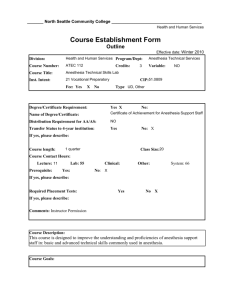

the anesthesia gas machine revsed july 2012

advertisement