Jenny Jun Yue Zhang WRIT340 Illumin Paper From biology to

advertisement

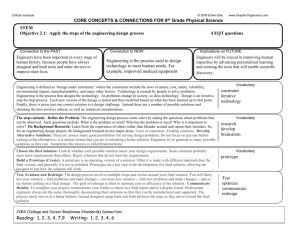

Jenny Jun Yue Zhang WRIT340 Illumin Paper From biology to technology: biomimicry in modern engineering Abstract Biomimicry is the emulation of natural systems in order to solve engineering problems with similar applications. The modern realm of biomimicry has reached well past exterior mechanical emulations such as the plane and the submarine. Our insight into the macroscopic and microscopic world, coupled with the energy constraints of our generation, has pushed biomimetic engineering towards optimizing existing technologies through natural mechanisms. This article will present a sampling of recent biomimetic engineering developments that have made our current technology more efficient. Introduction David Letterman has tried this on TV: wear a suit made of industrial strength Velcro and leap onto an inflatable Velcro wall—and try to stick. Despite its unassuming appearance, a twoinch square of Velcro can hold a 175lb person on a wall. The invention of Velcro is one of the most well known applications of biomimicry in engineering. The hook-and-loop fastener is the brainchild of Swiss engineer George de Mestral, who uncovered the concept when pondering the tenacity with which burrs clung to his dog’s hair. [2] Like the little seedpod hitchhikers, Velcro consists of one part tiny stiff plastic hooks that will catch anything with a loop, and another part loosely woven nylon fiber that acts much like the hair of Mestral’s dog. It took Mestral eight years to commercialize Velcro fasteners despite its simple concept—the effective transformation of a biological mechanism into mass synthesized product is not an easy task. [2] http://24.media.tumblr.com/tumblr_lw3yvnSaBg1qk01v6o3_500.jpg Figure 1. The hook and loop mechanism of Velcro fasteners Biomimetic engineering didn’t start to gain traction as an official academic discipline until early 1990s. Today, it is a highly interdisciplinary field that involves people anywhere from computer scientists, physicists, chemists, and philosophers working alongside biologists and engineers. [1] However, it’s an easy misconception that biomimetic engineering attempts to merely replicate the biological system in synthetic ways. As MIT chemical engineers stated: “You don’t have to reproduce a lizard skin to make a water collection device, or a moth eye to make an anti-reflective coating. The natural structure provides a clue to what is useful in a mechanism, but maybe you can do it better.” [2] To engineers, nature is merely the starting point of technology. As we gain insight into the macroscopic and microscopic world, biomimetic technology may emulate a chemical process, or even just a concept of a mechanism, and will not necessarily appear like their biological inspiration. It is the common belief that nature has found “the path of least resistance” to every function through billion years of evolution. Today, biomimetic research is re-evaluating many of our existing technology through the lenses of nature in order to improve their efficiency. The following three examples—the new digital screen inspired by butterfly wings, the self cleaning coating inspired by lotus leaves, and the aerodynamic car inspired by the boxfish—are all recent biomimetic engineering projects that utilize a natural mechanism to produce a more sustainable alternative to an existing technology. Structural Colors in Butterfly Wings: A New Generation of Display Technology http://www.extremetech.com/wp-content/uploads/2012/01/mirasol-640x353.jpg Figure 2. A preliminary tablet model using the Mirasol technology. In today’s competitive market for display technology, every company is vying for a balance between energy use, visibility, and color quality in both still and moving images. Liquid crystal displays (LCD) achieve vibrant color at the cost of energy consumption, while colored eink is still waiting on its faster and full color advancement. Meanwhile, there is another blossoming technology that utilizes a concept radically different from all existing giants in the field, and its inspiration came from a small butterfly. The inspiration Observe the wings of a morphos butterfly: its color holds a subtle iridescence and changes hues when viewed at different angles. The coloring of their wings is not from pigments, but rather a