Fabiola Helfer-Wiki

advertisement

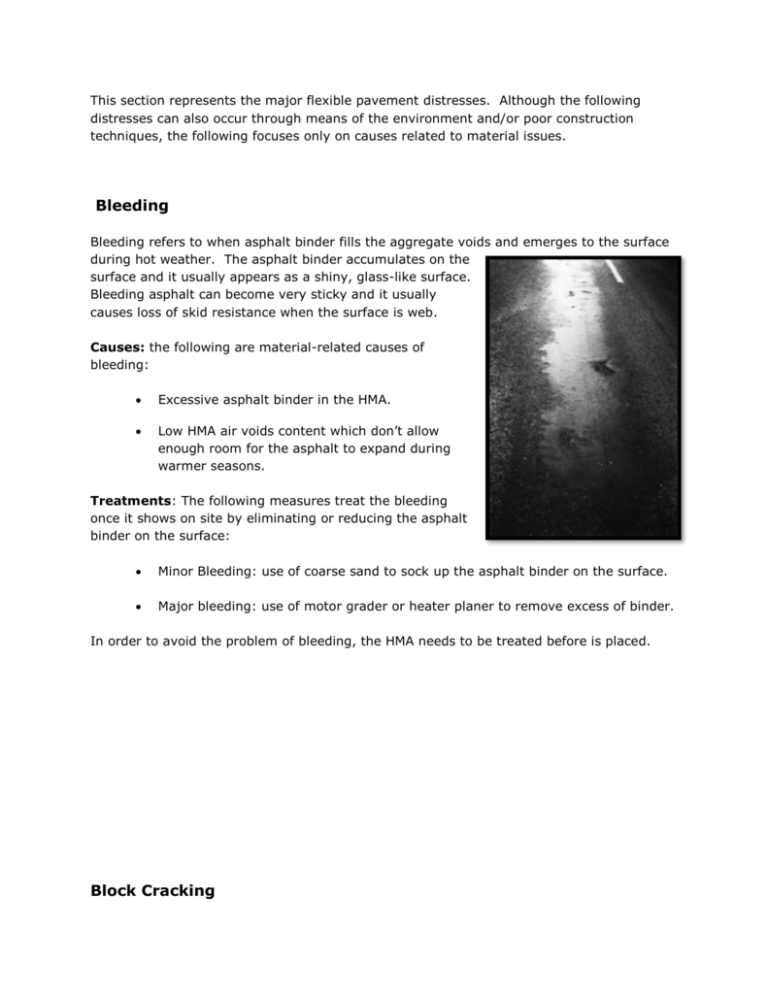

This section represents the major flexible pavement distresses. Although the following distresses can also occur through means of the environment and/or poor construction techniques, the following focuses only on causes related to material issues. Bleeding Bleeding refers to when asphalt binder fills the aggregate voids and emerges to the surface during hot weather. The asphalt binder accumulates on the surface and it usually appears as a shiny, glass-like surface. Bleeding asphalt can become very sticky and it usually causes loss of skid resistance when the surface is web. Causes: the following are material-related causes of bleeding: Excessive asphalt binder in the HMA. Low HMA air voids content which don’t allow enough room for the asphalt to expand during warmer seasons. Treatments: The following measures treat the bleeding once it shows on site by eliminating or reducing the asphalt binder on the surface: Minor Bleeding: use of coarse sand to sock up the asphalt binder on the surface. Major bleeding: use of motor grader or heater planer to remove excess of binder. In order to avoid the problem of bleeding, the HMA needs to be treated before is placed. Block Cracking Group of large cracks (usually one foot or more), that breaks the pavement into rectangular pieces. Block cracking usually covers a large area of pavement and it may occur on areas where there is no traffic. It permits water infiltration in the pavement structure and also causes irregularities in the pavement surface. Causes: Block cracking is caused by shrinkage of asphalt pavement due to temperature cycles. This is commonly associated with an ineffective selection of the asphalt binder in the mix design. Treatment: Depends on the severity of the damage: For cracks less than ½ inch wide, the application of crack seal is recommended. For cracks more that ½ inch wide, removing and replacing the pavement layer is recommended. Shoving Distortion of the pavement surface forming ripples across the pavement, perpendicular to the traffic direction. It occurs where high horizontal distresses are present such as intersections. It causes roughness on the pavement surface. Causes: Shoving is caused by the stop and go action of traffic along with the instability of the asphalt mix. This can be caused by mix contamination, inadequate mix design, low quality of asphalt mix manufacturing, and deficiency of aeration of asphalt emulsions. Treatment: Usually it is recommended to remove and replace damaged pavement area. Raveling Raveling is the loss of bond between the aggregate particles from the asphalt mix resulting in the wearing away of the aggregate from the HMA, beginning at the surface and progressing downwards. It causes many problems such as loose debris on the pavement surface, roughness, water accumulation which can result in hydroplaning and loss of skid resistance. Causes: There are a number of causes including: Presence of dust covering the aggregate impeding the asphalt binder to bond with the aggregate particles. Gradation, including less fines and more coarse aggregate with less points of contact. Treatment: Remove and replace damaged pavement. Rutting Is a linear surface depression in the wheelpath. Ruts can be filled with water and cause vehicle hydroplaning. There are two types of rutting: mix rutting and subgrade rutting. Mix rutting occurs when only the pavement surface shows rutting due to poor construction techniques and/or mix design issues. Subgrade rutting occurs when the subgrade shows rutting due to traffic loading. Causes: One material-related cause for rutting is the use of an inadequate mix design or manufacture, such as exaggerate asphalt content, mineral filler or lack of angular aggregate particles. Treatment: Ruts smaller than 1/3 inch deep generally don’t need treatment. For deeper ruts an overlay is recommended. Stripping Description: The loss of bond between aggregates and asphalt binder that typically begins at the bottom of the HMA layer and progresses upward. It causes rutting, shoving, raveling, or cracking. Causes: Stripping is difficult to identify because it manifests on the pavement surface as other forms of distress to include rutting, shoving/corrugations, raveling, or cracking. It is recommended to take a core to identify stripping as a pavement distress. A materialrelated factor that influences in striping is the poor aggregate surface chemistry. Treatment: A pavement that presents stripping generally needs to be removed and replaced. Also, correction of any drainage issues needs to take place before removing and replacing the pavement. References: Asphalt Institute: www.asphaltinstitute.org Pavement Interactive: www.pavementinteractive.gov Asphalt Magazine: www.asphaltmagazine.com