Pesticide - PentaChloroPhenol.info

advertisement

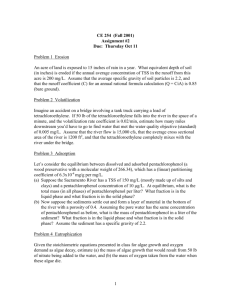

http://www.epa.gov/oppsrrd1/reregistration/REDs/pentachlorophenol_red.pdf “This presents two challenges for risk assessment. First, because very few chemicals are applied using retorts, limited data are available to estimate worker exposure. Second, because many of the Agency’s exposure models were designed to assess risk from agricultural chemicals, exposure estimates are expected to be conservative and may not be representative of “real world” exposure. The Agency acknowledges these challenges and considered these and other factors when making its reregistration and risk management decisions.” REAL WORLD INFORMATION Pentachlorophenol (PCP) was, and still is, one of the most frequently used fungicides and pesticides. The use of PCP has been more restricted during the last few years. PCP's most important industrial application is as a wood preservative. The pentachlorophenol can be absorbed into the body by all the routes of occupational exposure. Some epidemiological observations suggest that exposure to PCP solutions may result in an increased risk for certain diseases in humans, e.g., immunodeficiency, blood disorders, malignancies, congenital anomalies. Chronic poisoning is difficult to detect since symptoms are often vague. Acute poisoning is due to interference with oxidative phosphorylation and can present itself as an unexpected case of sudden death. Four cases of PCP poisoning, including one fatalitie, occurred in two small wood preservative plants. All cases presented with increased serum creatinine phosphokinasa. The clinical finding are reported, and treatment modalities commented. At present there is no antidote for PCP. The basis for treatment is intensive supportive care to maintain vital bodily function. In one patient plasmapheresis was used and rapid recover was obtained. It is suggested that such therapy may be lifesaving in such intoxications. A case of a 33-yr-old man who died following occupational exposure to pentachlorophenol is presented. Postmortem examination revealed cerebral edema and fatty degeneration of the viscera. Review of the literature indicates that the clinical syndrome of poisoning with the compound results from mitochondrial toxicity with derangement of aerobic metabolism. The effects of pentachlorophenol have been studied on diverse biological systems both in vivo and in vitro, however the cellular basis of the pronounced cytotoxicity of this organochlorine compound is poorly understood. In this work, morphological and biochemical analyses were carried out to identify the primary targets of pentachlorophenol toxicity in mammalian cells. Our results show that pentachlorophenol is a very potent cytotoxic drug that displays an unusual and interesting mode of action in Vero cells. Although this compound is a powerful uncoupler of oxidative phosphorylation, we present the novel finding that lysosome destabilization is an early cytotoxic response that precedes the mitochondrial dysfunction. In addition, soon after exposure to moderate doses of pentachlorophenol, a significant number of cells initiate an apoptotic death process identified by the condensed and fragmented state of their nuclei. These results demonstrate that there are multiple potential targets of PCP- 1 induced toxicity in mammalian cells, and the need to develop further experimental studies for the risk assessment of this environmental pollutant. Pentachlorophenol is an organic chemical compound, which is widely used in the timber industry. This chemical is also known as PCP, but this is different from the PCP, which is used as a recreational drug. The chemical’s most common use is as a preservative for wood; however, it has also been used historically as an insecticide, herbicide, and disinfectant. Due to concerns over pentachlorophenol toxicity, the sale of this chemical is restricted in many countries, including the USA and New Zealand. Both the production and use of the chemical is restricted in countries of the European Union. Some European countries have opted to ban it altogether. PCP wood preservative is manufactured by adding chlorine to a chemical precursor called phenol. This process requires the addition of a catalyst to increase the speed of the reaction between chlorine and phenol. The catalyst added is either ferric chloride or anhydrous aluminum. When the reaction is complete, the resulting chemical mixture is up to 90% pure, with the remaining 10% of the mixture being a range of other phenol byproducts. One