Australia`s Critical uses of Methyl Bromide

AUSTRALIA’S CRITICAL USES OF METHYL BROMIDE

May 2014

Introduction

In 2005, a strategy to provide for a phase out of critical uses of methyl bromide was developed to meet Australia’s international commitments under the Montreal Protocol on Substances that

Deplete the Ozone Layer (Montreal Protocol). The strategy describes how Australia will progress its phase out of critical uses of methyl bromide. It is available at http://www.environment.gov.au/resource/australias-critical-uses-methyl-bromide

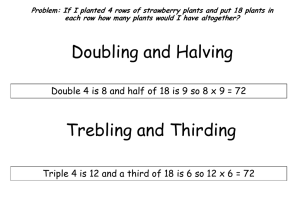

Since the strategy was published, there has been a substantial reduction in the volume of methyl bromide used for critical uses. Only one, out of the five industries initially considered, remains in the strategy (Table 1 and Figure 1).

This document is an update of the 2005 strategy and its subsequent update (2011). It provides the current outlook for soil treatment for strawberry runner production and post harvest fumigation of rice.

Table 1. Critical uses remaining in Australia

Year Uses Total tonnes used for critical use 1

119 (147) 2005 Pre-harvest (soil) uses (strawberry runners; strawberry fruit; and cut flowers)

Post-harvest uses (almonds and packaged rice)

2006 Pre-harvest (soil) uses (strawberry runners and cut flowers)

Post-harvest uses (almonds, packaged rice)

2007 Pre-harvest (soil) uses (strawberry runners; and cut flowers)

Post-harvest uses (packaged rice)

2008 Pre-harvest (soil) uses (strawberry runners and cut flowers)

Post-harvest uses (packaged rice)

2009 Pre-harvest (soil) uses (strawberry runners)

Post-harvest uses (packaged rice)

2010 Pre-harvest (soil) uses (strawberry runners)

Post-harvest uses (packaged rice)

2011 Pre-harvest (soil) uses (strawberry runners)

Post-harvest uses (packaged rice)

2012 Pre-harvest (soil) uses (strawberry runners)

Post-harvest uses (packaged rice)

2013 Pre-harvest (soil) uses (strawberry runners)

Post-harvest uses (packaged rice)

2014 Pre-harvest (soil) uses (strawberry runners)

Post-harvest uses (packaged rice)

2015 Pre-harvest (soil) uses (strawberry runners)

56 (75)

45 (49)

41 (49)

33 (38)

34 (36)

33 (34)

33 (33)

32 (32) n/a (31) n/a (29)

1 Volumes given in parentheses are the total critical use volumes approved for each year by the parties to the

Montreal Protocol. The volumes have been rounded to the nearest whole number. n/a – not available.

1

Figure 1. Comparison of volumes of non-quarantine and pre-shipment (non-QPS) methyl bromide imported and approved.

Mt

160

140

120

100

80

60

40

20

0

2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015

Imported - non-QPS (Mt) Approved non-QPS

Regulatory context

The regulatory context relating to non quarantine and pre-shipment (non-QPS) uses remains largely unchanged since 2005. The mechanism for implementing controls on the import, export and manufacture of methyl bromide for non-QPS purposes is the Ozone Protection and

Synthetic Greenhouse Gas Management Act 1989 (the Act) . The Act gives effect to Australia ’s obligations under the Montreal Protocol.

The Ozone Protection and Synthetic Greenhouse Gas Management Regulations 1995 (the

Regulations), which are made under the Act, provide a comprehensive system for the management of methyl bromide in Australia. The Regulations annually authorise non-QPS uses that have been approved by the Parties of the Montreal Protocol along with individual approved users, suppliers and maximum quantities that can be supplied to each user.

The Regulations provide safeguards against unauthorised use of non-QPS methyl bromide by providing for record keeping and/or reporting obligations for anyone selling and using it. The

Regulations create offence provisions for the illegal supply or use of methyl bromide.

Non-QPS methyl bromide uses in Australia

Non-QPS methyl bromide is used in only two industries: fumigation of packaged rice and soil treatment for strawberry runner production.

2

Packaged rice

The use of methyl bromide in the packaged rice sector will be phased out in 2014. The packaged rice sector is transitioning to phosphine fumigation.

Strawberry runner production

Strawberry runner growers in the Victorian district of Toolangi use methyl bromide as a soil fumigant. Methyl bromide minimises the risk of pest infestations and disease because the fumigant creates a partially sterile soil matrix. Pests, weeds and pathogens in the soil are reduced to a very low level. Without this treatment, pest, weed and disease infestations would cause significant production and quality losses in fruit production.

