11004_18_rA

advertisement

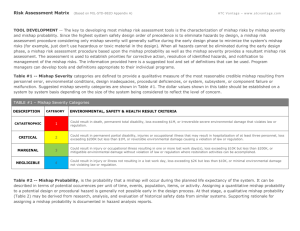

Massachusetts Institute of Technology Kavli Institute for Astrophysics and Space Research (MKI) TESS Instrument Pre Mishap Plan Dwg. No. 37-11004.18 Data Item 3-12 Revision A January 7, 2015 37-11004.18 Rev.A Page 1 of 9 Rev. Date Description of Change 01 02 8/14/14 10/21/14 Initial Release Correct figure 2.1 formatting A 01/07/15 Formal Release 37-11004.18 Rev.A Approved By Page 2 of 9 Pre-Mishap Plan 1.0 INTRODUCTON 1.1 Purpose This plan defines the process by which MIT Kavli Center for Astrophysics and Space Research (MKI) mishaps are investigated and reported at MKI and MIT Lincoln Laboratory (MIT/LL) for the TESS Project in accordance with MIT and MIT/LL policy and procedures. This plan excerpts language from the applicable work instruction(s) [see references] as a general synopsis of the protocol that will be followed in the event of an incident. This plan will also ensure emergency shutdown procedures are in place for powering off the TESS Instrument and associated electrical ground support equipment. Integration and Test personnel should be familiar with the content of this plan. MIT emergency management is documented and posted at: http://ehs.mit.edu/site/emergency For MIT Procedures, Manuals, Directives, and Plans, go to: http://ehs.mit.edu The TESS Preliminary Hazard Report (PHA) is available at http://snebulos.mit.edu/dbout/37data.html, document number 37-11004.08. The TESS Instrument Safety Analysis Report (ISAR) is available at http://snebulos.mit.edu/dbout/37-data.html, document number 37-11004.12. 1.2 Definitions 1.2.1 Close Call An occurrence or a condition of employee concern in which there is no injury or minor injury requiring first aid and/or no or minor equipment or property damage (less than $1000) but which possesses a potential to cause a mishap. 1.2.2 Incident An occurrence of a close call or a mishap. 1.2.3 Mishap An unplanned occurrence or series of occurrences that result in damage to property or personnel injury or illness and meets Type A, B, C, or D mishap criteria as identified including: Damage to developer, government, or customer-owned hardware property, or critical products Fatalities, injuries, or illnesses occurring on the TESS Instrument 1.2.3.1 Type A Mishap A mishap resulting in one or more of the following: (1) an occupational injury or illness resulting in a fatality, a permanent total disability, or the hospitalization for inpatient care of 3 or more people within 30 workdays of the mishap; (2) a total direct cost of mission failure and property damage of $2 million or more. 37-11004.18 Rev.A Page 3 of 9 1.2.3.2 Type B Mishap A mishap that caused an occupational injury or illness that resulted in a permanent partial disability, the hospitalization for inpatient care of 1-2 people within 30 workdays of the mishap, or a total direct cost of mission failure and property damage of at least $500,000 but less than $2,000,000. 1.2.3.3 Type C Mishap A mishap resulting in a nonfatal occupational injury or illness that caused any days away from work, restricted duty, or transfer to another job beyond the day or shift on which it occurred, or a total direct cost of mission failure and property damage of at least $50,000 but less than $500,000. 1.2.3.4 Type D Mishap A mishap that caused any nonfatal OSHA recordable occupational injury and/or illness that does not meet the definition of a Type C mishap, or a total direct cost of mission failure and property damage of at least $1,000 but less than $50,000. 1.2.4 Mishap Exclusions The following types of events are not reportable as mishaps, but may be reportable as failures or anomalies: Property Damage Exclusions: Items normally covered under Failure Reporting Malfunction or failure of component parts or equipment due to normal wear and tear where the malfunction is the only damage and the only action is to replace or repair the equipment Property damage from vandalism, arson, sabotage or Acts of God Anticipated damage to equipment or property was incurred during testing or manufacturing Product Test Failure Exclusions: Events involving damage to equipment or property as a result of testing, provided that all of the following are true: a) The testing is part of an authorized research, development, qualification, or certification program b) Damage is limited to the test article and test instrumentation c) Risk of damage to the test article and test instrumentation resulting from failure was accepted explicitly (e.g, documented) by TESS management and concurred on by Mission Assurance d) The test team performs a test failure analysis and generates a technical report instead of treating it as a mishap and completing a mishap report Acceptance Test Failure Exclusions: 37-11004.18 Rev.A Page 4 of 9 A failure resulting in damage to flight hardware during the ground Acceptance Test Procedure (ATP) is not a mishap when the following are true: a) b) c) d) e) Failure is a predictable outcome Only the flight article is damaged Test equipment functioned properly There were no anomalies in the facility or test procedures Test team performs a test failure analysis Injury Exclusions: Injuries and illnesses from non-occupational diseases Injuries that occur during work arrival or departure Injuries or illness sustained before working at MIT or MIT/LL unless specifically aggravated by current work assignment Injuries from non-work-related, pre-existing disorders or by minimum stress and strain Injuries from activities unrelated to work (e.g., recreational activities, workouts, etc.) 2.0 INCIDENT TIMELINE The following is a timeline of the actions that should be taken in the aftermath of an incident, see Figure 2.1: 1) 2) 3) 4) 5) 6) 7) Initial Incident Response (Immediate Reaction) Preservation of Scene Notification Gathering and Preservation of Evidence Investigation Analysis Corrective Action Plan 37-11004.18 Rev.A Page 5 of 9 IMMEDIATE REACTION (All Witnesses) Call Emergency Response (if required) Secure hardware to prevent further personnel injuries and/or damage. Notify Supervisor, Project Management and/or Project Safety Personnel. NOTIFICATION (Mgmt/Safety) COLLECTING & SAFEGUARDING EVIDENCE (IRT) Report facts concerning mishap to the Project Manager and the GSFC Personnel Collect data, witness statements and physical evidence. Immediately– Project Mgmt /Project SMA Within 1 Hr.