of two methods can be used to treat wood products with pentachlorophenol. The first method is called the pressure process method. In this process, wood products are immersed in a chemical bath and pressure is applied to saturate the wood with the preservative. The second method is called the non-pressure process method, and involves wood products being soaked in or sprayed with the chemical without pressure being applied. Pentachlorophenol exposure is a concern in industrial settings where the chemical is manufactured or used. This is because acute or chronic inhalation of air contaminated with solvent fumes, or contact with PCP-treated wood, can be toxic. In addition, exposure is a public health concern because ground water, soil, and even drinking water which has been contaminated with the chemical can also become a source of toxicity. This kind of toxicity is a risk particularly in locations near industrial facilities where the chemical is used, and near hazardous waste collection sites. Symptoms of pentachlorophenol toxicity may differ depending on whether exposure to the chemical is chronic or acute. Short-term exposure to high concentrations of the chemical can damage the central nervous system, gastrointestinal tract, and organs such as the kidneys, liver, and lungs. Chemical vapor can seriously damage the eyes and mouth. Long-term low concentrations of the chemical cause also damage the central nervous system, kidneys, and liver. Long-term exposure is also thought to increase the risk of certain types of cancer. Pure pentachlorophenol (PCP) consists of light tan to white, needlelike crystals and is relatively volatile. It is soluble in most organic solvents, but practically insoluble in water at the slightly acidic pH generated by its dissociation However, its salts, such as sodium pentachlorophenate (Na-PCP), are readily soluble in water. At the approximately neutral pH of most natural waters, PCP is more than 99% ionized. 2 Apart from other chlorophenols, unpurified technical PCP contains several microcontaminants, particularly polychlorinated dibenzo- p-dioxins (PCDDs) and polychlorinated dibenzofurans (PCDFs), of which H6CDD is the most relevant congener toxicologically. 2,3,7,8-T4CDD has only once been confirmed in commercial PCP samples (0.25 - 1.1 µg/kg). Depending on the thermolytic conditions, thermal decomposition of PCP or Na-PCP may yield significant amounts of PCDDs and PCDFs. The use and the uncontrolled incineration of technical grade PCP is one of the most important sources of PCDDs and PCDFs in the environment. PCP is mainly produced by the stepwise chlorination of phenols in the presence of catalysts. Until 1984, Na-PCP was partly synthesized by means of the alkaline hydrolysis of hexachlorobenzene, but it is now produced by dissolving PCP flakes in sodium hydroxide solution. Acutox; Chem-Penta; Chem-Tol; Cryptogilol; Dowicide 7; Dowicide EC-7; Dow Pentachlorophenol DP-2 Antimicrobial; Durotox; EP 30; Fungifen; Fungol; Glazd Penta; Grundier Arbezol; Lauxtol; Lauxtol A; Liroprem; Moosuran; NCI-C 54933; NCI-C 55378; NCI-C 56655; Pentacon; Penta-Kil; Pentasol; Penwar; Peratox; Permacide; Permagard; Permasan; Permatox; Priltox; Permite; Santophen; Santophen 20; Sinituho; Term-i-Trol; Thompson's Wood Fix; Weedone; Witophen P Albapin; Cryptogil Na; Dow Dormant Fungicide; Dowicide G-St; Dowicide G; Napclor-G; Santobrite; Weed-beads; Xylophene Na; Witophen N Human toxicity Characteristic features of an acute poisoning are dermatitis, strong irritation in eyes, weakness, seizures, acute lung injury, hepatotoxicity, heart failure, cerebral edema, and rapidly progressing coma in severe cases Chronic poisoning may produce anorexia, weight loss, weakness, dizziness, headache and anxiety. Prolonged or frequent contact with either solution or dust may cause dermatitis or systemic symptoms including damage to the circulatory system and the heart. PCP has moderate acute toxicity by ingestion and by skin contact and high toxicity by inhalation. The acute lethal oral dose is approximately 30 mg/kg body weight [1]. The mean lethal dose is 2 g in adults. Signs of systemic poisoning occur at the PCP blood concentrations > 40 mg/l. In several cases with fatal outcome blood concentrations ranged 46-173 mg/l. The mean lethal blood concentration, based on the data from several handbooks, is 100 mg/l. Carcinogenicity: according to US EPA, PCP belongs to chemical group B2, and it is a probable human carcinogen in humans. Occupational exposure with PCP may occur 3 in the workplaces; there are also some unique suicide cases. CDDs (mainly 2,3,7,8-TCDD) may be formed during the chlorine bleaching process used by pulp and paper mills. CDDs occur as a contaminant in the manufacturing process of certain chlorinated organic chemicals, such as chlorinated phenols. 