Elevator Maintenance Specifications

advertisement

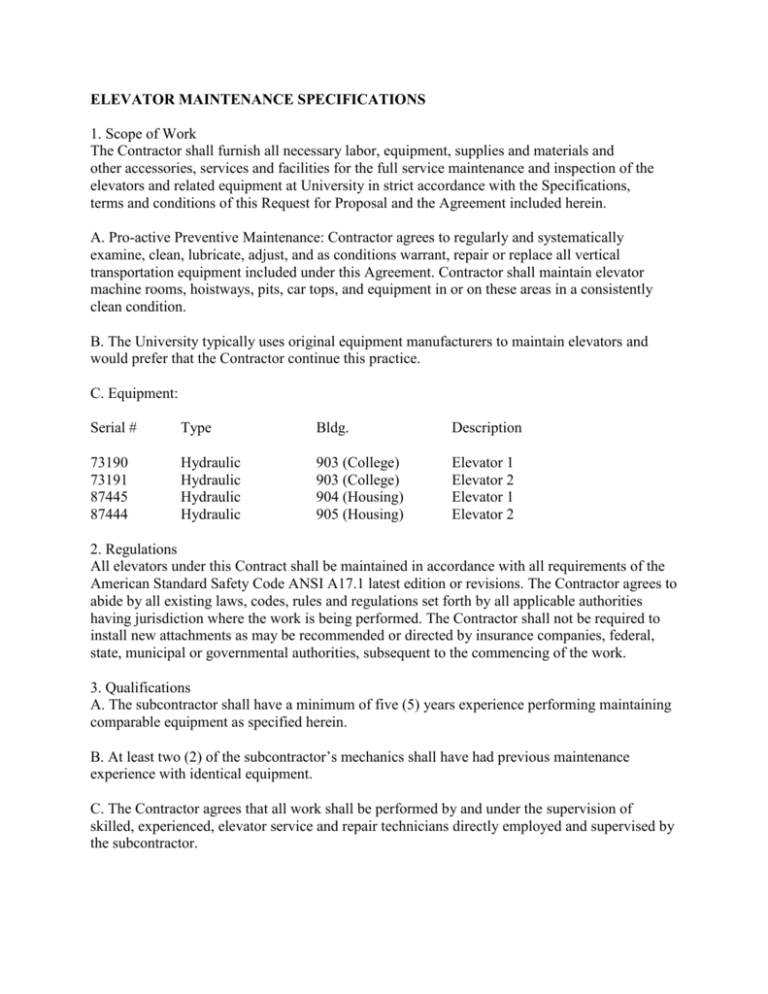

ELEVATOR MAINTENANCE SPECIFICATIONS 1. Scope of Work The Contractor shall furnish all necessary labor, equipment, supplies and materials and other accessories, services and facilities for the full service maintenance and inspection of the elevators and related equipment at University in strict accordance with the Specifications, terms and conditions of this Request for Proposal and the Agreement included herein. A. Pro-active Preventive Maintenance: Contractor agrees to regularly and systematically examine, clean, lubricate, adjust, and as conditions warrant, repair or replace all vertical transportation equipment included under this Agreement. Contractor shall maintain elevator machine rooms, hoistways, pits, car tops, and equipment in or on these areas in a consistently clean condition. B. The University typically uses original equipment manufacturers to maintain elevators and would prefer that the Contractor continue this practice. C. Equipment: Serial # Type Bldg. Description 73190 73191 87445 87444 Hydraulic Hydraulic Hydraulic Hydraulic 903 (College) 903 (College) 904 (Housing) 905 (Housing) Elevator 1 Elevator 2 Elevator 1 Elevator 2 2. Regulations All elevators under this Contract shall be maintained in accordance with all requirements of the American Standard Safety Code ANSI A17.1 latest edition or revisions. The Contractor agrees to abide by all existing laws, codes, rules and regulations set forth by all applicable authorities having jurisdiction where the work is being performed. The Contractor shall not be required to install new attachments as may be recommended or directed by insurance companies, federal, state, municipal or governmental authorities, subsequent to the commencing of the work. 3. Qualifications A. The subcontractor shall have a minimum of five (5) years experience performing maintaining comparable equipment as specified herein. B. At least two (2) of the subcontractor’s mechanics shall have had previous maintenance experience with identical equipment. C. The Contractor agrees that all work shall be performed by and under the supervision of skilled, experienced, elevator service and repair technicians directly employed and supervised by the subcontractor. 5. Service of Hydraulic Elevators Regularly and systematically examine, clean, lubricate, adjust and when conditions warrant, repair or replace the following: A. Power plant complete, consisting of its enclosure, pump, motor power transmission elements between the pump and motor, valves of every kind, strainers, mufflers, gaskets, and all other accessories. B. Entire controller and motor starter, including accessories. C. Entire "jack unit", including everything except excluded items listed hereinafter. D. All electrical wiring, conduit, ducts, traveling cables, etc., from and beyond the elevator equipment of every kind to the mainline disconnect switches, and hoist way outlets. E. All piping, fittings, and accessories; such as, vibration dampeners, silencers, etc. between the pumping plant and the jack unit. Underground piping not included. F. All heating or cooling elements, facilities, insulation, and accessories for controlling the oil temperature. G. Hydraulic fluid. H. Emergency lighting, if furnished and installed by same manufacturer. I. Fireman's service equipment. J. Automatic power door operators, landing and car door hangers, landing and car door contacts, door protective devices, hoist way door interlocks, bottom door guides, manual door closers, and auxiliary door closing devices. K. Conduct a yearly relief valve test and cylinder leakage test on all hydraulic elevators in accordance with Section 1001 ANSI A17.1 Code.L. Re-lamp all signals during regular examinations. L. All other miscellaneous equipment, materials, solid-state components, etc., not mentioned above or in the make-up of the complete elevator or elevators. M. Maintain a clean the elevator hoist way and related equipment including rails, inductors, hoist way door hangers and tracks, relating devices, switches, buffers, car tops and pit areas. N. Perform the following tests on the elevator equipment: Test car and counterweight safeties, governors, buffers, and all other safety devices. The car balance will be checked and the governor set. If required, the governor will be re-calibrated and sealed for proper tripping speed. 