WRIT 340 Illumin Article Prof. Harlynn Ramsey

advertisement

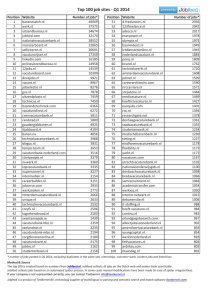

WRIT 340 Illumin Article Prof. Harlynn Ramsey Name: Shakya Sur Bio: A junior majoring in mechanical engineering with a passion for everything wild and natural, particularly creepy-crawlies. Keywords: nature, structure, construction, materials science, mechanics, spiders, spider web, silk, biomimetics, civil engineering Multimedia Suggestions: ‘A Typical Spider Web’ (Flash animation) http://science.howstuffworks.com/zoology/insectsarachnids/spider5.htm ‘BBC Invisible World – Spider, The Genius Architect’ http://www.youtube.com/watch?v=1JlLLpaCkI4 Abstract Although spider silk is widely celebrated amongst material scientists for its exceptional tensile strength and diverse engineering applications, only recently has significant research been done on mechanical characteristics of the spider’s web. After examining the architecture of a common orb-weaver’s web, this article looks at the micro-scale structure of spider silk and its role in the construction of the web. It shows that both the silk as well as its intricate arrangement are responsible for the spider web’s remarkable response to various kinds of external loading. In addition, there are valuable lessons to be learned from the spider’s construction, design and maintenance of its web that can be applied to improve our own engineering techniques. Webs That Inspire When King Bruce of Scotland sat moping in his cave after a string of defeats, little did he know that the same eight-legged creature that gave him his famous morale boost would continue to fascinate scientists and engineers many centuries later1. Spider silk has been extensively studied for its remarkable material properties, and numerous uses of the material have been proposed in engineering, military and manufacturing industries. Only recently, however, have spiders’ webs begun to attract attention themselves. As this article reveals, it is a marriage of the unusual characteristics of spider silk and its creator’s incredible craftsmanship that makes the web a highly optimized design. They are truly as unique 1 According to legend, after being defeated by the King of England six times in the 13th Century AD, King Bruce went into hiding in a cave while his army retreated. It was in this cave that he watched a spider trying to spin its web across the roof. After failing six times, the spider succeeded on its seventh attempt. This was supposed to have inspired King Bruce to rally his men to war once more. He finally emerged victorious against the King of England on his seventh attempt, and was immortalized as a hero both on the battlefield and in childrens’ stories. as the material they are made of, and carry enormous potential for creating new advances in the rapidly growing field of biomimetic engineering. Silk Production The spider’s web begins its journey in a set of glands in its abdomen, each dedicated to producing a specific kind of silk. Dragline silk, usually referred to as ‘spider silk’ in common parlance, is known to be secreted as a liquid in the major ampullate gland. It is the type used by spiders to construct the support structure for the web – the frame, radial spokes and quick escape paths to avoid predation [1]. Scientists speculate that it is also the most primitive variety of spider silk. Prehistoric spiders probably used it to find their way back to their dens, until their eureka moment arrived: they spotted the first unlucky insect trip across a stray dragline. As they began to construct elaborate webs, additional kinds of silk evolved, such as the special adhesive silk used to trap prey on webs, as well as silks used to wrap egg sacs [2]. Dragline silk is the strongest of them all, and consequently, the most commonly studied. It has a composite structure, made up of crystalline ‘blocks’ of one kind of protein embedded in an amorphous matrix of another type. Its celebrated material properties arise from an interplay between these two types of protein configurations when subjected to mechanical stresses (discussed later in detail). Before emerging through the abdomen, the silk undergoes several stages of chemical treatments in ducts called spigots that convert it into solid phase from an aqueous solution. It then emerges as streams of tiny threads, called ‘fibrils’, from the each spigot. Multiple fibrils are then twisted together to make a single strand of silk [5]. When it senses the presence of sufficient material, the spider coaxes the silk out with tiny claws on its hind legs. Constructing the web After accumulating enough dragline silk from its abdomen, the spider literally throws its chances into the wind. If it gets lucky, the first strand catches a branch and the spider quickly scurries over to secure the web’s first anchor. It then searches for a third node, such as a tree stump on the ground or a lower branch, to form the primary Y-shaped backbone for the web. The spider then connects the endpoints of the ‘Y’ structure and adds additional reinforcements to complete the framework. Next it begins work on the first of its two spirals reaching out from the hub to the outer fringes of the web. Using its non-adhesive silk for the last time, it creates a widely spaced ‘scaffolding’ spiral. This gives the spider a secure footing before it lays the sticky silky spiral, the killer trap, beginning at the outer edges of the web. The sequence of steps followed in the creation of the web are summarized in Fig 1. The spider truly justifies its reputation as a master craftsman during this last and most important phase of construction. Despite having poor vision and relying solely on its hind legs, the spider simultaneously combs strands of silk out from its Fig 1: The different steps in the construction of a spider’s web: (i) the first line is cast; (ii) The Y- spinnerets while measuring the distance to the previous frame takes shape (iii) The radial spokes and segment of sticky glue. Once satisfied, it carefully pins the free end of the strand to a point on the next radial arm. It