2,3,7,8TCDD is a by-product formed during the manufacture of 2,4,5- trichlorophenol (2,4,5TCP). 2,4,5-TCP was used to produce hexachlorophene (used to kill bacteria) and the herbicide, 2,4,5- trichlorophenoxyacetic acid (2,4,5-T). Various formulations of 2,4,5-T have been used extensively for weed control on crops and range lands, and along roadways throughout the world. 2,4,5-T was a component of Agent Orange, which was used extensively by the U.S. military in the Vietnam War. In most industrialized countries the use of products contaminated with CDDs has been greatly reduced. Use of hexachlorophene and the herbicide 2,4,5- T is currently restricted in the United States. Other chlorinated chemicals, like pentachlorophenol (PCP), used to preserve wood, do contain some of the more highly chlorinated CDDs (those with more chlorine atoms), but 2,3,7,8-TCDD is not usually found. The use of PCP has been restricted to certain manufacturing applications. Human Toxicity Excerpts: To evaluate the association between exposure to pentachlorophenol and the occurrence of chloracne, we studied the medical and personnel records for individuals employed in the manufacturing of pentachlorophenol. Forty seven cases of chloracne were identified among 648 workers (7.0%) assigned to pentachlorophenol production at a single plant between 1953 and 1978. The annual incidence rate varied considerably, ranging from 0 (in 1953) to 1.46 (in 1978). No linear trend in the risk of chloracne was observed with the duration of employment in the pentachlorophenol department. Workers with a documented episode of direct skin contact with pentachlorophenol had a significantly increased risk of chloracne compared with workers who did not have a documented episode of direct skin contact (cumulative incidence ratio = 4.6; 95% confidence interval 2.6-8.1). Results confirm that chloracne is associated with exposure to pentachlorophenol contamined with hexachlorinated, heptachlorinated, and octachlorinated dibenzo-p-dioxins and dibenzofurans. [O'Malley MA et al; Am J Ind Med 17 (4): 411-22 (1990)]**PEER REVIEWED** All members of a Spanish family (father, mother and six children) developed chloracne. The causative agent was found to be the family's stock of olive oil, which had become contaminated with dibenzo-pdioxins, dibenzofurans, pentachlorophenol, and hexachlorobenzene. The more highly chlorinated dibenzo-p-dioxins, in particular octachlorodibenzo-p-dioxin, were the predominant congeners in the oil. Three members of the family exhibited either an overt or a sub-clinical disturbance of kidney function. The father also had a chronic respiratory problem. These changes could not be 4 unequivocally attributed to the dibenzo-p-dioxins. Experimental toxicity of the oil was limited to the development of the oil ceased, contained high levels of the dibenzo-pdioxins and dibenzofurans. Extrapolation back to ingested dose was used to validate dosage estimates. The use of toxicity equivalence factors provided estimates of cumulative dosage to produce chloracne as 0.13-0.31 ug 2,3,7,8-tetrachlorodibenzopdioxin/kg (using EPA toxicity equivalence factors) or 6.7-16 ug 2,3,7,8tetrachlorodibenzo-p-dioxin/kg (using Nordic/NATO toxicity equivalence factors). This is the first incident in which human toxicity is related primarily to ingestion of dibenzo-pdioxins and for which estimates of dosage can be made. [Rodriguez-pichardo A et al; Hum Exp Toxicol 10 (5): 311-22 (1991)]**PEER REVIEWED** A case history of chloracne due to exposure to pentachlorophenol treated wood was described. A 32 yr old white male was seen at a university dermatology clinic complaining of an acne form eruption of 6 mo duration. The patient was part owner of a firm that constructed piers for small boat marinas. The lumber used was pretreated with pentachlorophenol. Within about 9 mo after beginning work, he noted a popular acne form eruption that occurred over the entire body. The eruption was characterized by multiple, small yellow/white papules. Areas most involved included the malar regions of the face, post auricular area, the trunk, buttocks, thighs, and lower legs. Some of the papules were inflamed. A trephine punch biopsy of one of the papules showed a small epithelial lined cystic structure that communicated with the surface. The lining epithelium was