MTLS 4T03 - Assignment 2

advertisement

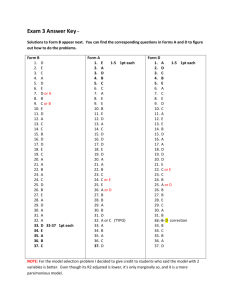

Student name: Student Id#: Materials Science and Engineering 4T03 Assignment 2 due the 2nd April Let’s consider a short fibre composite material under tension in the axis of the fibres. The matrix is an average Al matrix, and the reinforcement SiC fibers. We know the following: Em=70GPa, σym=400MPa, νm=0.33, Ef=400GPa, σyf=2400MPa Length of fibres 2L=200microns, and radius r=20 microns A From diffraction measurements, it is determined that under a given load, the stress seen at the fibre center is 550MPa at a strain of 0.2%. We want to first determine key parameters of the composite material and try to optimize it. One key parameter is the volume fraction of reinforcement which can determined indirectly. 1. Plot the internal stress in the fiber as a function of the constant n (1pt). 2. Determine either numerically or graphically the constant n suitable to achieve this level of stress at the centre of the fibre (2 decimals accuracy is enough) (1pt). 3. How does this value of n compare to what we should expect for this composite material (1pt)? 4. What is now the volume fraction of reinforcement (1pt)? 5. What maximum value of strength should we then expect for this composite (1pt)? Is there a simple model to calculate it? (1pt) B Now that we understand our composite material and we know the maximum strength it could achieve, we can look at optimizing it. 1. What are the basic assumptions behind the modeling of short fiber composites (3pts)? 2. The stress distribution along the fibres may be lower than expected. Calculate and plot the stress in the fiber as a function of a parameter x variable from the center to the end of a fibre (2pts). How does the stress distribution compare to the maximum value calculated in section A 5 (2pts)?. 3. Do the same for what we know for an average composite of value n (2pts). 4. What can explain the differences between 2 and 3 (2pts)? 5. From your perspective what can be done to optimize further the properties of the composite (2pts)? 6. One way to estimate simply what length the reinforcement should be to maximize the load transfer from the matrix to the fiber is to plot the stress towards the end of the fiber (say 99%) as a function of L. Describe what should happen to the stress distribution along the fiber as L increases (2pt)? Plot the stress as a function of L (1pt). What is the maximum stress reached (1pt)? What are the values of s and L (2pts)? 2