In the 2011 update of Australia’s critical uses of methyl bromide, the application of methyl iodide (MI) in combination with chloropicrin (Pic) was considered as the most likely alternative to methyl bromide. At the time, MI was in the process of being registered with the Australian

Pesticides and Veterinary Medicines Authority. However, in June 2012 MI was withdrawn from the registration process making it unavailable as an alternative to methyl bromide in the industry. For different, albeit commercial reasons, ethanedinitrile (EDN) is not available to the strawberry runner industry for research purposes.

Following these setbacks, industry conducted extensive consultations and meetings with government, universities, and private businesses to develop a new focus for research. Based on the outcomes of these meetings, the strawberry industry implemented a three year research plan to identify alternatives to methyl bromide.

The research plan is based on the development of integrated disinfestation systems, building on the research already undertaken under the programme, and/or more cost-effective soil-less systems. The concept is to apply low doses of existing registered fumigants (e.g. Pic, 1,3-D, and MITC generators) and herbicides (e.g. isoxaben, metolachlor, napropamide) in combinations that avoid crop phytotoxicity. In addition, the project will trial different soil-less systems, including substrates, hydroponics, and aeroponics, for production of runners.

To support the research effort, the Toolangi Certified Strawberry Runner Growers

Cooperative, the Victorian Strawberry Industry Certification Authority and the Australian

Government have committed approximately A$940,000 over the next three years to conduct the research programme.

Research results on alternatives trials

Two commercial trials on the efficacy of PicPlus® compared with MB/Pic were completed and a further two established in 2013. Results show that this alternative needs the development of complementary treatments to improve the control of weeds and pathogens, and increase runner yields to a similar level to the current production system.

New application technologies for MITC generators (spading machines) and formulations of

1,3-D/Pic (TF80®) were imported in Australia in 2013. A large replicated trial was established in 2013 investigating combinations of these alternatives, and the use of herbicides. Early data suggests that co-application of MITC and Pic improves pathogen control compared with either active applied alone. However, further data is needed on the effect of this combination on runner yields.

Following extensive research, the Victorian Strawberry Industry Certification Authority commissioned the construction of a screen house facility and soil-less systems for the production of Foundation stock of strawberry runners. The Victorian Strawberry Industry

3

Certification Authority has completed two seasons of commercial production using soil-less systems for Foundation stock. Production of subsequent generations (Mother and Certified) in soil-less substrates is not currently economically or technically viable according to an economic analysis conducted by the Victorian Strawberry Industry Certification Authority.

Further research on soil-less substrates has lead to the establishment of three early-stage trials. The results of the trails will be available in November 2014. The trials will investigate:

the use of different substrates (dried, imported coir fumigated with quarantine methyl bromide and then wrapped in plastic) to lower the risk of pathogen infection occurring in strawberry runners in soil-less production;

hydroponics and aeroponics systems to potentially lower costs for production of runner tips and plug plants, and investigation of chilling requirements for their improved fruit production.

The Victorian Strawberry Industry Certification Authority is also conducting tours to investigate technologies used overseas for production of runners in soil-less systems. A study tour of

Japanese rack systems has been completed, and further trips planned for the European

Union, United States and South Africa in 2014.

Transition plan

Previous transition plans were based on the assumptions that MI would be registered in

Australia. The withdrawal of MI means that previous transition plans are no longer possible.

Development of a new transition plan will commence when a new alternative is identified through the described research project. Runner certification and biosecurity authorities require at least two years of data demonstrating alternatives systems deliver equivalent efficacy to

MB/Pic before changes to the rules of the Certification Scheme, or approval of these treatments for market access of runners across state borders, could be granted. Therefore, a transition plan for phasing out methyl bromide will be developed by industry within two years of the commencement of the project (i.e. by 2015), providing alternatives prove feasible. The following issues will be taken into account in the development of a new transition plan:

Registration of any new treatment(s) must be approved through the Australian Pesticides and Veterinary Medicines Authority.

New alternatives require endorsement by the Victorian Strawberry Industry Certification

Authority for inclusion in the rules of the Scheme before they can be adopted for production of Certified runners.

State biosecurity authorities, by approval of the Australian Plant Health Committee, must accept pathogen threshold levels achieved with alternative treatments to allow market access of strawberry runners across Australian states.

Communication and training requirements.

4