product applications - Sustainable Design Resources

advertisement

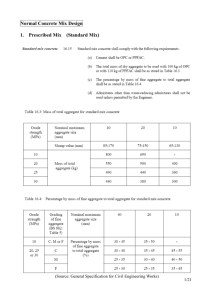

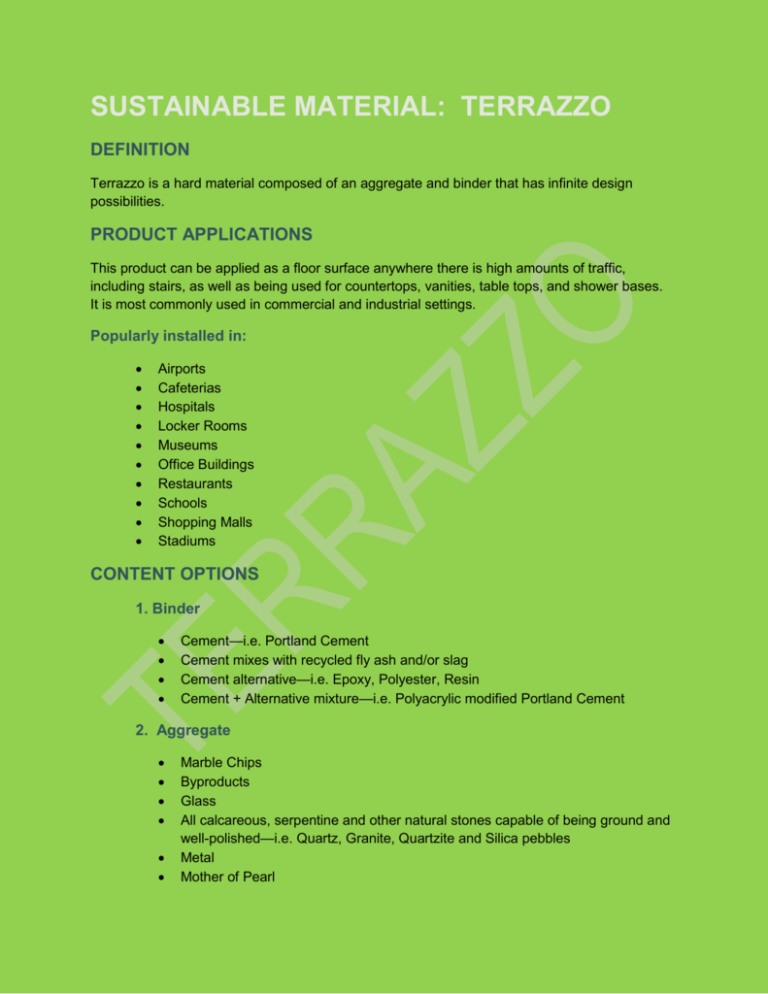

SUSTAINABLE MATERIAL: TERRAZZO DEFINITION Terrazzo is a hard material composed of an aggregate and binder that has infinite design possibilities. PRODUCT APPLICATIONS This product can be applied as a floor surface anywhere there is high amounts of traffic, including stairs, as well as being used for countertops, vanities, table tops, and shower bases. It is most commonly used in commercial and industrial settings. Popularly installed in: Airports Cafeterias Hospitals Locker Rooms Museums Office Buildings Restaurants Schools Shopping Malls Stadiums CONTENT OPTIONS 1. Binder Cement—i.e. Portland Cement Cement mixes with recycled fly ash and/or slag Cement alternative—i.e. Epoxy, Polyester, Resin Cement + Alternative mixture—i.e. Polyacrylic modified Portland Cement 2. Aggregate Marble Chips Byproducts Glass All calcareous, serpentine and other natural stones capable of being ground and well-polished—i.e. Quartz, Granite, Quartzite and Silica pebbles Metal Mother of Pearl Plastic Porcelain PRODUCT OPTIONS Binder Tint Metal or Plastic Dividers—for design flexibility Aggregate Color Aggregate Polish/Luster Terrazzo Finish/Sealant RECYCLABLE MATERIAL OPTIONS 100% recycled post-consumer glass 98% recycled industrial glass—which has no other recycling market—can be melted and colored 20% recycled plastic aggregate Recycled metal divider strips Recycled fly ash Can contain old tub/sink porcelain chips EMISSIONS Inorganic based binders contain no VOCs There is little to no off-gassing over the life of the cured floor MANUFACTURING PROCESS Materials are pulled and collected from local and regional companies. This aids in reducing costs and transportation. Glass from local projects and recycling programs aims to eliminate mining from the manufacturing process. All the mixing and pouring takes place on site, including the mixing of the binders, the mixing of the aggregate, smoothing, curing, and polishing. Doing this reduces waste, transportation and costs. 1. Aggregate is mixed with matrix in a 2 to 1 ratio. 2. The mixture is poured in place. 3. Additional aggregate is sprinkled on top. 4. The mixture is then troweled. 5. The terrazzo cures for at least three days. 6. The terrazzo is ground on a water-coated surfaced. MAINTENANCE Dust mop daily to remove grit. Scrub floors at least twice a week for the initial two to three months. Reduce scrubbing the floors to once a week. Seal with a water-based acrylic sealer. DO NOT USE: Purely surface wax All-purpose sealers All-purpose cleaners with water soluble inorganic or crystallizing salts Alkali acids PROTECTION AND RESISTANCE Due to no seams or grout, there is no space for mold, mildew and bacteria to grow. This helps to improve the indoor air quality. Terroxy Resin Matrixes (TRM)—epoxy resin systems—are resistant to chemicals, oils, grease and bacteria. TRM also keeps color lasting and prevents from wearing thin. RESTORATION Typically terrazzo floors last the lifetime of the building, which is approximately 40 years. However, one can restore the original luster of the floor instead of replacing it, saving lots of money. Periodic stripping and resealing can be done with environmentally friendly water-based products.