Toughened Glass Insulators

Toughened Glass Insulators

139

Toughened Glass Insulators

Introduction

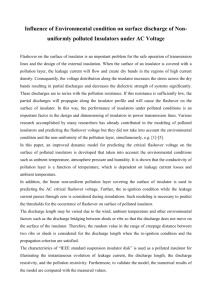

For many customers and applications, toughened glass provides the highest level of performance and long-term security for high voltage insulation. MacLean is pleased to be able to provide our customers toughened glass insulators from stock held at our South Carolina factory. The products have service experience dating back to 1957 with installations in a broad range of operating conditions with more than 300 utilities worldwide at voltages from 15 to 1150kV AC and up to 800kV DC. Insulators are manufactured in two factory locations to insure steady supply and sufficient capacity for even the largest projects. Both plants utilize the same manufacturing process and the same automated ‘Waltek’ equipment for the toughening process with an annual output of more than 14 million pieces.

The products of the two factories comply with the quality management systems of ISO 9001, 14001, and 18001. The products have been subjected to testing in the factory laboratories and international independent test centers to confirm the customer’s requirements and national standards. The toughened glass insulators are tested per ANSI, IEC, CSA and GOST.

Toughened glass has many inherent characteristics that makes it especially suitable for HV, EHV and DC applications:

■ Unlike porcelain or non-ceramic materials, toughened glass insulating material never ages.

■ The binary status (all or none) of TG is desirable for line maintenance. In the event of electrical or mechanical damage, the shell collapses allowing maintenance personnel to easily identify faults visually from the ground without any special instruments or tools

■ TG has 4 times the mechanical impact strength dictated by ANSI (90in/lb) compared to porcelain, which reduces losses due to shell damage during construction and handling

■ Even with the insulating shell absent, the toughened glass stub is guaranteed to retain its mechanical strength, eliminating the chance of line drop due to insulator separation

■ All units are subjected to routine mechanical proof load AND 4 minute electrical flashover test prior to shipment, so the

M&E integrity is guaranteed on every unit shipped.

The current designs are based on 50-year-old operating experience in the field of insulation at the important high-voltage objects in harsh environmental conditions:

■ Standard and FOG profile

■ Ultra-FOG glass insulator profiles

■ Silicone Coated

■ DC insulators

Zinc Sleeves

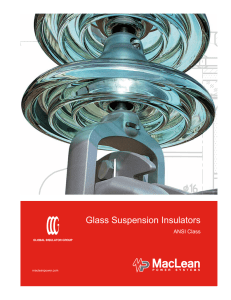

MacLean Toughened Glass Design Details

1. Cap – Cast Iron / Hot dip galvanized

2. Locking Device – Stainless Steel Cotter Pin

3. Toughened Glass Shell

4. Gasket – Interlaying Material

5. Pin – Forged Steel / Hot dip galvanized

6. Alumina Cement

7. Zinc Sleeve – Supplied standard on all MG Insulators

Insulator Markings – permanent markings, as required by

ANSI, are marked both on the Cap and Shell of the insulators.

Markings include MPS logo, M&E Rating, ANSI Class, Plant

MFG ID and Date Code.

© 2016 Copyright MacLean Power Systems

Technical information subject to change without notice

Standard Shell Profile

Features

■ Certified to ANSI C29.2B Standard / CSA / IEC

■ Zinc Sleeve Standard on all MG Insulators

■ Alumina Cement

■

■ Standard Pack = 6 Units / Wirebound Crate

■

400 in-lbs Toughened Glass Mechanical Impact Strength

Silicone Coated Insulators available

Shell Diameter

Catalog Number

ANSI Class

Coupling Type

MECHANICAL

MG523Z

52-3

B

Min. Mechanical

Failing Load

Proof Routine Test

Mech. Load lbs kN lbs kN

20,000

90

10,000

45

DIMENSIONS

Shell Diameter

Coupling Length in / mm 10.0

/ 255 in / mm 5.75

/ 146

Leakage Distance in / mm 13.1

/ 320

ELECTRICAL

MG525Z

52-5

10.0

5.75

13.1

J

30,000

136

15,000

68

/ 255

/ 146

/ 320

MG528Z

52-8

K

40,000

180

20,000

11.0

5.75

15.8

90

/ 280

/ 146

/ 385

Dry Flashover

Wet Flashover

CIFO +

CIFO -

Puncture Voltage

RIV Test Voltage

Max. RIV at 1 MHz

PACKAGING kV kV kV kV kV kV

µV

80

50

125

130

130

10

50

80

50

125

130

130

10

50

Weight / 1

# Units / Wirebound

Weight / Wirebound

# Units / Pallet lbs

Qty lbs

Qty

8.8

6

57

72 / 96

9.3

6

60

72 / 96

Weight / Pallet

Bulk Pack "-SC" lbs

Qty

734 / 962

210

770 / 1010

210

824

144

Weight / Bulk Pack lbs 1900 2000 2000

Notes:

