensitivity of performance function w.r.t Thermal_exp_coefficient of Material set %i =

%f \n', im,dgdx(DVn))

end

end

Subroutine to convert between random states to loads, material, and

real constants

function [Loads_Set,Real_Constants,Material_Properties] =

Convert(NLS,NREAL,NM,Xs,Loads_Set,Real_Constants,Material_Properties)

DVn=0;

for iL=1:NLS % No of Load sets

if Loads_Set(iL,3) ~= 0

DVn = DVn + 1;

Loads_Set(iL,2)=Xs(DVn); % Mean value

end

end

for ir = 1:NREAL

if Real_Constants(ir,2)~= 0

DVn = DVn + 1;

Real_Constants(ir,1)=Xs(DVn); % Mean value

end

if Real_Constants(ir,4)~= 0

DVn = DVn + 1;

Real_Constants(ir,3)=Xs(DVn); % Mean value

end

end

for im = 1:NM

if Material_Properties(im,2)~= 0

DVn = DVn + 1;

Material_Properties(im,1)=Xs(DVn); % Mean value

end

if Material_Properties(im,4)~= 0

DVn = DVn + 1;

Material_Properties(im,3)=Xs(DVn); % Mean value

end

if Material_Properties(im,6)~= 0

DVn = DVn + 1;

Material_Properties(im,5)=Xs(DVn); % Mean value

end

if Material_Properties(im,8)~= 0

DVn = DVn + 1;

Material_Properties(im,7)=Xs(DVn); % Mean value

end

end