scaffolding spiral are added (iv)The final sticky spiral is completed Adapted from: ‘How Spiders Work’ (Harris, T), howstuffworks.com often switches between clockwise to counter-clockwise directions to correct any missteps, but never strays from its scaffolding [2] [6]. A typical orb weaver spider meticulously prepares its sticky death-trap for twenty minutes, before finally settling down at the hub. Following completion, some spiders are known to spin a ‘stabilimentum’ across its web. Much debate prevails over the exact purpose of this apparently decorative zig-zagging element, but one study suggests that it signals birds to steer clear of their laborious handiwork [4]. This carries a trade-off, however, because potential prey are equally likely to detect the web’s presence. Field and laboratory observations conclude that spiders starving for a meal usually do not invest the time and effort needed for building stabilimenta, while their more successful brethren can afford to do otherwise [4]. Stabilimentum or no stabilimentum, the web is now complete, and the spider can let the waiting game begin. Time to feast Carrying out a task as sophisticated and labor-intensive such as web-building may speak volumes about the spider’s prowess, yet the true genius behind the web’s design is observed when it actually begins to perform its intended purpose. When an unwary insect flies into the sticky silk spiral, vibrations from the point of impact travel to the spider’s sensitive claws [6]. Guided by touch and knowing the web like the back of its – well – feet, the spider eagerly rushes to the source of disturbance along the nonsticky dragline members. Taking no chances with possible retaliation from its prey, the spider shrouds its helpless victim in even more silk before tucking in to its well-deserved feast. Unraveling the secrets Apart from the strong adhesive of the sticky spiral that helped capture the insect, researchers have identified two key aspects of the web’s design that proved crucial to the spider’s success. The web has a unique property of yielding slowly after impact, before quickly becoming stiff [1]. In addition, they limit distribution of stress only to those members in the immediate vicinity of the point of impact [1]. The first observation is a characteristic of a non-linear elastic response as illustrated in Fig 2, one that is not commonly encountered in everyday materials. Most ordinary materials can be modeled as a simple spring obeying Hooke’s Law, which after elongating under stress, spontaneously return to a value close to its original length [1]. If Fig 2: The characteristic non-linear response of spider silk. the web were to be replaced by a linearly-elastic material, spiders ‘Entropic unfolding’ refers to the unfurling of the crystalline protein molecules under stress would despise physics. Upon impact, the insect’s kinetic energy Source: ‘Nonlinear material behaviour of spider silk yields robust webs’ (Buehler et al, 2012) would be rapidly converted into potential energy of the fabric (and any irrecoverable forms of energy such as sound or heat) as it slowed the insect down. However, because of its linear behavior, the stored energy would be reconverted into kinetic energy as the fabric returned to its un-stretched state – thus giving the insect a better chance of making a quick getaway. Spider webs, on the other hand, convert most of the impact kinetic energy into forms from which kinetic energy cannot be recovered. The difference between the two responses can be easily demonstrated by first dropping a bowling ball on a sand pit and then on a strong trampoline from the same vertical height: both would absorb the same amount of kinetic energy on impact, but the sand pit would dissipate energy among its countless grains of sand instead of returning it to the bowling ball. The second characteristic behavior, where distribution of impact forces is limited by the web, helps retain its structural integrity when struck by a flying object. If they were allowed to uniformly distribute among various structural elements, a larger portion of the web would be subjected to deformation. In turn, this elongation could risk being permanent due to the non-linear response described earlier, and compromise the spider’s future chances of success. The secret to these unique features of the web can be found in a few tricks up the spider’s eight sleeves and quite literally entangled in the silk itself Spider silk under the microscope The composite structure of spider silk consists of blocks of crystalline protein embedded in a matrix of amorphous protein as shown in Fig 3. [5]. Under normal conditions, indicated by (i), these crystalline protein molecules are randomly dispersed and remain coiled up throughout the amorphous matrix. Under stress however, they start clustering and tend to line up alongside each other, as shown in (iii). During the time it takes for the crystals to unfurl themselves and align, Fig3: The different stages of uncoiling of protein crystals (i-iv) Adapted from: ’A Materiomics Approach to Spider Silk: Protein Molecules to Webs’ (Tarakanova et al., 2012) the silk fibril starts to deform and yield. When most of the crystals attain a linear structure, strong hydrogen bonds develop between the protein molecules and the silk fibril transitions from yielding to stiffening (Fig 2). Beyond this point, in stage (iv) of Fig 3, increasing applied stress brings these crystalline protein molecules closer together, thus making hydrogen bonds stronger. In this condition, indicated by the steeply inclined part of the curve, the silk absorbs a lot of stress while deforming very little. The ultimate breaking point is reached when the crystalline protein cannot come any closer, and the overall structure disintegrates when they begin sliding past each other under excessive loads [5]. This response to an external applied force can explain how the kinetic energy from an insect’s impact cannot be easily recovered by the web: initial energy gets transferred to composite protein matrix, and pushes crystalline protein