1) For Bulk Pack option, add suffix “-SC” to the catalog number [MG525Z-SC]

2) For Silicone Coated option, add suffix “-SIL” to the catalog number [MG525Z-SIL]

13.6

6

86

54

80

50

125

130

130

10

50

MG5211Z

52-11

K

50,000

222

25,000

111

11.0

6.14

17.5

/ 280

/ 156

/ 428

80

50

140

140

130

10

50

17.4

6

110

54

1040

144

2550

MG300Z

IEC-24

67,400

300

33,700

150

12.6 / 320

7.7 / 195

19.1 / 485

95

55

145

145

130

10

50

25.4

6

158

54

1472

—

—

MG400Z

IEC-28

90,000

400

45,000

200

14.2 / 360

8.1 / 205

21.7 / 550

35.7

6

216

54

1644

—

—

105

60

155

155

130

10

50

© 2016 Copyright MacLean Power Systems

Technical information subject to change without notice 140

141

Toughened Glass Insulators

Flashover for 52-3, 52-5, and 52-8

Number of insulators in the string

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

Connectioin Length

Inch

11.50

17.25

23.00

28.75

34.50

40.25

46.00

51.75

57.50

63.25

69.00

74.75

80.50

86.25

92.00

97.75

103.50

109.25

115.00

120.75

126.50

132.25

138.00

143.75

149.50

155.25

161.00

166.75

mm

292

438

584

730

876

1022

1168

1314

1461

1607

1753

1899

2045

2191

2337

2483

2629

2775

2921

3067

3213

3359

3505

3651

3797

3943

4089

4235

Power frequency flashover voltage, kV dry

145

205

270

325

380

435

485

540

590

640

690

735

785

830

875

920

965

1010

1050

1100

1135

1180

1220

1260

1300

1340

1380

1425 wet

90

130

170

215

255

295

335

375

415

455

490

525

565

600

635

670

705

740

775

810

845

880

915

950

985

1015

1045

1080

30 172.50

4382 1460 1110

Notes:

■ Flashover voltages are based on the tests according to ANSI C 29.1.

■ Characteristics are given for the strings without screens and arcing horns.

■ Dry power frequency flashover voltage ±5%

■ Wet power frequency flashover voltage ±10%

■ Critical impulse flashover voltage ±8%

2065

2145

2220

2300

2375

2455

2530

1425

1505

1585

1665

1745

1825

1905

1985

760

845

930

1015

1105

1185

1265

1345

Critical impulse flashover voltage, kV

Positive Negative

220

315

225

320

410

500

595

670

420

510

605

695

1105

1190

1275

1360

780

860

945

1025

2125

2210

2295

2380

2465

2550

2635

1440

1530

1615

1700

1785

1870

1955

2040

© 2016 Copyright MacLean Power Systems

Technical information subject to change without notice

Flashover for 52-11

Number of insulators in the string

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

Connectioin Length

Inch

12.28

18.43

24.57

30.71

36.85

42.99

49.13

55.28

61.42

67.56

73.70

79.84

85.98

92.13

98.27

104.41

110.55

116.69

122.83

128.98

135.12

141.26

147.40

153.54

159.69

165.83

171.97

178.11

mm

312

468

624

780

936

1092

1248

1404

1560

1716

1872

2028

2184

2340

2496

2652

2808

2964

3120

3276

3432

3588

3744

3900

4056

4212

4368

4524

Power frequency flashover voltage, kV dry

145

205

270

345

400

455

510

570

640

690

735

785

830

875

920

965

1010

1050

1100

1135

1180

1220

1260

1300

1340

1380

1425

1460 wet

90

130

170

225

275

315

360

405

455

490

525

565

600

635

670

705

740

775

810

845

880

915

950

985

1015

1045

1080

1110

30 184.25

4680 1495

Notes:

■ Flashover voltages are based on the tests according to ANSI C 29.1.

■ Characteristics are given for the strings without screens and arcing horns.

■ Dry power frequency flashover voltage ±5%

■ Wet power frequency flashover voltage ±10%

■ Critical impulse flashover voltage ±8%

1140

2145

2220

2300

2375

2455

2530

2605

1505

1585

1665

1745

1825

1905

1985

2065

765

920

1015

1105

1185

1265

1345

1425

Critical impulse flashover voltage, kV

Positive Negative

220

315

225

320

410

520

615

690

420

530

625

715

815

925

1025

1105

1190

1275

1360

1440

2210

2295

2380

2465

2550

2635

2720

1530

1615

1700

1785

1870

1955

2040

2125

© 2016 Copyright MacLean Power Systems

Technical information subject to change without notice 142