composed of atrophic, but normal appearing, epidermis. Contained within the cyst was keratin like material. The condition was diagnosed as chloracne. The patient's condition improved after 6 wk oral treatment with isotretinoin. The patient remained asymptomatic for the ensuing 2 yr of observation. The patient returned to work wearing appropriate protective clothing. A sample of pentachlorophenol used by the firm and samples of treated wood were analyzed for OCDD. Samples from the surface of the lumber contained about ten to 40 times the amount of OCDD as did the wood itself. The undiluted pentachlorophenol contained 1600 ppm OCDD. It was concluded that the patient developed chloracne after exposure to pentachlorophenol treated lumber. The OCDD containing surface residue seemed to be the major source of the intoxication. [Cole GW et al; Contact Dermatitis 15 (3): 164-8 (1986)]**PEER REVIEWED** 5 GENERAL LINKS http://patch.com/new-york/easthampton/senator-schumer-called-epa-investigate-usetoxic-chemical http://www.amazon.co.uk/Xylophene-100-Natural-Interior-Treatment/dp/B008F7WXC8 http://www.ncbi.nlm.nih.gov/pubmed/4026386 http://www.tuv.com/en/usa/about_us/regulations_and_standard_updates/latest_regulati ons_us/latest_regulation_pdf_161908.jsp https://www.wewear.org/assets/1/7/RSL12english-March2013.pdf http://www.reach-clp-biozid-helpdesk.de/en/Downloads/REACH-Verordnung-19072006-en.pdf?__blob=publicationFile&v=2 Pentachlorophenol intoxication: report of a fatal case, with comments on the clinical course and pathologic anatomy. Gray RE, Gilliland RD, Smith EE, Lockard VG, Hume AS. Abstract A case of a 33-yr-old man who died following occupational exposure to pentachlorophenol is presented. Postmortem examination revealed cerebral edema and fatty degeneration of the viscera. Review of the literature indicates that the clinical syndrome of poisoning with the compound results from mitochondrial toxicity with derangement of aerobic metabolism. http://www.ncbi.nlm.nih.gov/pubmed/10859827 http://www.epa.gov/oppsrrd1/reregistration/REDs/pentachlorophenol_red.pdf http://www.kornegayengineering.com/wp-content/uploads/2011/05/structural-utilitydistribution-light-poles-whitepaper-acrosby.pdf http://www.fema.gov/media-library-data/20130726-1509-204903997/fema55_volii_ch13.pdf http://www.fema.gov/media-library-data/20130726-1502-20490-1177/fema_p85_ch8.pdf http://www.npr.org/templates/story/story.php?storyId=15811496 6 http://www.fema.gov/media-library-data/20130726-1502-20490-8377/fema_p85.pdf http://www.naic.org/documents/committees_c_catastrophe_091207_drywall_hearing.pd f http://msdefenselaw.org/wp-content/uploads/2014/01/Fall20101.pdf http://www.utmb.edu/cet/downloads/Sediment_analysis_report_Galveston.pdf http://rebuildnwflorida.blogspot.com/ Pentachlorophenol (PCP)- Directive 94/783/EC http://www.artfactory.com/understanding-leather-how-its-made-lsp800-p-4862.html http://buyisabelmarant.blogspot.com/ http://www.intertek.com/ http://www.artfactory.com/understanding-leather-how-its-made-lsp800-p-4862.html This process is known as "Pickling." The common salt penetrates the substance twice as fast as the acid and checks the ill effect of sudden drop of pH. Tanning can be performed with either vegetable or mineral methods. Before tanning, the skins are unhaired, degreased, desalted and soaked in water over a period of 6 hours to 2 days. To prevent damage of the skin by bacterial growth during the soaking period, biocides, such as pentachlorophenol, are used. http://www.intertek.com/uploadedfiles/intertek/divisions/consumer_goods/media/ pdfs/services/footwear%20leathergoods%20and%20safety%20footwear.pdf http://www.ncbi.nlm.nih.gov/pubmed/7904464 http://wiki.nasa.gov/wstf-environmental-informationrepository/files/2013/06/2007_04_30nasaPart_D.pdf 7 This process is known as "Pickling." The common salt penetrates the substance twice as fast as the acid and checks the ill effect of sudden drop of pH. Tanning can be performed with either vegetable or mineral methods. Before tanning, the skins are unhaired, degreased, desalted and soaked in water over a period of 6 hours to 2 days. To prevent damage of the skin by bacterial growth during the soaking period, biocides, such as pentachlorophenol, are used. Two men pressing the leather near the end of the tanning process in an American tannery. http://www.intertek.com/uploadedfiles/intertek/divisions/consumer_goods/media/ pdfs/services/footwear%20leathergoods%20and%20safety%20footwear.pdf 8 http://wiki.nasa.gov/wstf-environmental-informationrepository/files/2013/06/2007_04_30nasaPart_D.pdf 9