Influence of Environmental condition on surface discharge of Non

advertisement

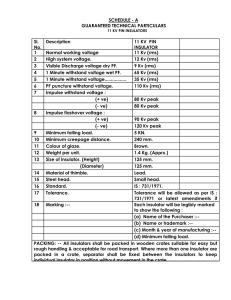

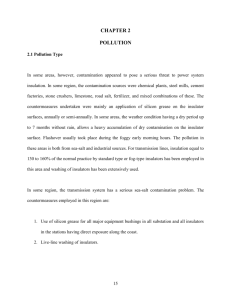

Influence of Environmental condition on surface discharge of Nonuniformly polluted Insulators under AC Voltage Flashover on the surface of insulator is an important problem for the safe operation of transmission lines and the design of the external insulation. When the surface of an insulator is covered with a pollution layer, the leakage current will flow and create dry bands in the regions of high current density. Consequently, the voltage distribution along the insulator increases the stress across the dry bands resulting in partial discharges and decreases the dielectric strength of systems significantly. These discharges are in series with the pollution resistance. If this resistance is sufficiently low, the partial discharges will propagate along the insulator profile and will cause the flashover on the surface of insulator. In this way, the performance of insulators under polluted conditions is an important factor in the design and dimensioning of insulators in power transmission lines. Various research accomplished by many researchers has already contributed in the modeling of polluted insulators and predicting the flashover voltage but they did not take into account the environmental condition and the non-uniformity of the pollution layer, simultaneously, e.g. [1]-[5]. In this paper, an improved dynamic model for predicting the critical flashover voltage on the surface of polluted insulators is developed that taken into account the environmental conditions such as ambient temperature, atmosphere pressure and humidity. It is shown that the conductivity of pollution layer is a function of temperature, which is dependent on leakage current losses and ambient temperature. In addition, the linear non-uniform pollution layer covering the surface of insulator is used in predicting the AC critical flashover voltage. Further, the re-ignition condition while the leakage current passes through zero is considered during simulations. Such modeling is necessary to predict the thresholds for the occurrence of flashover on surface of polluted insulator. The discharge length may be varied due to the wind, ambient temperature and other environmental factors such as the discharge bridging between sheds or ribs so that the discharge does not move on the surface of the insulator. Therefore, the random value in the range of creepage distance between two ribs or sheds is considered for the discharge length when the re-ignition condition and the propagation criterion are satisfied. The characteristics of “IEEE standard suspension insulator disk” is used as a polluted insulator for illustrating the instantaneous evolution of leakage current, the discharge length, the discharge resistivity, and the pollution resistivity. Furthermore, to validate the model, the numerical results of the model are compared with the measured values. [1] Cigre Working Group 33-04, “The Measurement of Site Pollution Severity and its Application to Insulator Dimensioning for ac Systems”, Electra, No. 64, pp.101-116, 1979. [2] N. Dhahbi-Megriche and A. B´eroual, and L. Krahenbuhl, ‘‘A New Proposed Model for Polluted Insulators Flashover’’, Journal of. Physics. Vol.30, pp. 889-894, 1997. [3] C. Volat, M. Farzaneh and N. Mhaguen, “Improved FEM Models of One- and Two-arcs to Predict AC Critical Flashover Voltage of Ice-covered Insulators”, IEEE Transactions on Dielectrics and Electrical Insulation Vol. 18, No. 2, pp. 393-400, April 2011. [4] J.Y.Li, C.X.Sun, S.A.Sebo, “Humidity and Contamination Severity Impact on the Leakage Currents of Porcelain Insulators”, IET on Generation, Transmission and Distribution, Vol.5, No.1, pp. 19-28, January 2011. [5] L. Bo and R. S. Gorur, “Modeling Flashover of AC Outdoor Insulators under Contaminated Conditions with Dry Band Formation and Arcing”, IEEE Transactions on Dielectrics and Electrical Insulation Vol. 19, No. 3, pp.1037-1043, June 2012.