result of the bending of light through the complicated cell structures in the butterfly’s wing tissues. The tissues are comprised of layers upon layers of transparent fiber and air cuticles. Instead of absorbing and reflecting only a certain light wavelength as pigments and dyes do, these cuticles can both cancel out and reflect selective wavelengths to achieve a full range of colors. This kind of dynamic coloring is called structural color. [3] [4] http://www.asknature.org/images/uploads/strategy/1d00d97a206855365c038d57832ebafa/morpho_feature.jpg Figure 2. layered cuticles that produce structural coloring on the wings of a morphos butterfly The technology The new Mirasol technology sought to emulate the butterfly wing’s ability to dynamically control wavelength interactions. The wing cuticles are mimicked by micro-scale plates with a tiny separation between them. Both plates are conductive; the top is a thin film on a transparent glass substrate, while the bottom is a reflective membrane (figure 3). Current passing through the plates can control the gap between plates through electrostatic repulsion, and thus control the absorption of red, yellow, and blue light. When no current is passing through a plate, its default state is closed, which absorbs no light and corresponds to a black display. [5] http://www.mirasoldisplays.com/how-it-works Figure 3. The assembly of micro-scale plates used in Mirasol displays To assemble complex colors, a large array of these plates is fabricated in layers not unlike the butterfly’s tissues. Strips of these plates will form the pixels on the display screen. The unique color corresponding to the gap in each plate is overlaid to achieve complex colors (figure 4). The plate separation can be adjusted a thousand times a second, creating color that’s faster than e-ink but at a lower energy cost than LCD. What’s better, the Mirasol screen absorbs sunlight, so it’s both antiglare and energy saving. [5] http://www.mirasoldisplays.com/how-it-works Figure 4. The Mirasol display combines trips of micro-sized plates to display complex color. The future The preliminary models of the Mirasol screen have already been adopted by some cell phone companies and e-readers in Asia. As the technology matures, engineers are working to improve the coordination between digital signals and final display in order to achieve fast and smooth video performance. [4] The Mirasol screen heralds the new generation of structural display technology. The full color energy-sipping tablet may soon become reality. The Lotus Effect: nanotechnology in self-cleaning and easy-cleaning materials Outside the field of display technology, another well-known example of biomimicry is in materials engineering. For this field, the search for a durable, self-cleaning, and repellent coating has endless incentives; from paint, to architectural and machine exteriors, to camping and other recreational products, self-cleaning surfaces can reduce the labor cost and extend a material’s life cycle. For this magic surface, the inspiration is even more humble than the butterfly—it is the lotus. The inspiration In many eastern cultures, the lotus is a symbol of purity. As it turns out, this reputation is well deserved. The lotus leaves have a super-hydrophobic effect: water does not wet it, but instead rolls off the leaves, carrying dirt and soot with it. This famous self-cleaning effect was discovered by botanist Wilhelm Barthlott in 1973, and later patented as the “Lotus Effect.” [6] http://www.biomimicryinstitute.org/images/stories/lotus_detail2.jpg Figure 5. Water droplets sitting on the tips of nano-scale wax crystals on the lotus leaf. The secret to super-hydrophobicity lies in a nano-textured surface. A combination of tiny, nipple-like wax crystals around one nanometer in diameter is systematically arranged throughout the lotus leaf surface (it will take thousands of these wax crystals just to cover the diameter of a strand of human hair). In fact, the water droplet is only in contact with about 23% of the area covered by the droplet. [6] The interplay of surface tension and low contact area causes the water to ball up and sit on the tip of the wax crystals (figure 5). This nano-scale roughness is essential to self-cleaning; on a smoother surface, water will simply slide rather than roll, thus drastically reducing its ability to pick up surface impurities. [6] The