6. Procedures A. All tests performed on the elevator equipment described herein will be in accordance with the most recent ANSI/ASME A17 Code requirements. Written reports of all tests shall be submitted and reviewed with the University's Representative within thirty (30) days following completion of all tests. B. The elevator mechanic shall provide preventative maintenance at the job site a minimum of one (1) hour per unit per inspection for elevators. C. The maintaining of this equipment, in a safe condition within proper operating limits, as originally specified, and with minimum downtime is of paramount importance. 7. Schedule A. All work specified herein, except emergency minor adjustment callback service, shall be performed during the University's regular working hours. B. The scheduling, frequency, and performance of the maintenance service procedures specified above shall be done in accordance with the manufacturer's established procedures. 8. Items Excluded From Contract The following items of elevator equipment, hoist way, and machine room enclosures are not included in this Contract: A. Car enclosure, including side walls, interior paneling, handrails, bases, car tops, car lighting fixtures, reflectors, and drop ceilings, and if necessary, refinishing, repairing, or replacing these items. B. Car fan, gates and/or doors, hoist way enclosure, rail alignment, hoist way doors, door frames, sills, hoist way gates, finished flooring, power feeders switches and their wiring and fusing, car light diffuses, light tubes or bulbs, smoke or heat sensors. 9. Inventory The subcontractor shall maintain on a cost reimbursable basis, a sufficient amount of replacement parts, by the original manufacturer, to maintain the equipment in first class and safe operating condition. These parts shall be made available for inspection by the University's Representative upon request. The inventory shall include, but not be limited to, the following: A. Elevators 1. 1 spare pump 2. 1 set of belts for pump to motor 3. 1 set of jack packing, each size 4. 1 door operator motor 5. 1 set of door operator belts 6. 1 set of door operator rectifiers 7. 6 control relays, each size 8. 1 motor starter contact kit 9. 1 motor starter coil 10. 1 set of motor starter overloads 11. 1 car stop switch 12. 1 set of car pushbuttons 13. 1 set of hall pushbuttons, each kind 14. 1 limit switch 15. 1 hoist way door interlock 16. 2 interlock door hanger rollers 17. 6 car door rollers 18. 1 photo cell (2 units) 19. 1 photo cell amplifier 20. 6 photo cell bulbs 21. 8 motor brushes of each type 22. 1 electrical relay coil of each type 23. 5 normally open contacts of each type 24. 5 normally closed contacts of each type 25. 5 moveable contacts 26. 2 CPU I/O card rack and boards 27. 2 I/O card rack and boards 28. 2 relay interface 29. 2 resistor boards 30. 2 cable-relay interface to input 31. 2 cable-relay interface to output B. Special Tools 1. The following special tools shall be kept at the Rosen Campus: a. Wheel puller b. Shaft knurler 2. The following special tools shall be kept in the local service office: Diagnostic service tools - microprocessor systems. 10. Microprocessors and Reprogramming The subcontractor shall maintain, in stock, available for immediate usage, an inventory of replacement parts for any microprocessor equipment used in the elevator system. The subcontractor shall have full capabilities to reprogram or change the program of the elevator microprocessor. 11. Inspection The Contractor shall have examined the premises and satisfied himself as to the existing conditions under which he will be obligated to operate in performing the work specified herein. The Contractor shall use an independent certified state inspector to perform annual state inspections. 12. Quality Performance and Repair Log The Contractor shall provide and maintain in each machine room, a maintenance schedule and record, a call-back and repair log, and shall make all these documents available to the University upon request. The University will be closely involved with the quality and level of maintenance service of these elevators. The University and elevator contractor shall meet quarterly to discuss and review performance reports on the service level of the University elevators. END OF SECTION