together. Subsequently, with the formation of hydrogen bonds between strands, part of that kinetic energy is released in the form of heat. The rest is dissipated by other means such as sound or heat, or damping by air [1]. Magical ‘Globules’ For all its unique material properties, however, the silk would be of limited use if the spider didn’t fully exploit its merits. When constructing the web’s support structure, at every intersection between two members of dragline silk, it placed a globular cluster of silk [6] as shown in Fig 4. These globules, or droplets, contained additional reserves of the folded composite matrix, waiting to be uncoiled when something snagged on a connecting strand. Therefore, although forces from the initial impact do tend to disperse throughout the web, they Fig4: (i) Under normal conditions, cannot get far beyond the nearest droplet. These droplets thus bear the brunt of proteins remain coiled inside the droplets (ii) When subjected to a impact forces without letting them deform the rest of the structure. These tiny force, they stretch and uncoil droplets also play an important role in protecting the web when subjected to stresses other than point impacts [6]. Source: ‘Spider, the Genius Architect’, Invisible World (BBC), http://www.youtube.com/watch? v=1JlLLpaCkI4 Facing the elements Webs need to be capable of withstanding severe winds and swaying movements of anchor points, in addition to stresses due to collisions. These forces are applied to the web taken as a whole and lead to tensile forces on every strand. In Fig 5, three webs made of different materials were exposed to winds at varying speeds and corresponding Fig 3: The web’s response (dragline silk denoted by A,B) to varying wind speeds Source: ‘Nonlinear material behaviour of spider silk yields robust webs’ (Buehler et al, 2012) deformations were recorded. Buehler’s data, plotted in Fig 5, reveals that the web made of spider silk (A, B) deforms the most before failing [1]. Once again, the numerous droplets scattered across the web were responsible for allowing the strands of crystalline protein to unfurl, letting the entire web stretch more than it would have otherwise. The other webs (A’, A”), in contrast, were elongated to their limits earlier, and consequently failed at a smaller magnitude of strain [1]. Each droplet can thus be thought of as storehouses of extra silk material, which uncoil immediately when an insect catches a single strand, or in tandem with other droplets when external forces affect the entire web. Spider webs have been regarded as perfect examples of optimized engineering design – they operate ideally, utilizing the full potential of available material resources under a host of loading conditions. They are subjected to stresses of varying magnitudes and durations, yet they respond in a manner that is the envy of our structural engineers. Under impact loading, they localize dissipation of forces and prevent the entire structure from deforming due to a point load, while under forces applied to the whole surface, they permit maximum elongation for a given stress. Buehler argues that if the concept of sacrificial elements in man-made structures were altered from ‘the element that fails first’ to one that ‘not only fails first but also prevents other components from suffering excessively large displacements’, damage to buildings could be significantly limited and confined to a specific region [1]. In trying to mimic the spiders’ superior building skills, merely substituting the magical spider silk for conventional building materials won’t suffice, as the critical role played by the droplets proves. The coiled crystalline protein blocks in those globules essentially provide a secondary means of dissipating kinetic energy, forming a two-step process of energy dispersal. Perhaps engineers can take the benefits of spider silk a notch higher and create a three-tier stress-strain response, which will let the material yield in multiple stages before failing. This would amount to creating a second transition point after the ‘stiffening’ in the stress-strain curve of Figure 2. Such an improvisation can be carried out at the nanoscale to create a fundamentally new material, but the same idea can be implemented with relative ease by physically constructing multiple levels of sacrificial elements in man-made structures. These would fail in a planned sequence, thereby limiting and ideally preventing damage to the overall structure. Most of the present knowledge about spider silk and spider webs has been gathered from research conducted on only a handful of species out of the 40,000 that inhabit an incredible array of habitats across the world [2]. If the webs of orb weavers can provide such a fascinating insight into how we can learn from these tiny master engineers, other kinds of webs can only offer so much more. Spider silk shows an astonishing diversity of material properties not only across different species, but also within a particular species – depending on the spider’s size, shape and its health, apart from environmental factors [2]. When such variations of fundamental properties are introduced into the differences in web construction from one species to another, the resulting combinations are practically endless – and so are the possibilities for drawing inspiration from these little critters. Works Cited [1] Buehler et al., “Nonlinear material behaviour of spider silk yields robust webs” Nature, Vol 482, pp 72-75, February 2012. [2] Savory, T.H., “Spider Webs”, Scientific American, pp 115-124,1960. [3] Harris, T., “A Typical Orb Web” http://science.howstuffworks.com/zoology/insectsarachnids/spider5.htm [online] (13 Nov 2013) [4] Blackledge et al. “Do Stabilimenta in Orb Webs Attract Prey or Defend Spiders?” Behavioral Ecology, Vol 10, pp 372-376, December 1999 [5] Tarakanova et al. “Materiomics Approach to Spider Silk: Protein Molecules to Webs” JOM, Vol. 64, No. 2, pp 214-224, 2012 [6] “Spider, the Genius Architect”, Invisible World (BBC) http://www.youtube.com/watch?v=1JlLLpaCkI4 [online] (13 Nov 2013)