technology When the lotus effect was first discovered in 1973, nanotechnology was not yet advanced enough to enable engineers to utilize the concept. But now, with the advancement of nanotechnology and the Sol-Gel method, engineers can produce controlled growth and aggregation of nano-crystals. The Sol-Gel method involves a unique fluid solution that will slowly change from liquid to gel, and finally be eliminated from the crystal structure through chemical drying. Initially, the individual crystal particles are suspended in the liquid, and as the fluid morphology changes to gel, crystals form through slow linking of the suspended particles. Dipping compatible materials into the Sol-Gel solution can therefore produce a thin film coating with nano-sized pores and protrusions. [6] Today, engineers use this technology in repellent paint for industrial housing, which uses silicon nanoparticles suspended in resin to form a super-hydrophobic surface. Other engineers are utilizing composite materials such as polypropylene (a kind of plastic found in textiles and banknotes) to create matrixes of nanoparticles and deposit them on fabric surfaces. [7] GreenShield is one such recent coating technology that combines nanoparticles of composites and fluorocarbons in order to create super-hydrophobic fabrics. These fabrics are extremely stain and water resistant (figure 6), and heralds a new market for parasols, sails, tents, and even housing materials. [7] Combining particles on a nano-scale enable engineers http://www.asknature.org/images/uploads/strategy/714e970954253ace485abf1cee376ad8/greenshield_feature.jpg Figure 6. GreenShield coats textile fibers with liquid repelling nanoparticle, reducing the need to use environmentally dangerous fluorocarbons. Here red wine, water, and soy sauce is shown rolling on GreenShield fabric. to reduce fluorocarbon usage by 90%. [7] Fluoro-chemicals, though a necessary component in most repellent coatings, is a chronic toxin that bio-accumulates in the body and persists in the environment. Therefore the technology of nano-scale surfaces is making the repellent coating industry much more environmental friendly. The future For the future, the main challenge for super-hydrophobic surfaces is a balance between cost, application, and longevity. Self-cleaning buildings would be a good payback, but selfcleaning tablecloths? Not so much. The deposition of lotus effect coatings can still be relatively unstable on extremely smooth surfaces. [6] Engineers continue to seek out more suitable nanoparticles that will withstand the caustic damages present in nature. Aerodynamics of a boxfish: the engineering of the Mercedes-Benz bionic car Returning to the realm of the visible, the natural grace of biological structures still inspire some of our most effective transportation designs. In 2005, DaimlerChrysler presented the preliminary model for the most aerodynamic car in its compact class—the bionic car. But the sleekness of this car does not boast its design inspiration from agile animals such as the dolphin or the shark, but instead from a funny looking little fish. The inspiration Although the boxfish has an angular appearance, it’s a surprisingly agile swimmer. With a stiff outer coat comprised of hexagonal bone plates, the fish can withstand very high pressures while at the same time navigate with minimal dorsal movement. [9] http://images.gizmag.com/gallery_lrg/4133_80605113337.jpg Figure 7. Aerodynamic study of the boxfish body in free flow. The new Mercedes bionic car has almost exactly duplicated this aerodynamic structure. In free flow, the body of the boxfish has a drag coefficient as low as 0.06. [9] The drag coefficient measures the resistance of an object to the flow of air or fluid, and the coefficient of a teardrop, which is widely recognized as the ideal streamlined form, is only 0.02 lower than that of the boxfish. When engineers scoured nature for a model, the structure of the boxfish immediately stood out as a combination of good space, energy efficiency and passenger safety. The technology Following the boxfish body almost contour by contour, the bionic car design boasts a drag coefficient of 0.19 (even a smaller Honda Civic has a drag coefficient of 0.31). This places the car about 65% more aerodynamic than average compact cars, and makes it one of the world’s most aerodynamic car designs today. [9] To minimize