– GSFC Collect data Collect witness statements Within 8 Hrs.– OSHA (if required) Collect physical evidence React Within 24 Hrs.– GSFC follow-up INVESTIGATION (MI Authority) Investigate the circumstances surrounding the mishap to determine root cause. Interview witnesses Review evidence Draw conclusion Report Findings Figure 2.1: Top Level Mishap Response Sequence 37-11004.18 Rev.A Page 6 of 9 3.0 RESPONSIBILITY Each MIT and MIT/LL employee is responsible for the timely reporting of observed mishaps and close calls. It is the responsibility of the stated designees below to transmit initial mishap notifications, perform mishap investigations, and prepare interim and final mishap reports. 3.1 Mishap Discovery, Initial Notification, and Initiation of Investigation 3.1.1 Person(s) Observing a Mishap 1. Immediately stop any work activity or process that jeopardizes hardware, property,critical products, personnel safety, or the environment. 2. Call Emergency Response (if required) 3. Safe and secure the area. 4. Notify the program Supervisor. 3.1.2 Supervisor or Individual Responsible for Directing the Work 1. Immediately notify Mission Assurance Manager 2. Verify safe and secure conditions. 3.1.3 Mission Assurance Manager 1. Notify the TESS Program Manager (PM) 2. Establish an Initial Response Team (IRT) which includes the Mission Assurance Manager, Facility Management and others as appropriate. 3. Impound or copy pertinent data, gather initial witness statements, take photos and gather information necessary to make an initial notification. 4. Draft initial mishap notification. 5. Submit initial mishap notification to the NASA Chief Safety and Mission Office (CSO) and Project Safety Manager (PSM) and Project Safety Engineer (PSE) within no more than 24 hours (reference notification timetable in Figure 2.1). 6. Enter information into the Mishap database (or applicable system) 3.1.4 Hardware Quality Engineer 1. Convene a Material/Failure/Anomaly Review Board if applicable. 3.1.5 Program Manager 1. Communicate mishap information to pertinent MKI and MIT/LL personnel and GSFC customer personnel within no more than 24 hours of event (reference notification timetable in Figure 2.1) 3.2 Mishap Investigation 3.2.1 Program Manager 1. Establish a Mishap Investigation Team (MIT), which includes the Mission Assurance Manager, Facility Management and others as appropriate (i.e., Public Affairs, Local Security, Manufacturing, Design, Integration and Test personnel). 3.2.2 Mishap Investigation Team 1. Gather physical evidence and facts. 2. Collect witness statements. 3. Review and analyze data. 37-11004.18 Rev.A Page 7 of 9 4. Determine final classification of mishap. 5. Identify direct cause(s), intermediate cause(s), and root cause(s). 6. Formulate conclusions and develop recommendations regarding root and intermediate causes. 7. Generate corrective and preventive actions, recommendations, and lessons learned. 8. Submit Preventive/Corrective Action(s) (PCA) for open corrective and preventive actions. 9. Contact PM, the Mission Assurance Manager, and other appropriate personnel regarding corrective actions. 10. Support customer investigations. 11. Based on the conclusions of the mishap investigation and with PM and/or Facility Management support, determine and document appropriate corrective, preventive actions and lessons learned. 3.2.3 EHS Personnel 1. If the mishap involves personnel injury, illness, or environmental releases or spills of hazardous materials, assist SSE personnel in the mishap investigation. 3.3 Mishap Reporting (MIT Report) 3.3.1 Mishap Investigation Team 1. Complete the interim (if applicable) and final mishap report. 2. File the interim and final mishap report. 3. Provide Type A/B Mishap Reports to Senior Management as required 4. Submit mishap report to designated GSFC Project Safety Manager. 3.3.2 Program Manager 1. Review and approve mishap report. 2. Manage the completion of program corrective actions. 3.3.3 Contracts Personnel 1. Submit copies of mishap reports to Customer Contracts and to internal MKI or MIT/LL personnel. 2. Retain the documentation for five years. 37-11004.18 Rev.A Page 8 of 9 4.0 PROGRAM CONTACTS 4.1.1 MKI and MIT/LL Contacts Title Name Emergency Response Phone Mobile Email http://emergency.mit.edu Dial 100 from a campus phone or 1(617) 253-1212 1(617) 253-1212 Program Manager Tony Smith 1(617) 253-6134 1(508) 752-5275 Asst. Program Manager Joe Scillieri 1(617) 253-3319 1(857) 928-4815 Mission Assurance Manager Brian Klatt 1(617) 253-7555 1(508) 314-0838 MKI Deputy Director Mark Bautz 1(617) 253-7502 Greg Berthiaume NASA/LL Liaison 1(781) 981-7975 jss@space.mit.edu bk@space.mit.edu mwb@space.mit.edu gdb@ll.mit.edu 4.1.2 GSFC Contacts (listed in order of contact precedence starting with any GSFC employee on site at developer) Title Name Office Project Safety Manager Project Chief Safety and Mission Assurance Officer TESS Program Manager William Conn Teresa James 1(301) 286-8388 1(301) 614-5928 1(410) 353-1016 teresa.a.james@nasa.gov Jeff Volosian 1(301) 286-9924 1(301) 356-3056 jeffrey.f.volosin@nasa.gov 37-11004.18 Rev.A Mobile Email william.e.conn@nasa.gov Page 9 of 9