weight and maximize structural strength, engineers also model their reinforcement system after the hexagonal skeletal structure of the boxfish. Using the Soft Kill Option, which is a computer simulation that configures the body and suspension components of the car, engineers can better identify areas of high stress. [8] This way, materials can be made thinner in lower load areas, while highly stressed areas (such as the car door) are reinforced with a honeycomb structure. The end product is a car with 40% increase in stiffness and a 30% decrease in weight. [8] http://www.carbodydesign.com/archive/2008/03/01-mercedes-benz-bionic-car-at-the-moma/ Figure 8. Soft Kill simulation reduced materials used in lower load areas while reinforcing highly stressed areas. The future The bionic car may very well be the desired model for our future automobiles. The combination of aerodynamic design, light weight, and fuel efficient engine gives the car a dazzling fuel range of 70 miles per gallon, which ultimately makes the car 20% more economical than other compact models today. [8] Conclusion: A Brave New World? The three examples given here are but a sampling of the endless applications of biomimetic engineering. Today, biomimetic applications have expanded to realms of even architecture and renewable energy. In Zimbabwe, midrise buildings are modeled after termite mounds, which utilizes air draft alone to maintain an interior temperature around 31 degrees Celsius despite fluctuations of outside temperature from 3 to 42 degrees. Also, windmill blades are modeled after the aerodynamic shape of shake fins and coated with sharkskin inspired paint to increase its wind energy utilization. Gradually, biomimetic engineering is redefining the traditional “heat, beat, and treat” procedure of manufacturing, in which raw materials are heated with enormous amounts of energy, twisted into shape through heavy machinery, and finally strengthened through chemical treatments. More and more, technology is becoming smaller scaled, more efficient, and more environmentally friendly through the direct or indirect application of biomimicry. However, the task to translate nature’s solution into technology will always remain a challenge that requires innovative simplifications. As engineer Mark Cutkosky, the Co-Director for the Center of Research Design at Stanford University, says, “The price that we pay for complexity at small scales is vastly higher than the price nature pays…and nature is fabulously, wantonly complex.” We may yet encounter many cases, such as the lotus effect, in which the concept emerges before current technology can successfully transform it into a commercialized product. But as technological advances turn more and more scientific concepts into reality, we will witness a whole new dimension to our current technologies lead by biomimetic engineering. Sources 1. D. Tyler. “The growth of biomimetics as an academic discipline.” Internet: http://www.arn.org/blogs/index.php/literature/2007/07/18/the_growth_of_biomime tics_as_an_academic. [July 18, 2007]. 2. T. Mueller. “Biomimetics: Design by Nature.” Internet: http://www.core.formula.com/2008/04/15/biomimetics-design-by-nature/. [April 15, 2008]. 3. AskNature. “Wing scales diffract and scatter light: Morpho butterflies.” Internet: http://www.asknature.org/strategy/1d00d97a206855365c038d57832ebafa. [Jan. 4, 2012]. 4. T. McKeag. “What Qualcomm’s Butterfly-Inspired Display Could Do for Your Paint.” GreenBiz. Internet: http://www.greenbiz.com/blog/2011/09/27/what-qualcommsbutterfly-inspired-display-could-do-your-paint?page=0%2C1. [Sep 27, 2011]. 5. Mirasol. “How it Works.” Internet: http://www.mirasoldisplays.com/how-it-works. [2012]. 6. Kalaugher, Elizabeth. “Lotus Effect Shakes off Dirt.” Nanotechweb. Internet: http://nanotechweb.org/cws/article/tech/16392. [Nov 8, 2002]. 7. “Stain-resistant fabric with less flourochemical usage.” Internet: http://www.asknature.org/product/28dac96ae850e0972f1a61db94844994. [Oct 31, 2011]. 8. T. Marco. “Mercedes-Benz bionic car at the MoMA.” Internet: http://www.carbodydesign.com/archive/2008/03/01-mercedes-benz-bionic-car-atthe-moma/. [Mar 1, 2008]. 9. B. Denton. “Biomimicry: Solving engineering problems and inefficiency by observing nature.” Internet: http://conservationreport.com/2008/12/29/biomimicry-solvingengineering-problems-and-inefficiency-by-observing-nature/. [Dec 29, 2008].